Helical tooth roller type peanut picking device

A helical-toothed, roller-type technology, applied in the field of helical-toothed and roller-type peanut picking devices, to achieve the effects of reducing the rotating speed of the drum, improving adaptability, and reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

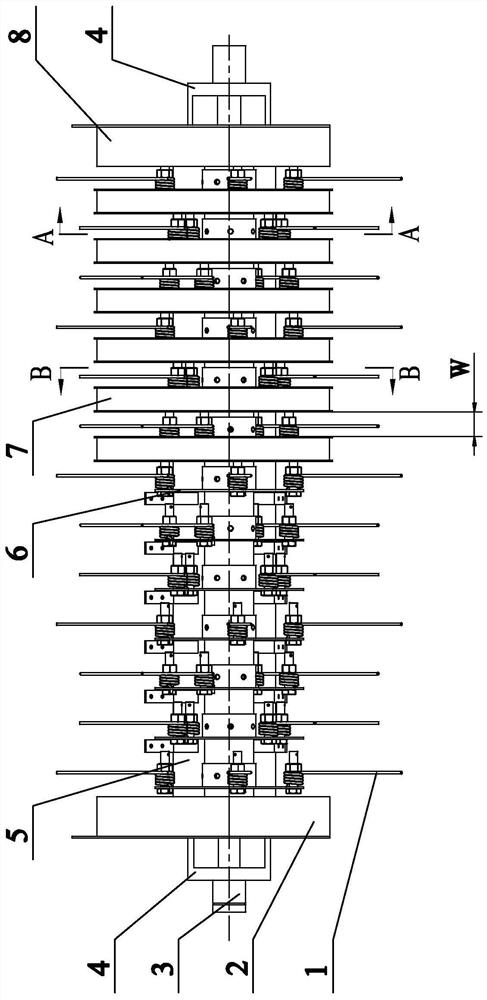

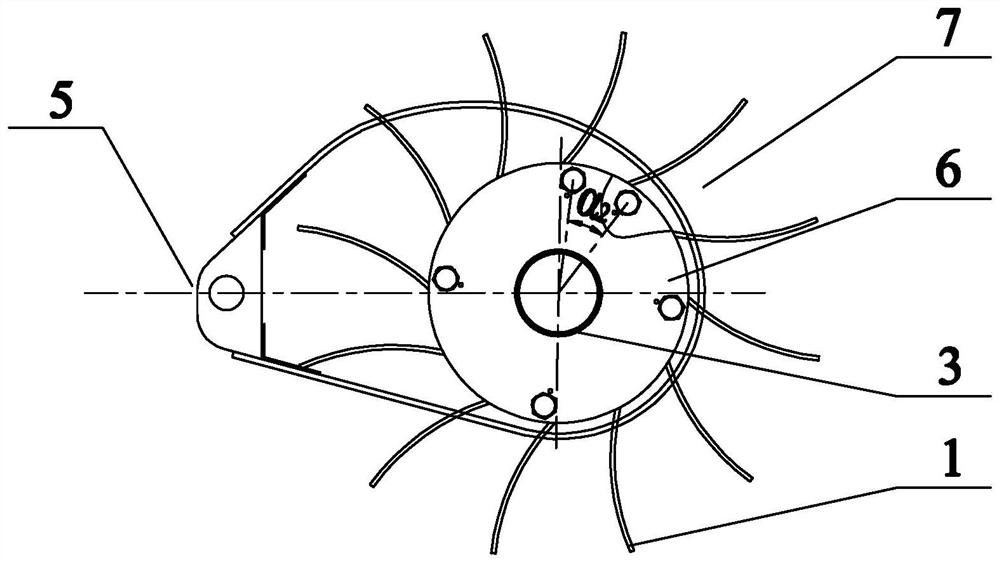

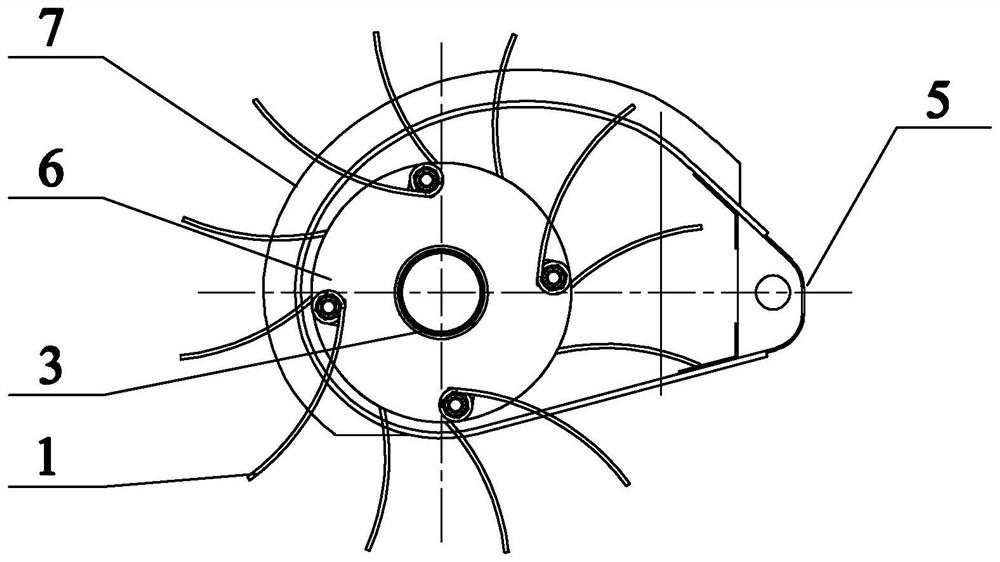

[0055] Example 1: as Figure 1-Figure 9 As shown in the figure, a helical gear roller type peanut pickup device of the present invention includes a pickup tooth 1, a drum guard 7, a pickup drum, a left side plate 2, a right side plate 8, and a rear side plate 5, and the center shaft 3 of the pickup drum is installed On the bearings of the left side plate 2 and the right side plate 8, the left side plate 2 and the right side plate 8 are fixedly connected with the rear side plate 5; the roller guard 7 is interposed between the adjacent toothed roller seats 6 of the pick-up roller and installed at the rear On the side plate 5, the pick-up drum rotates with the central shaft 3, and cooperates with the unit to move the pick-up tooth 1 forward to pick up the peanut plants from bottom to top, and complete a working cycle of picking, lifting, pushing, and emptying in turn.

[0056] like figure 1 , Image 6 , Figure 7 As shown, the pick-up drum includes a central shaft 3 and a plur...

Embodiment 2

[0068] Example 2: as Figure 1-Figure 9 As shown, the difference between this example and Example 1 is: the toothed roller disc in this example is evenly provided with 5 picking teeth 1 along its circumferential direction, and the circumferential offset angle α between the picking teeth