Motorcycle frame middle connecting structure

A technology for connecting structures and motorcycles, used in motorcycles, bicycle frames, motor vehicles, etc., can solve the problems of difficulty in ensuring the design strength of the frame, unreasonable force in the middle of the frame, and high production cost of steel castings, and can achieve high reliability. Reasonable force, simple structure and easy transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

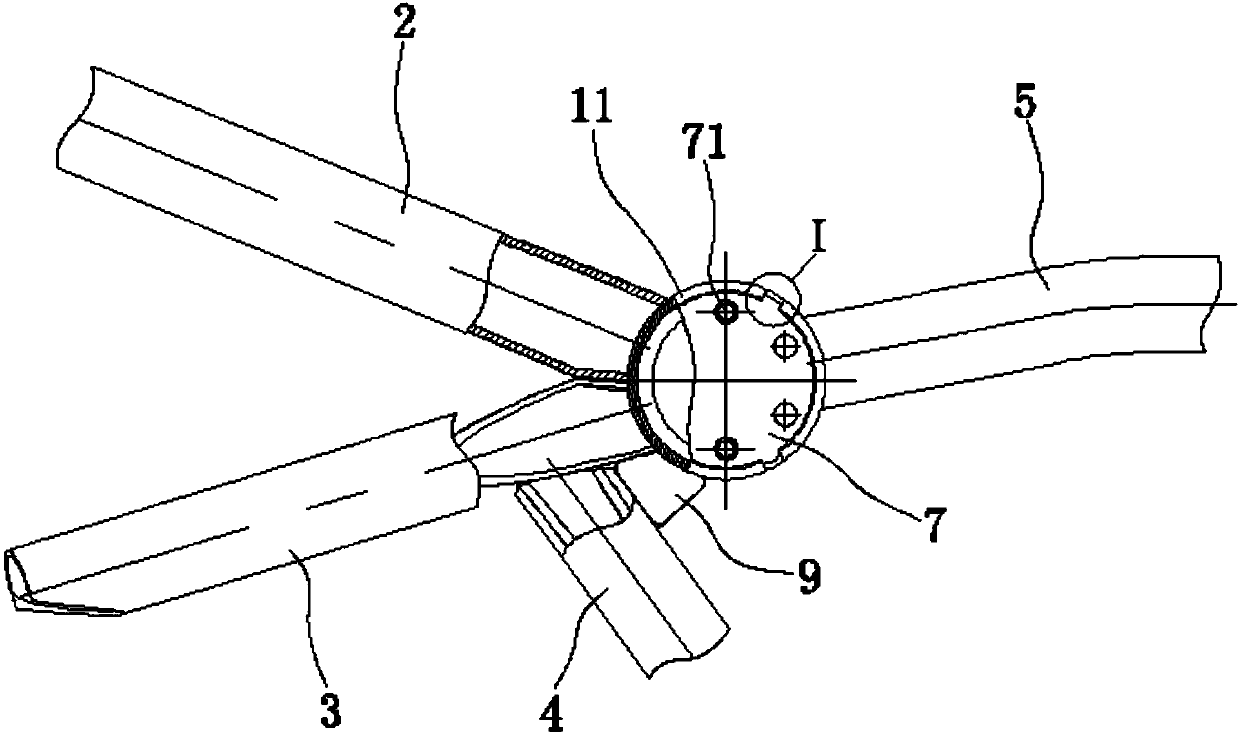

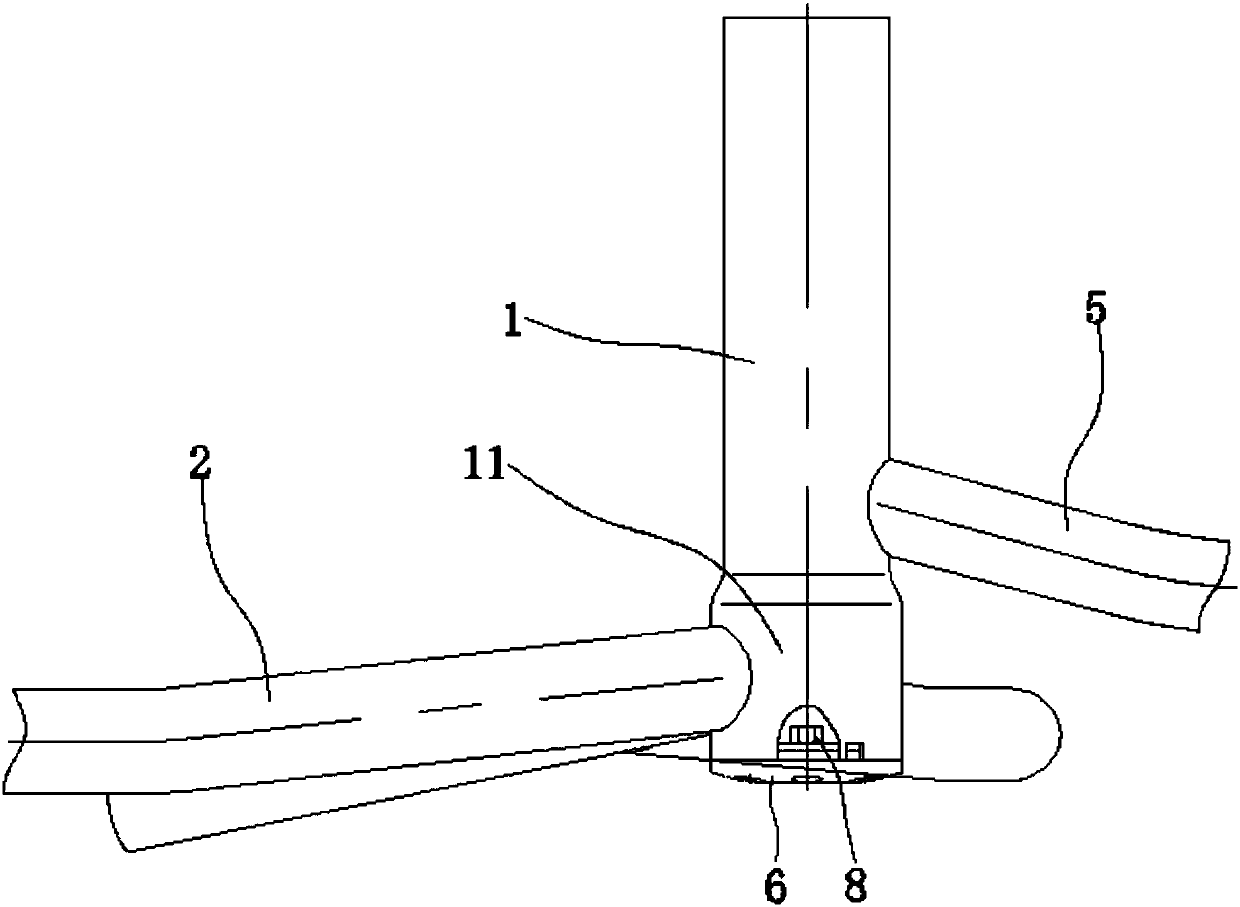

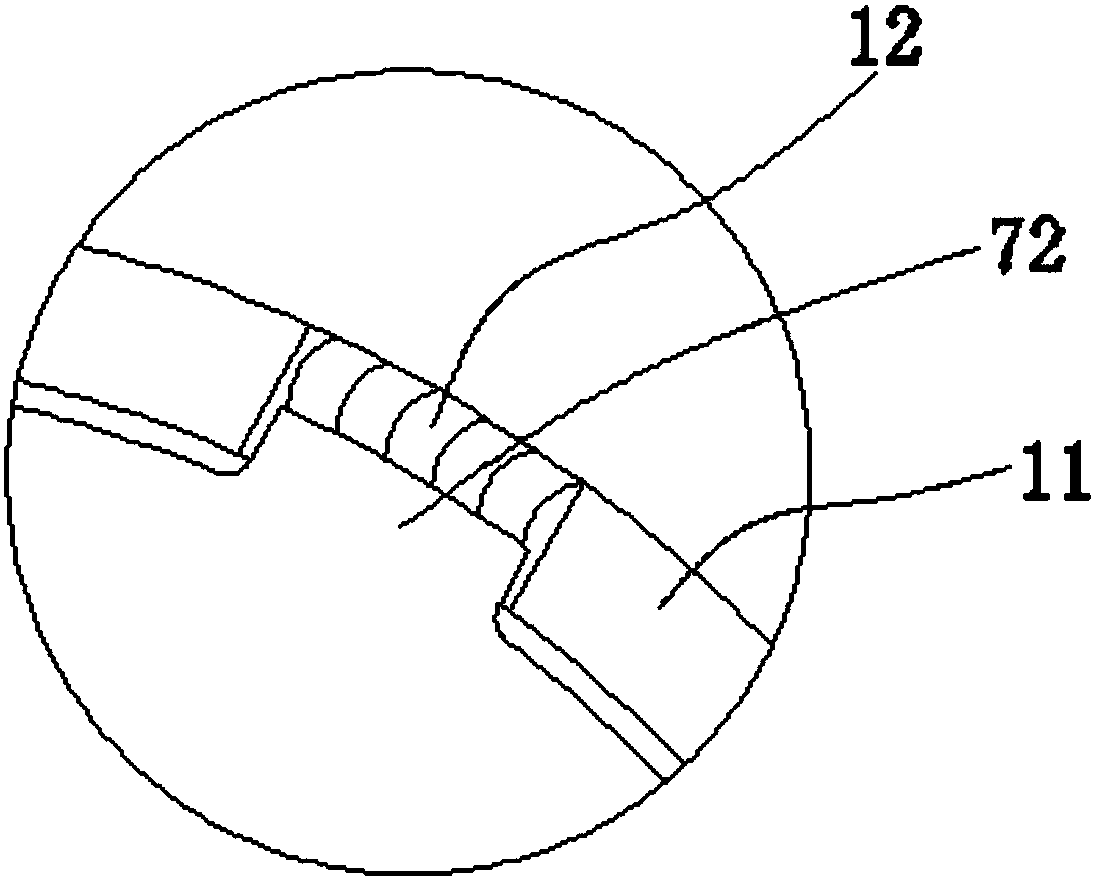

[0019] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the left and right connecting pipes 1 in the middle of the motorcycle frame are made of steel pipes. The left ends of the left and right connecting pipes 1 extend integrally to the left, and a large-diameter section 11 is formed by expanding the pipes. The rear left main pipe 5 is welded to the left and right connecting pipes 1 , the welding place is close to the large-diameter section 11, the front left main pipe 2 and the left support pipe 3 are welded on the large-diameter section 11, the lower connecting pipe 4 is welded to the left support pipe 3, the front left main pipe 2, the left support pipe 3, and the lower connection Pipe 4 and rear left main pipe 5 are also made of steel pipe. In order to avoid interference, the front left main pipe 2 and the left support pipe 3 are flattened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com