Patents

Literature

62results about How to "Evenly vented" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

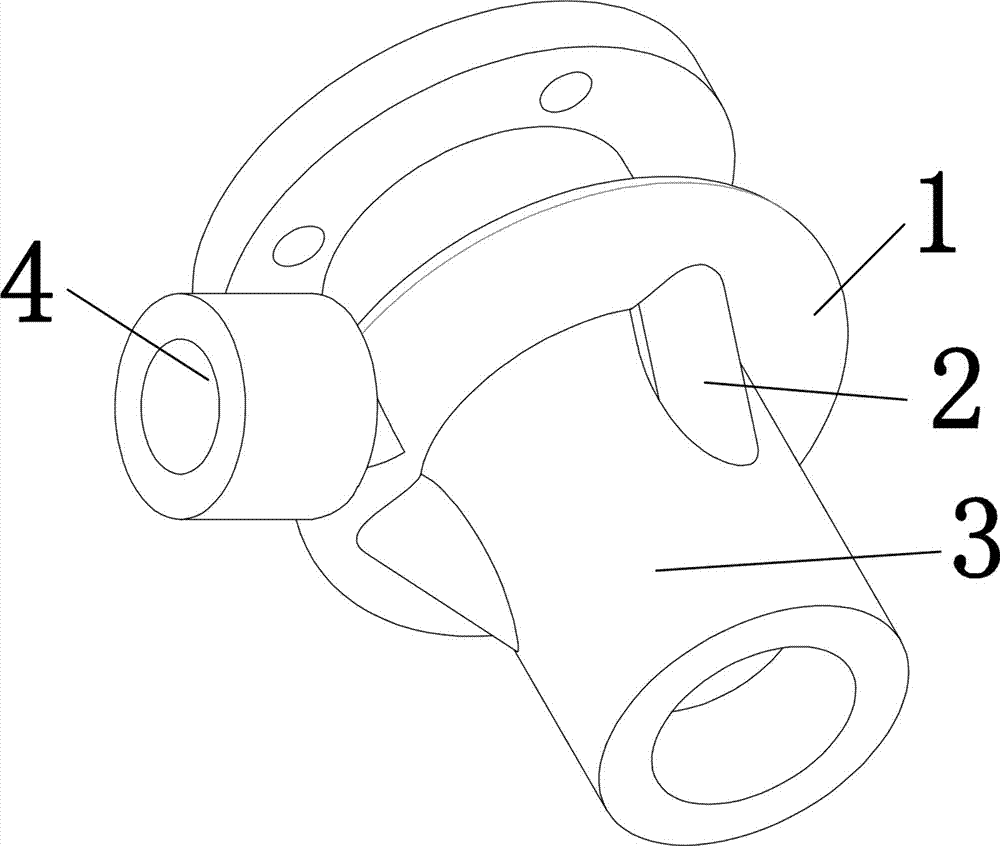

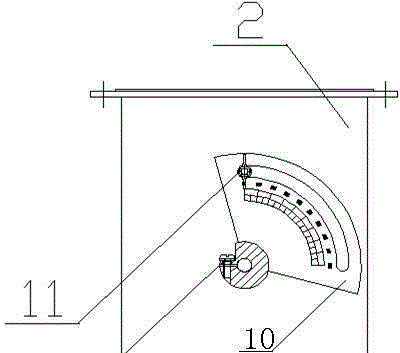

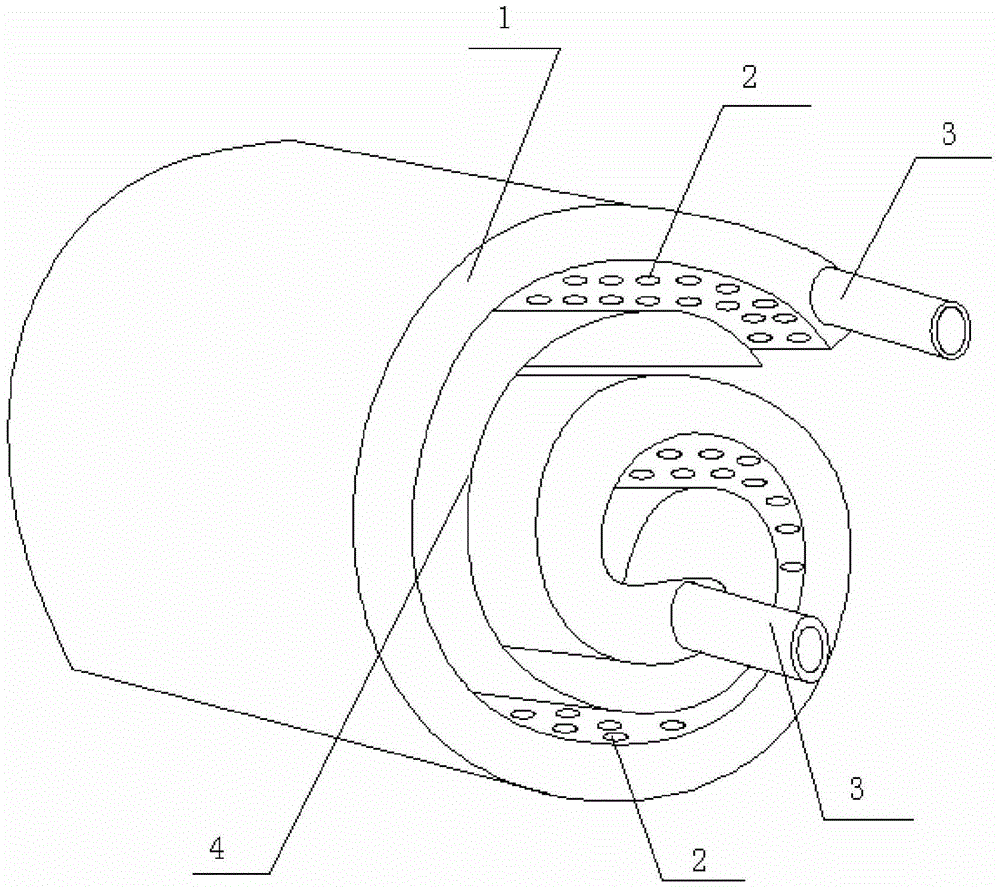

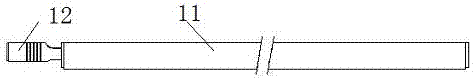

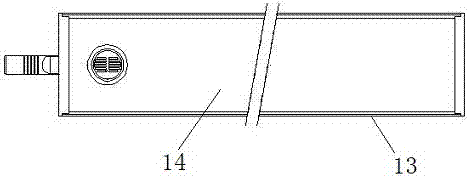

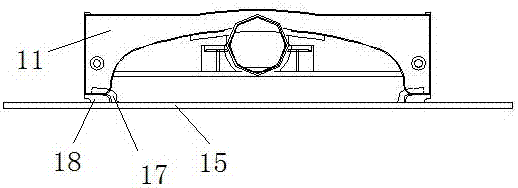

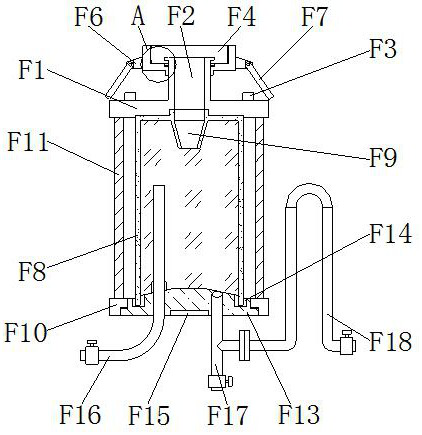

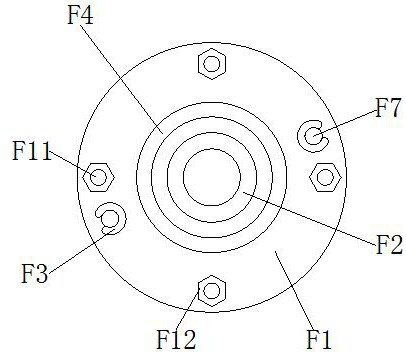

Structure and method for coaxial protection gas blowing of laser welding machine

ActiveCN106984899ANot easily oxidizedEvenly ventedLaser beam welding apparatusAcute angleEngineering

The invention discloses a structure for coaxial protection gas blowing of a laser welding machine. The structure comprises a surrounding coil pipe and protection gas inlet pipes. The surrounding coil pipe is wound around the outer side of a laser coaxial sleeve. One end of the surrounding coil pipe is connected with a protection gas inlet. The three protection gas inlet pipes are arranged and arranged at the lower end of the surrounding coil pipe to connect the surrounding coil pipe with the laser coaxial sleeve. The included angle between each protection gas inlet pipe and the laser coaxial sleeve is an acute angle. The position, connected with the protection gas inlet pipes, of the laser coaxial sleeve is provided with a coaxial sleeve protection gas inlet. The structure has the beneficial effects that through the arrangement of the surrounding coil pipe and the protection gas inlet pipes, protection gas is evenly distributed on the periphery of a welding head, gas outflow is even, a welding line is not prone to oxidization during welding, the welding process is stable, the welding line is smooth, the quality is enhanced, and welding gas holes are avoided; and compared with side-face single-direction gas inflow, waste of the protection gas is not prone to being caused, the usage amount of the protection gas is reduced, splashing objects entering the coaxial sleeve during welding can be blown away, and lens damage is prevented.

Owner:WUHAN YIFI LASER EQUIP CO LTD

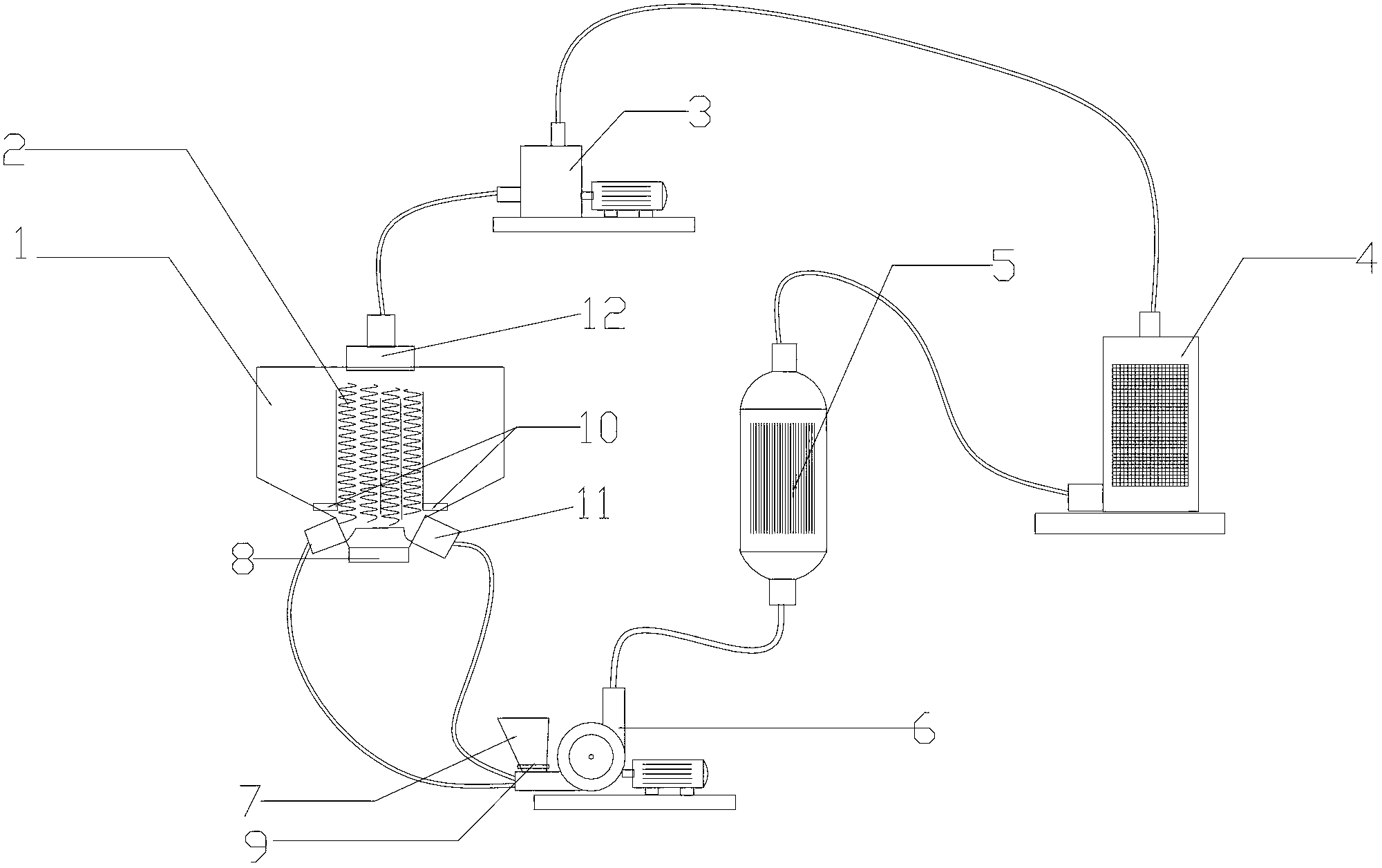

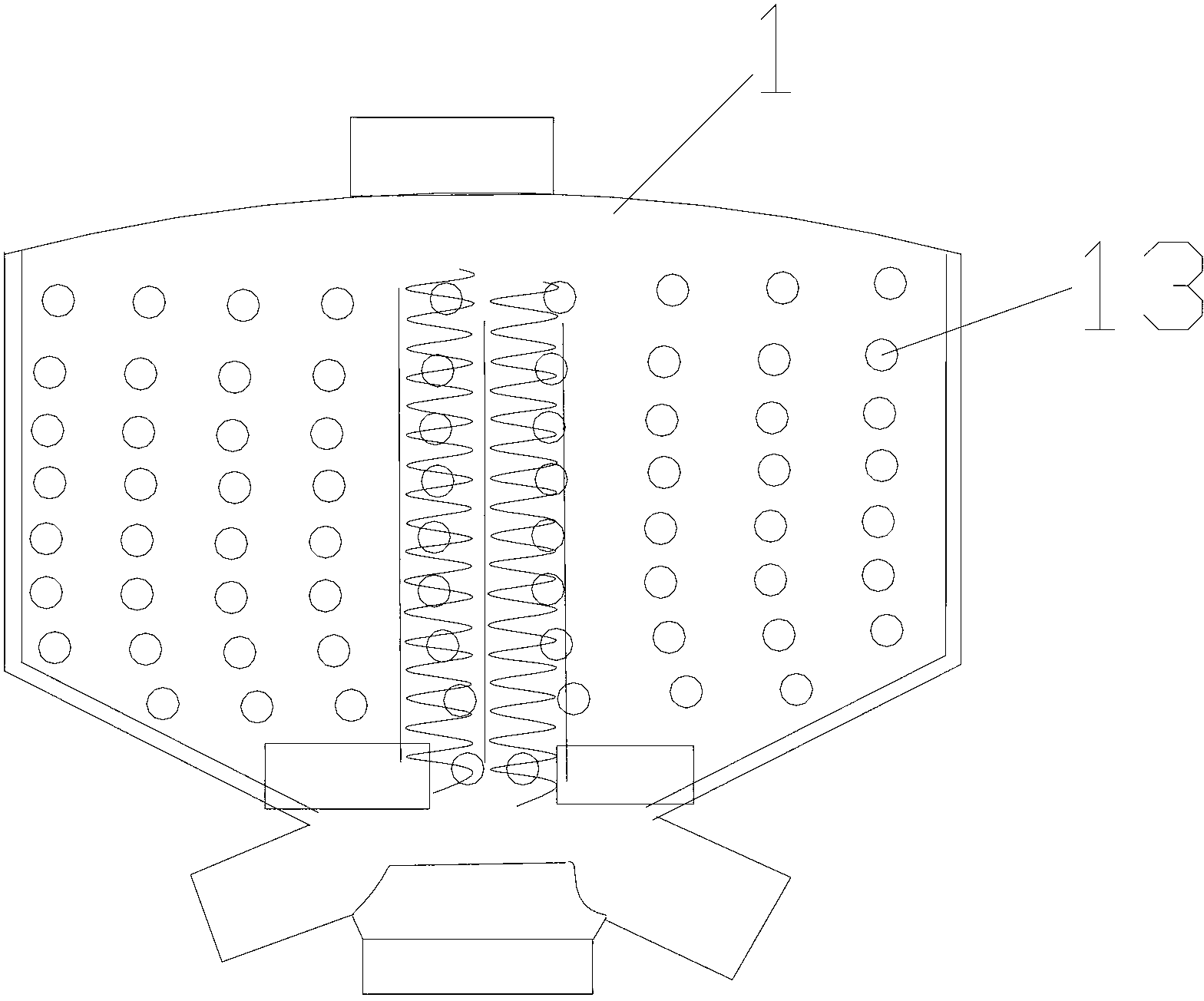

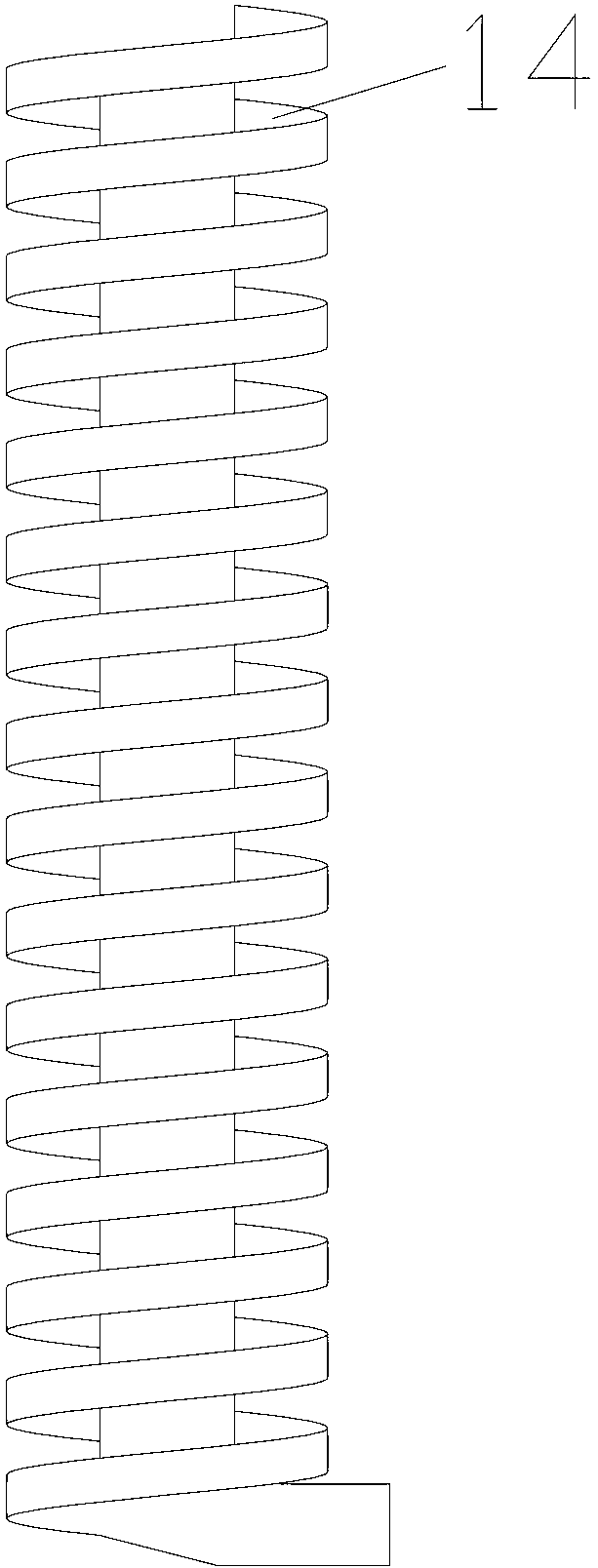

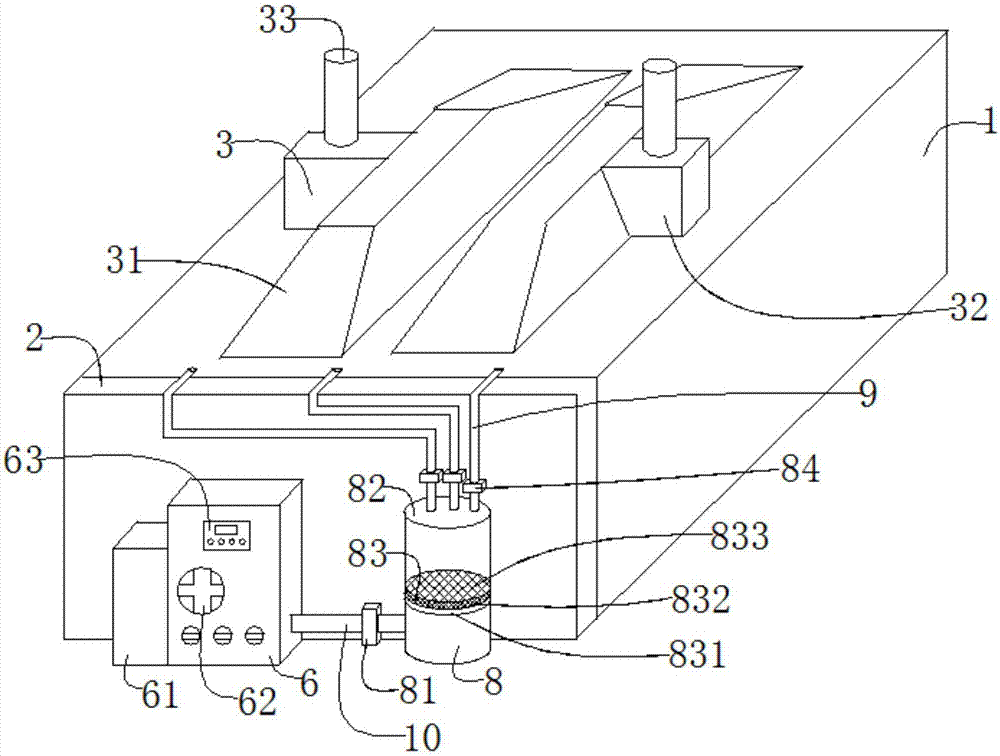

Biomass particle gasification process for kiln

ActiveCN102703123AHigh densityIncrease replacement rateCombustible gas productionWood shavingsHigh energy

The invention discloses a biomass particle gasification process for a kiln, which comprises the following steps of: smashing and pressing sawdust and wood shavings into biomass particles; adding the biomass particles into a biomass gas gasification furnace according to certain weight to carry out a thermalization cracking reaction to generate mixed gas by controlling the burning temperature in the furnace to be 900-1,200 DEG C; spraying the outlet mixed gas, and introducing the sprayed gas into a purifier for heat exchange; cooling, then introducing the gas into a cyclone chamber, and separating out ash content in the gas under the action of cyclone separation; and introducing gas after the cyclone separation into a separator, and under the condensation action of the separator, further separating out clean gas and liquid residues by controlling the clean gas output temperature to be 20-25 DEG C. Compared with the prior art, the biomass particle gasification process for the kiln has the advantages of high energy conversion ratio, high gas heat value, good purification effect, low tar content, large gas output and uniform gas outlet.

