Diamond oscillating film

A vibrating membrane and diamond technology, applied in the directions of non-planar vibrating membrane/paper cone, diaphragm structure, sensor, etc., can solve the problems of bonding technology, large bonding agent, difficult bonding operation, and difficult application of diamond materials, etc. The effect of large bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

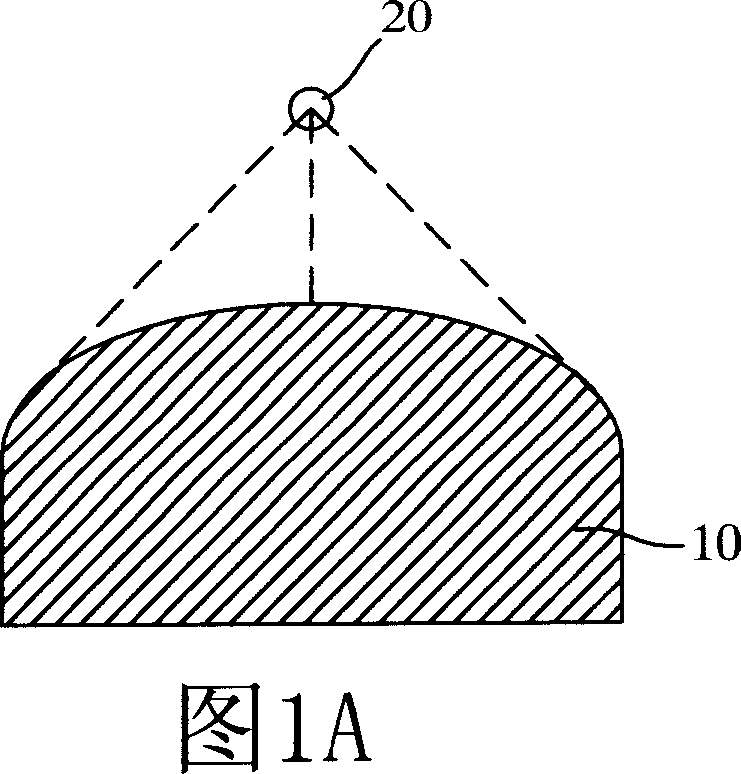

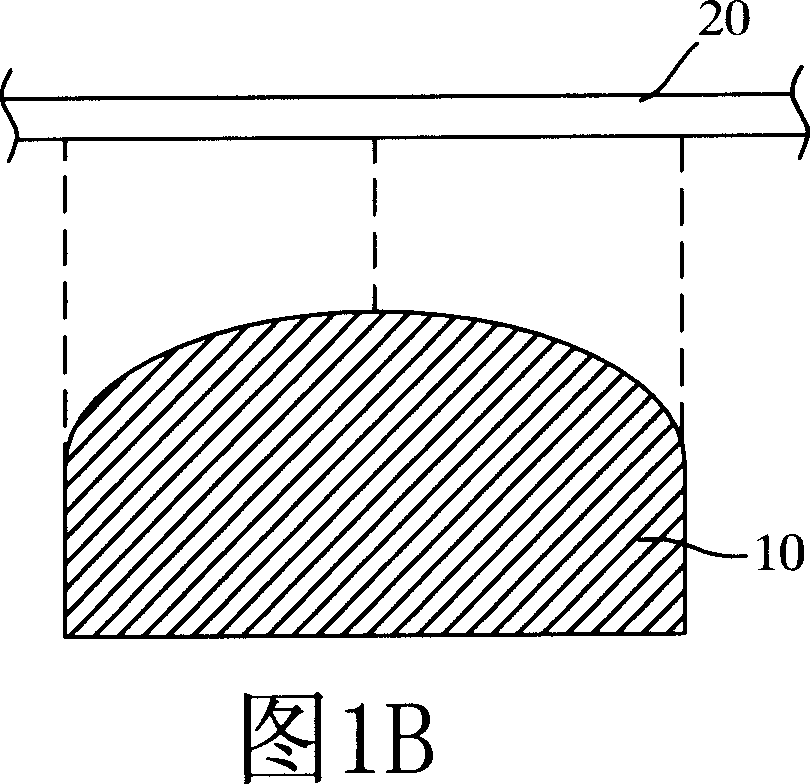

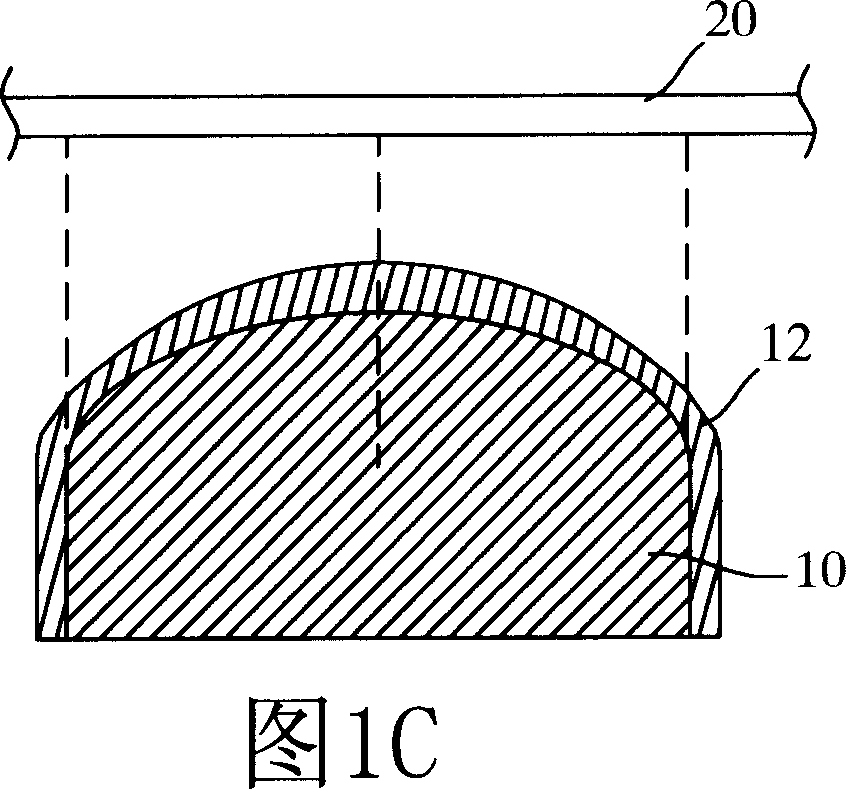

[0024] Please refer to FIGS. 1A-1D , which are a diamond vibrating membrane disclosed in the first preferred embodiment of the present invention. The manufacturing method is to provide a mold 10, the shape of the mold 10 is designed according to the shape of the vibrating membrane to be manufactured, and a curved surface shape with a middle protrusion is formed. Then pass a non-homogeneous energy that can excite the dissociated gas on the mold 10, such as high-temperature thermal resistance wire, plasma, flame, etc., the present embodiment adopts a thermal resistance wire 20 to generate this non-homogeneous energy, heat The resistance wire 20 can be made of high-temperature-resistant tungsten, tantalum, and tungsten carbide, and its temperature can be heated to 1900-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com