High-speed needle insertion apparatus

A pin insertion device and high-speed technology, applied in the field of automation, can solve problems such as slow pin insertion speed, unequal number of PINs, and low productivity, and achieve the effects of improving production efficiency, improving production efficiency, and reducing equipment noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

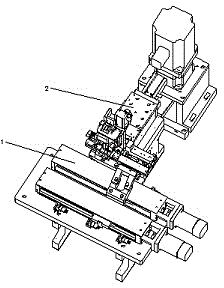

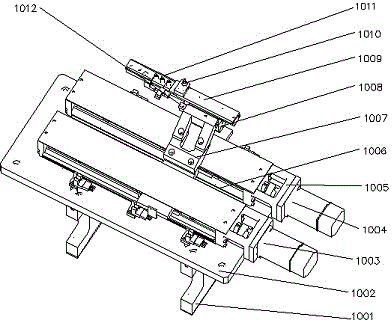

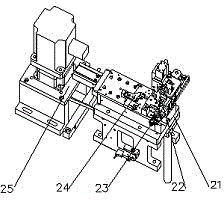

[0035] Such as figure 1 and figure 2 As shown, the present invention includes a product feeding mechanism 1 and a cam feeding pin mechanism 2. The feeding bracket 1001 is fixedly connected to the first feeding motor 1003 and the second feeding motor 1004 through the first connecting plate 1002, and the first feeding horse 1003 is connected to the first feeding motor 1004. The KK module 1005 is fixedly connected, the second feeding motor 1004 is fixedly connected with the second KK module 1006, the second KK module 1006 is fixedly connected with the second finger 1012 through the finger connector 1007, and the product track 1009 is located at the first finger The top of the claw 1008 is fixedly connected with the product pressing block 1011 through the positioning cover plate 1010 .

[0036] The product feeding mechanism 1 uses two sets of feeding structures. When one set is already working, the other set can return to the next product and follow the first set of mechanisms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com