High-temperature resistant corrugated expansion joint

A corrugated expansion joint and high temperature resistance technology, applied in the field of pipeline expansion joints, can solve the problems of pipeline matching that are not suitable for high temperature medium, and achieve the effects of improving the heat insulation effect, easy production and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

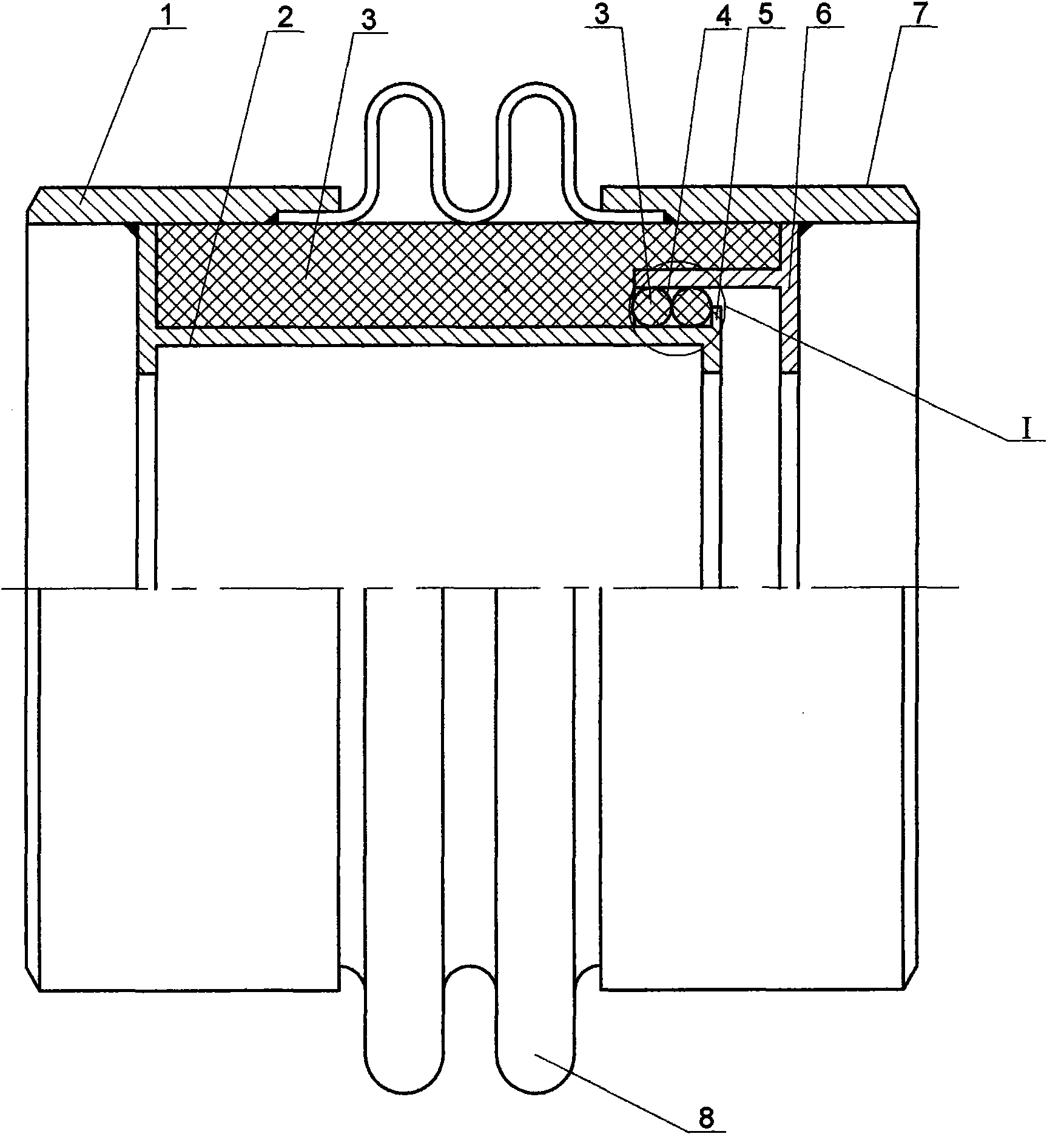

[0014] The present invention will be further described below according to accompanying drawing.

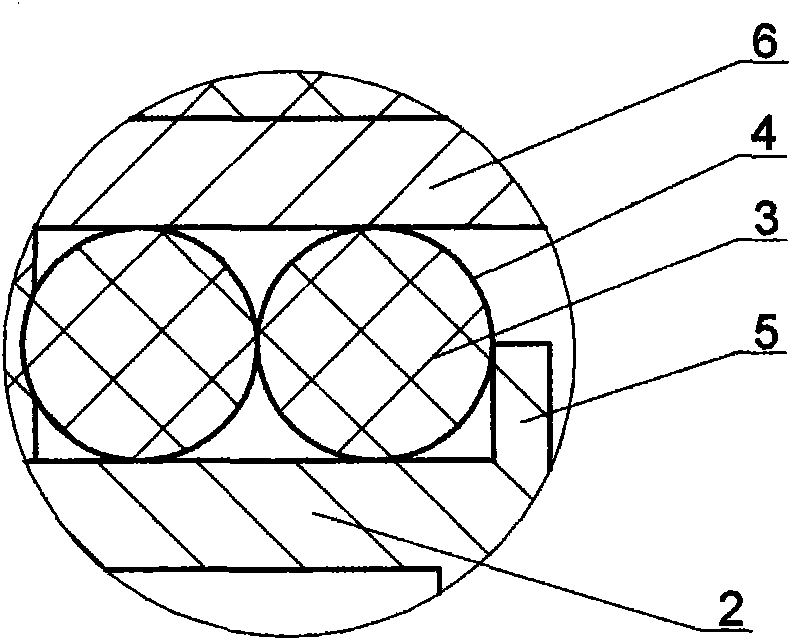

[0015] figure 1 The shown high temperature corrugated expansion joint is used on the steelmaking furnace exhaust duct, and it includes a cylindrical left connecting pipe 1, a bellows 8 and a right connecting pipe 7 which are sequentially sealed and connected. The inner wall of the left connecting pipe 1 is fixedly connected to the guide tube 2 opening to the right, and the inner wall of the right connecting tube 7 is fixedly connected to the auxiliary guide tube 6 opening to the left. The inner diameter of the shorter auxiliary guide tube 6 is greater than the outer diameter of the guide tube 2 , both coaxial and partially fitted. At the gap between the guide tube 2 and the auxiliary guide tube 6, there is a sealing structure that can move relative to the axial direction, which is formed by the metal mesh 4 cover heat insulation material 3. The annular boss 5 seals, not only pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com