Vibration dampener for support braces in vehicles

A technology for automobiles and supporting frames, which is applied to vehicle components, superstructure sub-assemblies, transportation and packaging, etc., which can solve problems such as aging of elastic components, impracticality, and difficulty in installing rubber bushings, and achieve a reduction in the range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

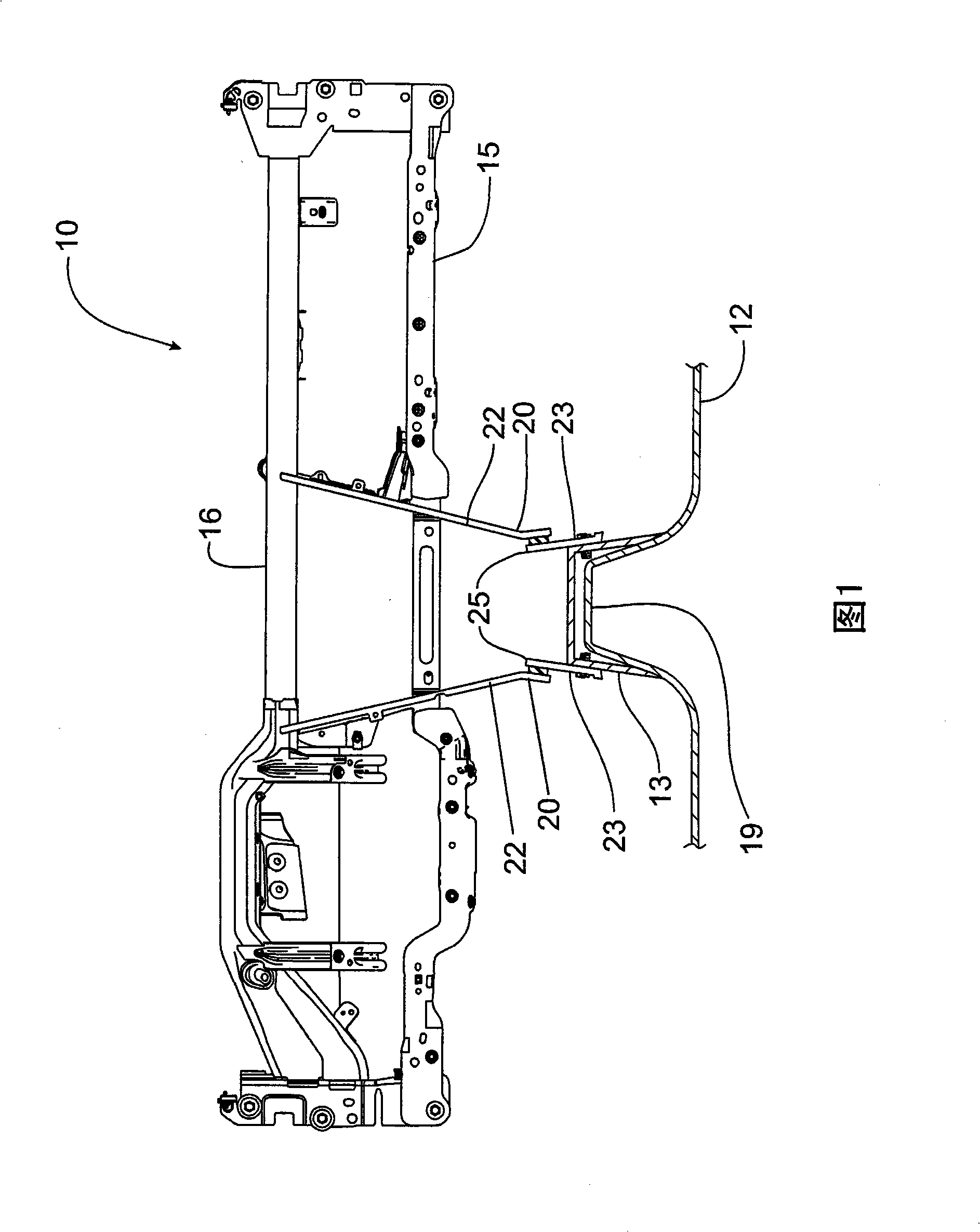

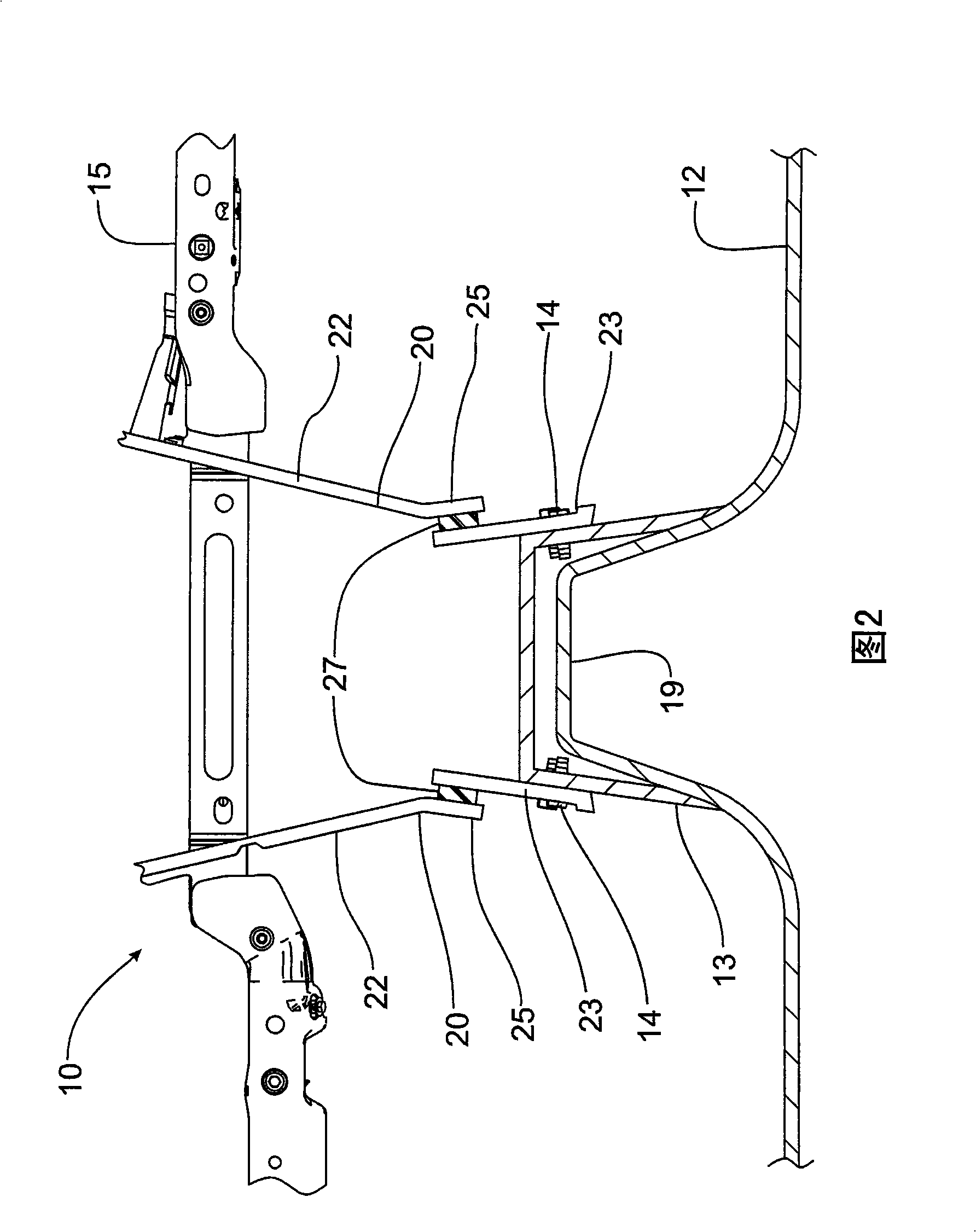

