Artificial-intelligence-based feed putting device

A feeding device and artificial intelligence technology, applied in the field of artificial intelligence, can solve the problems of affecting the feeding effect, uneven feeding, high labor intensity, etc., and achieve the effect of improving the moving effect, ensuring the quality of the feed, and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

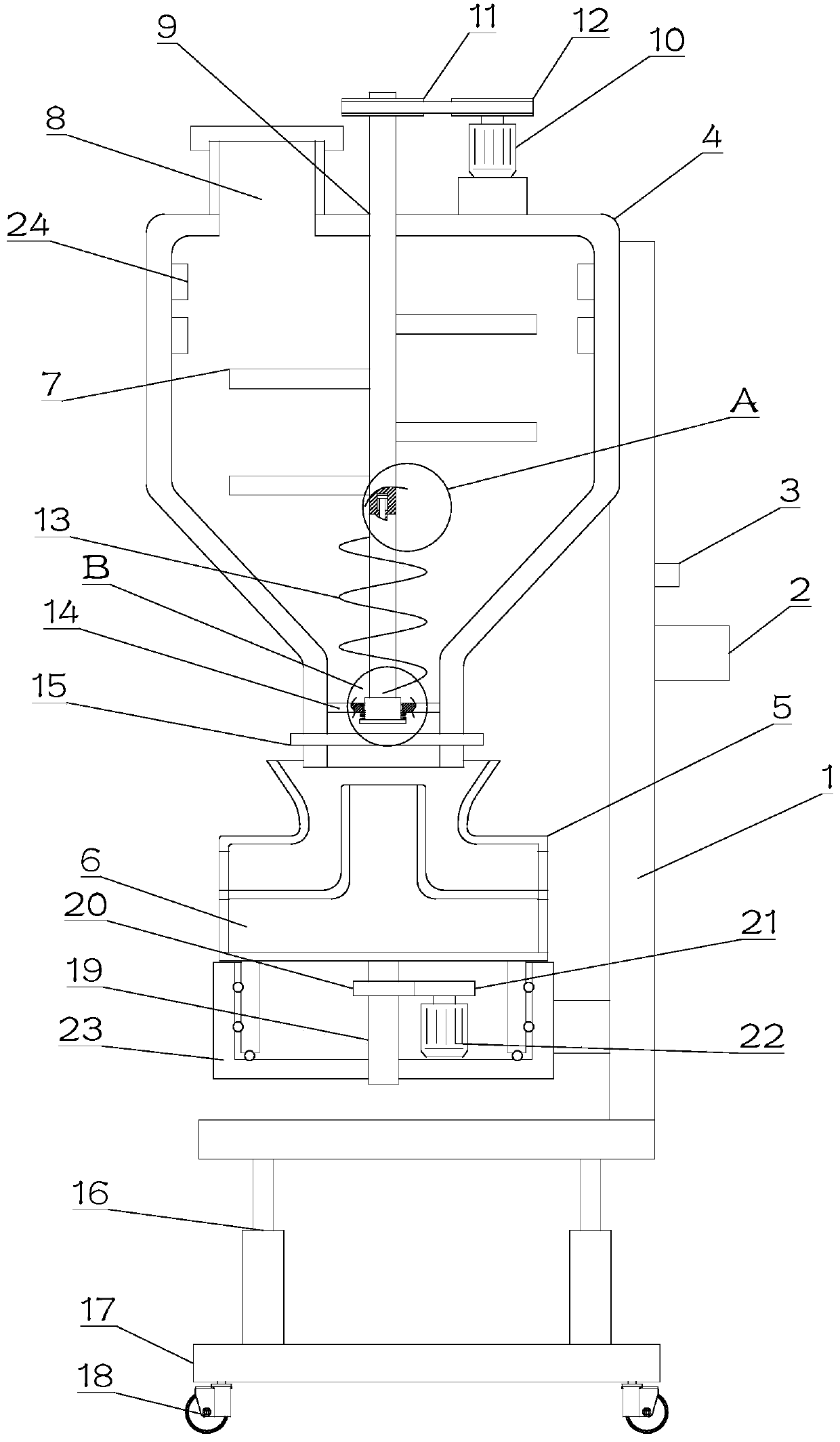

[0023] see figure 1 , in Embodiment 1 of the present invention, an artificial intelligence-based feeding device includes a bracket 1, and the bracket 1 is sequentially provided with a material storage box 4 and a material distribution box 5 from top to bottom, and the first rotating shaft 9 runs through the material storage box 4. The top is provided with a driving mechanism on the top of the first rotating shaft 9, and a stirring rod 7 is fixedly installed on the first rotating shaft 9. A feeding auger 13 is installed at the bottom of the first rotating shaft 9. A discharge port is arranged at the bottom of the material box 4, and the conveying auger 13 is arranged inside the discharge port, and an on-off valve 15 is arranged on the discharge port, and the on-off valve 15 is set to control the switch of the discharge port.