Owner:柳州东侯生物能源科技有限公司

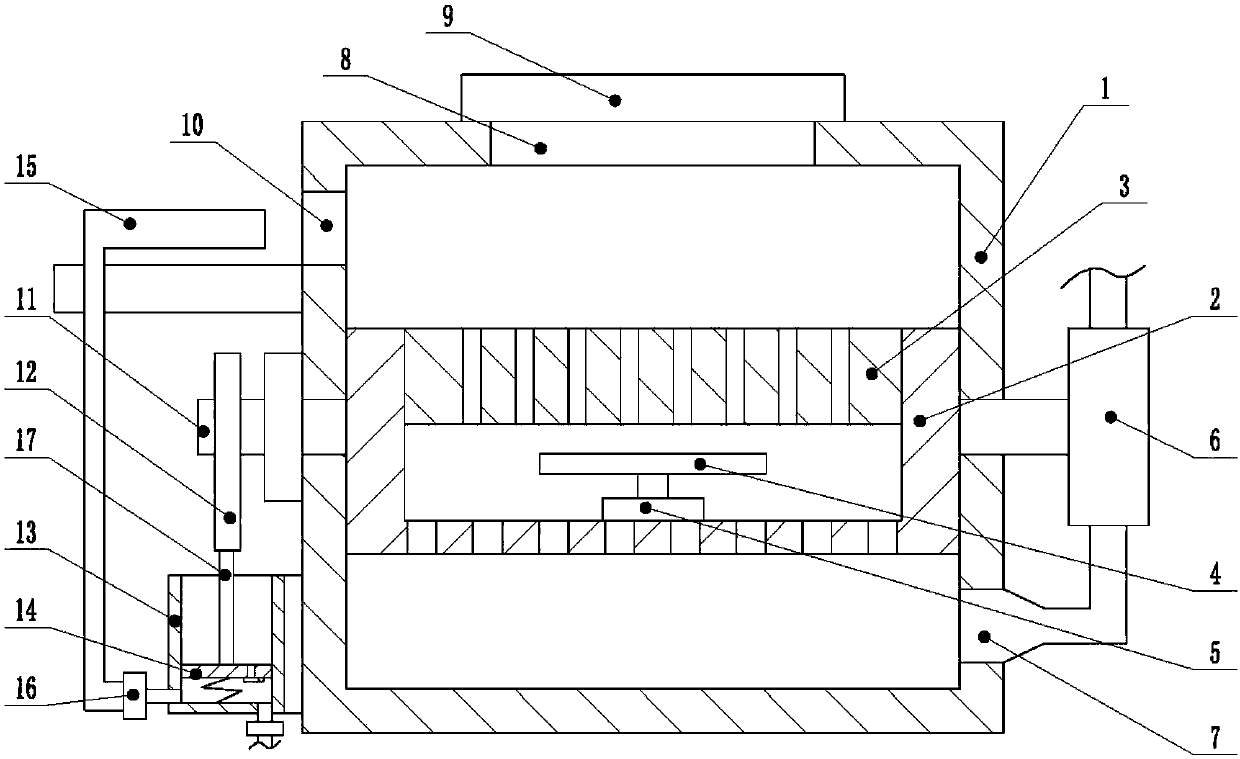

Energy-saving drying machine and energy-saving drying method

ActiveCN102706111AAvoid cakingFully contactedDrying using combination processesDrying gas arrangementsVacuum pumpingAgricultural engineering

The invention relates to an energy-saving drying machine. The energy-saving drying machine comprises a drying hopper, a vortex separating device and a charging hopper and further comprises a vacuum pumping device, an air moisture filtering device, an air heating device and a hot air pressurizing device which are connected in turn, wherein an air outlet is arranged above the drying hopper; an air inlet is arranged under the drying hopper; the vacuum pumping device is connected with the air outlet; the hot air pressurizing device is connected with the air inlet; the charging hopper is connected between the air inlet and the hot air pressurizing device; the vortex separating device is arranged in the drying hopper and comprises a spiral ascending guide chute; and the air inlet is opposite to the lower end of the guide chute. The invention also relates to an energy-saving drying method. The energy-saving drying machine has the advantages that the materials are difficult to accumulate, agglomerate and decompose, the drying effect is good, the drying efficiency is high, the energy consumption is effectively reduced and the drying time is shortened.

Owner:合诚技术股份有限公司

Cotton fabric drying device

InactiveCN107916552APrevent roll upAvoid wrinklesTextiles and paperLaundry driersState of artPulp and paper industry

The invention relates to a cotton fabric drying device which comprises a drying cylinder, wherein a rotating shaft is rotationally connected inside the drying cylinder; a collection tank is fixedly connected with the rotating shaft; a collecting disc is fixed on the collection tank; vent holes are formed in the bottom of the collection tank; drying holes are formed in the collection disc; negativepressure blades are rotationally connected inside the collection tank; the negative pressure blades are positioned bellow the collection disc; an air inlet hole is formed in the drying cylinder abovethe collection disc; an electric heating wire is arranged inside the air inlet hole; an air outlet hole is formed in the drying cylinder below the collection tank; an air outlet tube is communicatedto the air outlet hole; a turbine is rotationally connected inside the air outlet tube; and the turbine is fixed on the rotating shaft. Compared with the prior art, the cotton fabric drying device provided by the scheme of the invention is capable of sucking and fixing clothes on the collection disc through the collection tank, the drying cylinder, the turbine and the like, and is capable of drying clothes through hot air along with rotation of the collection tank, not only is air flowing around the clothes intensified, but also the clothes are prevented from being tangled together and prevented from wrinkles, the contact area of hot air with the clothes is ensured, and the drying efficiency is increased.

Owner:NINGBO WENZE TEXTILE CO LTD

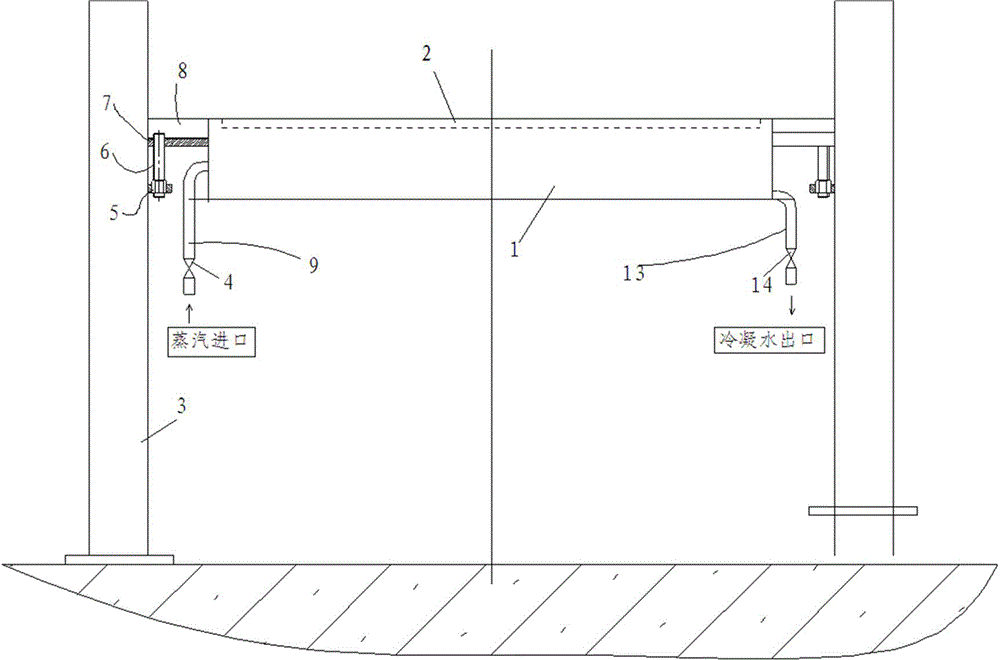

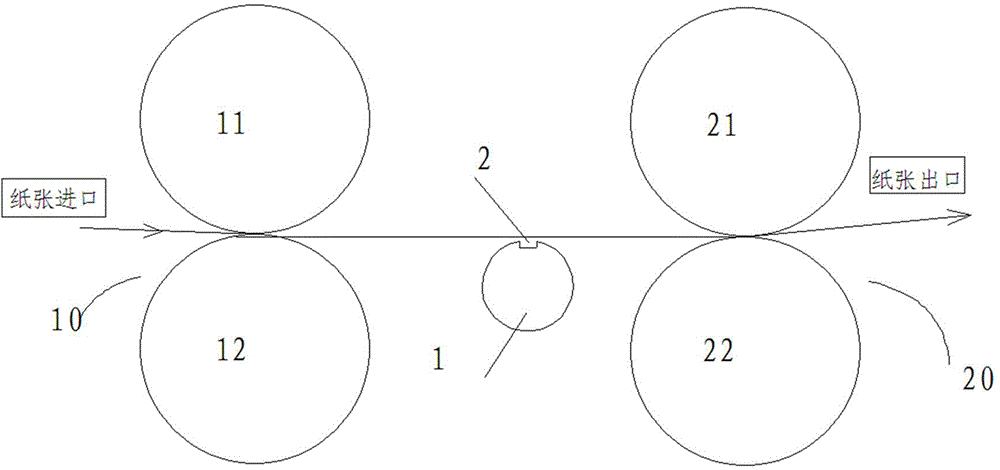

Humidifying device of calender

ActiveCN104153239AIncrease moistureImprove smoothnessDamping devicesPulp and paper industryControl valves

The invention discloses a humidifying device of a calendar. The humidifying device of the calendar comprises a steam box, the steam box is arranged at the position between a first calender and a second calender, the steam box is of a cylindrical structure, the axis of the cylinder is parallel to the axis of the first calender and the axis of the second calender, the steam box is provided with an upward air outlet which is parallel to the axis of the steam box, the axial width of the air outlet is identical with the width of a paper web, the air outlet is arranged below paper, supporting arms are arranged at the two ends of the upper portion of the steam box, the supporting arms are connected with a rack through a supporting structure, one end of the steam box is provided with an air inlet, the air inlet is connected with a steam inlet pipe, a condensed water outlet is formed in the other end of the steam box and connected with a water outlet pipe, the steam inlet pipe is provided with a steam flow control valve, and the water outlet pipe is provided with a condensed water outlet valve. Steam is sprayed to the surface of paper through small openings, moisture on the surface of the water is improved, the smoothness of the paper surface during subsequent calendaring is increased, and product quality is improved.

Owner:SHANDONG TIANYANG PAPER

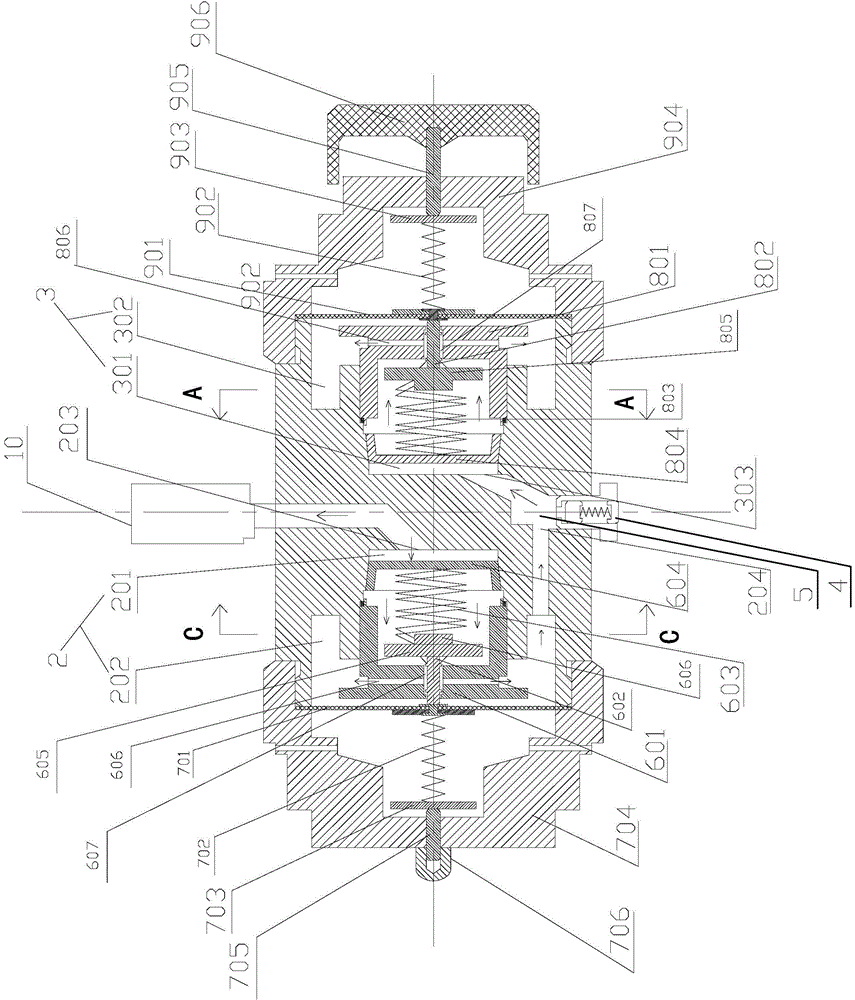

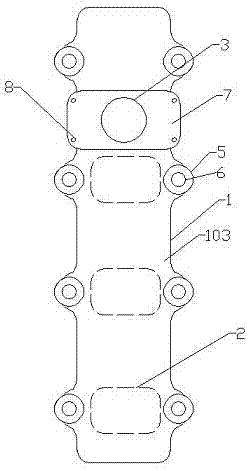

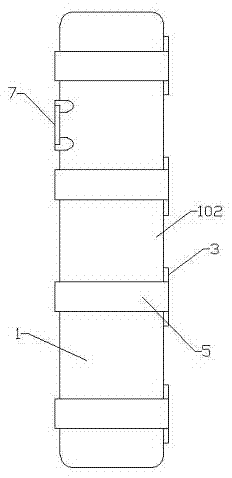

Double-stage gas energy-saving valve

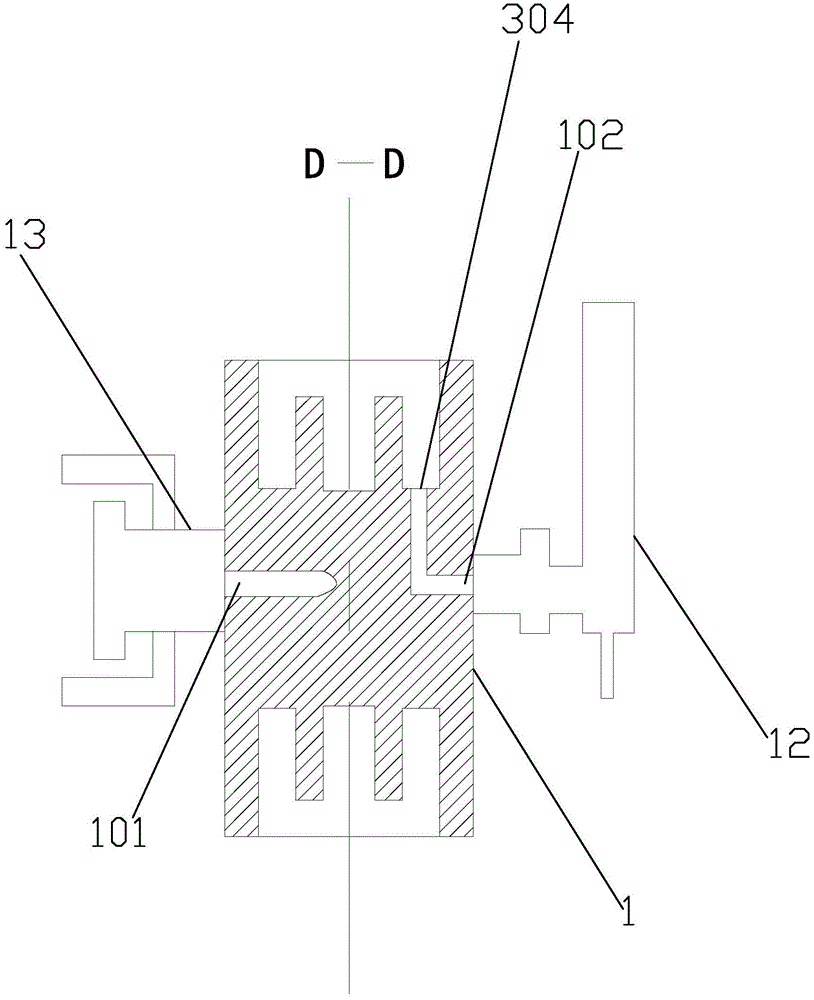

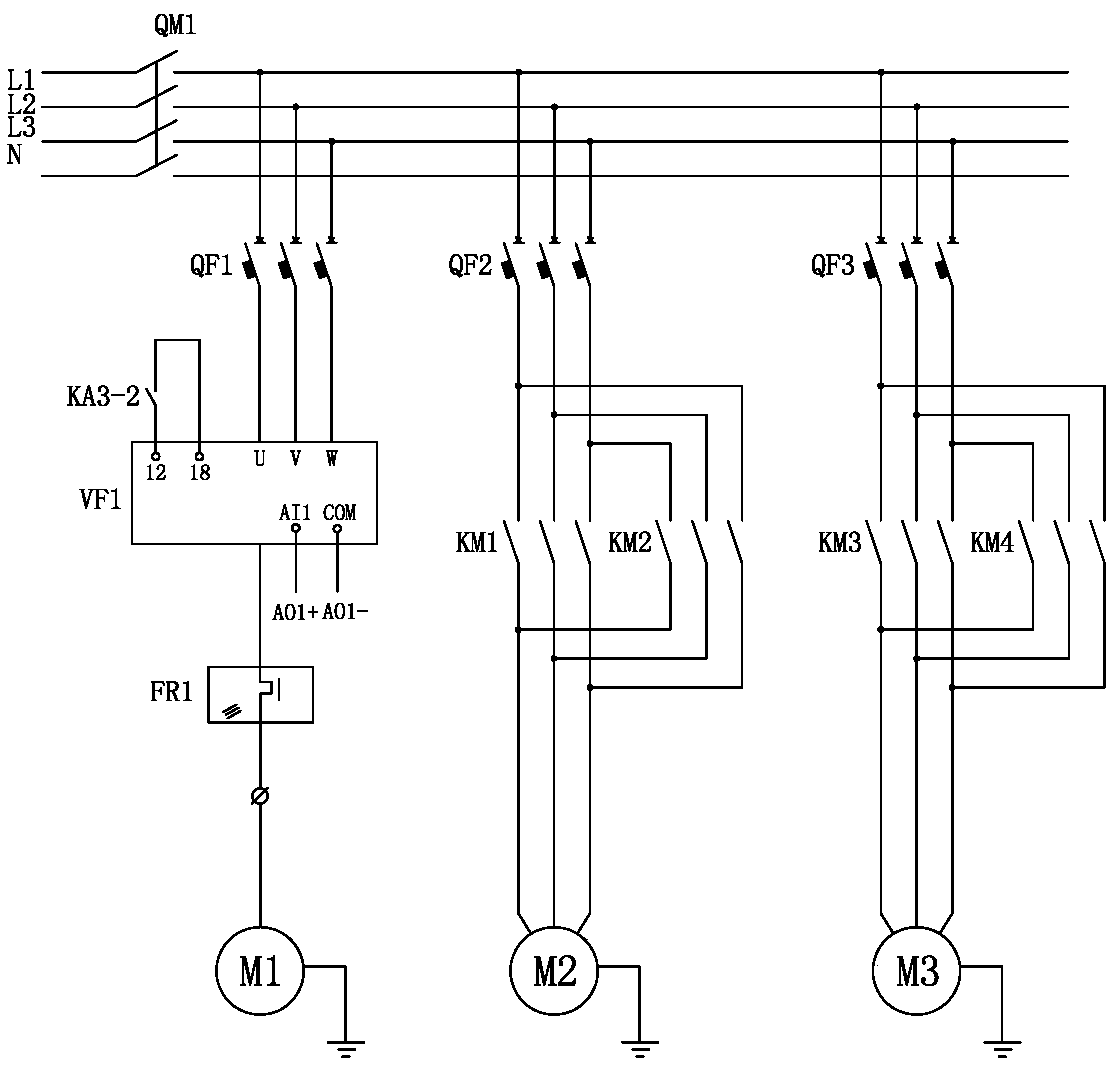

ActiveCN104676062AReduce momentumReduce flow rateValve members for heating/coolingEqualizing valvesEngineeringPressure reduction

