Soil and powder removing, smashing and rubbing integrated machine for straw forage

An all-in-one machine and fodder technology, applied in solid separation, agricultural machinery and implements, and sieves, can solve problems such as difficult soil screening, lack of dust and debris removal, and lack of soil removal functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

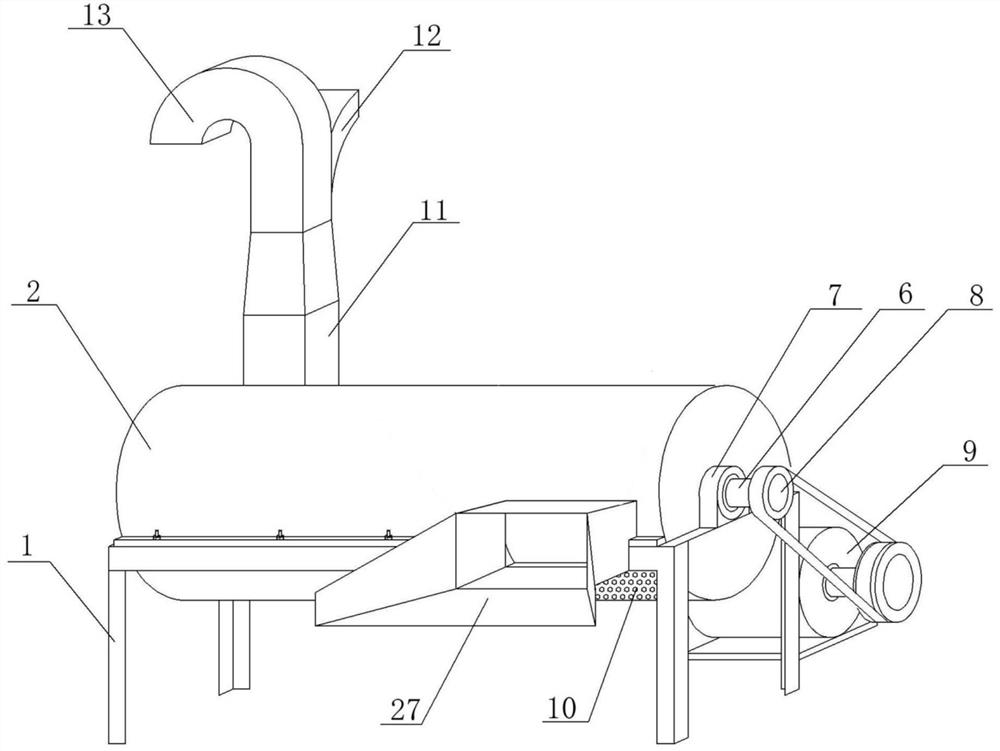

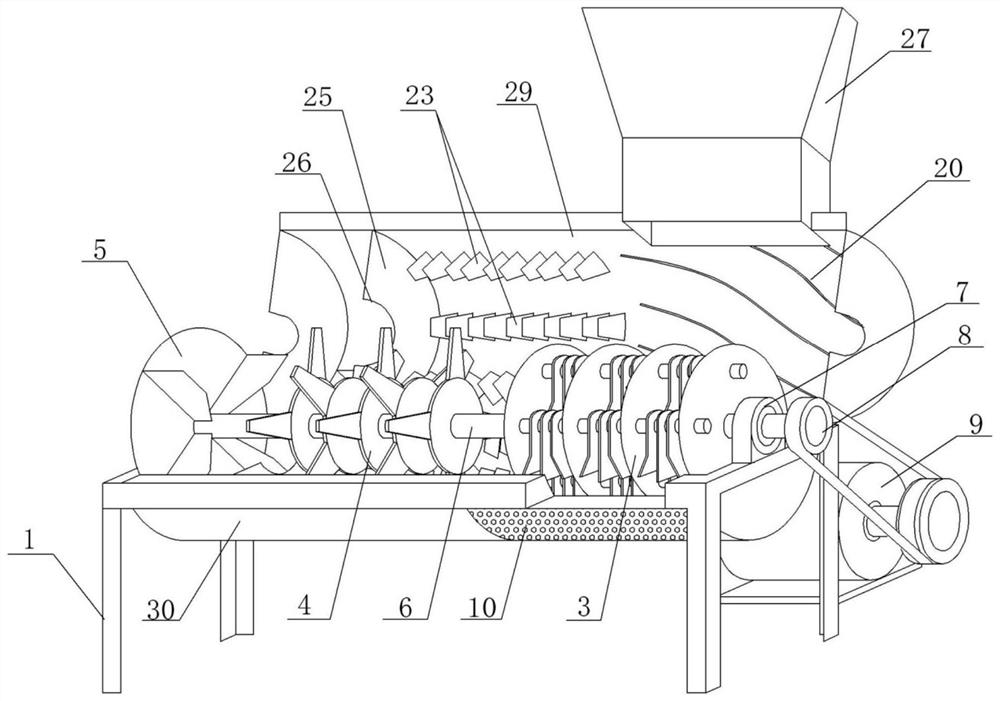

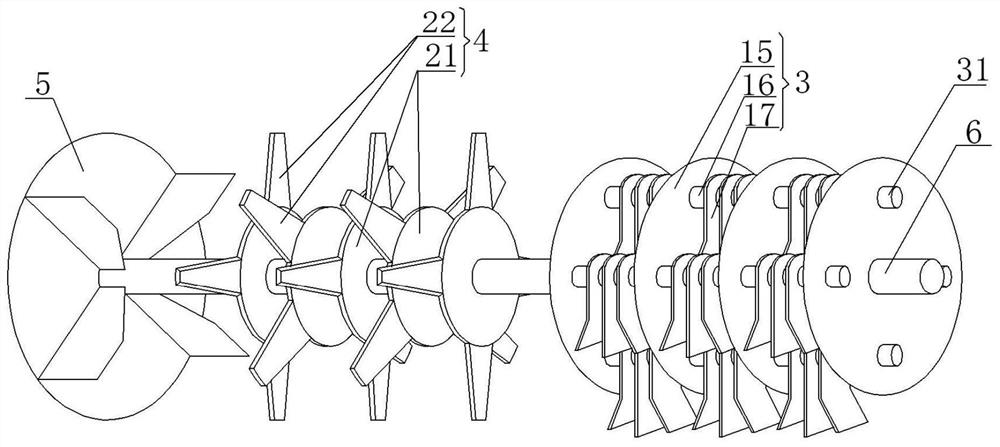

[0038] Example 1: Please refer to Figure 1-10 Shown:

[0039] The present invention provides an integrated machine for removing soil, dust, and crushing and kneading straw forage, which includes a frame body 1, a cylinder body 2, a soil removal mechanism 3, a crushing and kneading mechanism 4, a fan 5 and a main shaft 6. The cylinder body 2 Set on the frame body 1, the cylinder body 2 is provided with a soil removal mechanism 3, a crushing and kneading mechanism 4, a blower fan 5 and a main shaft 6, and the two ends of the main shaft 6 are pivotally connected to the frame body 1 through support bearings 7, one of which is The transmission wheel 8 is connected, and is connected to the output shaft of the motor 9 through the transmission wheel 8 and the transmission belt. A feed inlet is provided, and a soil filter screen 10 is provided at the lower part of the corresponding cylinder body 2; a discharge pipe 11 is provided on the cylinder body 2 corresponding to the fan 5, and...

Embodiment 2

[0054] refer to Figure 11 As shown, as another embodiment, the upper part of the cylinder body 2 corresponding to the soil removal mechanism 3 is provided with an upper feed port, and a feed hopper 28 is provided at the upper feed port, and the short straw or straw can be fed from the The hopper 28 drops into the cylinder body 2 . Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com