Die cutting method and device for conductive cloth with ultra-thin single-sided adhesive layer

A single-sided adhesive, conductive cloth technology, applied in lamination devices, chemical instruments and methods, lamination and other directions, can solve the problems of large processing errors, low accuracy, low production efficiency, etc., to reduce production costs and improve production. High efficiency and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

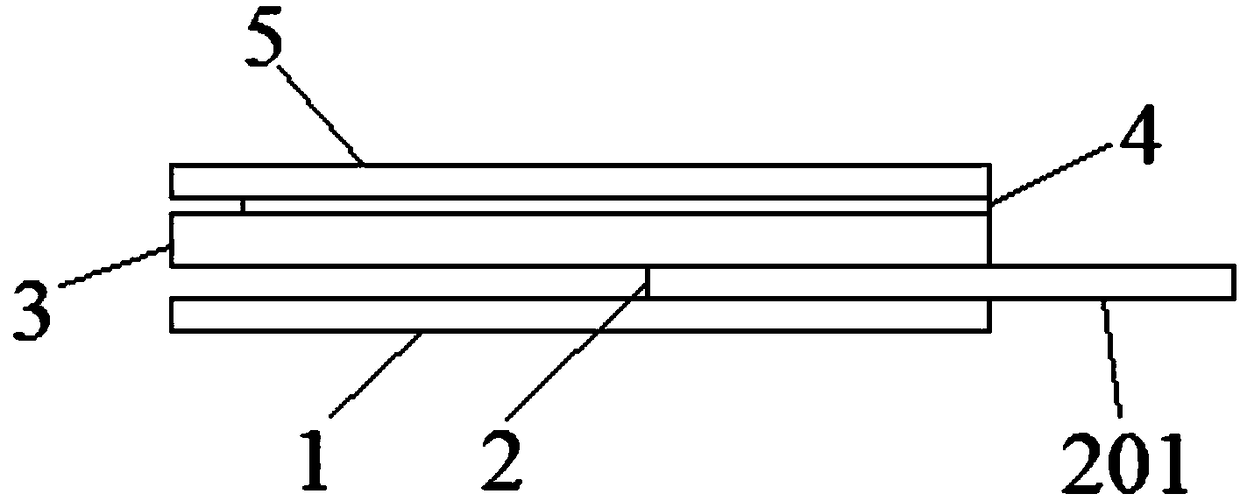

[0050] A die-cutting method of conductive cloth with ultra-thin single-sided adhesive layer, such as figure 1 As shown, the conductive cloth includes a conductive cloth layer protective film 1, a blue film layer 2, a conductive cloth layer 3, a single-sided adhesive layer 4, and a single-sided adhesive layer protective film 5, which are laminated sequentially from bottom to top. The width of 4 is less than the width of the conductive cloth layer 3, and the blue film layer 2 is provided with a handle 201 that exposes the conductive cloth layer 3, and the die-cutting method specifically includes the following steps:

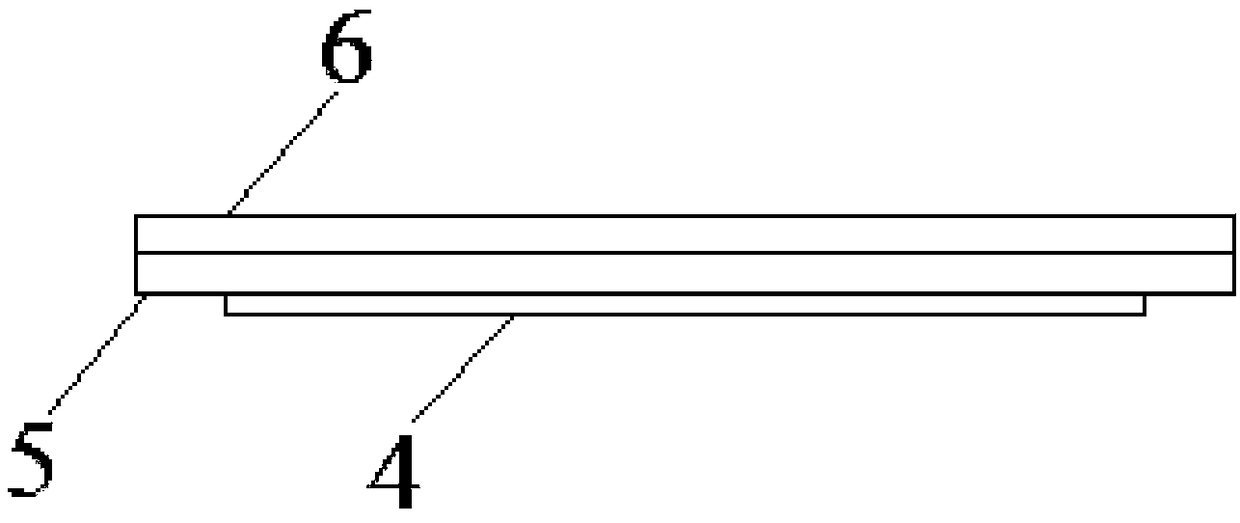

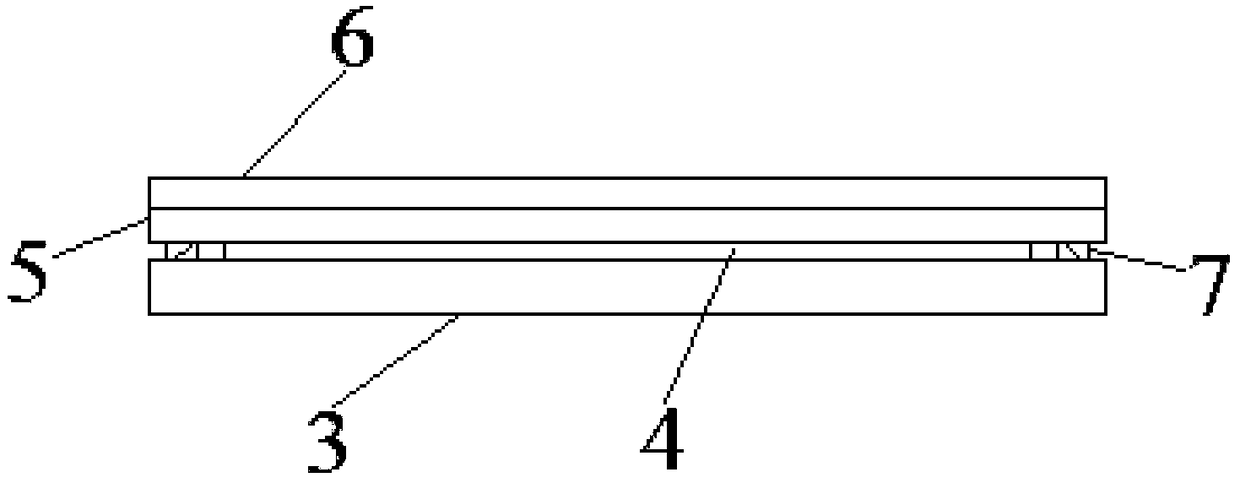

[0051] 1) if figure 2 As shown, stick the single-sided adhesive layer 4 and the single-sided adhesive layer protective film 5 together, and attach the auxiliary protective film 6 on the single-sided adhesive layer protective film 5, and then perform the first die-cutting, respectively The surface adhesive layer 4 and the single-sided adhesive layer protective fil...

Embodiment 2

[0066] In this embodiment, the thickness of the single-sided adhesive layer 4 is 0.005 mm, and the rest are the same as in Embodiment 1.

Embodiment 3

[0068] In this embodiment, the thickness of the single-sided adhesive layer 4 is 0.01 mm, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com