The invention discloses a double-stage gas energy-saving valve. The double-stage gas energy-saving valve comprises a pressure reducing valve main body (1), wherein the pressure reducing valve main body (1) is provided with a main air inlet (101) and a main air outlet (102); one end of the pressure reducing valve main body (1) is provided with a first enclosed cavity (2) for reducing the pressure of gas; the air inlet (203) of the first enclosed cavity is communicated with the main air inlet (101); the first enclosed cavity (2) is communicated with a second enclosed cavity (3); the other end of the pressure reducing valve main body (1) is provided with the second enclosed cavity (3) for reducing the pressure of gas; the air outlet (304) of the second enclosed cavity is communicated with the main air outlet (102). The double-stage gas energy-saving valve has the advantages that secondary pressure reduction of gas is finished in the same pressure reducing valve, so that the impact force and flow speed of output low-pressure gas are small and low.

Owner:NINGBO SUNRISE ELECTOR MECHANICAL

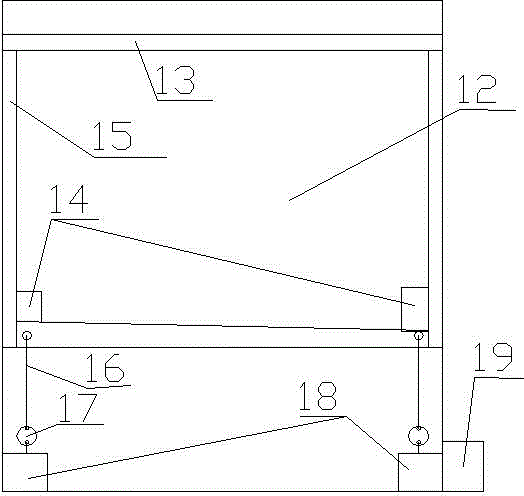

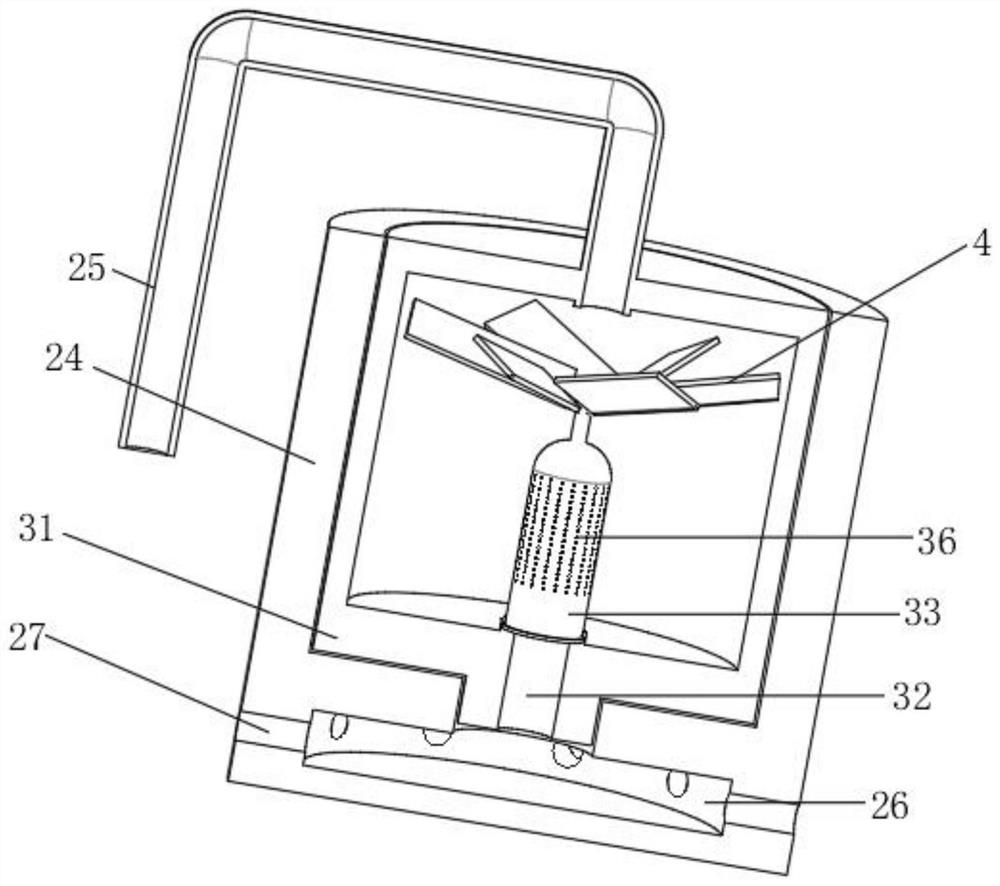

Damp-proof ventilation wardrobe

The invention discloses a damp-proof ventilation wardrobe which is a cloth drying wardrobe capable of achieving uniform air supply. The damp-proof ventilation wardrobe comprises a wardrobe body, a hanging rod and a cold and hot fan. A steam outlet is formed in the top of the wardrobe body. The two sides inside a back plate of the wardrobe body are provided with sliding ways. The damp-proof ventilation wardrobe is characterized by further comprising an air volume adjusting valve and an air pipe, wherein the air volume adjusting valve is connected with an air outlet of the cold and hot fan, the air pipe is connected with the air volume adjusting valve, the two ends of the air pipe are installed inside the sliding ways, the inner sides of the two ends of the air pipe are connected with the front ends of connecting rods through shaft pins, the rear end of each connecting rod is connected to the circumference of an eccentric wheel through a pin shaft, each eccentric wheel is connected to a small motor, the small motors are arranged at the bottom end inside the wardrobe body, the air volume adjusting valve comprises a valve pipe, a central spindle, a valve plate and an adjusting device, the central spindle is installed on the valve pipe, the valve plate is installed inside the valve pipe and fixed to the central spindle through a bolt, the adjusting device is connected with the end, outside the valve pipe, of the central spindle, and the air pipe is of a diameter-changing structure, wherein the port, connected with the air volume adjusting valve, of the air pipe is larger than an air outlet of the air pipe. Clothes inside the wardrobe are good in ventilation performance and not likely to deform or be affected with damp.

Owner:QINGDAO DONGCHANGYUAN INSTR

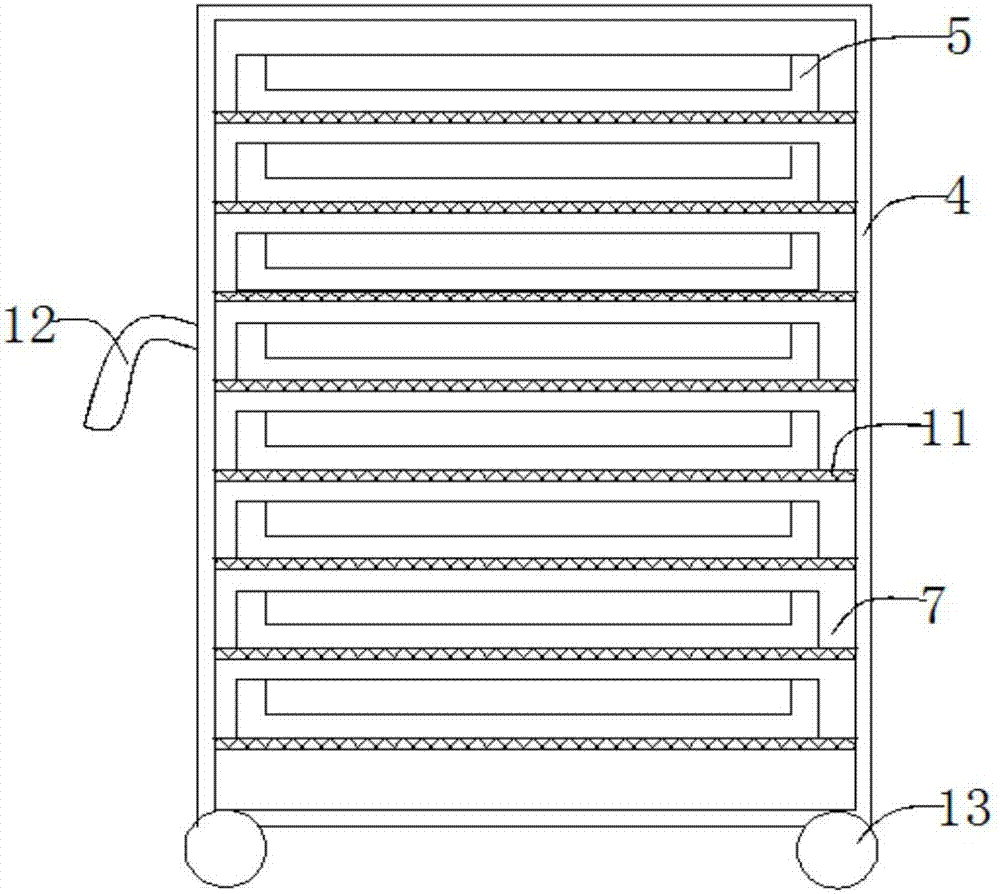

Pueraria lobata particle drying device

InactiveCN107289750ARealize Regulatory ControlEvenly distributedGranular material dryingDrying gas arrangementsFirewoodLobata

The invention discloses a pueraria lobata particle drying device which comprises a drying room. Cement plates are placed on the ground and the periphery of the drying room. The pueraria lobata particle drying device further comprises an exhaust mechanism, multiple drying frames, multiple drying screens and a heating mechanism. The exhaust mechanism is arranged on the top of the drying room. The multiple drying frames are arranged in the drying room. Multiple partition layers are formed by the drying frames through multiple steel wire meshes. The multiple drying screens are sequentially placed on the steel wire meshes in the partition layers. The heating mechanism is arranged on the outer side of the drying room, and the heating mechanism is connected with an adjusting filtering mechanism. The adjusting filtering mechanism is connected with the interior of the drying room through multiple heat transmission pipes. By means of the pueraria lobata particle drying device, even distribution and adjustment control of hot air in the drying room are achieved, the problem that the environment is polluted due to traditional firewood heating is solved, biological energy sources are adopted so that more energy is saved and environment friendliness is better achieved, in addition, the drying efficiency of pueraria lobata particles is high, and the effect is good. Furthermore, the pueraria lobata particle drying device is compact in structure, easy to operate, safe, reliable, high in heating speed and capable of being used for drying work of large batches of pueraria lobata particles.

Owner:广西藤县绿葛葛业有限公司

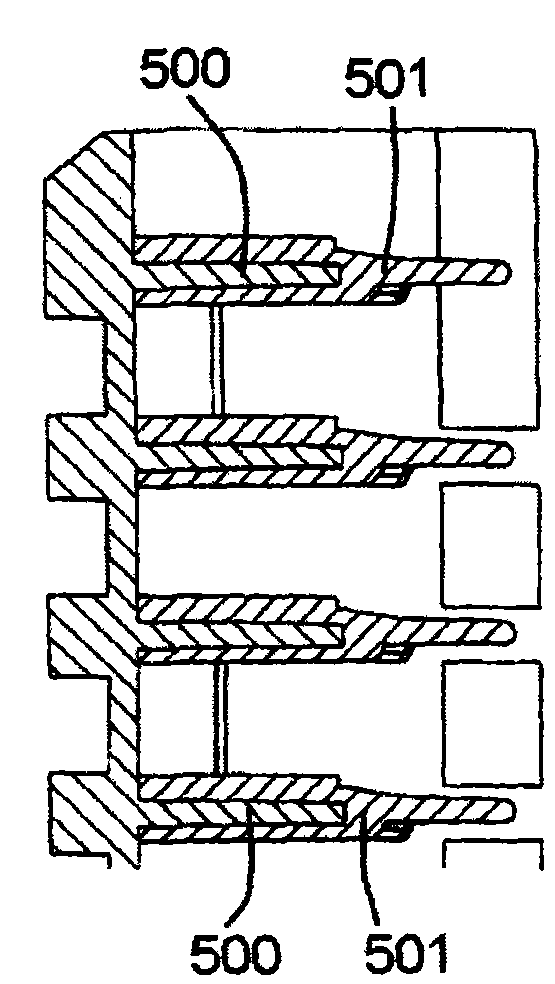

Front open type wafer box provided with inflatable support element module

InactiveCN102610547AAvoid formingAvoid pollutionSemiconductor/solid-state device manufacturingEngineeringOpen type

The invention provides a front open type wafer box. An inflatable support element module is arranged at a position of the side wall of the front open type wafer box adjacent to the back wall and is provided with a buffer air chamber, in addition, an air inlet is arranged at one end of the buffer air chamber, the air inlet is connected with an air valve arranged at the bottom surface of the buffer air chamber, an air outlet passage is arranged in a direction of the inflatable support element module facing an opening of the front open type wafer box, in addition, a long seam is arranged at one end of the air outlet passage, in addition, a porous material is arranged in the long seam, an air flow passage is arranged between the air outlet passage and the buffer air chamber so that the air outlet passage and the buffer air chamber can be mutually communicated, and in addition, a plurality of support ribs which are in arrangement vertical to the long seam at intervals are arranged on one side edge of the long seam.

