Manufacturing method of environment-resistant electric connector shell made of titanium alloy

A technology of electrical connectors and titanium alloys, which is applied in the field of manufacturing environment-resistant titanium alloy electrical connector shells, can solve the problems that the electrical connector shells cannot meet harsh environments, and achieve low production costs and high material utilization rates , good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: The environment-resistant titanium alloy electrical connector housing described in this embodiment is made of a titanium alloy material, and the titanium content in the titanium alloy material is 87.5wt% to 99.8wt%. One or more combinations of Ni, Pd, Ta, Mo, Ru, Zr, V, Sn.

[0013] When the balance is a combination of Ni, Pd, Ta, Mo, Ru, Zr, V, Sn, the ratio of each component is any ratio.

[0014] The ratio of various components in the titanium alloy material can be: Ti-6Al-2Sn-1Mo-1V, Ti-0.05Ni-0.05Ru, Ti-2Al-4Mo-4Zr, Ti-4Al-3Mo-1V, Ti- 5Ta-0.4Mo-0.3Al, Ti-6.5Al-5Zr-1V or Ti-0.3Mo-0.8Ni.

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment describes the method for manufacturing the environment-resistant titanium alloy electrical connector housing described in Embodiment 1. Its specific process is as follows:

[0016] Mold making: first make a mold according to the shape of the electrical connector;

[0017] Mixing process, mixing titanium powder and other metal element powders, wherein the particle diameter of titanium powder and other metal element powders is 10 μm to 120 μm, and the other metal element powders are Ni, Pd, Ta, Mo, Ru, Zr , V, a mixture of metal powders or multiple metal powders in Sn; wherein the content of titanium powder is 87.5wt% to 99.8wt%; the powder mixing time lasts for 0.5 hours to 20 hours, so that all the powders are mixed evenly;

[0018] In the pressing process, the uniformly mixed powder is added to the mold, and a pressure of 30MPa-400MPa is applied at room temperature for 1-10 hours to prepare a powder blank;

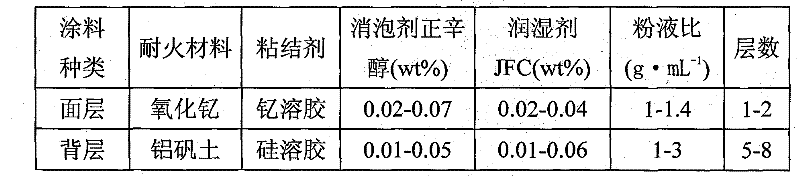

[0019] In the sintering proces...

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is a specific example of Embodiment 2.

[0026] The raw material that adopts in the present embodiment is: Ti-0.3Mo-0.8Ni, concrete technological process is:

[0027] Mold making, first make a mold according to the shape of the electrical connector;

[0028] In the mixing process, the titanium powder, Mo powder and Ni powder with a particle size of 10 μm to 50 μm are mixed, and the mixing time lasts for 12 hours to 14 hours, so that all the powders are mixed evenly;

[0029] Pressing process: Add the uniformly mixed powder into the mold, apply a pressure of 300MPa-400MPa at room temperature and continue for 2 hours to 8 hours, and prepare a powder blank; in this process, the purpose of increasing the density and strength of the blank is achieved;

[0030] Sintering process: put the mold with the powder blank into a vacuum sintering furnace for sintering, and the vacuum degree in the vacuum sintering furnace is controlled at 1×10 -4 Pa, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com