[0024] The storage box 4 is also provided with a feeding port 8, which is convenient for adding materials to the storage box 4. The inside of the storage...

Embodiment 2

[0030] see Figure 1~4 The main difference between this embodiment 2 and embodiment 1 is that the drive mechanism includes an A pulley 11 installed on the first rotating shaft 9, and the A pulley 11 is connected to the B pulley on the output end of the first motor 10 through a belt. 12 on.

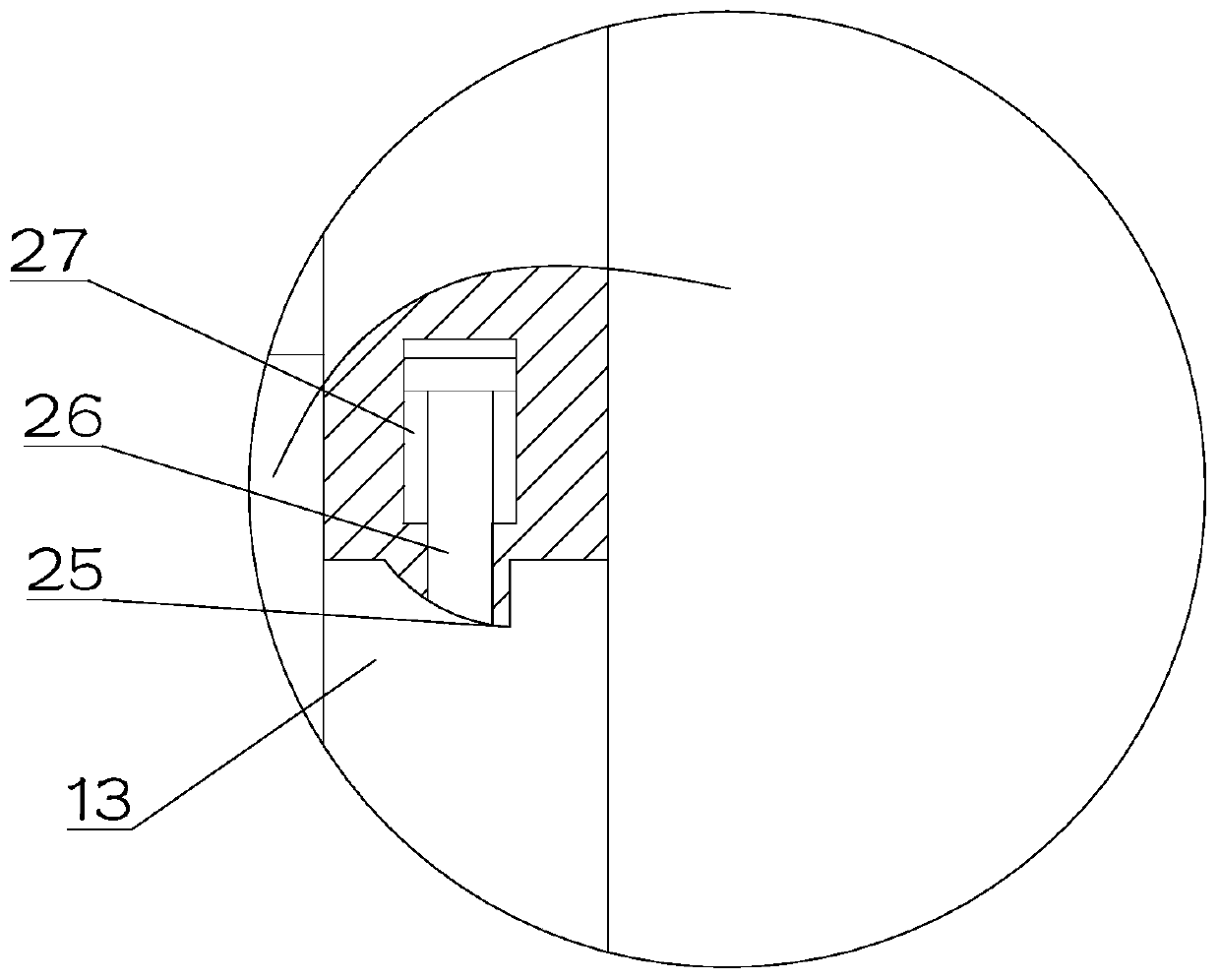

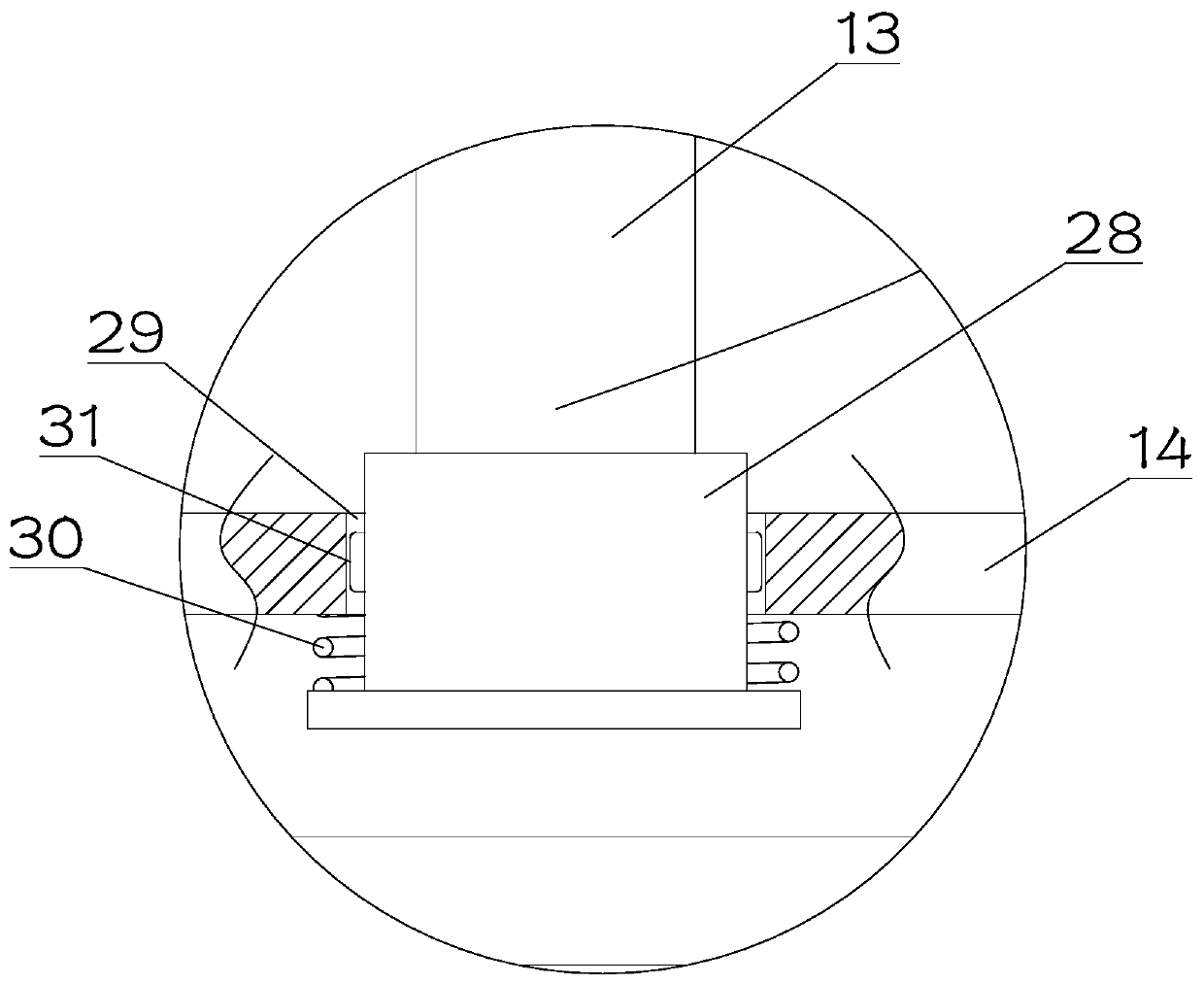

[0031] The top of the feeding auger 13 is provided with a groove 25 cooperating with the bump on the first rotating shaft 9, the right side of the groove 25 is vertically arranged, and the left side is arc-shaped; the top of the feeding auger 13 is The center position is provided with a slide bar 26, the upper end of the slide bar 26 is provided with a slide block, the slide block is set in the chute 27 on the first rotating shaft 9, and the bottom of the feeding auger 13 is rotated and set on the second In the rotating shaft 28, the two sides of the second rotating shaft 28 are provided with sliders 31 installed on the chute 29, the sliding blocks 31 are arranged on the support rod 14, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com