Owner:GUDENG PRECISION IND CO LTD

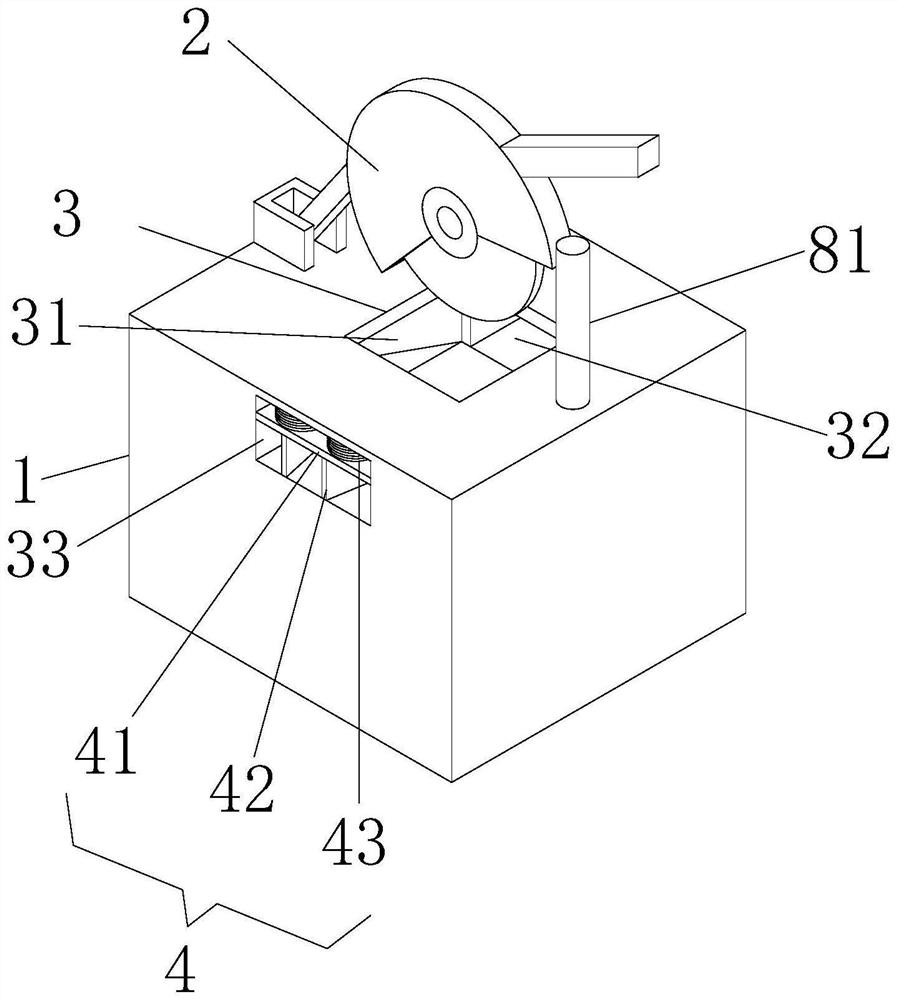

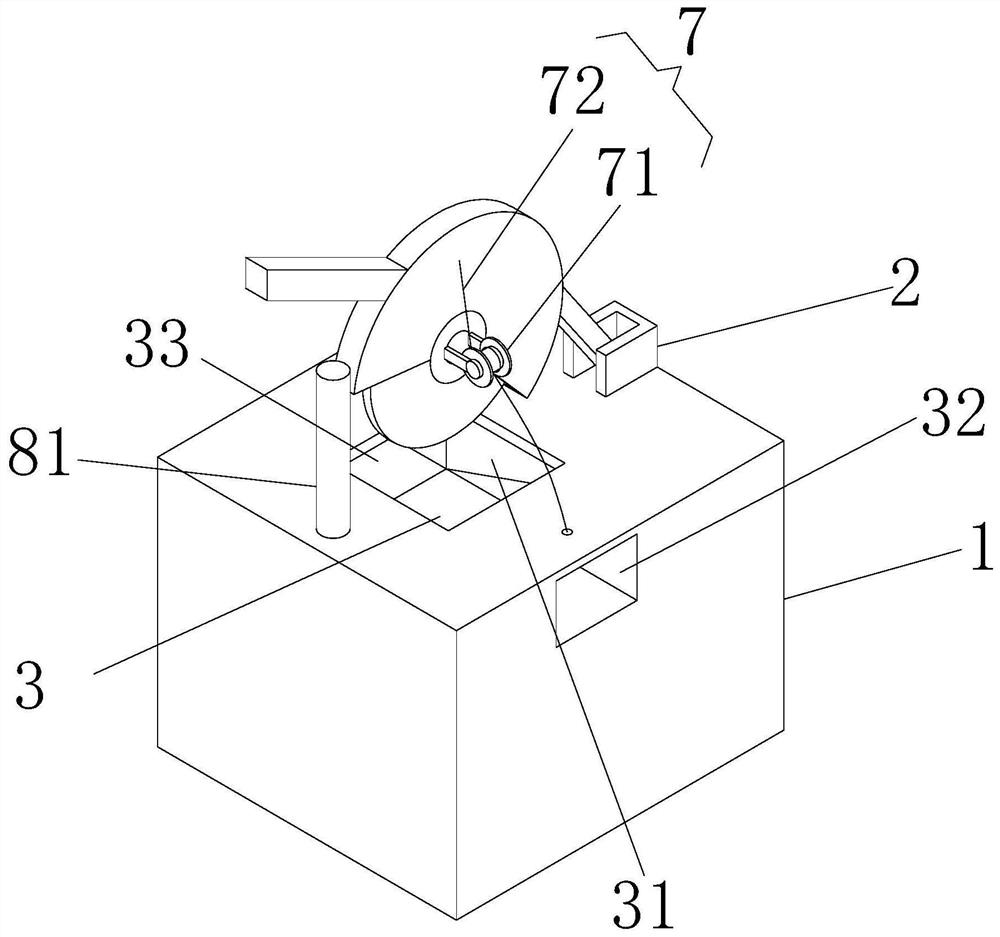

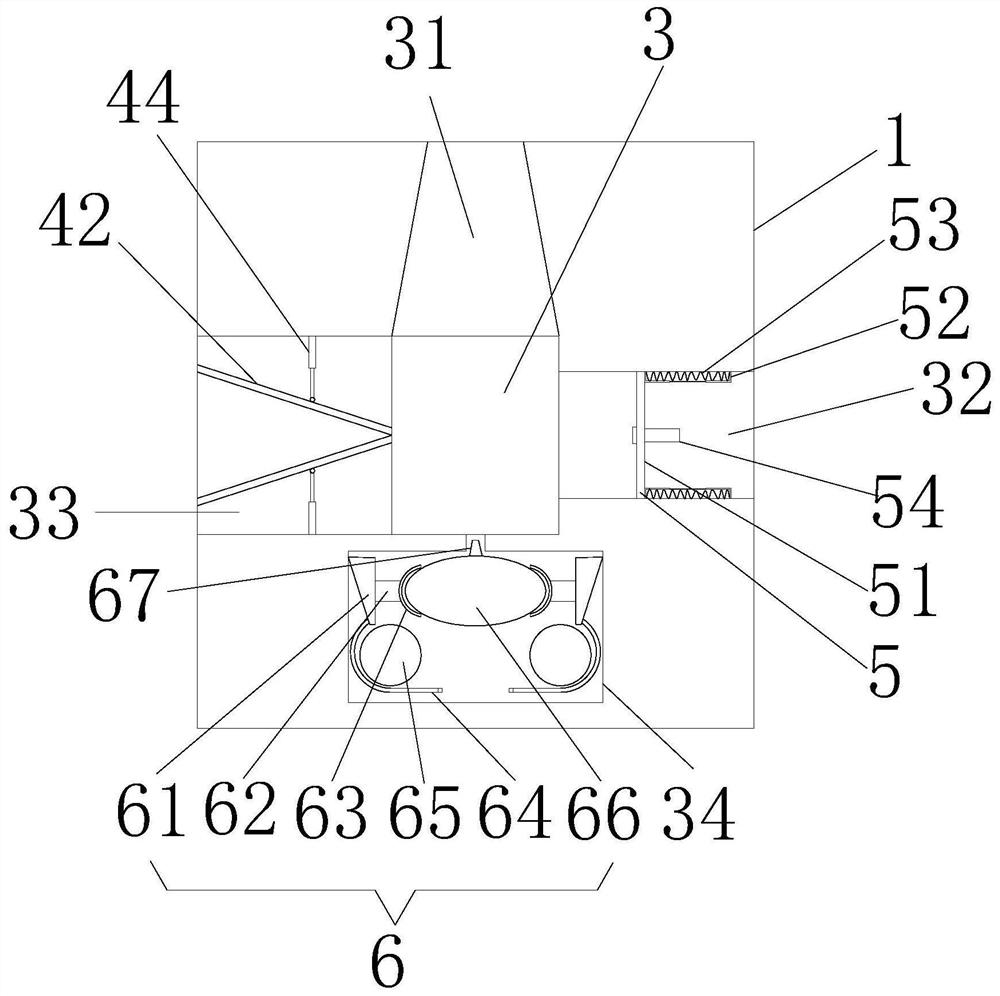

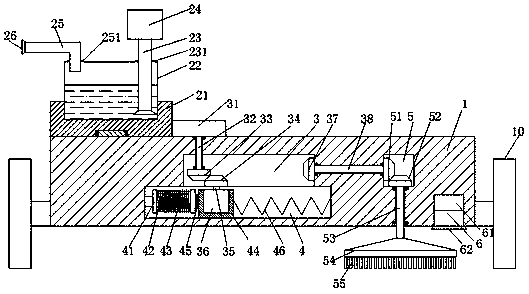

Cutting device for aluminum alloy window frame machining

ActiveCN112091312AGuaranteed collection effectSteady fallShearing machinesMaintainance and safety accessoriesStructural engineeringAluminium alloy

The invention relates to the technical field of aluminum alloy door and window machining, and discloses a cutting device for aluminum alloy window frame machining. The cutting device comprises a cutting table and a cutting machine, the cutting machine is arranged above the cutting table and movably connected with the cutting table, and a cutting groove is formed in the position, below a cutting knife of the cutting machine, of the cutting table; and an air outlet groove, a dust collecting groove, an inlet groove and a positioning groove are formed in the front, back, left and right sides in the cutting groove correspondingly. According to the cutting device for aluminum alloy window frame machining, cutting is conducted through the arrangement of the inlet groove, the positioning groove and the dust collecting groove, when a user conducts cutting, insertion from the position between two inclined clamping plates of the inlet groove can be achieved, an inserting end extends into the positioning groove for cutting, and the position of the dust collecting groove is the same as the cutting direction, so that chippings can be collected when an aluminum alloy window frame is cut by the cutting machine; and meanwhile, the chippings can more stably fall to the bottom of the dust collecting groove after being cut and falling due to the shape of the dust collecting groove, and therefore the collecting effect of the chippings is ensured.

Owner:重庆市东余塑钢有限公司

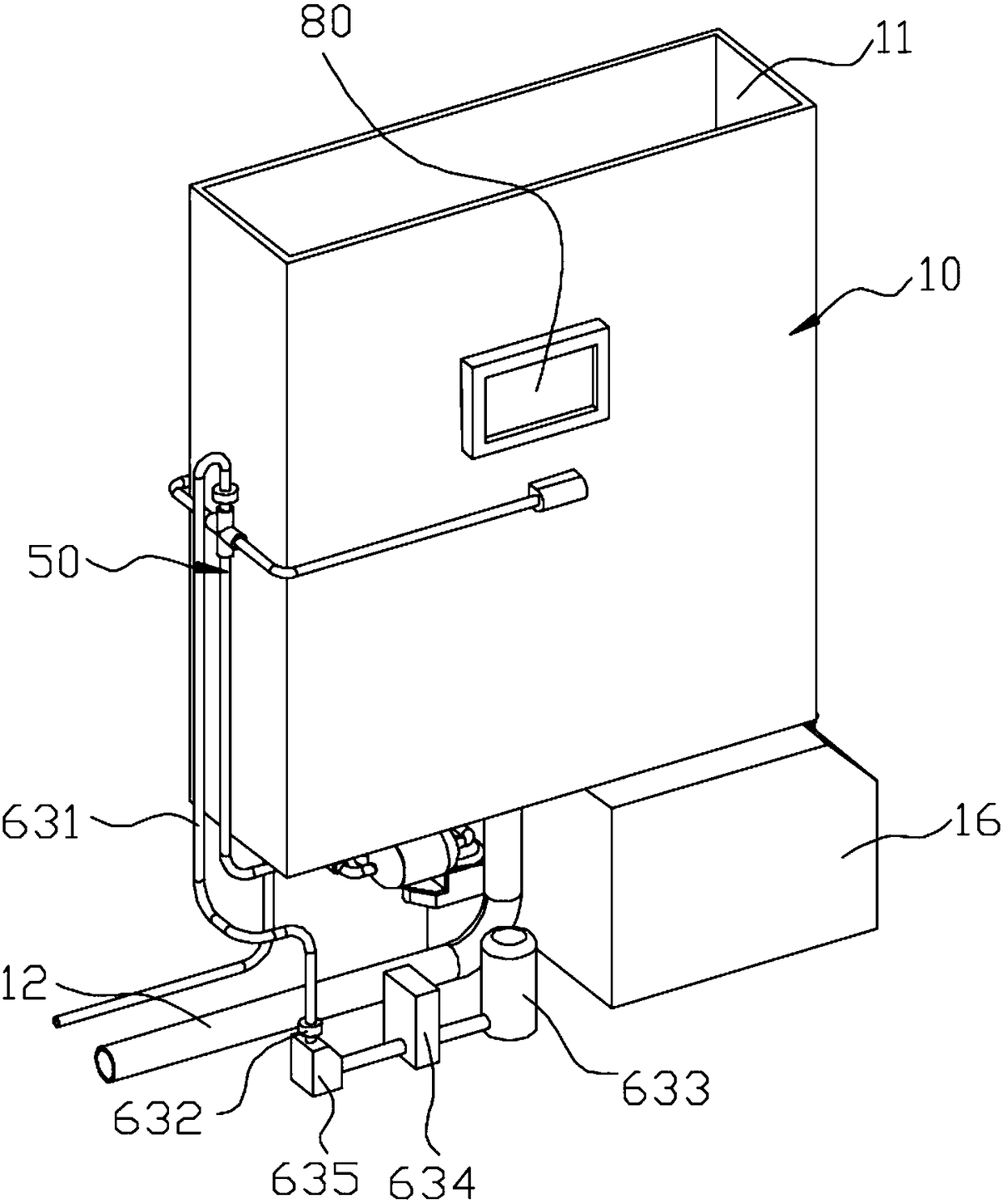

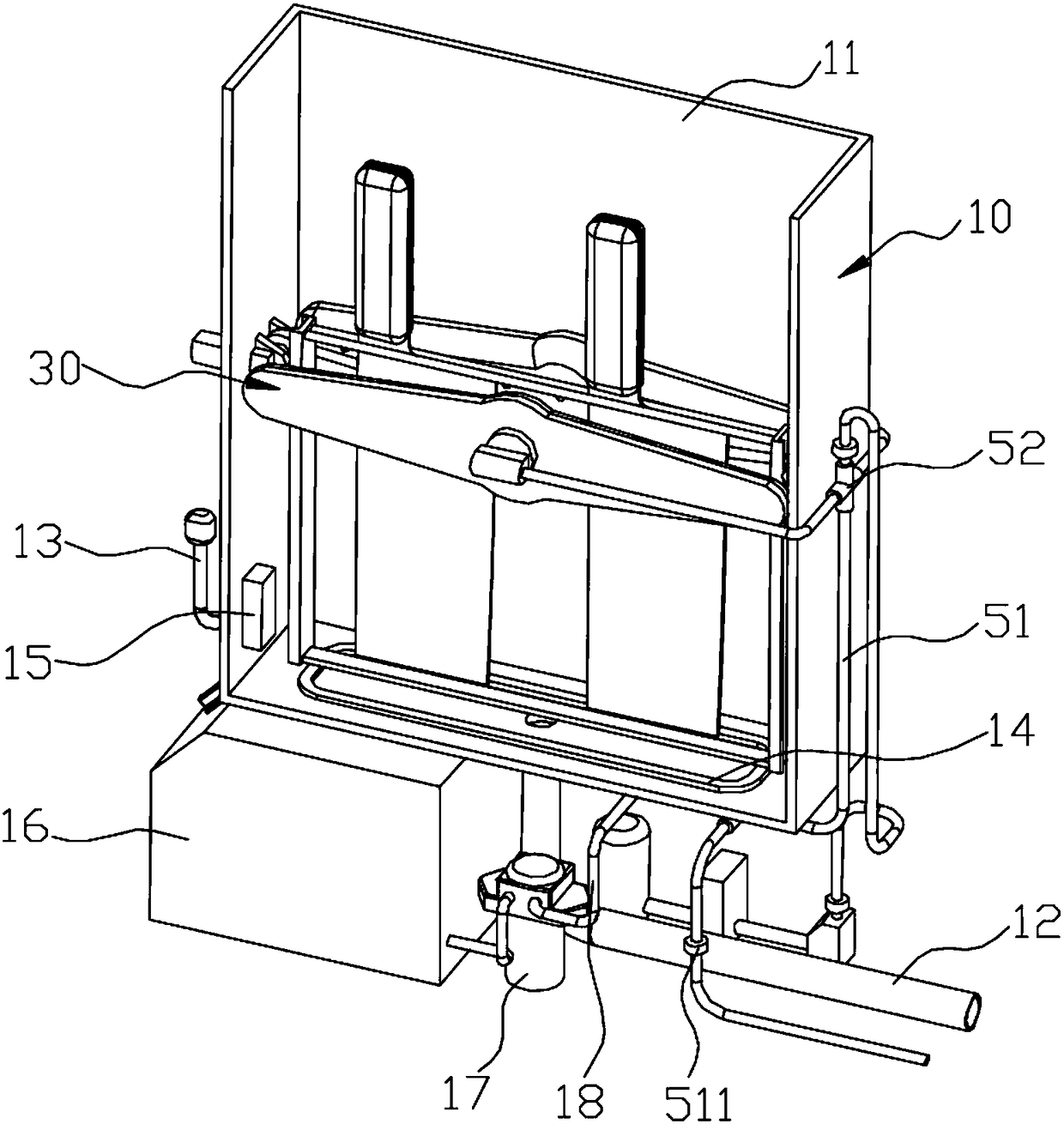

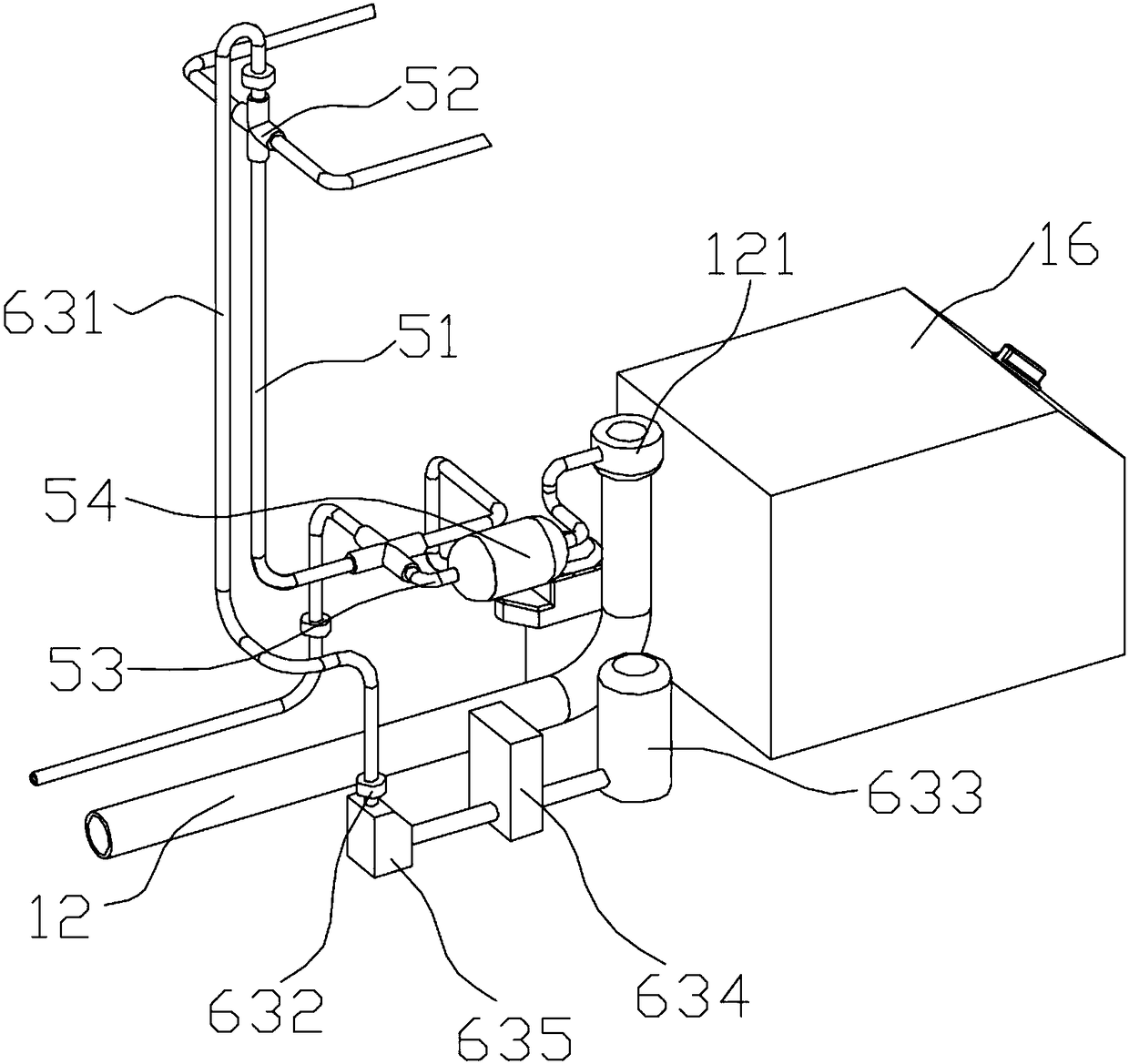

Intelligent tool washing device

InactiveCN108499947ARealize remote controlReal-time monitoring of working parametersCleaning using liquidsChemicalsRemote controlComputer terminal

The invention discloses an intelligent tool washing device. The intelligent tool washing device comprises a box body, a tool rest, at least one spraying arm and a master controller, wherein the box body is internally provided with a hollow cavity; the tool rest is used for bearing tools and arranged in the hollow cavity of the box body; the spraying arms are located on the side portions of the tool rest and are internally provided with flow guide channels, one side of each spraying arm is connected with a water washing pipeline unit communicating with the corresponding flow guide channel, andthe other side of each spraying arm is provided with a plurality of spraying holes communicating with the corresponding flow guide channel; when the water washing pipeline units spray gas or liquid flow into the flow guide channels of the spraying arms and the gas or liquid flow is sprayed out of the spraying holes, the action force of the sprayed gas or liquid flow enables the spraying arms to rotate; and the master controller is connected with a mobile terminal through a wireless transmitter / receiver, and the mobile terminal controls the master controller through the wireless transmitter / receiver so as to achieve remote control over the intelligent tool washing device. The intelligent tool washing device is safe and reliable, cleaning is convenient, and washing is efficient.

