CO2 adsorption system and continuous CO2 adsorption method

An adsorption system and adsorbent technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high energy consumption, low concentration, poor adsorption efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

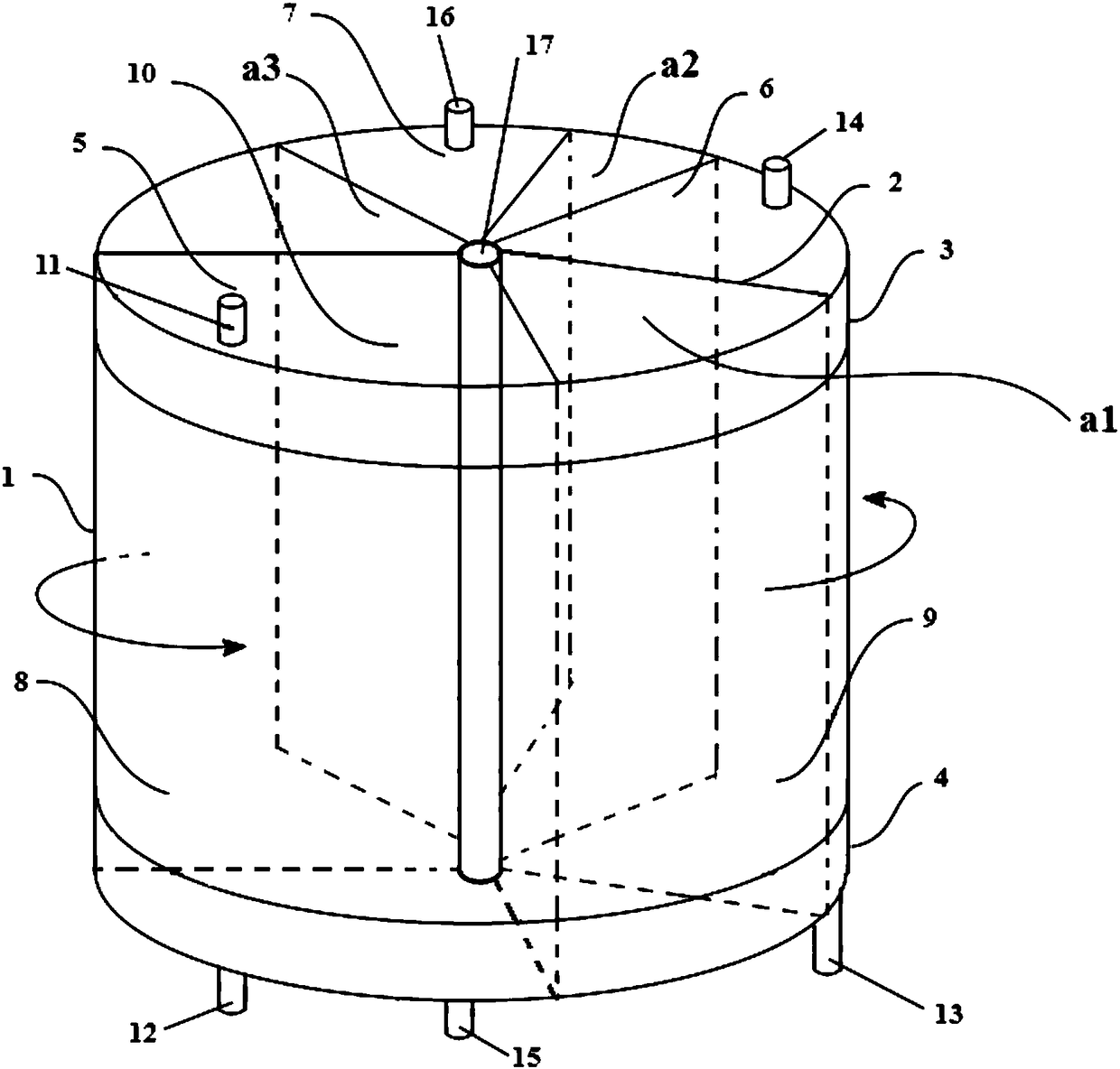

[0070] this invention figure 1 CO shown 2In the adsorption system, the cylinder is a cylinder with a diameter of 1m and a height of 0.8m with openings at both ends. There are 19 baffles inside to divide the internal space of the cylinder into 20 adsorbent filling areas.

[0071] The upper cover and the lower cover are provided with an adsorption zone, a desorption zone, a cooling zone, and buffer zones a1, a2 and a3, and the formed adsorption section accounts for 40% by volume, the desorption section accounts for 20% by volume, and the cooling section accounts for 20% by volume , the total volume of the buffer section accounts for 20% by volume.

[0072] The adsorption section contains 8 adsorbent filling areas, the desorption section contains 4 adsorbent filling areas, the cooling section contains 4 adsorbent filling areas, and the buffer section contains 4 adsorbent filling areas (among them, a1 contains 2 and a2 contains 1, a3 contains 1).

[0073] Barriers are set at bo...

Embodiment 2

[0082] this invention figure 1 CO shown 2 In the adsorption system, the cylinder is a cylinder with a diameter of 2m and a height of 1m with openings at both ends. There are 17 baffles inside to divide the internal space of the cylinder into 18 adsorbent filling areas.

[0083] The upper cover and the lower cover are provided with an adsorption area, a desorption area and a cooling area, and the formed adsorption section accounts for 50% by volume, the desorption section accounts for 20% by volume, the cooling section accounts for 15% by volume, and the total volume of the buffer section accounts for 15% by volume .

[0084] The adsorption section contains 8 adsorbent filling areas, the desorption section contains 3 adsorbent filling areas, the cooling section contains 3 adsorbent filling areas, and the buffer section contains 4 adsorbent filling areas (among them, a1 contains 2 and a2 contains 1, a3 contains 1).

[0085] Barriers are set at both ends of the cylinder with a...

Embodiment 3

[0094] this invention figure 1 CO shown 2 In the adsorption system, the cylinder is a cylinder with a diameter of 3m and a height of 2m with openings at both ends. There are 23 baffles inside to divide the internal space of the cylinder into 24 adsorbent filling areas.

[0095] The upper cover and the lower cover are provided with an adsorption area, a desorption area and a cooling area, and the formed adsorption section accounts for 45% by volume, the desorption section accounts for 20% by volume, the cooling section accounts for 15% by volume, and the total volume of the buffer section accounts for 20% by volume .

[0096] The adsorption section contains 11 adsorbent filling areas, the desorption section contains 4 adsorbent filling areas, the cooling section contains 3 adsorbent filling areas, and the buffer section contains 6 adsorbent filling areas (among them, a1 contains 2 and a2 contains 2, a3 contains 2).

[0097] Barriers are set at both ends of the cylinder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com