Feeding equipment for wheat flour blending treatment and working method thereof

A technology for wheat flour and material addition, which is applied in the pretreatment of mixed materials, chemical instruments and methods, mixer accessories, etc., can solve the problems of long time for adding and mixing, poor consistency of mixing and feeding, and inability to mix and mix powder. To achieve the effect of saving the time of adding materials, increasing the speed of adding materials, and speeding up the stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

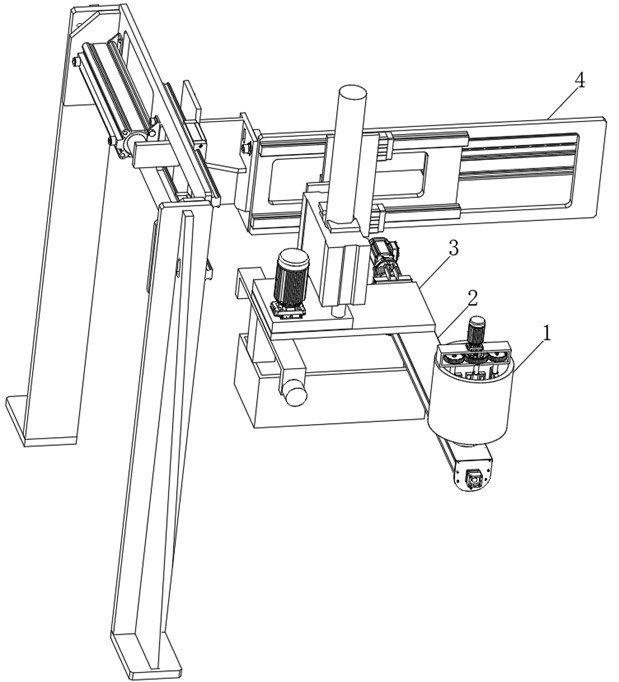

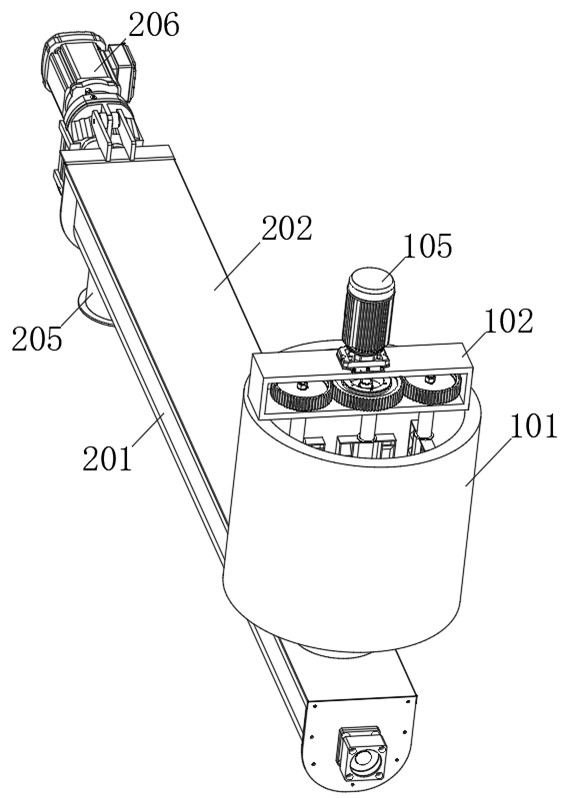

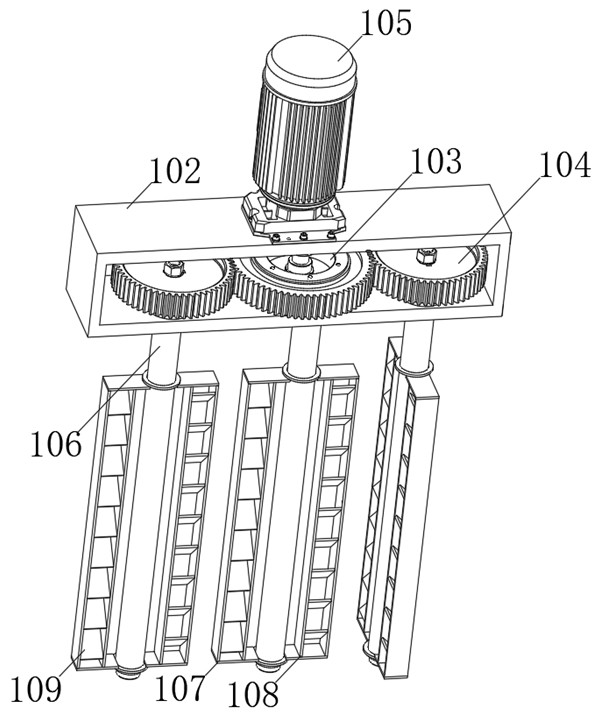

[0031] like Figure 1-Figure 9 As shown in the figure, a feeding device for wheat flour mixing and processing includes a mixing component 1, a conveying component 2, a feeding component 3 and a displacement component 4. The mixing component 1 is installed above one end of the conveying component 2, and the conveying component 2 is installed inside the feeding assembly 3, and the feeding assembly 3 is installed below the displacement assembly 4. The mixing assembly 1 includes a mixing tank 101, a mounting frame 102 and three stirring frames 107. The mounting frame 102 is welded and fixed on the On the top of the mixing barrel 101, the three stirring racks 107 are located inside the mixing barrel 101, and three connecting columns 106 are rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com