Continuous transfer system and material receiving device thereof

A technology of receiving device and unloading device, which is applied to storage devices, transportation and packaging, conveyor control devices, etc., can solve the problems of unconnected open-pit mines, dust pollution of transportation lines, and high transfer costs, and improve operation. Efficiency, reduced transshipment costs, and the effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

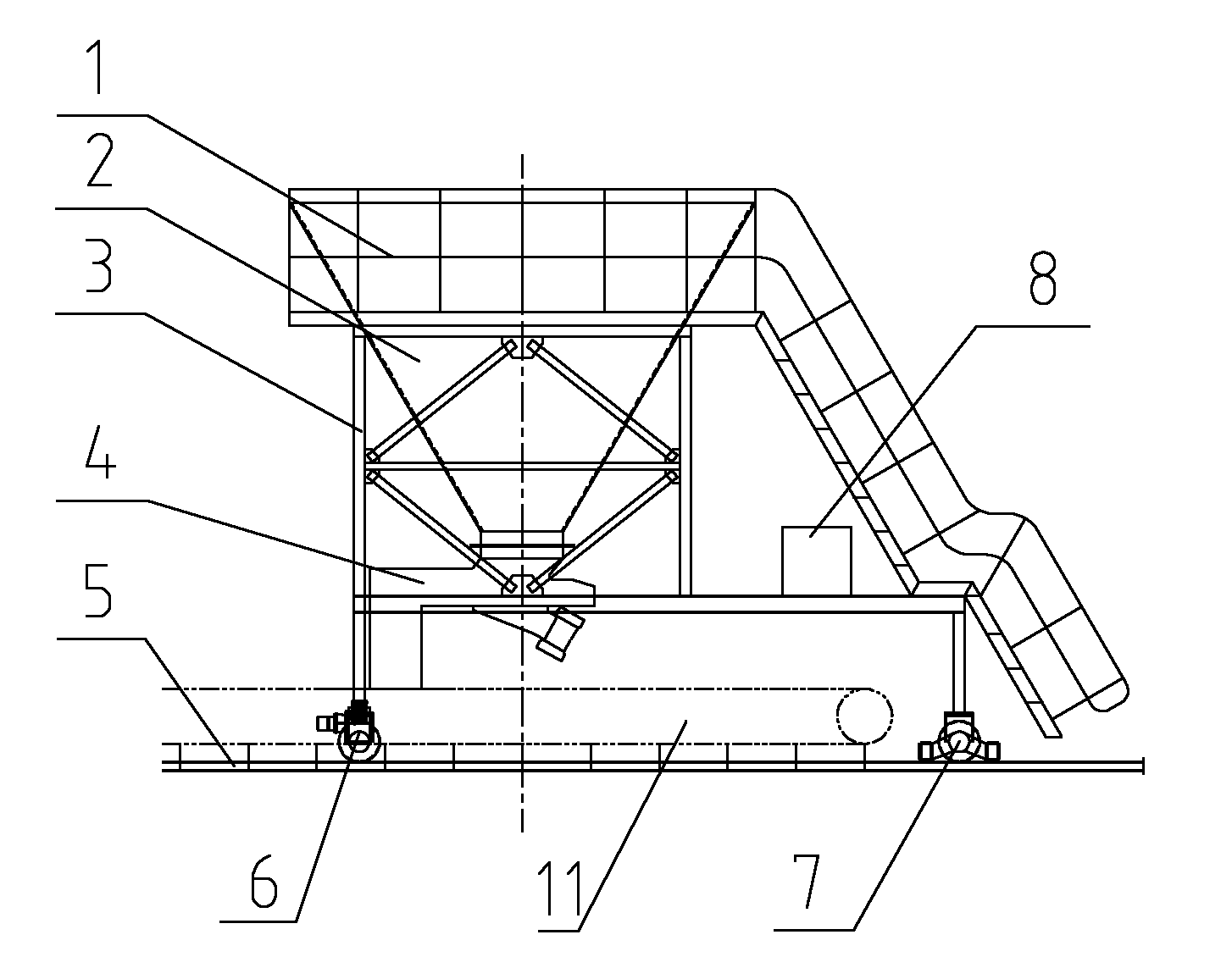

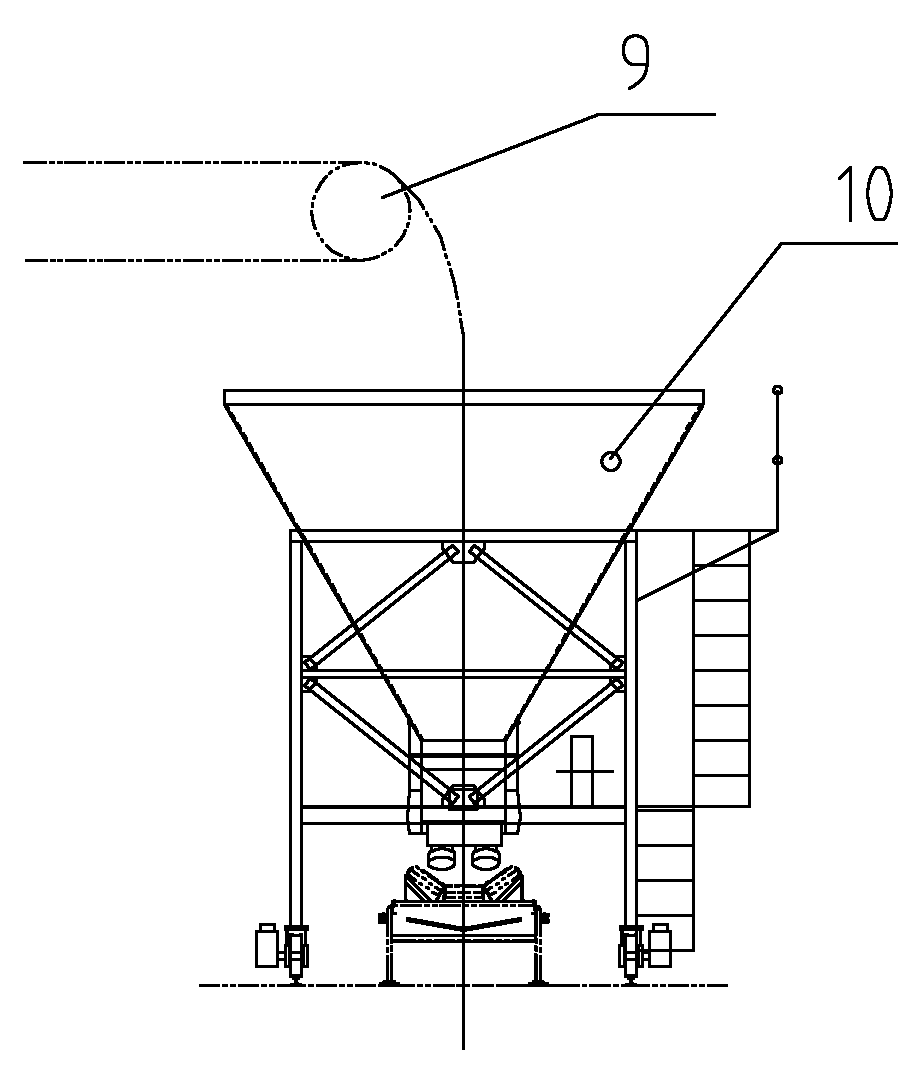

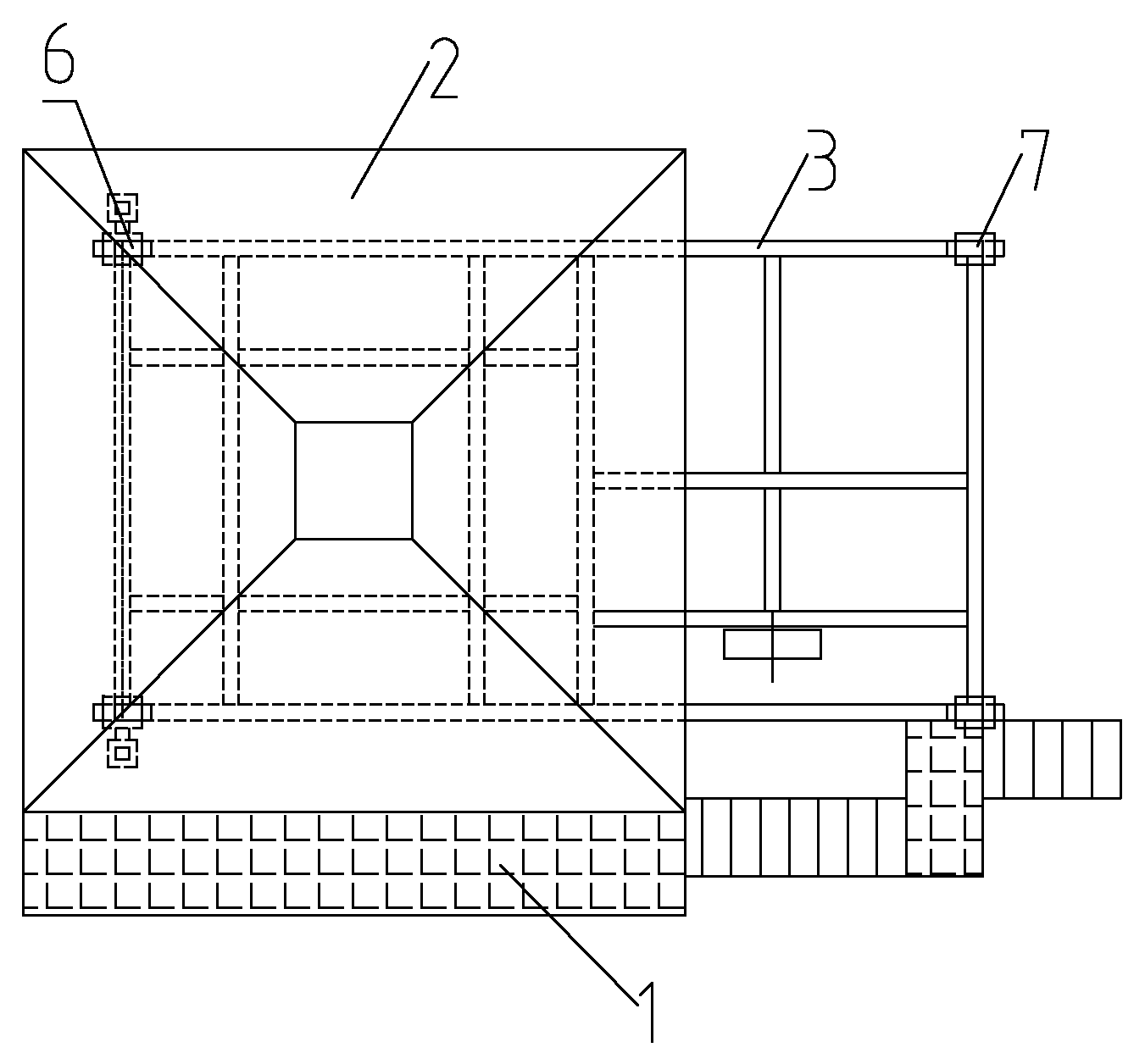

[0025] As one aspect of the present invention, the present invention provides a material receiving device of a continuous transfer system. Such as Figure 1-3 As shown, the material receiving device of the continuous transfer system in the present invention includes: frame 3 and hopper 2; wherein, hopper 2 is arranged on the frame 3; frame 3 straddles the belt conveyor 11 of the continuous transfer system Above and along the conveying direction of the belt conveyor 11, it is movably arranged. Preferably, a stair walking platform 1 is arranged on the frame 3, through which the operator can reach various inspection and maintenance points of the material receiving device, so as to perform corresponding operations. Preferably, the inner side of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com