Separate type injection deashing device

A soot cleaning device and separate technology, which is applied in the field of separate blowing soot cleaning devices, can solve the problems of heavy maintenance workload and high investment costs, achieve the effects of saving investment and operation and maintenance costs, and improving economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

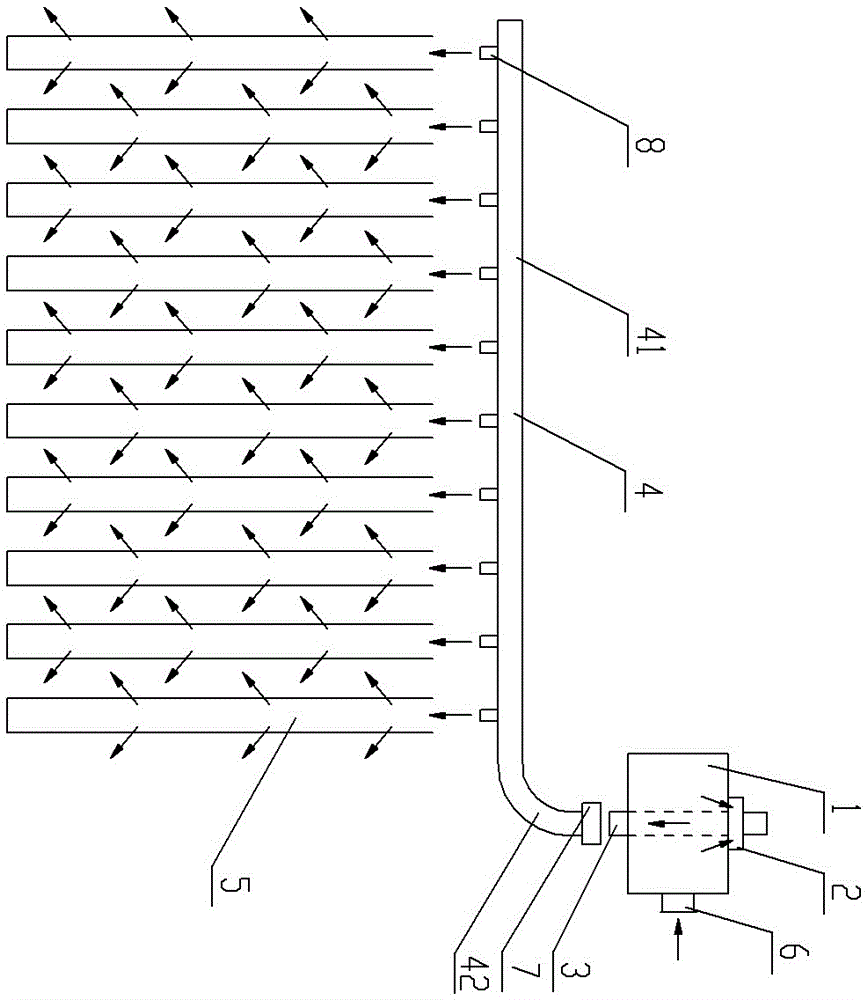

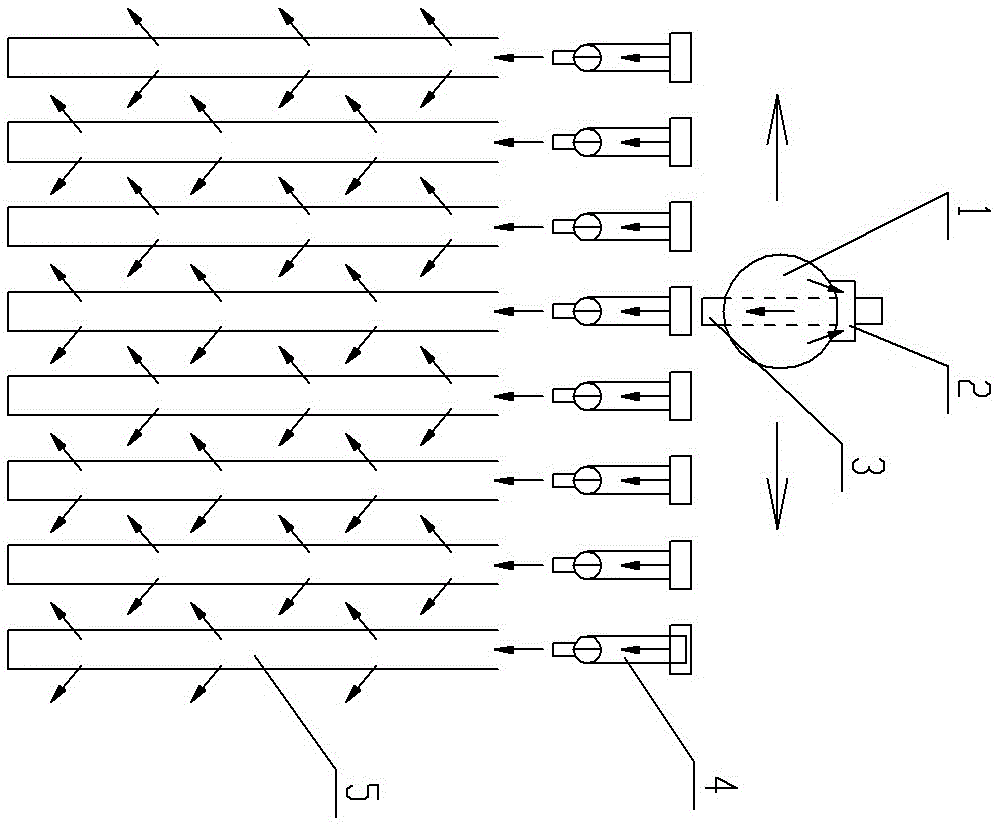

[0010] See figure 1 , figure 2 , the present invention includes an air bag 1, a pulse valve 2, a short connecting pipe 3, a blowing pipe 4, and a filter bag 5. The pulse valve 2 adopts a submerged pulse valve, and the compressed air source is connected to the air bag inlet 6. On the air bag 1 There is an air outlet of the air bag, and it is located on the upper part of the air bag 1. The valve seat of the pulse valve 2 is embedded in the air outlet of the air bag. The air inlet of the pulse valve 2 is connected to the air outlet of the air bag. The air outlet of the pulse valve 2 is set on Inside the air bag 1, one end of the connecting short pipe 3 passes through the lower bottom surface of the air bag 1 and communicates with the air outlet of the pulse valve 2 inside the air bag 1, and the other end of the connecting short pipe 3 and the corresponding blowing pipe 4 below pass through the sealer 7 detachable connection, the outlet of the nozzle 8 on the lower side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com