Lifting and descending device for electric energy meter checking device

A technology of lifting device and electric energy meter, which is applied in the direction of measuring device, measuring electric variables, instruments, etc., can solve the problems of inconvenient assembly and disassembly of meters, adjustment of photoelectric head, long distance of staff walking back and forth, and easy fatigue of staff, etc. Achieve the effect of small footprint, simple structure and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

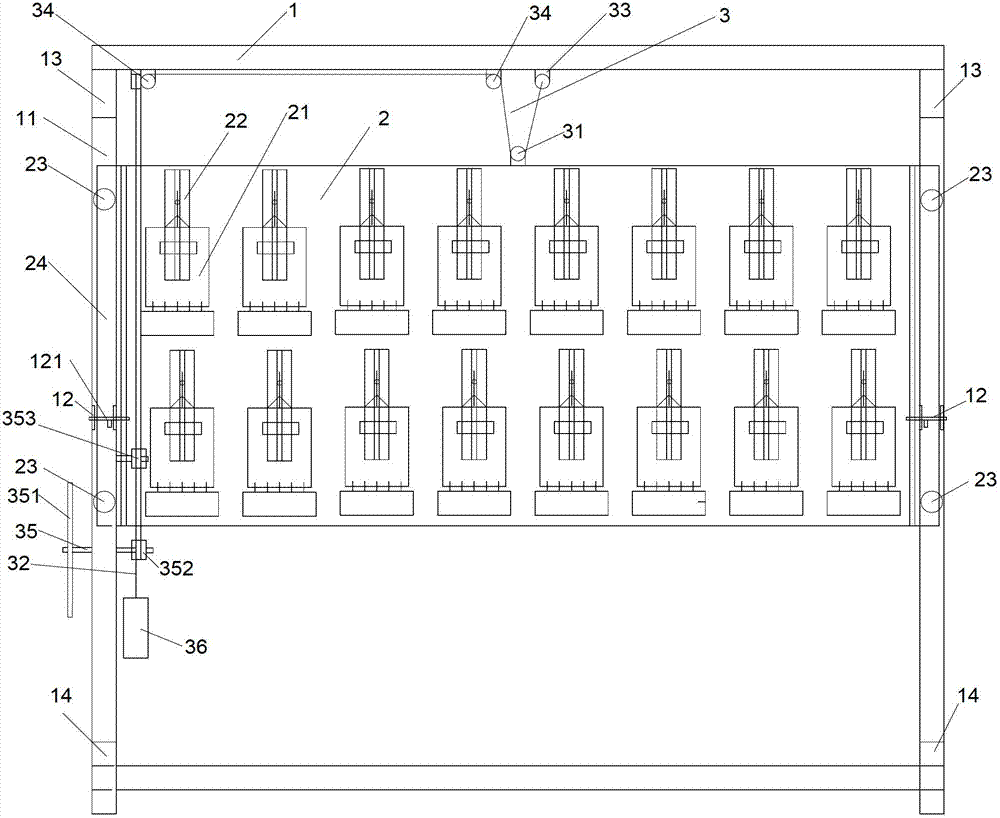

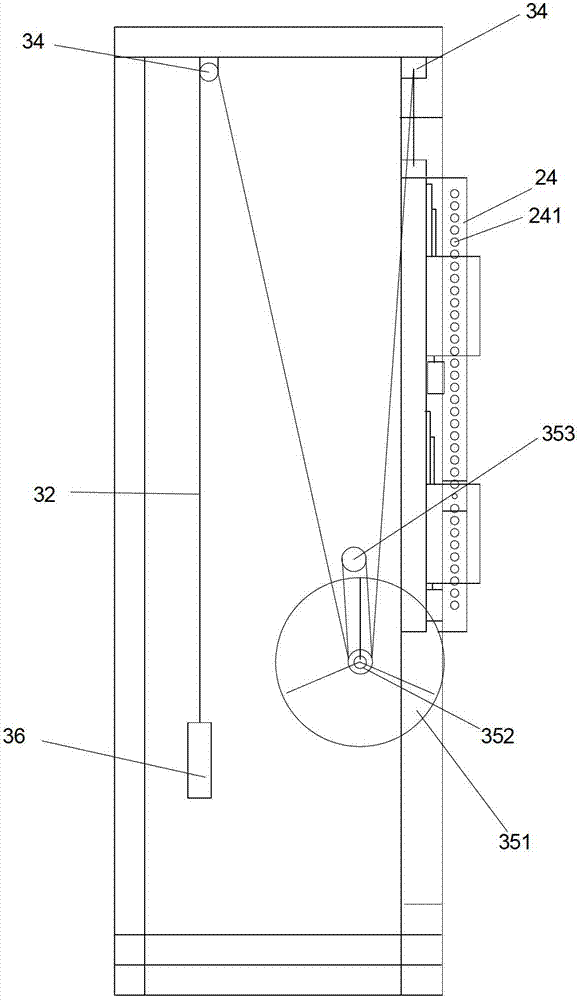

[0025] Such as figure 1 , figure 2 and Figure 5 Shown, a kind of lifting device that is used for electric energy meter detection device comprises fixed frame 1, is provided with movable plate 2 in fixed frame 1, and electric energy meter 21 is housed on movable plate 2, between fixed frame 1 and movable plate 2 There is a drive mechanism 3 for controlling the up and down movement of the movable plate 2. The drive mechanism 3 can control the movement of the movable plate 2 up and down on the fixed frame 1, so that the movable plate 2 stays at a suitable height, which is convenient for the staff to check the electric energy meter.

