Performance adjusting system and performance adjusting method for sodium silicate molding sand

A technology of adjusting system and water glass, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc. It can solve the problems of poor mixing effect, sinking of raw materials, and affecting the performance of molding sand. To achieve the effect of guaranteeing performance, avoiding bottom sinking and ensuring mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

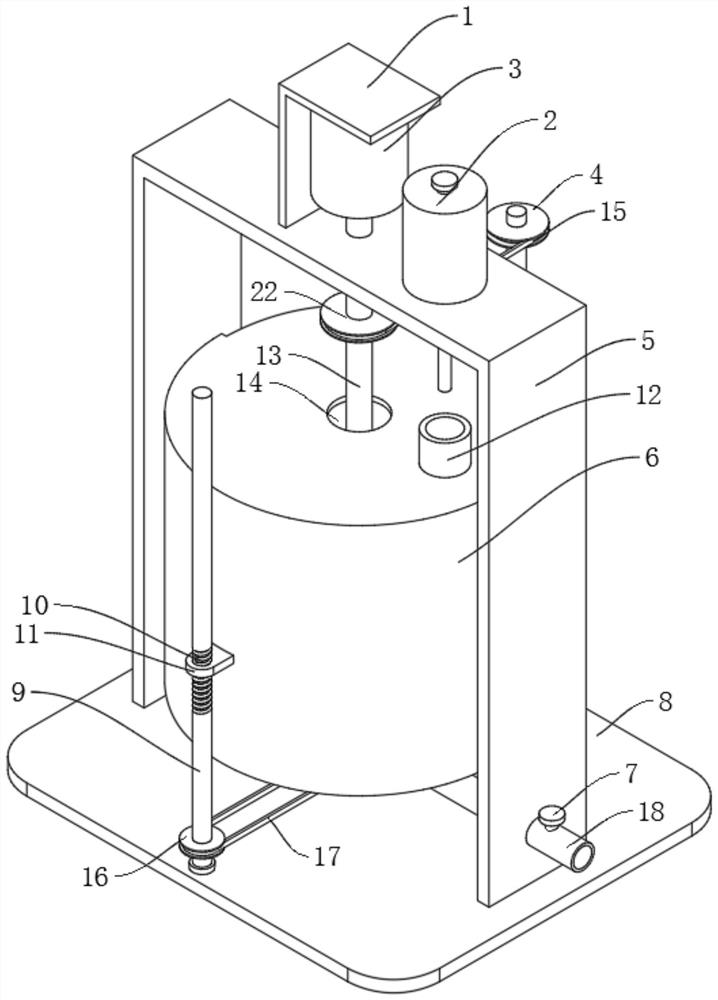

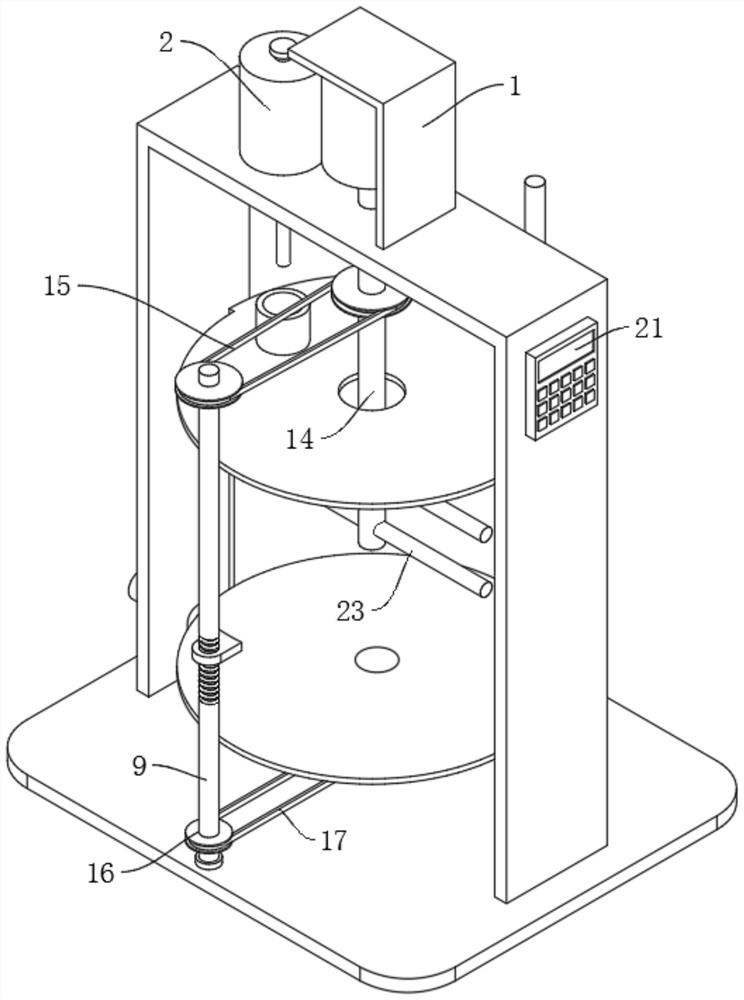

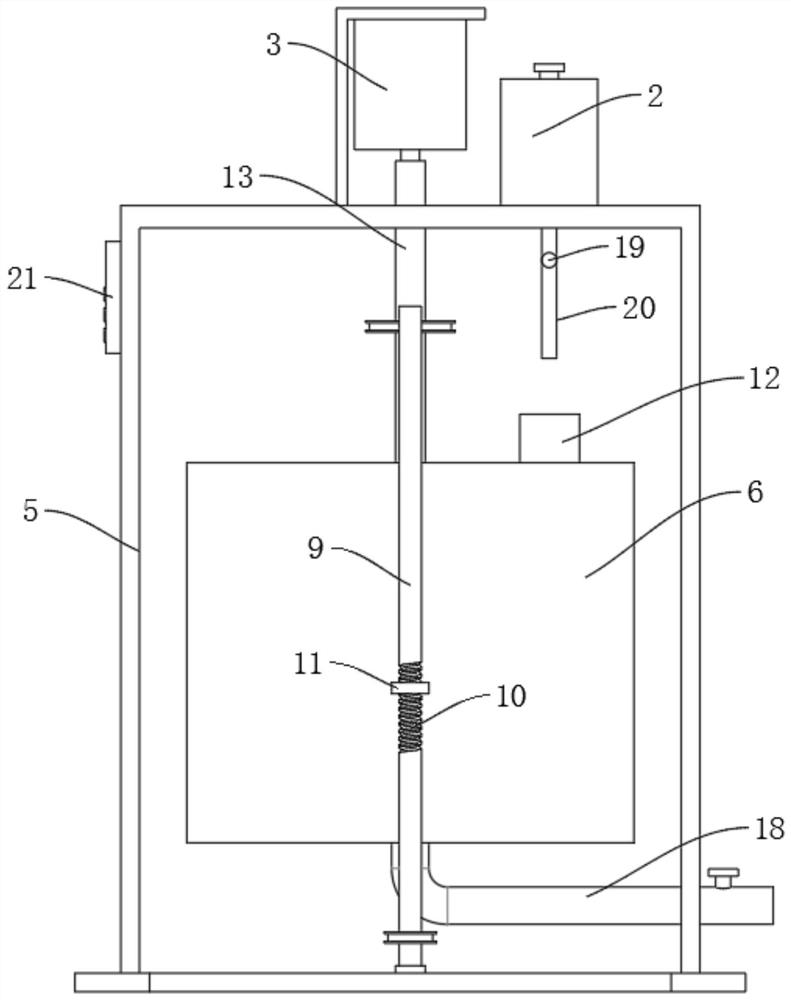

[0023] refer to Figure 1-5 , a performance adjustment system for water glass molding sand, comprising a stirring device, a performance detector 24, a spray mechanism, and a controller 21, the stirring device includes a bottom plate 8, the bottom plate 8 is fixedly connected with a support frame 5, and the support frame 5 is fixedly connected There is an L-shaped plate 1, a motor 3 is fixedly connected to the L-shaped plate 1, and a stirring shaft 13 is fixedly connected to the output shaft of the motor 3. The stirring shaft 13 is connected to the support frame 5 through bearing rotation, and the two ends of the bottom plate 8 pass through The bearing is rotatably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com