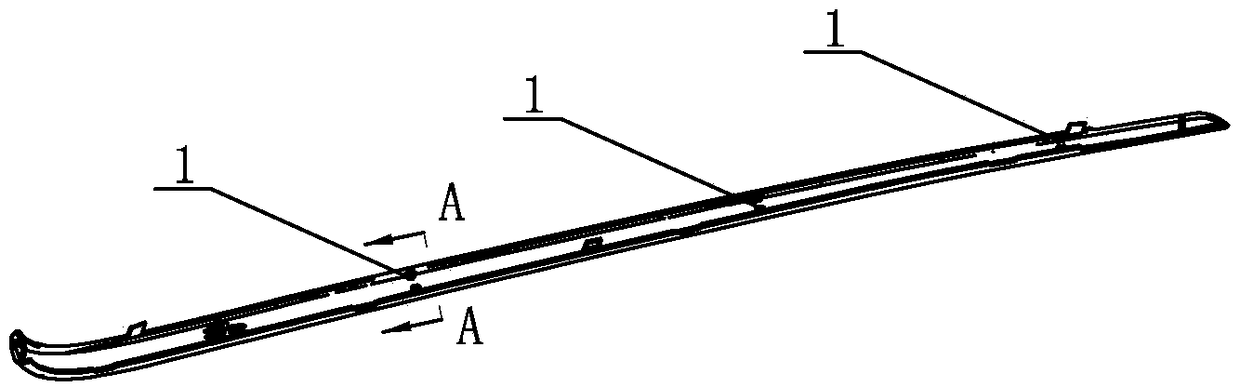

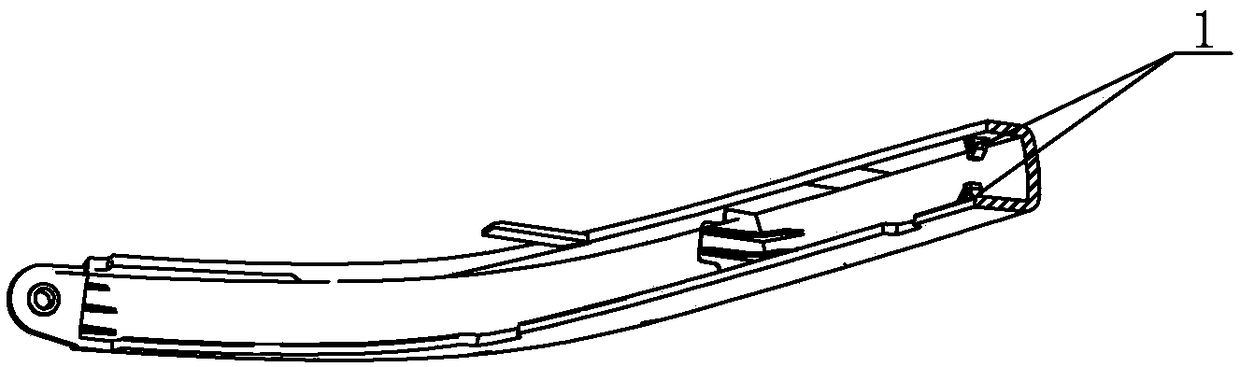

Injection mold for automobile trims

A technology for automotive trim strips and injection molds, applied in the field of injection molds, can solve problems such as affecting production efficiency and difficulty in picking up parts, and achieve the effects of low production cost, improved production efficiency, and smooth demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

