Fur pulp recovery device for spinning

A kind of recovery device, technology of wool pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

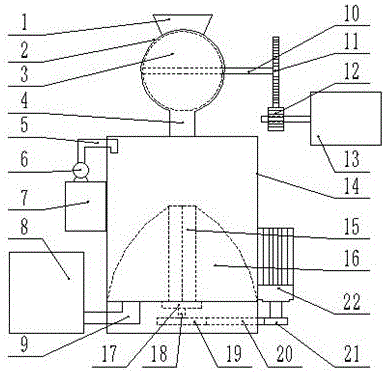

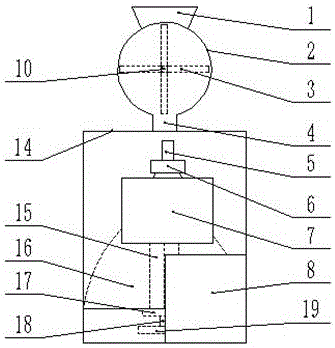

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0018] Such as figure 1 , figure 2 As shown, the structure of this kind of fluff pulp recovery device for textiles includes a feed port 1, a feed box 2 is arranged below the feed port 1, and a feed blade 3 is arranged inside the feed box 2, and the feed blade 3 is connected to On the transmission rod 10, a large gear 11 is connected to the end of the transmission rod 10, and the large gear 11 meshes with the pinion 12 connected to the feed motor 13. The lower end of the feed box 2 is provided with a feed pipe 4. Therefore, during use, The feed inlet 1 is fan-shaped, which enlarges the feed area, the feed box 2 plays a protective role, and the feed blade 3 realizes the shunting of the fluff pulp, preventing the feed pipe 4 from being blocked, and through the large gear 11 and the pinion 12 The cooperatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com