Owner:SUZHOU LUZHIYAO TECH

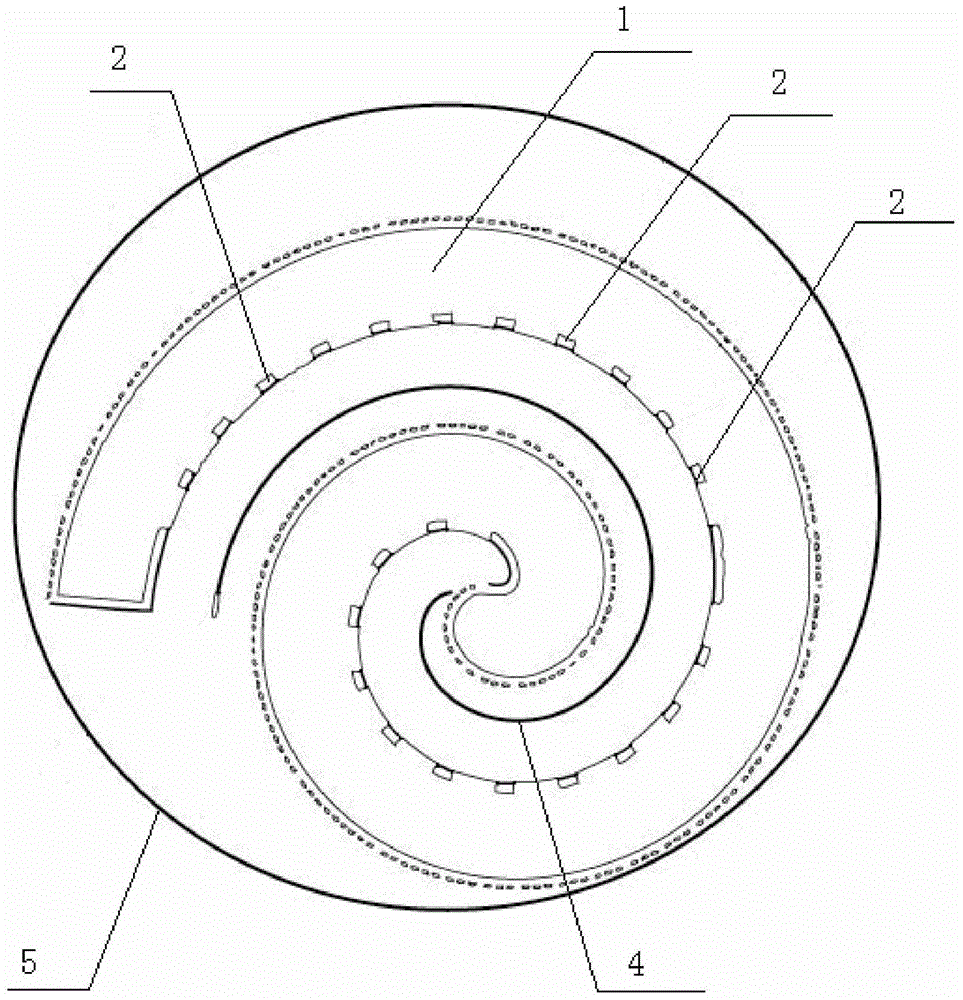

Device for growing graphene in large areas

The invention relates to the technical field of graphene growth devices and particularly relates to a device for growing graphene in large areas. The device comprises a quartz tube, a vent cavity and a metal substrate, wherein the vent cavity is internally hollow and is of a spiral cylindrical structure, the shape of the metal substrate is matched with that of the vent cavity, the metal substrate is spirally crimped along the inner surface of the vent cavity, the end part of the innermost ring of the vent cavity is fixedly connected with the end part of the innermost ring of the metal substrate, an air inlet is formed in each of one side of the innermost ring and the same side of the outermost ring of the vent cavity, a plurality of air outlet holes are formed in the inner surface of the vent cavity, the quartz tube sleeves outside the vent cavity and wraps the entire vent cavity. The device has the beneficial effects that the structure is simple, the crimping growth of graphene in the large areas is facilitated, the space is saved, furthermore graphene evenly grows and the yield is increased.

Owner:CHONGQING GRAPHENE TECH +1

Square plate type air radiation device and installation mode

PendingCN107226540AIncrease the aeration areaHigh oxygen utilizationWater aerationSustainable biological treatmentOxygen utilization rateEthylene-propylene-diene-monomer

The invention provides a square plate type air radiation device and an installation mode. The square plate type air radiation device comprises a square frame body, an air connecting head and a diaphragm, wherein the air connecting head is arranged at the outer side or the inside of the square frame body; the diaphragm is positioned in the frame body; the diaphragm covers the space inside the whole frame body; the diaphragm is an EPDM (ethylene propylene diene monomer) diaphragm with a PTFE (polytetrafluoroethylene) coating; the installation mode of the square plate type air radiation device is the connection through a belt type fastener; the belt type fastener is of a symmetrical structure. The square plate type air radiation device disclosed by the invention has the advantages that the aeration area is larger; the oxygen utilization rate is higher; meanwhile, the EPDM diaphragm with the PTFE coating is used; the characteristics of good toughness and uniform air outlet of the EPDM are remained; meanwhile, the direct contact between the sewage and the EPDM is effectively isolated through the PTFE coating; the acid resistance and alkali resistance are high; the practicability on the sewage is higher; the combined installation mode is more flexible.

Owner:JIANGSU PHILIP ENVIRONMENT ENG

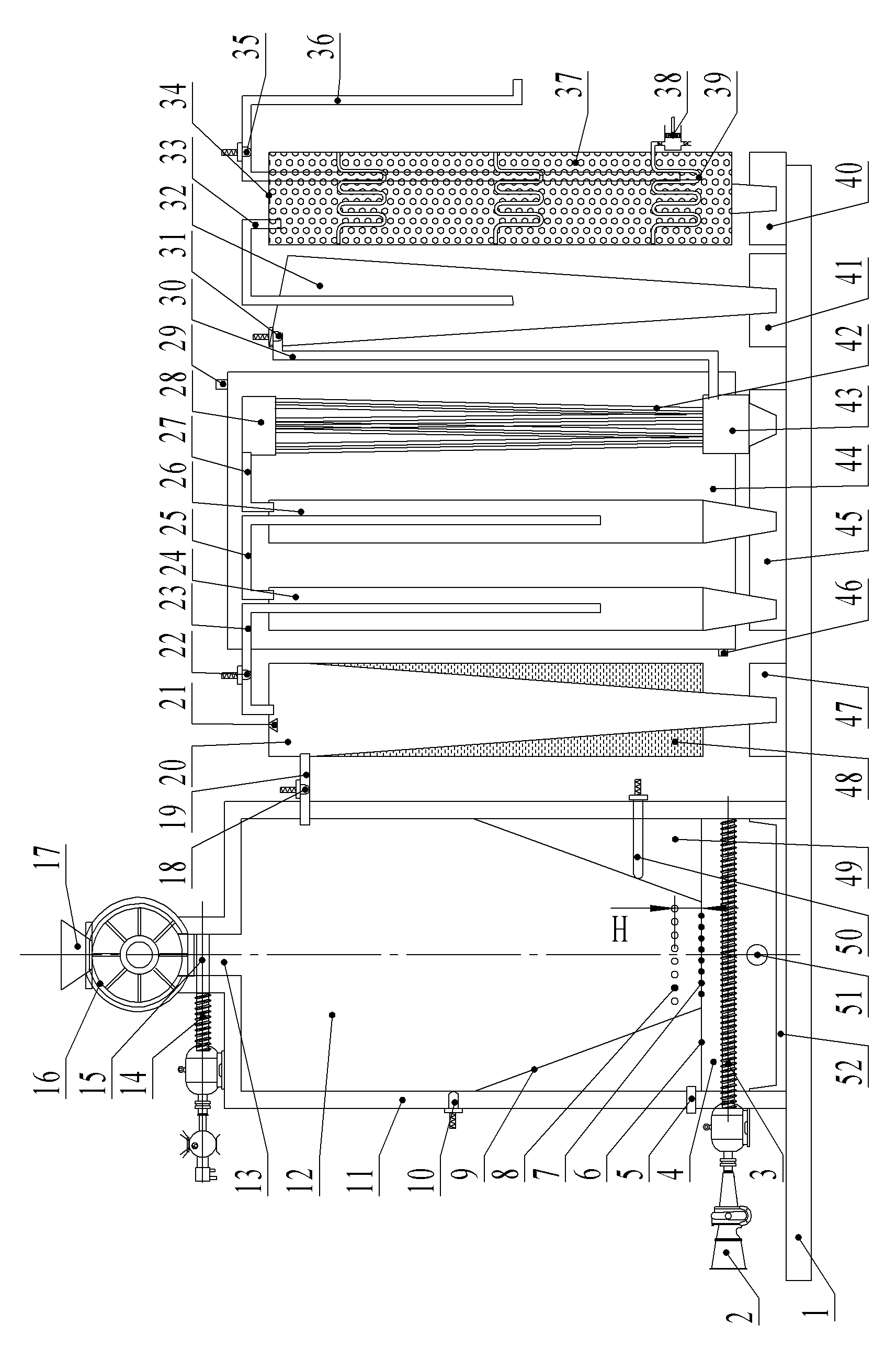

Chemically cross-linked polyethylene foam device

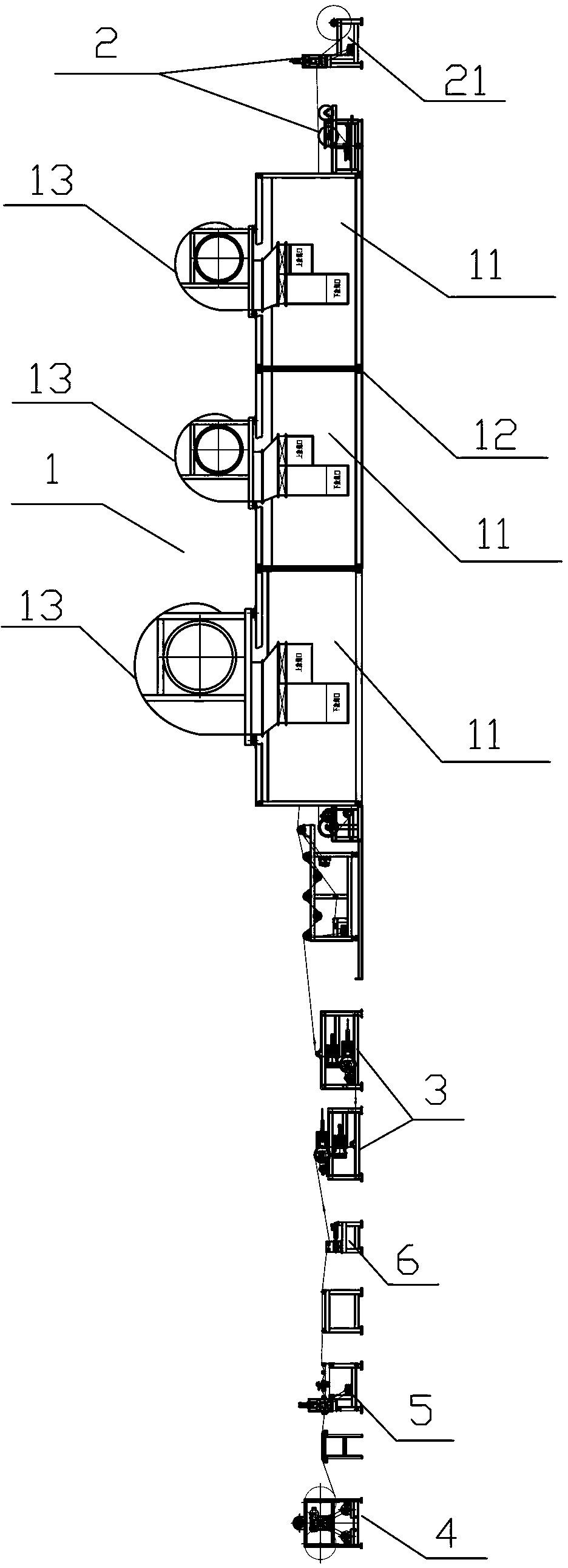

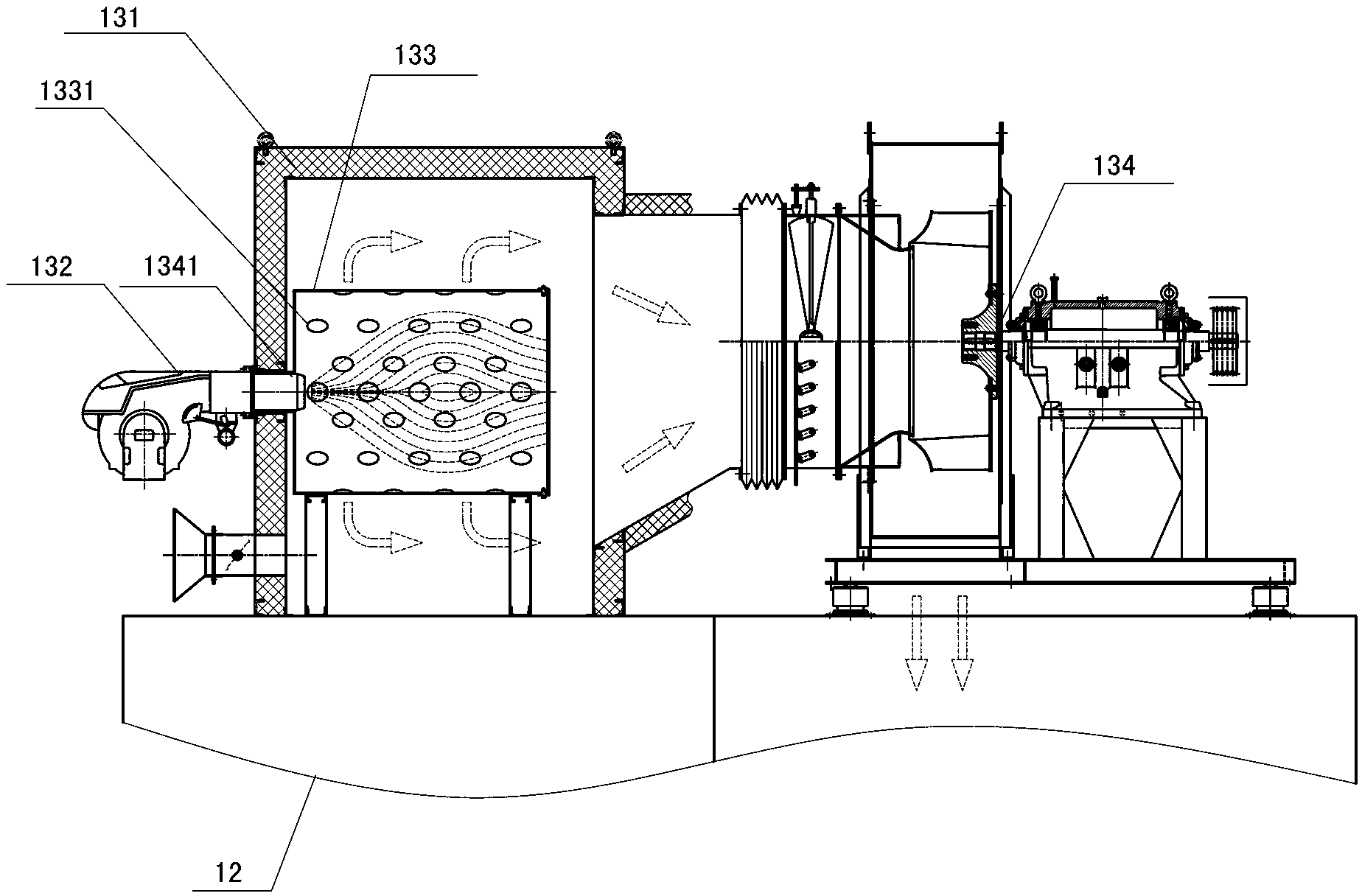

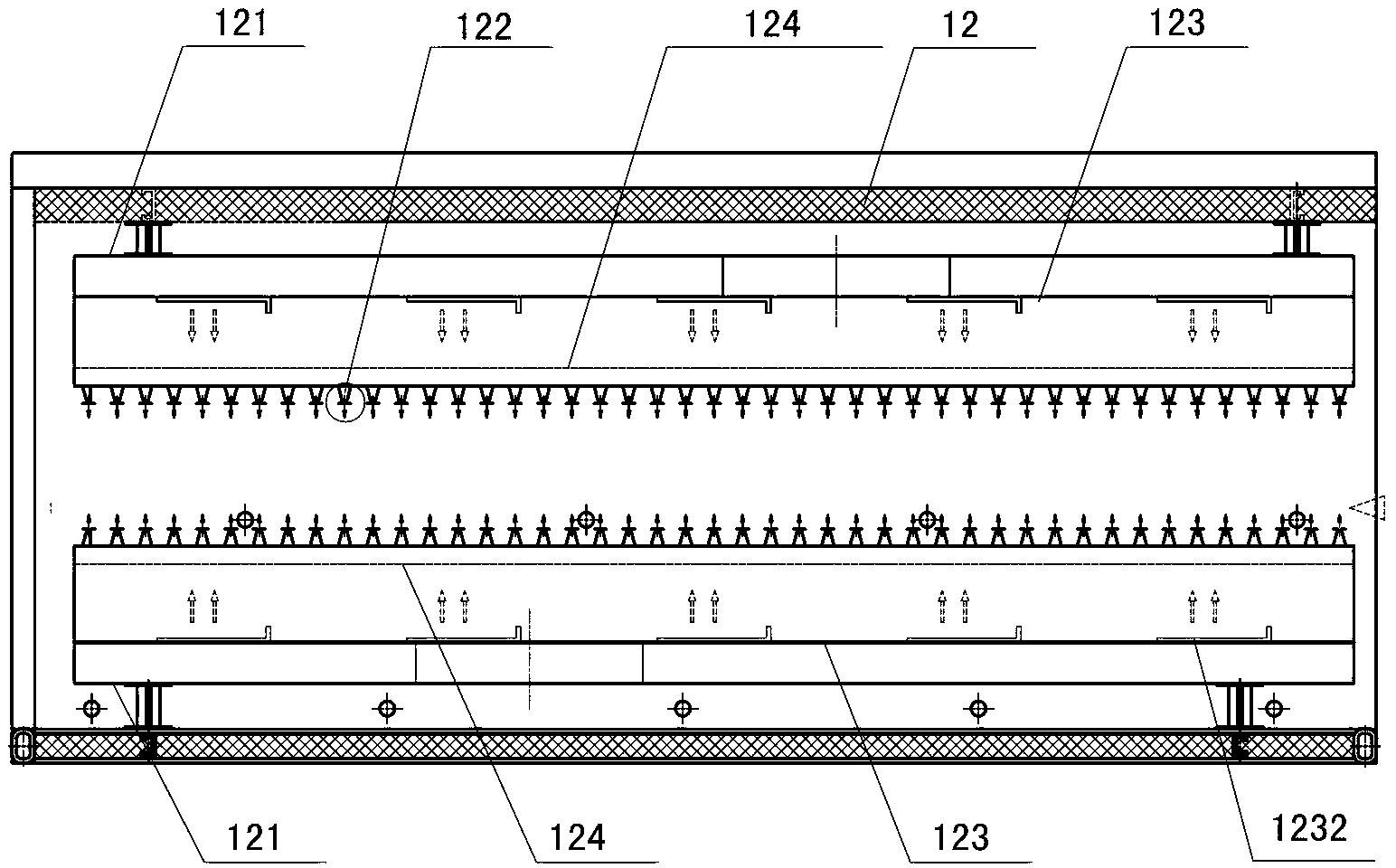

The invention discloses a chemically cross-linked polyethylene foam device which comprises a feed apparatus, a horizontal foaming apparatus, a front-back press polish apparatus and a roll apparatus sequentially arranged, wherein the horizontal foaming apparatus is sequentially provides with a horizontal foaming furnace with three heating areas, three cyclic heating mechanisms arranged above the horizontal foaming furnace and correspondingly communicated with heating areas, the cyclic heating mechanisms comprises a box body fixed on and communicated with the horizontal foaming furnace, a gas combustion machine fixed on the box body, a heat exchange system located in the box body and connected with the gas combustion machine, and a hot air circulation fan used for transferring the heat in the box body to the foaming areas; the heat exchange system comprises a combustion cylinder with one opened end and one closed end, the opened end of the combustion cylinder is communicated with a flame port of the gas combustion machine, and sidewalls of the combustion cylinder is provided with a plurality of output holes in intervals. The device is advantageous by preventing entry of the flames into impellers to deform and damage the impellers, and improving service life of the hot air circulation fan.

