Assembled large-scale buckling-restrained bracing member

A buckling-resistant support, large-scale technology, applied in the direction of building components, earthquake resistance, protective buildings/shelters, etc., can solve the problem of buckling-resistant support low-cycle fatigue performance and compression stability bearing capacity weakening, inner core design yield strength Unable to guarantee and other problems, to achieve the effect of breaking through the restrictions of plate and section steel specifications, improving energy consumption capacity, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

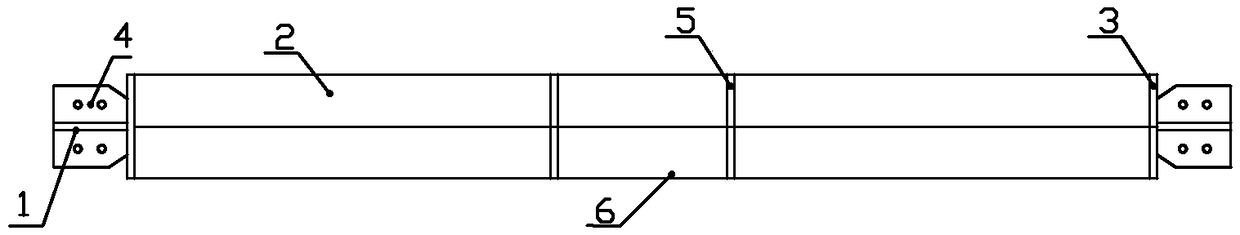

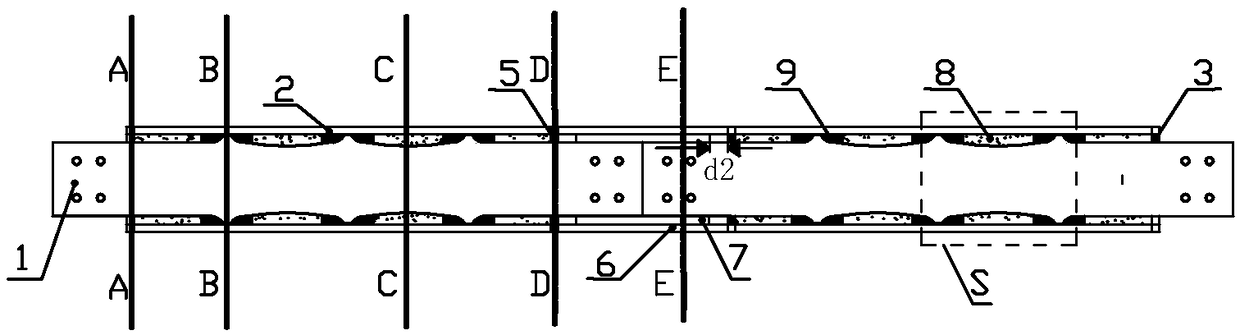

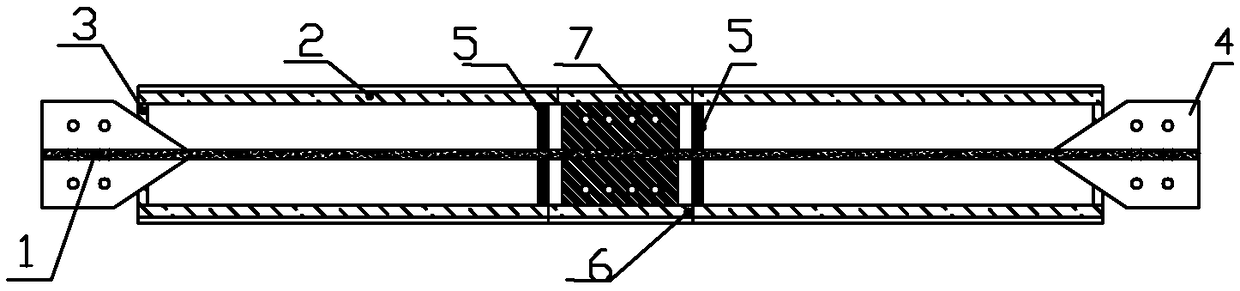

[0033] Please check Figure 1-5 , an assembled large-scale anti-buckling support member of this embodiment, including at least two sub-buckling-resistant supports, and connecting nodes for connecting the sub-buckling-resistant supports;

[0034] The anti-buckling support includes an inline inner core 1 and a square steel pipe restraint 2, the inline inner core 1 is arranged in the square steel pipe restraint 2 along the diagonal of the square steel pipe restraint 2, and the inline inner core 1 The core 1 includes several inner core units. The inner core unit has a structure whose width gradually decreases from both ends to the middle. Therefore, under the action of axial force, the anti-buckling support can realize segmental yielding, and the yielding position is controllable. Thereby improving the energy dissipation capacity of the anti-buckling support; the inner core unit also includes a limit card 15, the limit card 15 is arranged at the widest point at both ends of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com