Wearable papermaking coating scraper

A scraper and coating technology, applied in scraper, papermaking, paper machine, etc., can solve the problems of mismatching mechanical properties between ceramic coating and scraper substrate, difficulty in spraying and grinding, reducing scraper service life, etc., to achieve manufacturability Effects of improving, improving coating performance, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

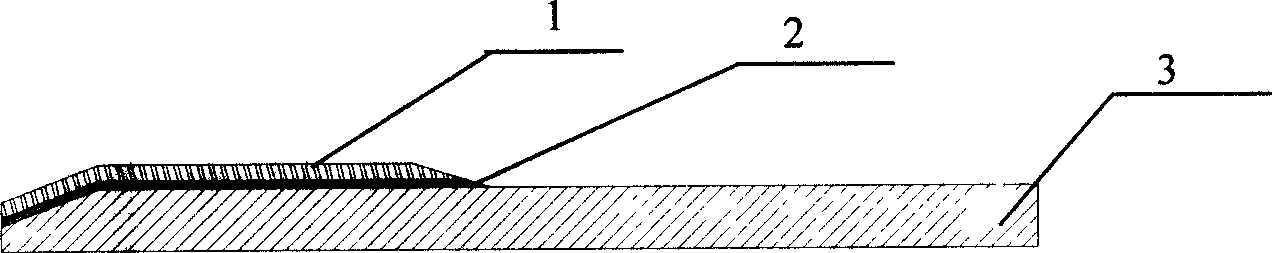

[0011] The following is to obtain NiCr alloy-NiAl intermetallic compound / Al on the steel scraper 2 o 3 The ceramic composite coating is taken as an example to describe the implementation process of this application.

[0012] 1. Clean the surface of the steel scraper base 3 and sandblast to form an active metal surface. The sandblasting sand particle size is 25-35 mesh, the sandblasting air pressure is 0.5-0.6MPa, the sandblasting distance is 10-15mm, and the surface after sandblasting Dust.

[0013] 2. Plasma spray NiCr alloy coating on the active metal surface as transition layer 2; spraying distance 150-200mm, current 450A, argon gas flow rate 1200L / h, nitrogen gas flow rate 1000L / h, coating thickness 0.05mm.

[0014] 3. Plasma spray NiAl / Al on the surface of NiCr alloy coating 2 o 3 The composite material powder is used as the working layer 1; the spraying distance is 150-200mm, the current is 500A, the flow rate of argon gas is 1500L / h, the flow rate of nitrogen gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com