Cast-in-place prestressed slab and beam mould, construction method thereof and cast-in-place slab and beam manufactured by same

A prestressed and prestressed tendon technology, applied in the direction of floors, joists, girders, etc., can solve the problems of increasing the amount of steel bars, the weight of the floor body, and the complicated construction, so as to increase the bearing capacity, strengthen the structure, strengthen the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

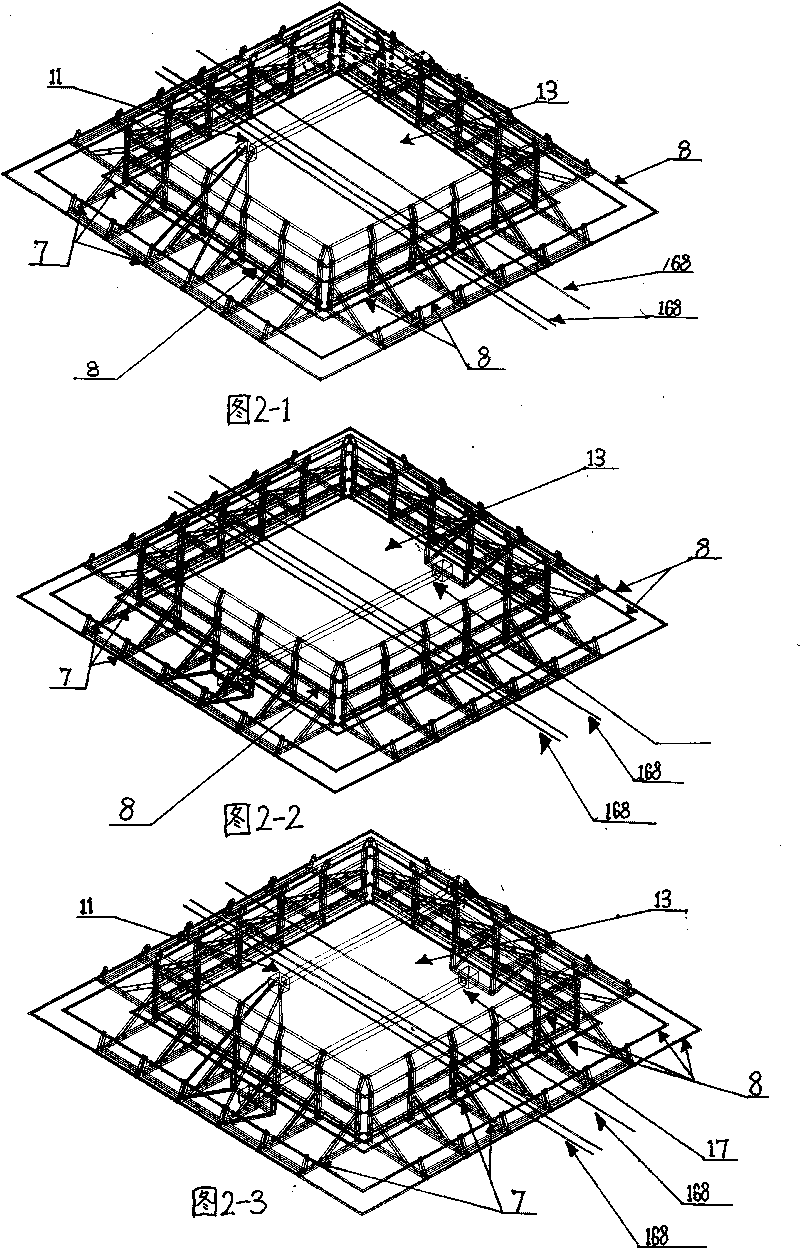

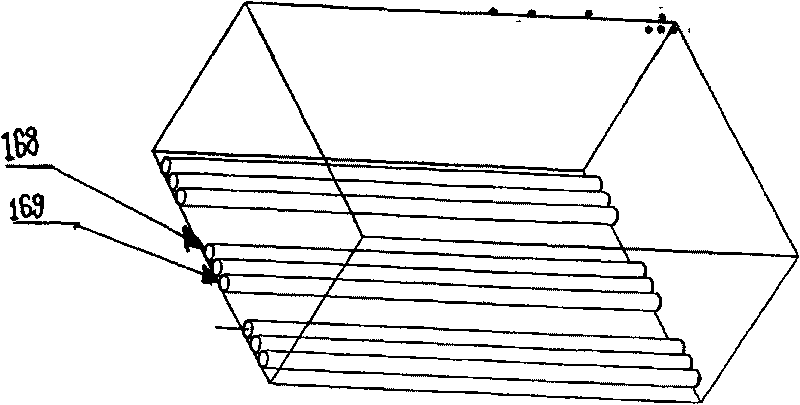

[0030] The concrete cast-in-situ prestressed plate (beam) mold of the present invention will be further described with reference to the accompanying drawings.

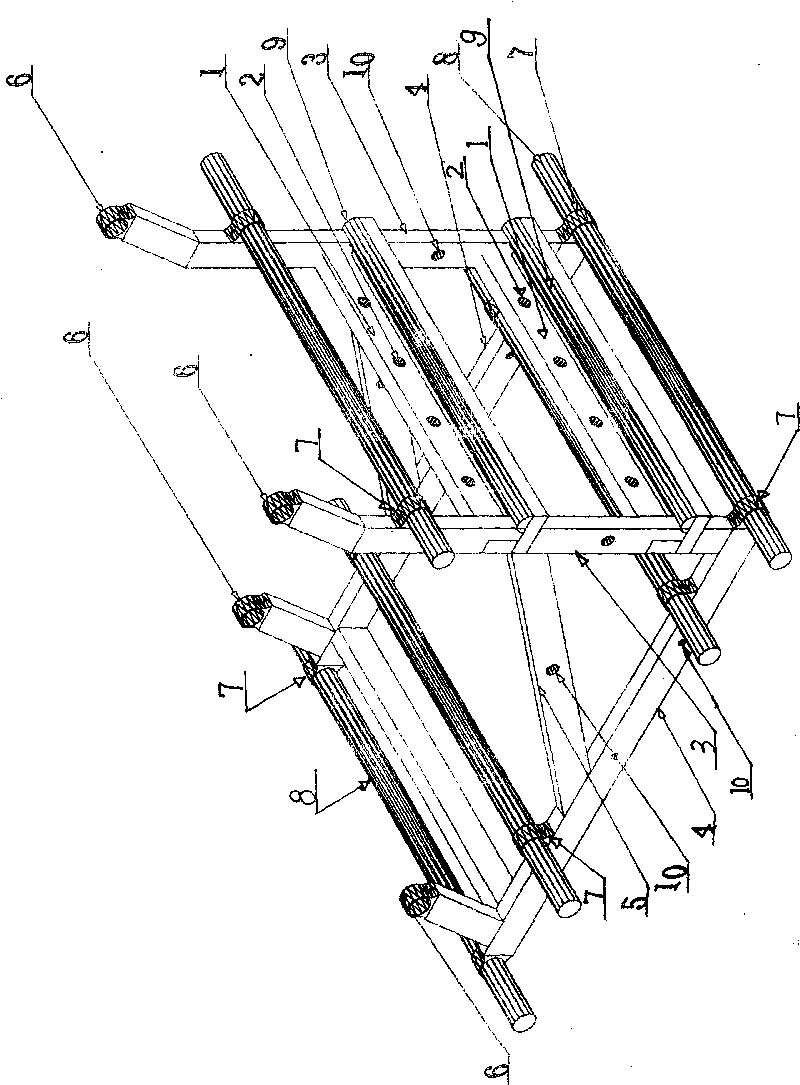

[0031] see figure 1, the single mold includes a number of frames (1) connected together, the frame is provided with a number of steel grooves, holes (2), a number of columns (3) perpendicular to the frame at 90 degrees, and a number of vertical columns at 90 degrees The main beam (4), several connecting brackets (5) between the main beam and the column, several support frame seat buckles (6) arranged on the main beam and the column, and several connecting buckle seats arranged on the main beam and the column (7), a number of pipes and columns for the mutual connection and support of several mold monomers arranged on the main beam and the column (8), and a number of pipes and columns for the interconnection of several mold monomers arranged on the main beam and the column. Screw holes (10), straight strips (9) for lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com