Owner:宁波辉门科技有限公司

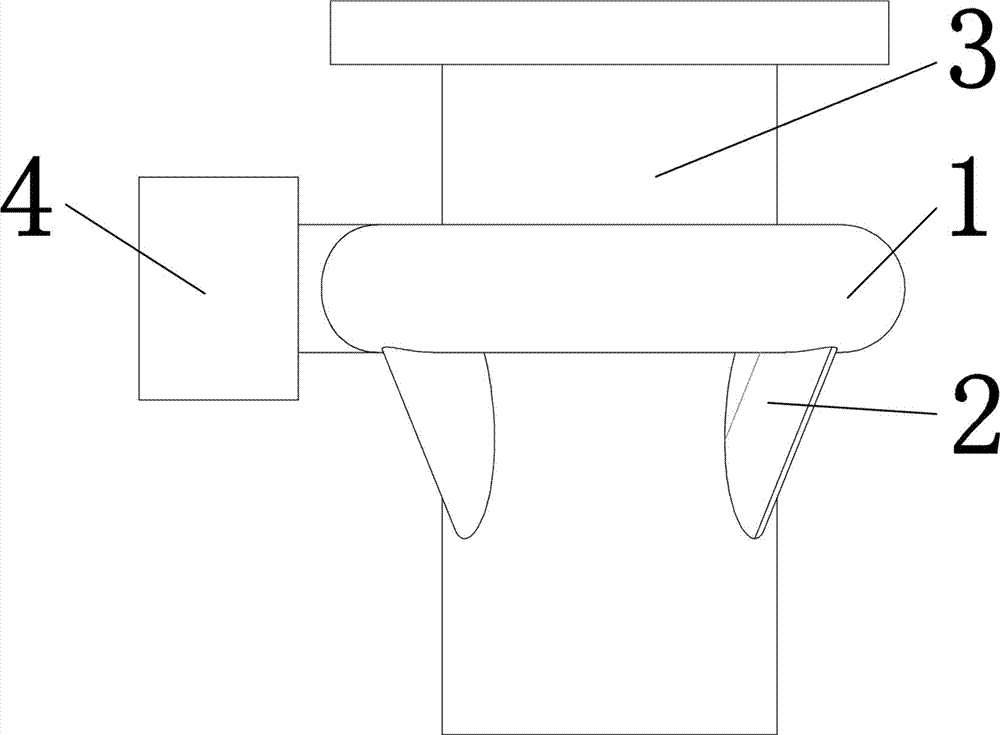

Engine intake pipe

InactiveCN104775951AReduce resistanceEasy to processCombustion-air/fuel-air treatmentMachines/enginesPressure castingEngineering

The invention discloses an engine intake pipe which comprises a core tube, wherein a casing made of an aluminum material is arranged on the outer surface of the core tube in a pressure casting way, and an air inlet and an air outlet which communicate with each other are formed in the casing. The core tube made of a seamless steel tube is arranged inside the intake pipe and the aluminum casing is arranged on the outer portion of the intake pipe in a pressure casting way, so the degree of finish of an air path in the intake pipe is ensured, airflow resistance is reduced, air intake is more fluent, and the inflation efficiency is improved; the core tube is arranged at the interior and the aluminum die-cast casing is arranged on the outer portion so the density and the strength of the intake pipe are improved and intake pipe cracking is effectively prevented.

Owner:张勤军

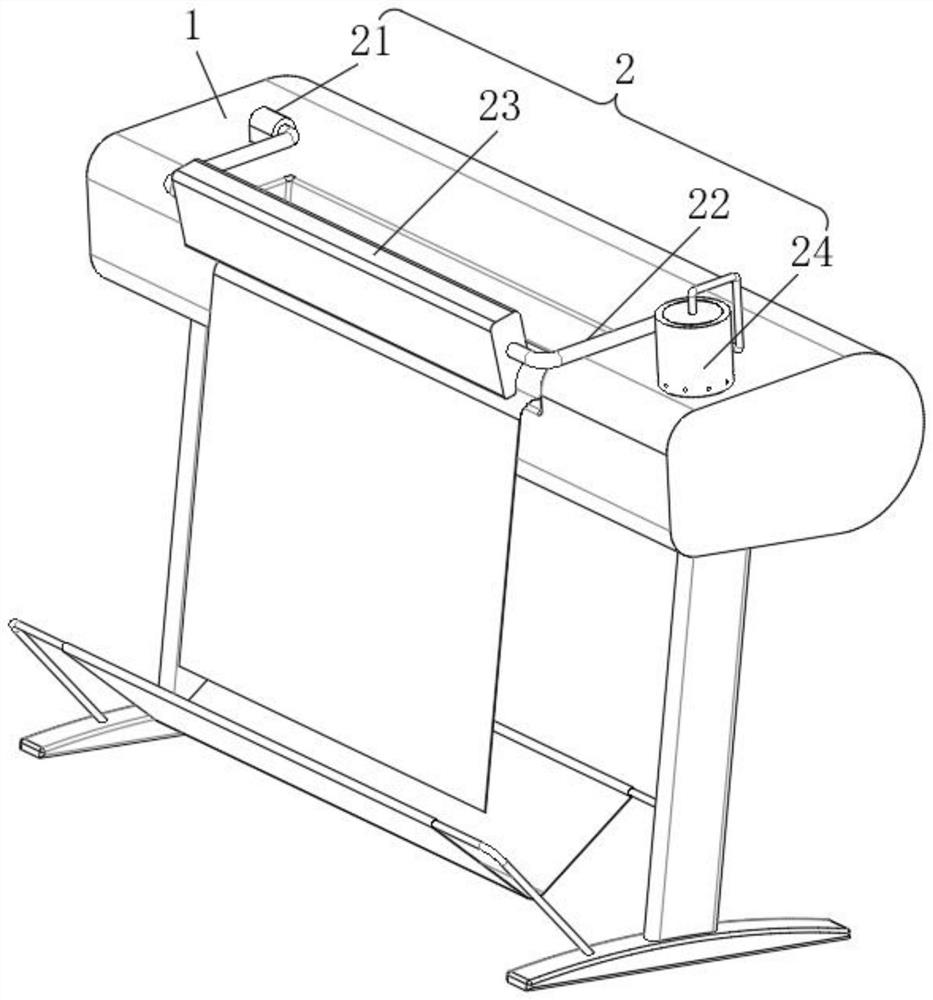

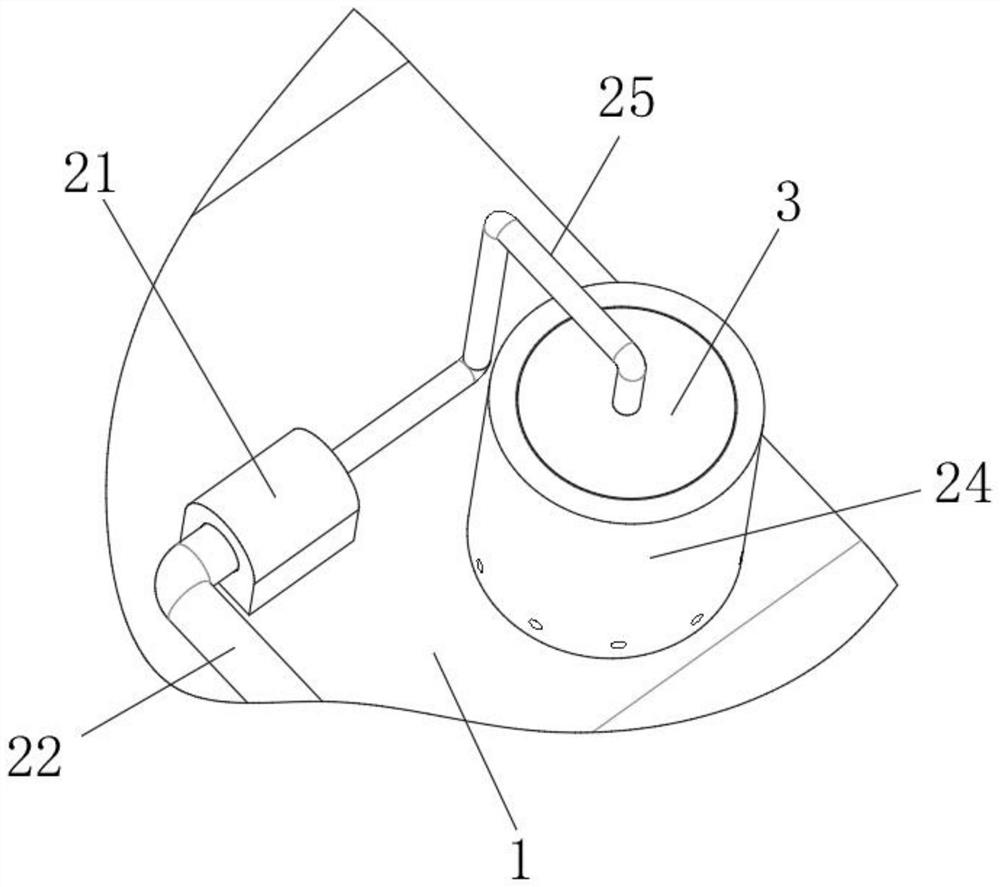

Computer image output device

PendingCN113750693AInk dries fastPrevent rubbing and fadingDrawing from basic elementsUsing liquid separation agentPhysicsEngineering

The invention discloses a computer image output device. The device comprises a drawing table, wherein a canvas is arranged at an outlet of the drawing table, a drying mechanism for air-drying ink on the surface of the canvas is arranged at the top of the drawing table, and the drying mechanism comprises an inflation pipe fitting. According to the computer image output device, a cleaning mechanism is adopted to purify air blown out by the drying mechanism, the air firstly enters an inner cover through a bottom hole, and the inner cover is pushed by air pressure to move upwards along with more and more airflow entering the inner cover and the internal pressure exceeding the pulling limit of a pressure storage spring, so connecting holes of the inner cover and an outer cover are in butt joint, and high-pressure air accumulated in the inner cover is instantly ejected through the connecting holes; a fan continuously conveys air, the air flushes into a cleaning solution through the small connecting holes, dust in the air is mixed with the cleaning solution, and the air turns into bubbles which emerge from a water surface and are used by the drying mechanism; and therefore, the blown air has small influence on a drawn pattern, and the bright color of the pattern is ensured.

