Treatment method for purifying sewage and tail gas from furnace gas in acid production from gypsum

A technology for furnace gas purification and tail gas treatment, applied in degassed water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Solve the high cost of sulfuric acid tail gas desulfurization, achieve the effect of reducing emission costs, low desulfurization costs, and achieving emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

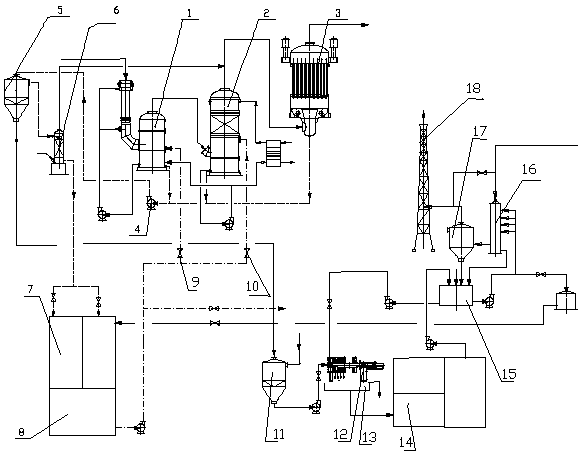

[0011] The present invention will be further described in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following situations.

[0012] The treatment method of the gypsum acid making furnace gas purification sewage and tail gas according to the present invention is mainly divided into three large process flow cycles, that is, the first is the acidic sewage cycle of the purification system, the second is the acidic sewage treatment cycle of the sulfuric acid system, and the third is the sulfuric acid system. Tail gas treatment cycle, according to the needs of process requirements in each process cycle and the characteristics of materials, the present invention rationally reengineers the process, uses the acid sewage generated by the acid sewage cycle of the purification system as the raw material for the acid sewage treatment station of the sulfuric acid system, and converts the acid sewage of the sulfuric acid system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com