of adjacent toothed roller discs 2 =24°, arranged in the same direction of rotation. The arrangement of the picking teeth 1 in this example is a left-handed arrangement; Figure 10 As shown in the figure, the thickness is 2-5mm, the working surface is concave arc, and the tooth root is hinged with the toothed roller seat by an elastic structure, that is, the tooth root of the pick-up tooth 1 is connected to the toothed roller seat by a torsion spring, and it oscillates repeatedly within 10-20° , to avoid damage when encountering obstacles during pickup. This example is made of wear-resistant composite material, which can increase the frictional force and centripetal force of the pick-up tooth...

Embodiment 3

[0075] Example 3: The difference between this example and Example 1 is: as Figure 1-Figure 9 As shown in the figure, the toothed roller disc in this example is evenly provided with 8 pickup teeth 1 along its circumferential direction, and the circumferential offset angle α between the pickup teeth of the adjacent toothed roller discs 2 =15°, arranged in the same direction of rotation. The arrangement of the picking teeth 1 in this example is a right-handed arrangement. The arc radius R of the pick-up tooth 1 4 =163.1mm. Pick-up tooth length L 1 is 128.9mm, the mounting angle β of the pick-up tooth 1 5 = 28.7°.

[0076] The phase angles of the pick-up drum corresponding to the pick-up, lift, push and idling positions along the circumference are β respectively. 1 ~β 4 , in this case β 1 =79.8°, β 2 =90°, β 3 =79.1°, β 4 =111.1°.

[0077] (1) The curve section of the pick-up station consists of an arc constitute; of which, for the same section O 1 is the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com