Owner:伊犁师范大学

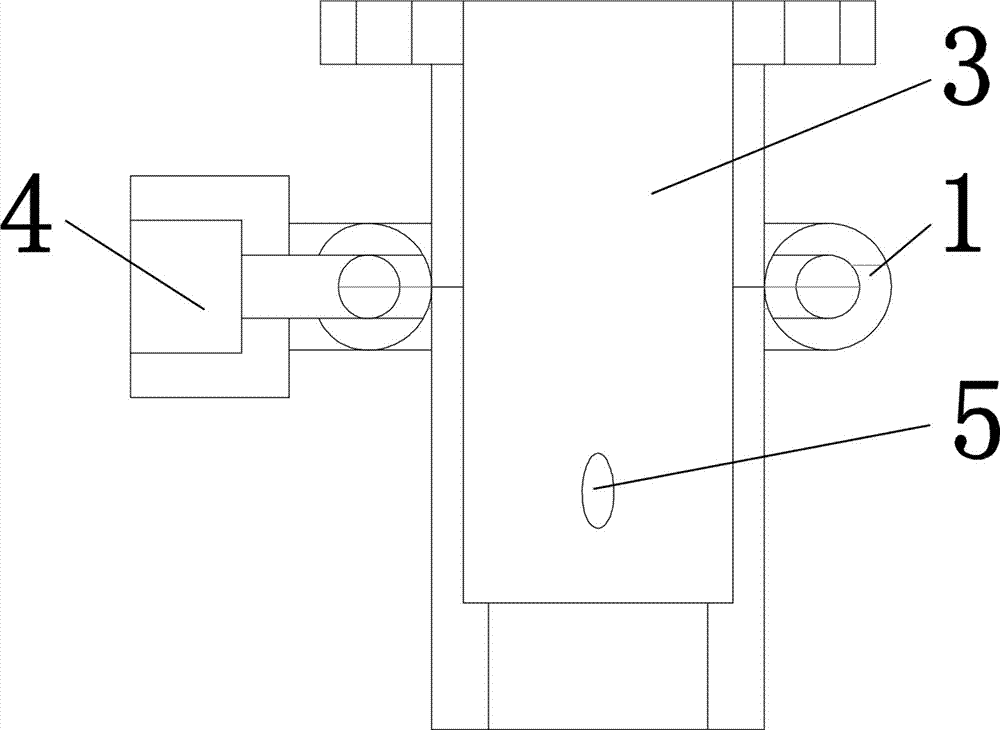

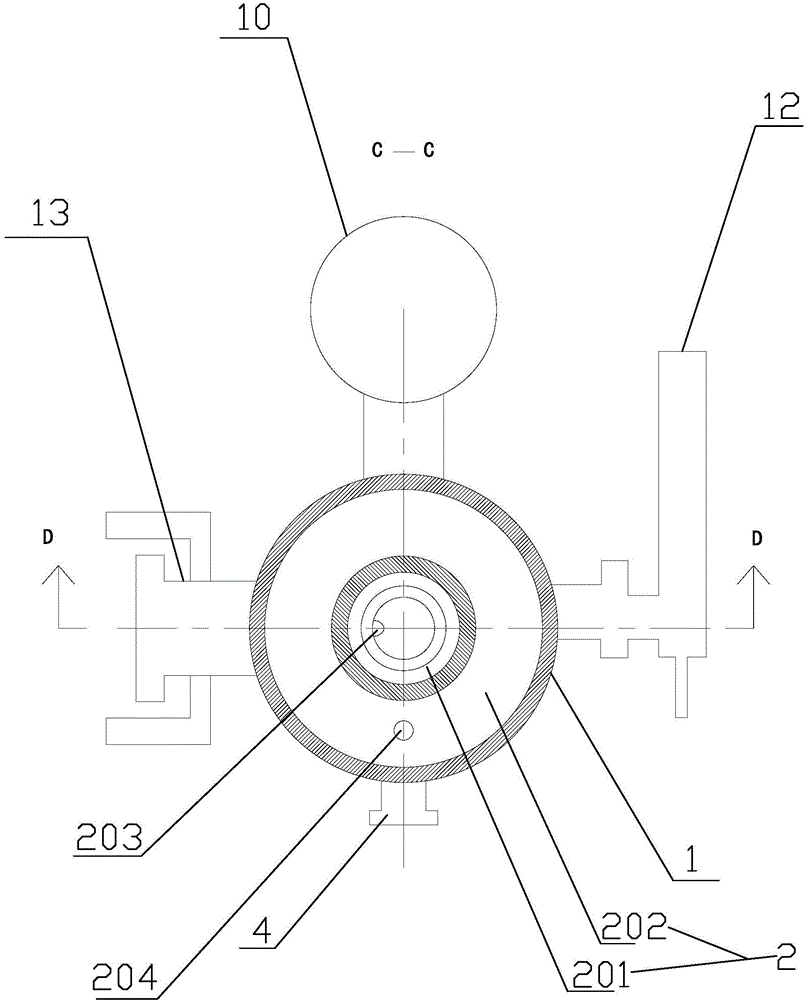

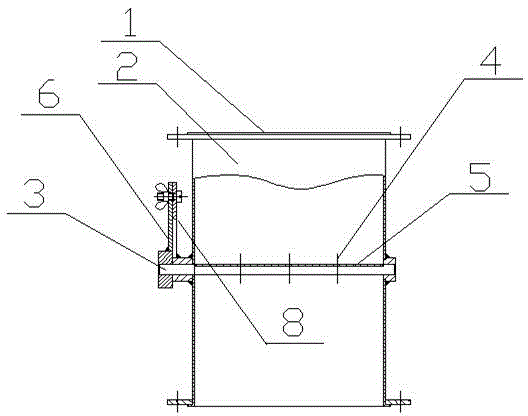

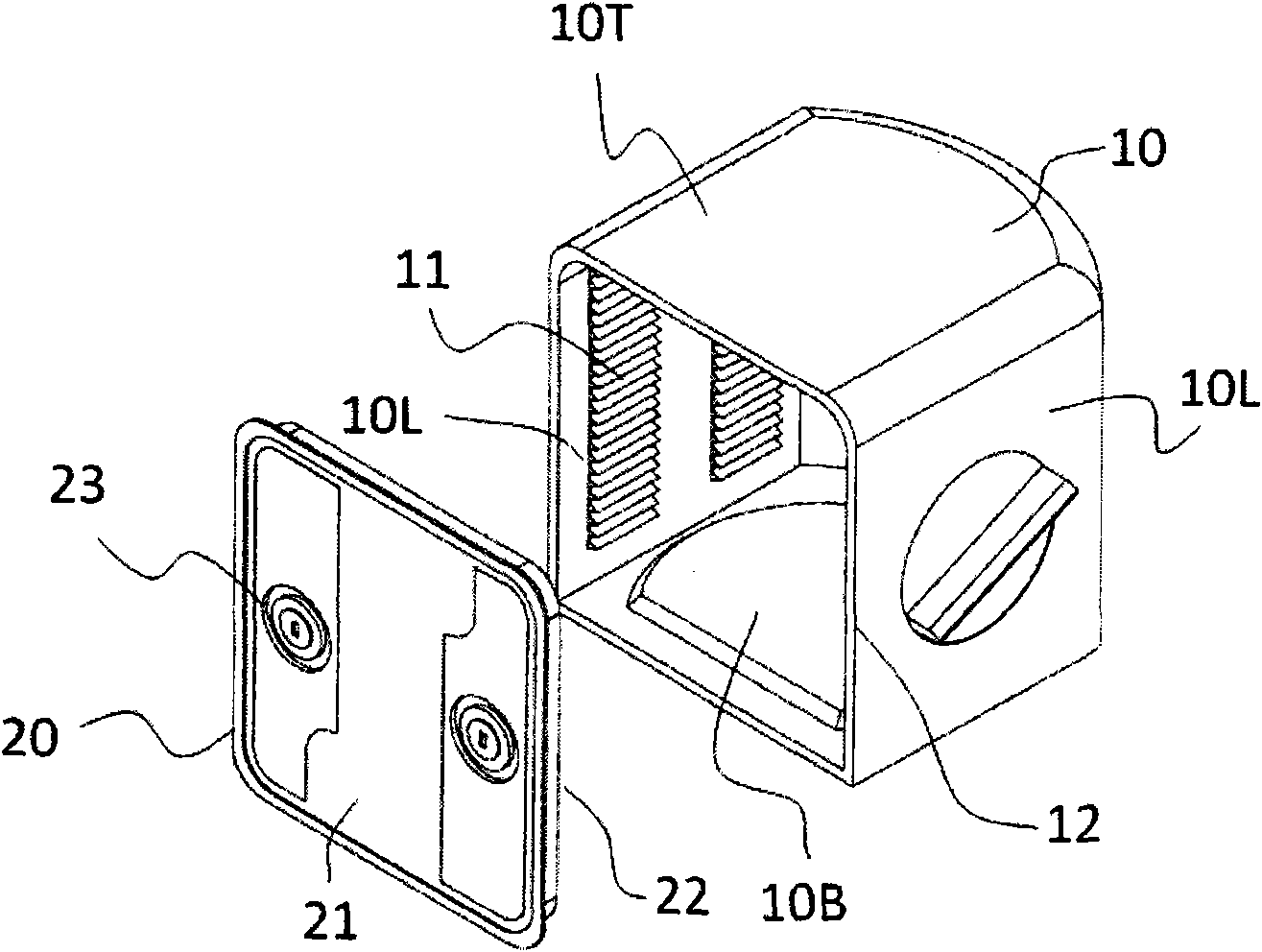

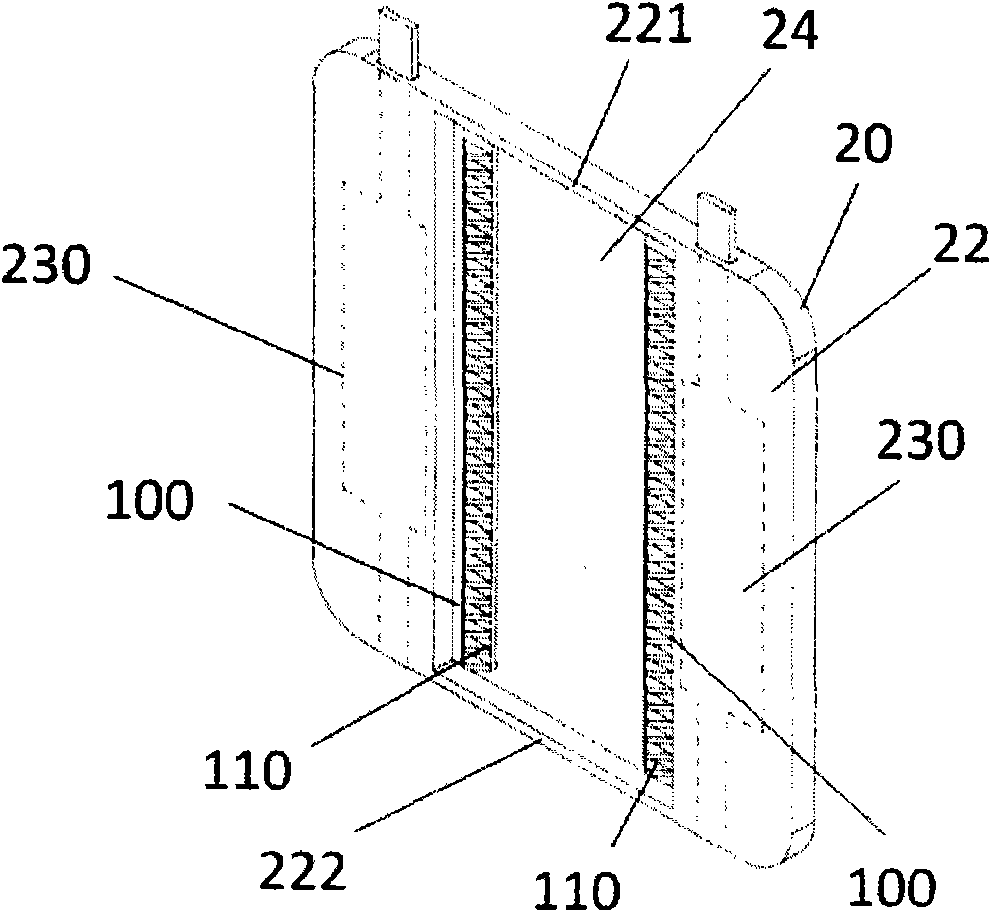

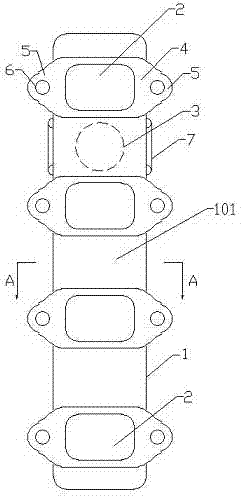

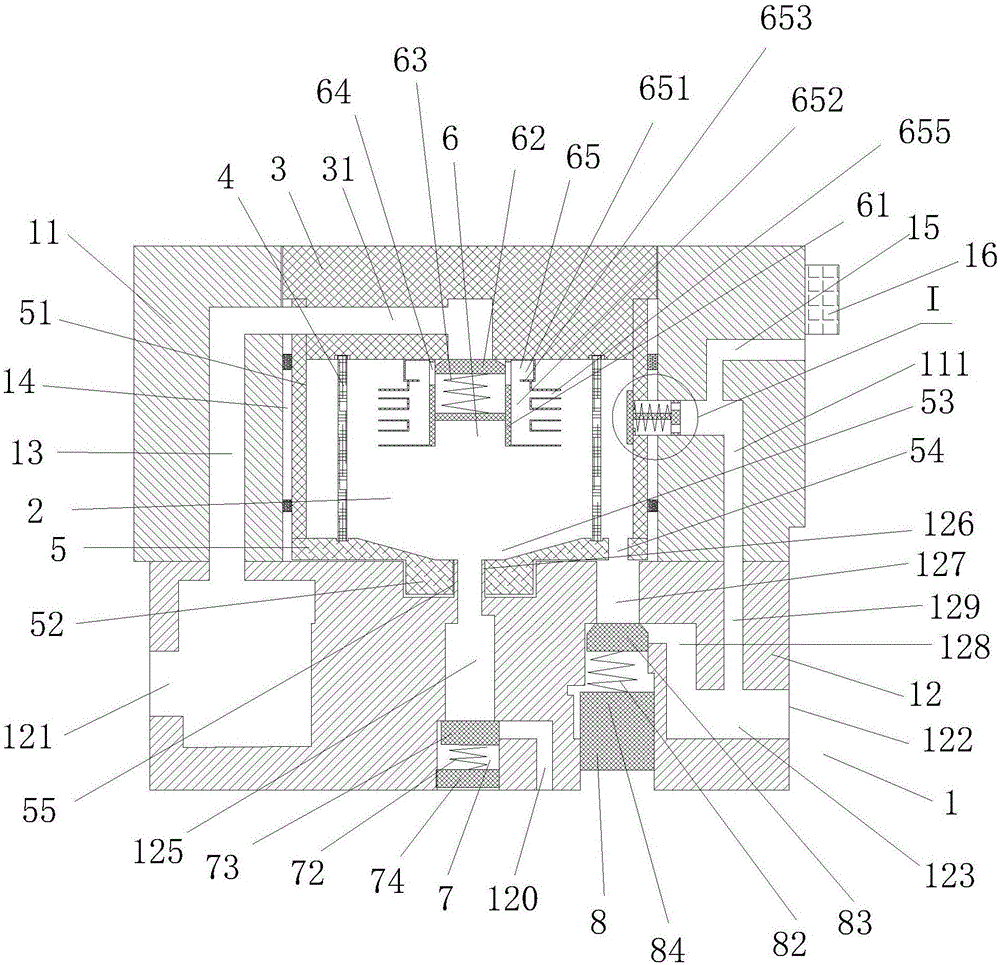

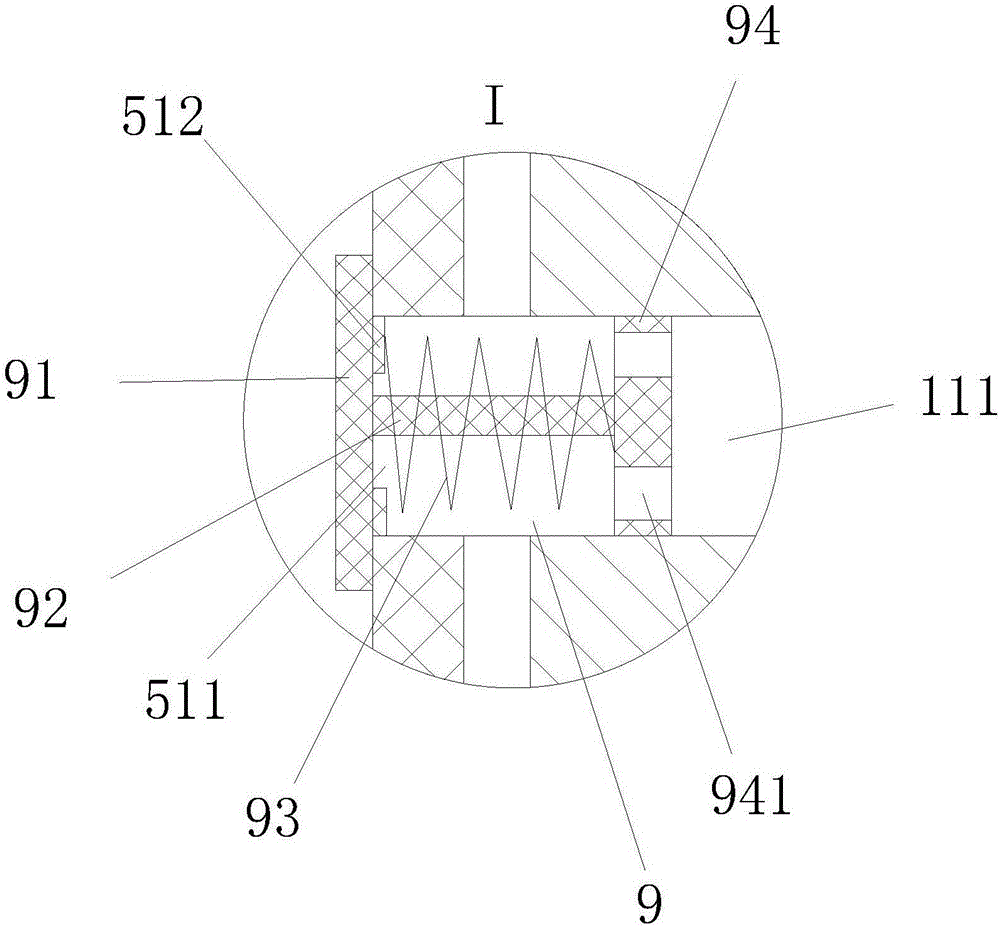

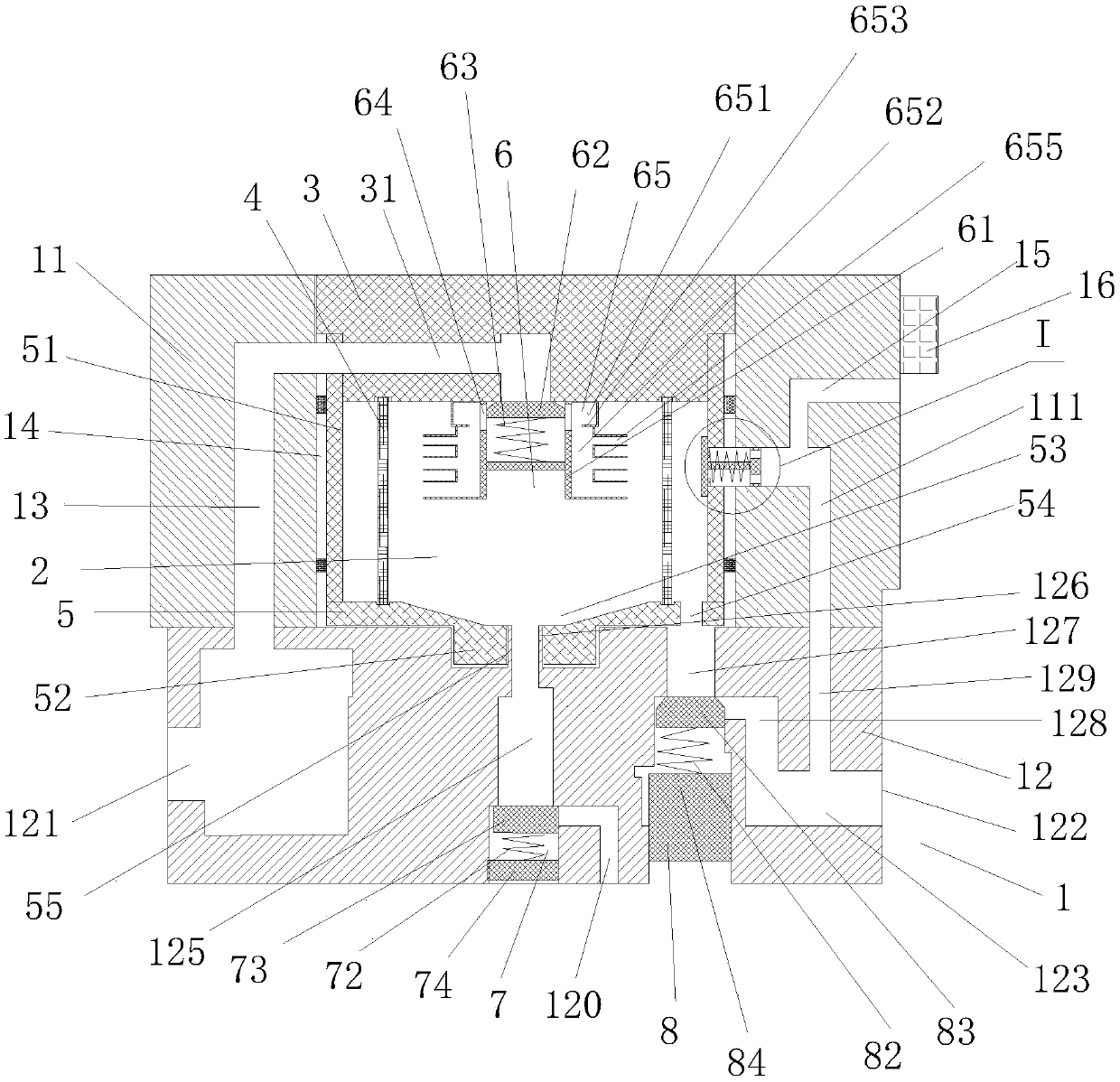

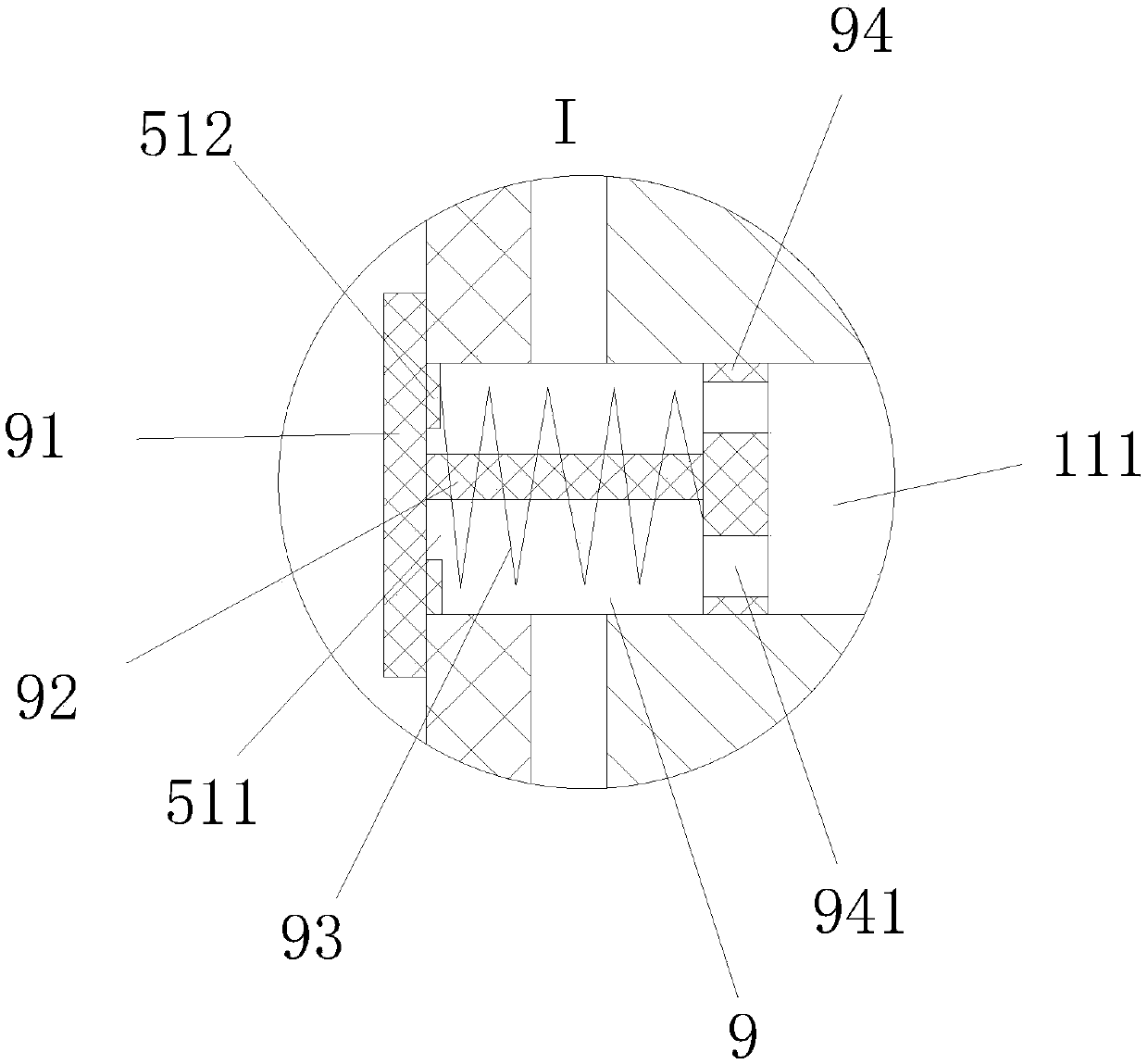

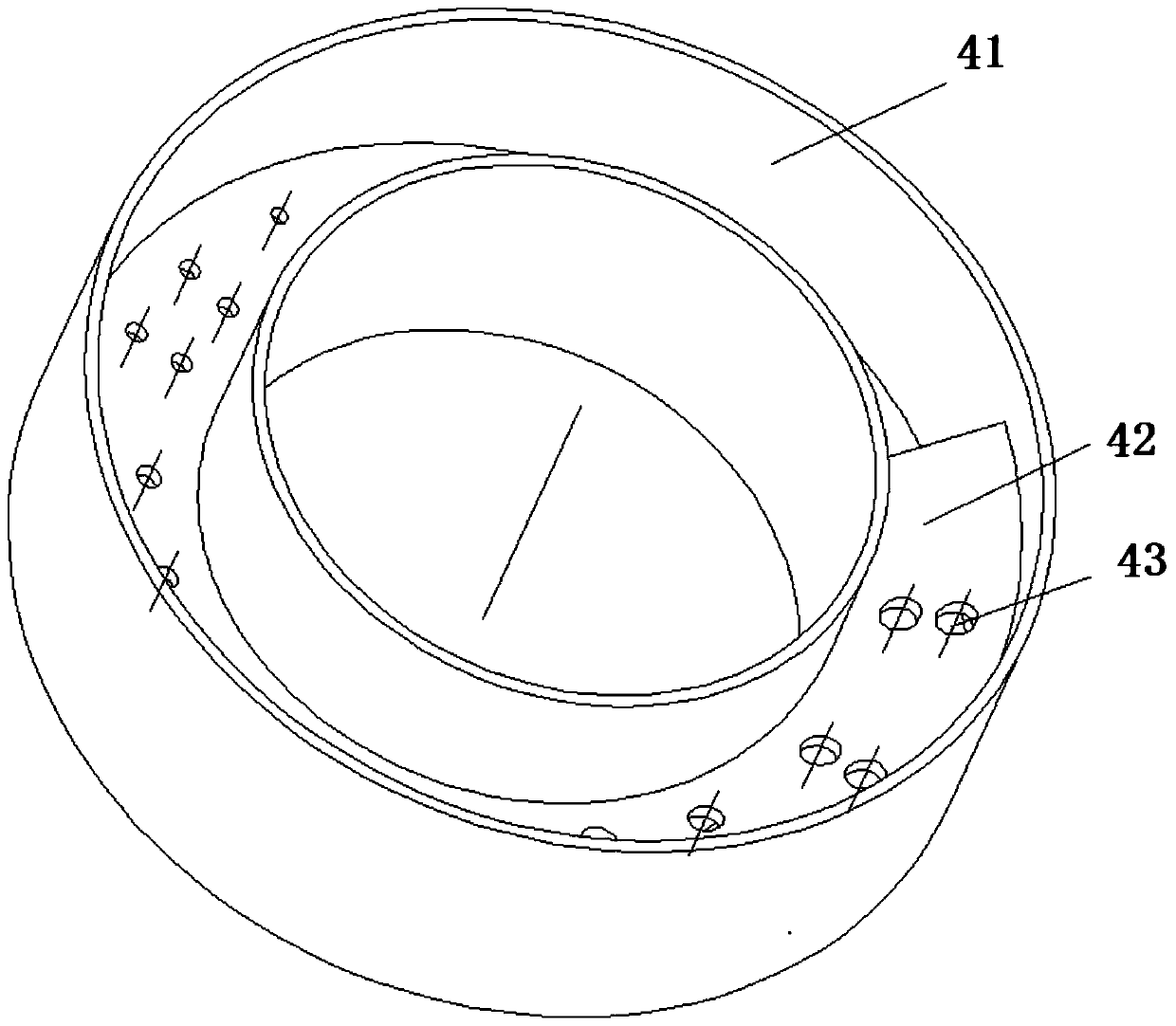

Commercial vehicle combined type unloading valve

ActiveCN107176154AExtended service lifeSimple pressure relief actionMultiple way valvesApplication and release valvesMolecular sieveEngineering

The invention relates to the field of air valves of commercial vehicle braking systems and discloses a commercial vehicle combined type unloading valve. A filter (2) is arranged in a valve body (1), the valve body (1) comprises an upper valve main body (11) and a lower valve main body (12) which are connected in the up-down direction, and the side face of the lower valve main body (12) is provided with an air inlet connector (121), an air outlet connector (122) and an air outlet cavity (123) connected with the air outlet connector (122); a first air inlet passageway (13) is formed in the upper valve main body (11), a mounting cavity (14) penetrating through the lower end face of the upper valve main body (11) is formed in the upper end face of the upper valve main body (11), and the filter (2) is mounted in the mounting cavity (14) and comprises an upper mounting end cover (3), a molecular sieve filtering net (4) and a base (5); and a reverse blowing passageway is formed in the valve body (1) simultaneously. According to the commercial vehicle combined type unloading valve, the simple pressure relief action can be conducted, and meanwhile compressed air can be subjected to filtering and condensation water separating; and the compressed air is filtered from the interior of the filtering net to the exterior of the filtering net, and filtering accuracy is higher.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