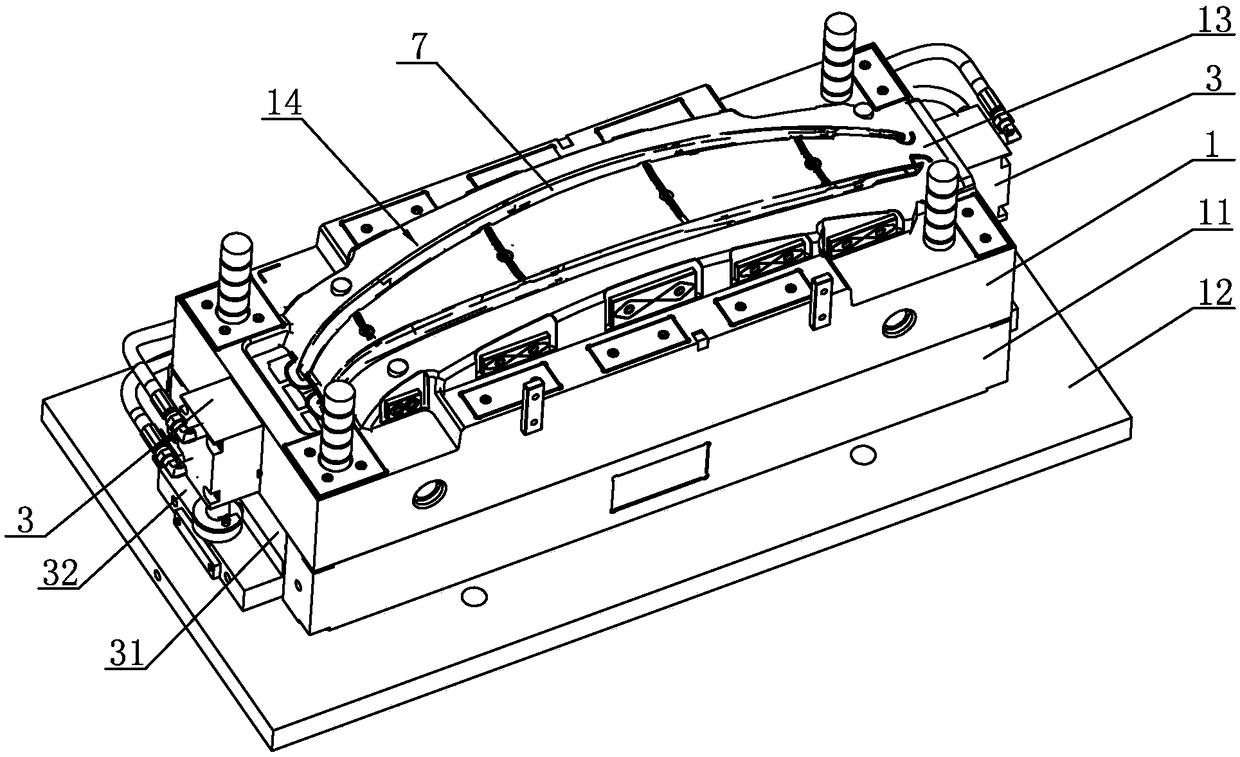

Embodiment 1

[0025] The automobile decorative strip injection mold of embodiment 1, such as Figure 3 to Figure 9As shown, it includes a movable template assembly and a fixed template assembly. The movable template assembly includes a movable template 1, a mold foot 11 and a movable mold fixed plate 12 arranged up and down. The top of the movable template 1 is provided with a movable mold core 13, and the movable mold core 13 The top is provided with a first cavity 14, and an ejection mechanism is provided between the movable template 1 and the movable mold fixed plate 12. The fixed template assembly includes a fixed template 2 arranged up and down, a hot runner mounting plate 21 and a fixed mold fixed plate 22. The hot runner assembly 23 is installed on the channel mounting plate 21, the top of the fixed template 2 is provided with a fixed mold core 24, and the top of the fixed mold core 24 is provided with a second cavity 25. On the formwork assembly, the first cavity 14 and the second c...

Embodiment 2

[0028] The difference between the automobile molding injection mold of embodiment 2 and embodiment 1 is that in embodiment 2, as shown in the figure, the driving mechanism includes a movable block 41, a striker 42, a reset block 43 and a mounting seat 44, and the mounting seat 44 is set Between the thimble fixed plate 31 and the thimble bottom plate 32, the mounting seat 44 is fixed on the thimble fixed plate 31, the movable block 41 is installed on the mounting seat 44 through a rotating pin 4, and the reset block 43 is arranged under the movable block 41, resets The block 43 is fixed on the movable mold fixed plate 12 by screws, and one side of the movable block 41 is provided with a concave first groove 45, and the bottom end of the accelerating thimble 5 is integrally provided with a first radial boss 51, and the first diameter Extend into the first groove 45 toward one side of the boss 51, the other side of the first radial boss 51 is inserted with the anti-rotation pin 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com