Double-tank double-pump front mixed abrasive jet continuous working system

A pre-mixed abrasive, working system technology, applied in abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problems of uneven abrasive mixing, inability to work stably, abrasive supply interruption, etc., to promote full mixing, reduce The effect of equipment fatigue and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

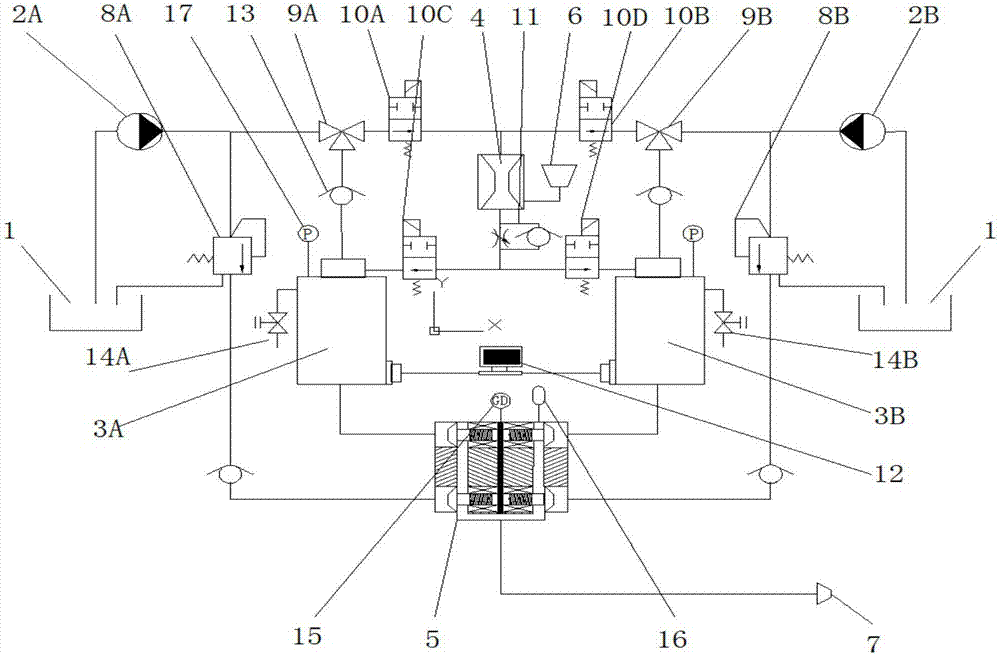

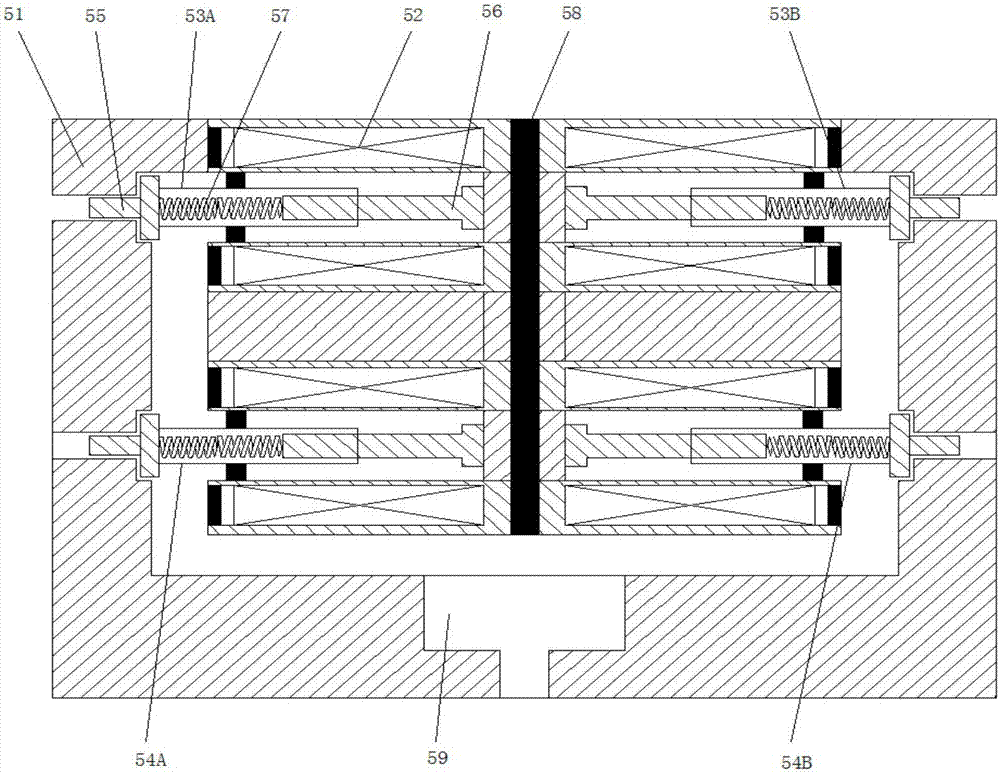

[0027] A double-tank double-pump type pre-mixed abrasive jet continuous working system, including: water tank 1, two sets of water pumps 2A, 2B, two sets of high-pressure abrasive tanks 3A, 3B, jet pump 4, sand adding funnel 6, pre-boosting device 5 , ultrasonic abrasive monitoring system 12, nozzle 7, tee pipe 9A, 9B, pressure gauge 17, accumulator 16, DC motor 15, one-way valve 13, one-way throttle valve 11, overflow valve 8A, 8B, two Position two-way electromagnetic reversing valve 10A, 10B, 10C, 10D; pre-boost device 5 includes: high-pressure housing 51, electromagnet 52, movable valve core 53A, 53B, 54A, 54B, T-shaped valve head 55, fixed iron Block 56, rigid spring 57, magnetic isolation plate 58, mixing chamber 59.

[0028] The water pumps 2A, 2B and the pre-boosting device 5 are equipped with overflow valves 8A, 8B and a one-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com