Bait putting machine used for aquaculture

A technology of aquaculture and bait feeding machine, which is applied in application, fish farming, climate change adaptation, etc. It can solve the problems of small feeding area, sinking bottom, waste of bait, etc., achieve long feeding distance, avoid sinking bottom, and improve feeding area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

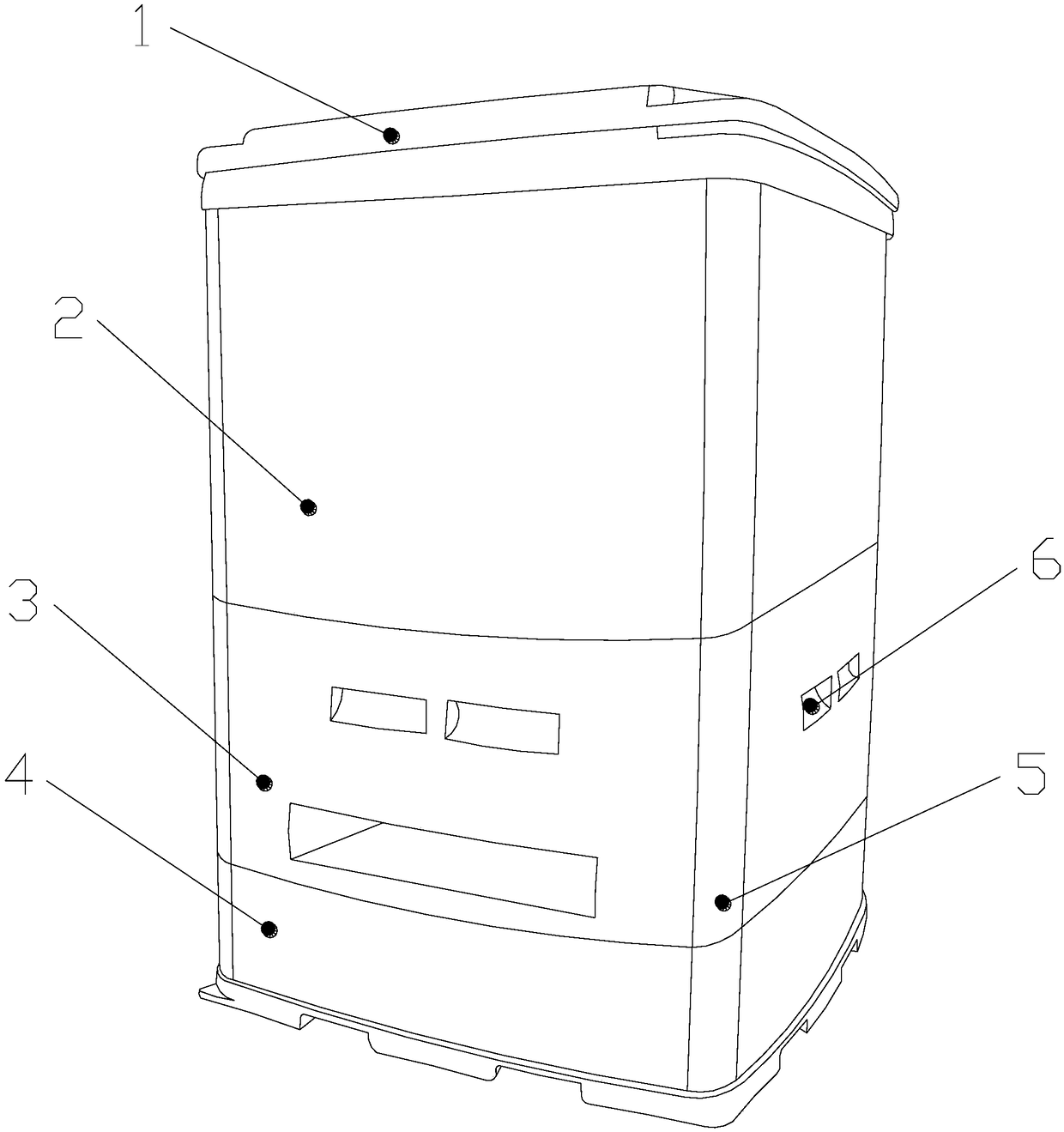

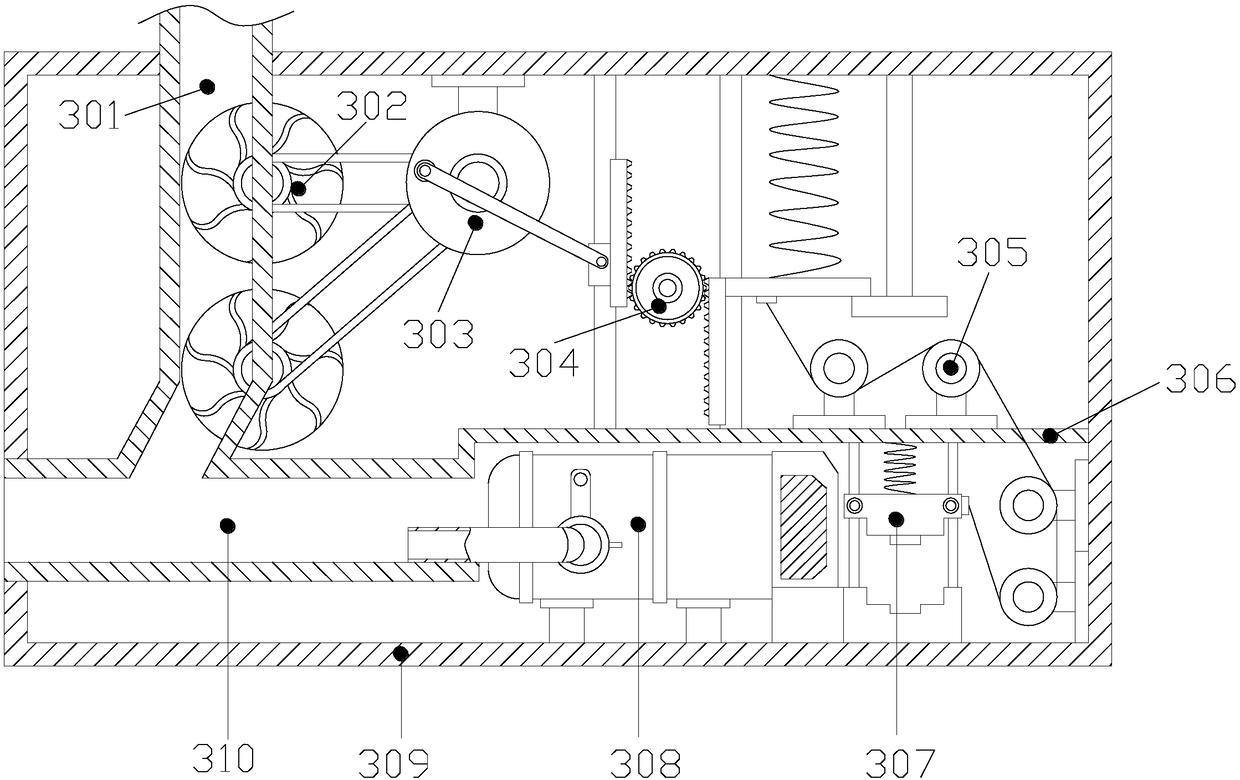

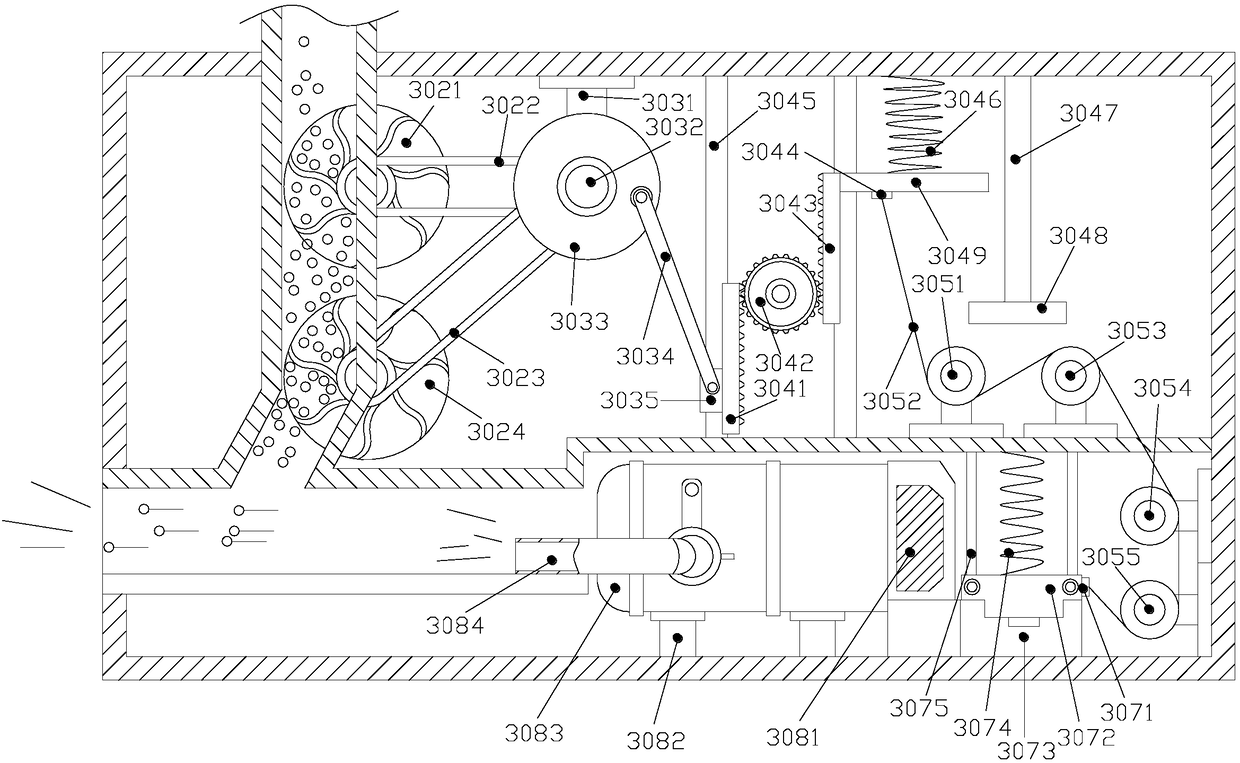

[0023] see Figure 1-Figure 3, the present invention provides a kind of bait feeding machine for aquaculture: its structure comprises sealing upper cover 1, material storage box 2, bait feeding box 3, moisture-proof base 4, art line 5, convenient handle groove 6, described moisture-proof The base 4 is a rectangular structure and the upper end is installed on the bottom of the bait box 3 by means of connection. The upper end of the bait box 3 is provided with a groove for buckling the storage box 2, and the sealing upper cover 1 is arranged on the storage box. 2. The top is connected by hinges. The convenient handle grooves 6 are provided with more than two and are evenly and equidistantly distributed in the middle of the side of the bait box 3 and are integrally formed. The fastening method is vertically installed on the four corners of the storage box 2, the bait box 3, and the moisture-proof base 4. The bait box 3 includes a feed port 301, a toggle mechanism 302, a first tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com