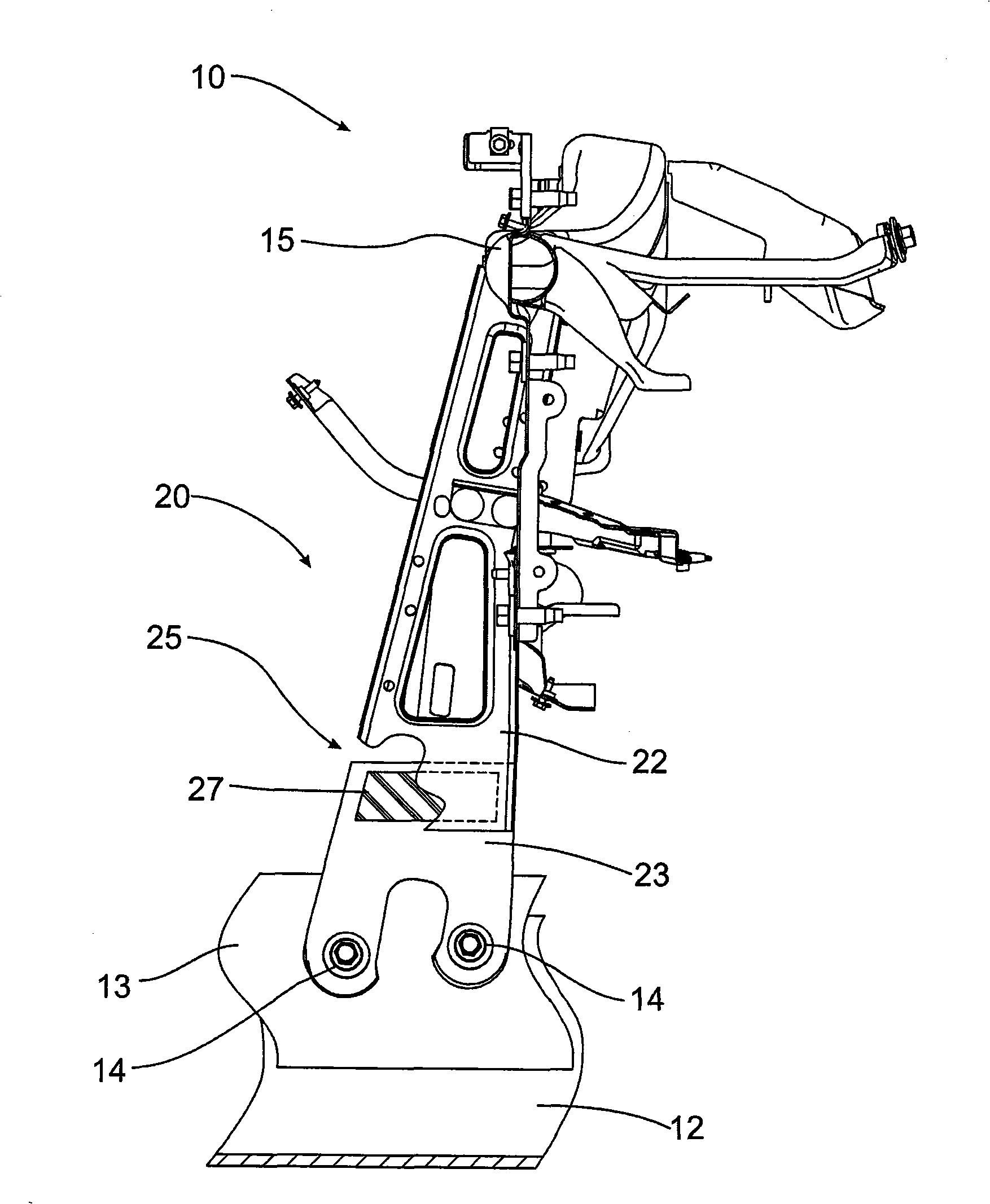

[0025] Refer to Figure 1- Figure 4 , best shows a bracket for supporting an automotive dashboard incorporating the principles of the present invention. The frame 10 extends from the vehicle floor 12 and stretches across the vehicle to support an instrument panel (not shown), and includes a cockpit cross member 15 which provides structural stability to the vehicle chassis, and a vertically extending intermediate bracket 20 . Attachment brackets 13 are welded to the bedplate 12 and provide attachment points for brackets 20 on opposite sides of a bedplate hump 19 which typically covers the transmission (not shown) and may also cover the propshaft of a rear wheel drive vehicle.

[0026] On each side of the connecting bracket 13 , a bracket 20 is connected to the connecting bracket 13 and extends upwardly therefrom to connect to the lower cockpit beam 15 and the upper cockpit beam 16 . A steering wheel (not shown) is supported on the cockpit upper beam 16 so as to receive vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com