[0026] In the present invention, the driving mechanism 3 includes a movable pulley 31 arranged on the movable plate 2, a wire rope 32 passing through the movable pulley 31, a fixed ring 33 and a guide wheel 34 arranged on the fixed frame 1, and one end of the wire rope 32 is tied to the fixed On the ring 33, the other end passes through the movab...

Embodiment 2

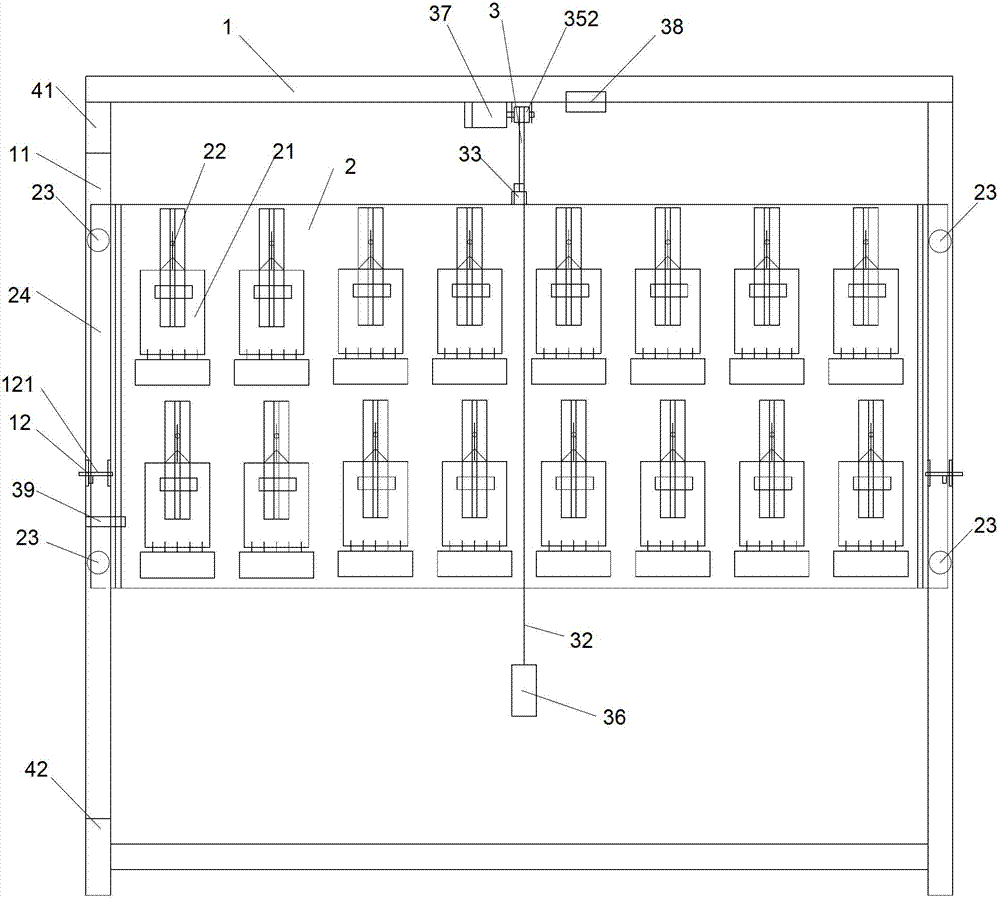

[0036] Such as image 3 , Figure 4 and Figure 5Shown, a kind of lifting device that is used for electric energy meter detection device comprises fixed frame 1, is provided with movable plate 2 in fixed frame 1, and electric energy meter 21 is housed on movable plate 2, between fixed frame 1 and movable plate 2 There is a drive mechanism 3 for controlling the up and down movement of the movable plate 2. The drive mechanism 3 can control the movement of the movable plate 2 up and down on the fixed frame 1, so that the movable plate 2 stays at a suitable height, which is convenient for the staff to check the electric energy meter.

[0037] In the present invention, the drive mechanism 3 includes a fixed ring 33 arranged above the frame of the movable plate 2, a self-locking reduction motor 37 arranged above the fixed frame 1, a pulling wheel 352 arranged at the shaft extension end of the self-locking reduction motor 37, One end is fixedly bolted to the steel wire rope 32 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com