Preparation method of edible Chinese mugwort extract

PendingCN111617124AEfficient removalReduce generationChemicalsFractional distillationBiotechnologyAqueous solution

The invention relates to a preparation method of an edible Chinese mugwort extract. The preparation method comprises the steps of step (1) thoroughly cleaning Chinese mugwort stems and leaves free from pathogen infestation, soaking the cleaned Chinese mugwort stems and leaves in a sodium chloride aqueous solution, and performing ultrasonic treatment and ozone sterilization and disinfection duringsoaking; step (2) immersing the cut-up Chinese mugwort stems and leaves in liquid nitrogen, performing scooping up, performing freeze-drying, putting small broken segments into a fine crushing machine, and performing crushing to obtain stem and leaf powder; step (3) putting the stem and leaf powder into a solvent, and performing soaking; step (4) placing the stem and leaf powder and the solvent inan extraction kettle to obtain a preliminary Chinese mugwort extract; and step (5) putting the preliminary Chinese mugwort extract in a distillation column, performing high-temperature distillation,enabling gas generated after distillation to flow out of the top of the distillation column, performing liquefaction on the gas through a condensing tube to obtain liquid, and enabling the liquid to enter a collecting tube so as to obtain the Chinese mugwort extract. According to the preparation method of the Chinese mugwort extract disclosed by the invention, loss of effective components in a Chinese mugwort extraction process can be effectively avoided, quality and yield of Chinese mugwort extracts are increased, and industrialized production is easy to realize.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

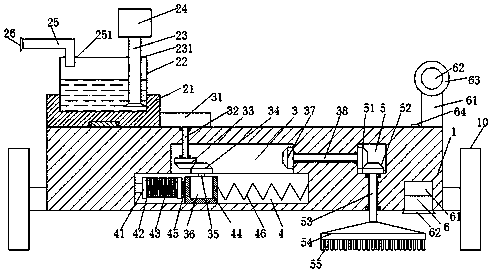

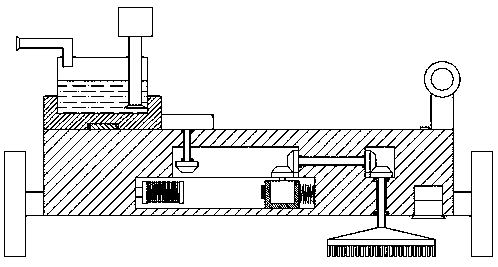

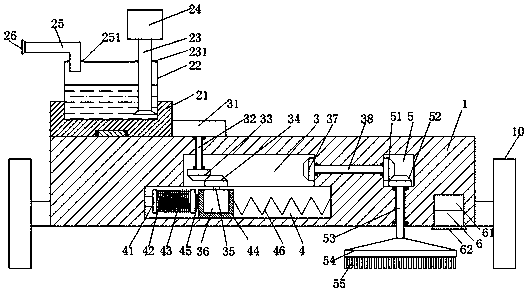

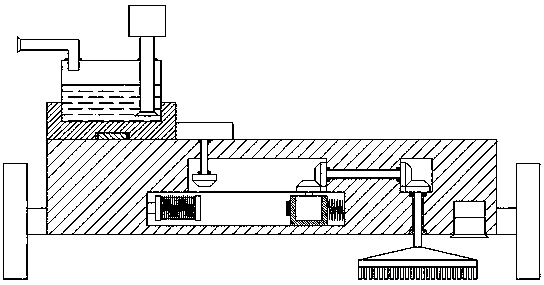

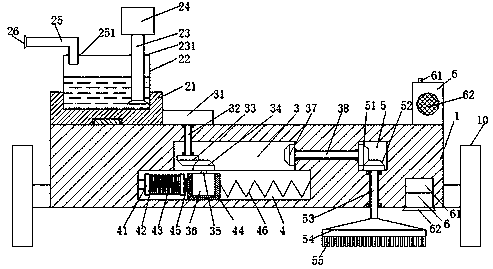

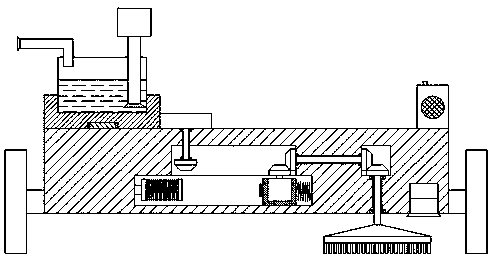

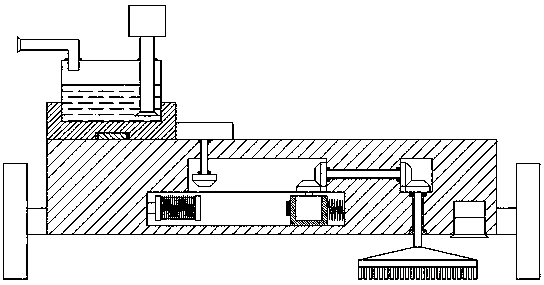

Improved urban pollution treatment device

ActiveCN108330877AAvoid flyingProtect your healthUsing liquid separation agentRoad cleaningAir cleaningPollutant

The invention discloses an improved urban pollution treatment device. The device comprises a device body and walking wheels arranged on two side walls of the device body, an air purification structureis arranged at a position on the left side of the top end surface of the device body, a first transmission chamber is arranged in the middle of the inner wall body of the device body, an accommodating chamber is communicated with the lower portion of the first transmission chamber, an energizing solenoid assembly is fixedly arranged on the left side wall of the accommodating chamber, a tension spring is fixedly arranged on the right side wall of the accommodating chamber, a sliding base is fixedly connected to the left end of the tension spring, and a permanent magnet is fixedly arranged on the end surface of the left side of the sliding base. The device has the advantages of being small in size, simple in operation and convenient to operate in a narrow street, integration of urban road cleaning work and urban air purification work is achieved, and road cleaning and dust collection are conducted synchronously to prevent dust from flying; water in a water tank is utilized to adsorb pollutants in the air, the cost is low, and the air purification structure can be rotated as a whole.

Owner:盐城市权航科技有限公司

Urban pollution management device

ActiveCN108035288AAvoid flyingProtect your healthUsing liquid separation agentRoad cleaningPollutantMagnet

The invention discloses an urban pollution management device which comprises an equipment body and walking wheels arranged on two side walls of the equipment body. An air purifying structure is arranged on the left side of the top end face of the equipment body, a first transmission cavity is arranged in the middle of the inner wall of the equipment body, a containing cavity is communicated belowthe first transmission cavity, an electrifying solenoid component is fixedly arranged on the left-side wall of the containing cavity, a tension spring is fixedly arranged on the right-side wall of thecontaining cavity, a sliding base is fixedly arranged at the left end of the tension spring, and a permanent magnet is fixedly arranged on the left-side end face of the sliding base. The urban pollution managing device is small in size, simple and convenient to operate and convenient for working in narrow streets, integration of urban road cleaning and urban air purifying is realized, road cleaning and dust collection are realized at the same time, and dust flying is prevented; water in a water tank is utilized to adsorb pollutants in air, the urban pollution managing device is low in cost, and an air purifying structure is rotatable integrally.

Owner:江苏凯亚环保科技有限公司

Novel urban pollution control device

The invention discloses a novel urban pollution control device comprising a device main body and walking wheels arranged at two side walls of the device main body, wherein an air purification structure is arranged at the left side of the top end surface of the device main body; a first transmission cavity is arranged in the middle of the inner wall body of the device main body; a holding cavity isarranged under and communicates with the first transmission cavity; an electrified solenoid assembly is fixedly arranged at the left wall body of the holding cavity; a tension spring is fixedly arranged at the right wall body of the holding cavity; a sliding base is fixedly connected to the left end of the tension spring; and a permanent magnet is fixedly arranged at the left end surface of the sliding base. The novel urban pollution control device has the advantages of small size, simple operation, convenient operation in narrow streets, integration of urban road cleaning work and urban airpurification work, simultaneous road cleaning and dust suction and prevention of dust rising. The novel urban pollution control device utilizes the water in a water tank to absorb pollutants in the air, so that the cost is low. The air purification structure can be rotated as a whole.

Owner:江苏宝华环保科技有限公司

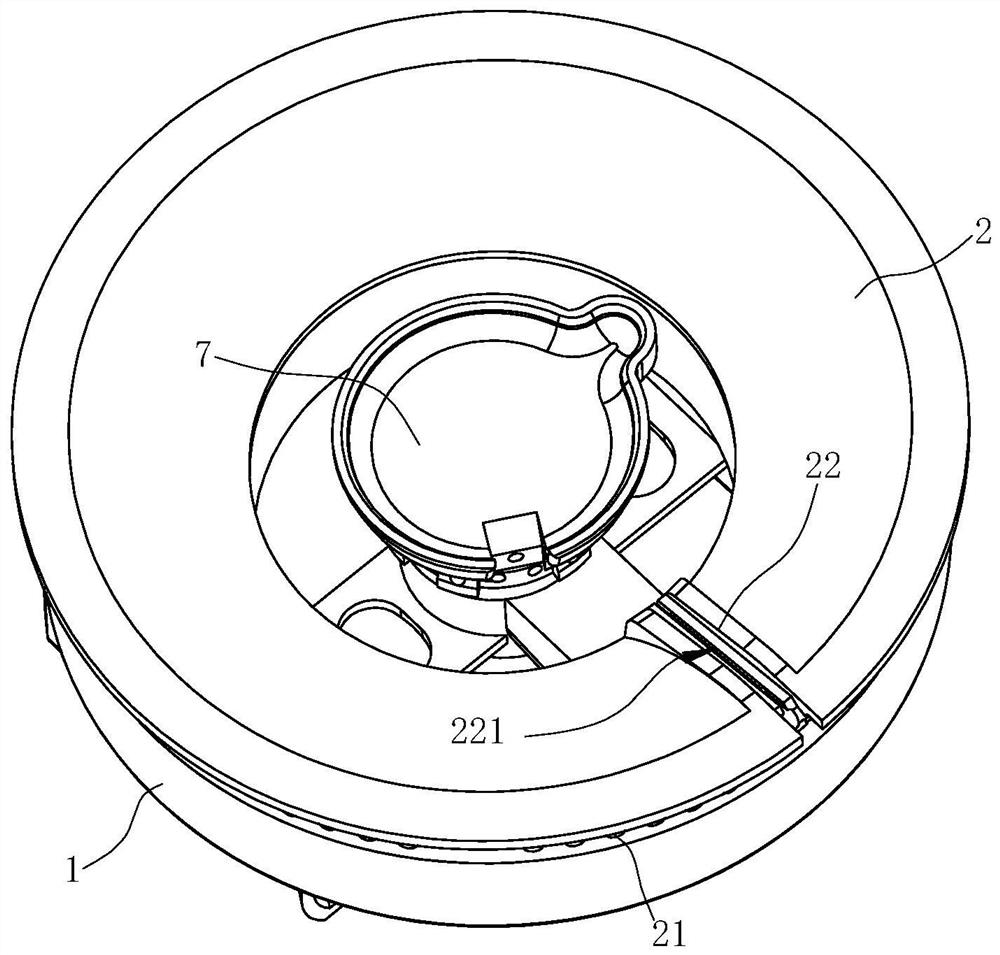

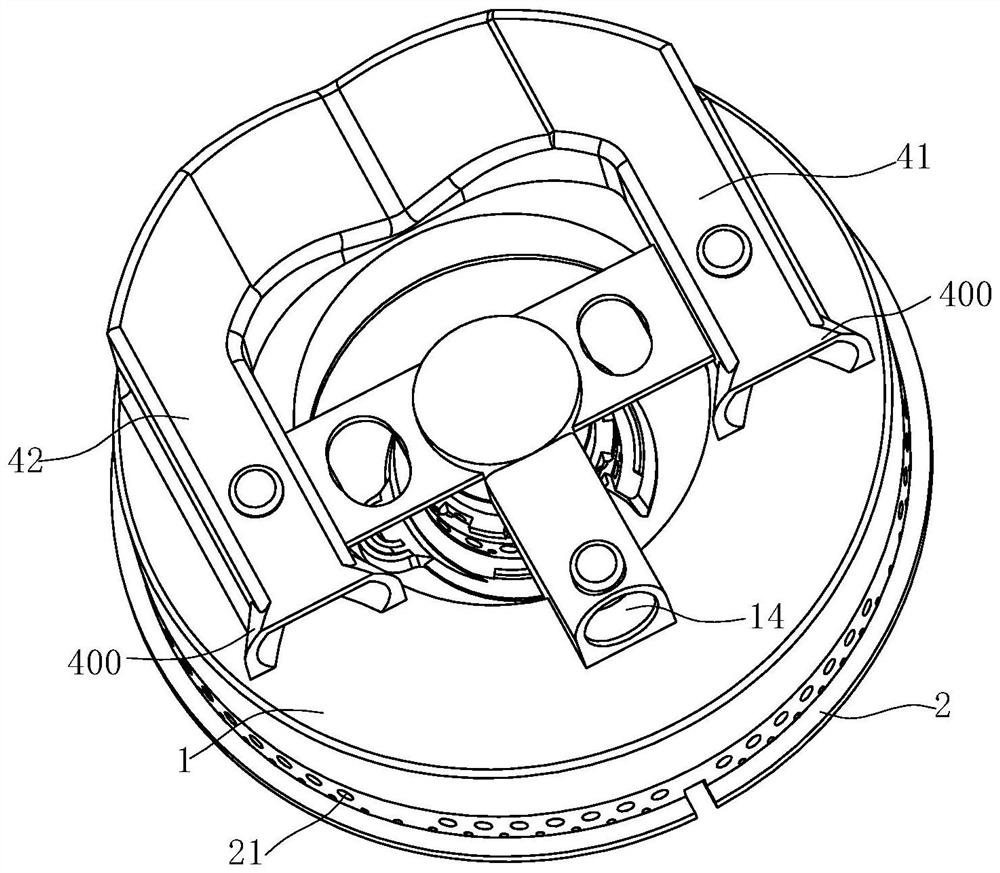

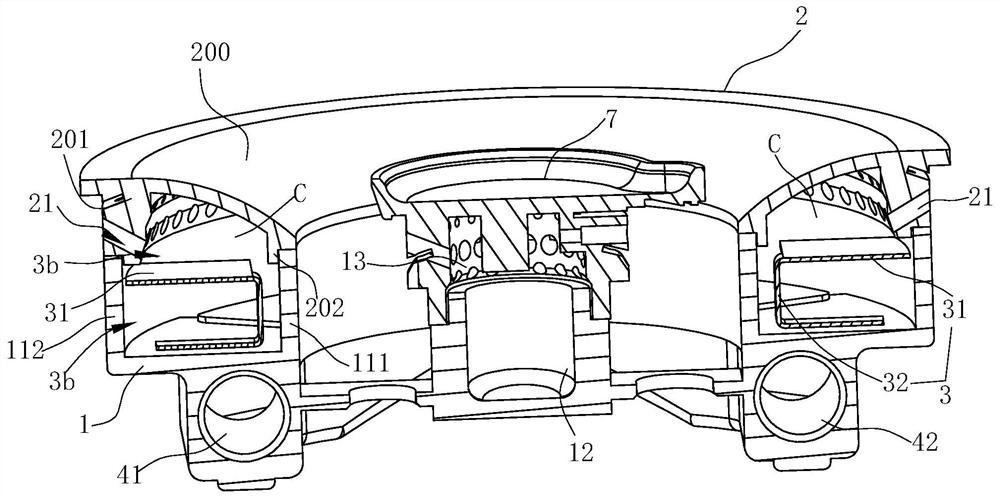

Combustor for cooking utensils

The invention relates to a combustor for cooking utensils. The combustor comprises a base, an outer ring fire cover, a first outer ring ejector tube and a second outer ring ejector tube, wherein the outer ring fire cover covers a top opening of an outer ring cavity body of the base and an outer ring gas mixing chamber is formed by encircling the outer ring fire cover and the outer ring cavity body; the first outer ring ejector tube is horizontally arranged on the base and communicates with the outer ring gas mixing chamber; and the second outer ring ejector tube is horizontally arranged on thebase, the second outer ring ejector tube and the first outer ring ejector tube are arranged at intervals, and the second outer ring ejector tube communicates with the outer ring gas mixing chamber. The combustor is characterized in that a first gas ventilation hole, communicated with the outer ring gas mixing chamber, of the first outer ring ejector tube is basically in L shape, and the first gasventilation hole is adjacent to the inner ring wall of the outer ring cavity body; a second gas ventilation hole, communicated with the outer ring gas mixing chamber, of the second outer ring ejectortube is also basically in L shape, and the second gas ventilation hole is adjacent to the outer ring wall of the outer ring cavity body; and a partitioning plate is arranged between the second gas ventilation hole and the first gas ventilation hole. By adopting the combustor disclosed by the invention, the two-sided gas can smoothly and quickly flow to respective directions and opposed-impingement phenomenon is avoided, a flame state of the whole combustor is better, and the gas can come out more evenly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Production process and device of degradable sponge product

The invention discloses a production process and device of a degradable sponge product. The sponge product is prepared by taking wood meal, bamboo meal and three kinds of agriculture and forestry residues as initial raw materials through pretreatment, dissolution, pore forming, forming, freezing point aging, regeneration in a sulfuric acid coagulating bath, flushing to be neutral and drying, and pore forming comprises the steps of adding an auxiliary agent and a pore forming agent, stirring at a high speed, mixing and then forming pores. A forming device is a three-face top forming device, first limiting blocks movably connected with supporting plates and second limiting blocks movably connected with a cover plate are arranged in a containing space, and the first limiting blocks, the second limiting blocks and the two supporting plates perpendicularly connected with the two second limiting blocks are matched with one another to form the containing cavity for containing sponge to be formed. According to the process and the device, hemicellulose dissolution limitation in the reaction process is reduced, a low-cost sponge production process is provided, holes formed in the interior and the surface of the sponge are uniform and consistent in size and density, and the sponge product is stable in performance, low in production cost and free of pollution to the environment.

Owner:NINGBO NECO SPONGE TECHONOLOGY CO LTD

Combined unloading valve for commercial vehicles

ActiveCN107176154BExtended service lifeSimple pressure relief actionMultiple way valvesApplication and release valvesMolecular sieveEngineering

The invention relates to the field of air valves of commercial vehicle braking systems and discloses a commercial vehicle combined type unloading valve. A filter (2) is arranged in a valve body (1), the valve body (1) comprises an upper valve main body (11) and a lower valve main body (12) which are connected in the up-down direction, and the side face of the lower valve main body (12) is provided with an air inlet connector (121), an air outlet connector (122) and an air outlet cavity (123) connected with the air outlet connector (122); a first air inlet passageway (13) is formed in the upper valve main body (11), a mounting cavity (14) penetrating through the lower end face of the upper valve main body (11) is formed in the upper end face of the upper valve main body (11), and the filter (2) is mounted in the mounting cavity (14) and comprises an upper mounting end cover (3), a molecular sieve filtering net (4) and a base (5); and a reverse blowing passageway is formed in the valve body (1) simultaneously. According to the commercial vehicle combined type unloading valve, the simple pressure relief action can be conducted, and meanwhile compressed air can be subjected to filtering and condensation water separating; and the compressed air is filtered from the interior of the filtering net to the exterior of the filtering net, and filtering accuracy is higher.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

An urban pollution control device

ActiveCN108035288BAvoid flyingProtect your healthUsing liquid separation agentRoad cleaningEngineeringAir purification

The invention discloses an urban pollution management device which comprises an equipment body and walking wheels arranged on two side walls of the equipment body. An air purifying structure is arranged on the left side of the top end face of the equipment body, a first transmission cavity is arranged in the middle of the inner wall of the equipment body, a containing cavity is communicated belowthe first transmission cavity, an electrifying solenoid component is fixedly arranged on the left-side wall of the containing cavity, a tension spring is fixedly arranged on the right-side wall of thecontaining cavity, a sliding base is fixedly arranged at the left end of the tension spring, and a permanent magnet is fixedly arranged on the left-side end face of the sliding base. The urban pollution managing device is small in size, simple and convenient to operate and convenient for working in narrow streets, integration of urban road cleaning and urban air purifying is realized, road cleaning and dust collection are realized at the same time, and dust flying is prevented; water in a water tank is utilized to adsorb pollutants in air, the urban pollution managing device is low in cost, and an air purifying structure is rotatable integrally.

Owner:江苏凯亚环保科技有限公司

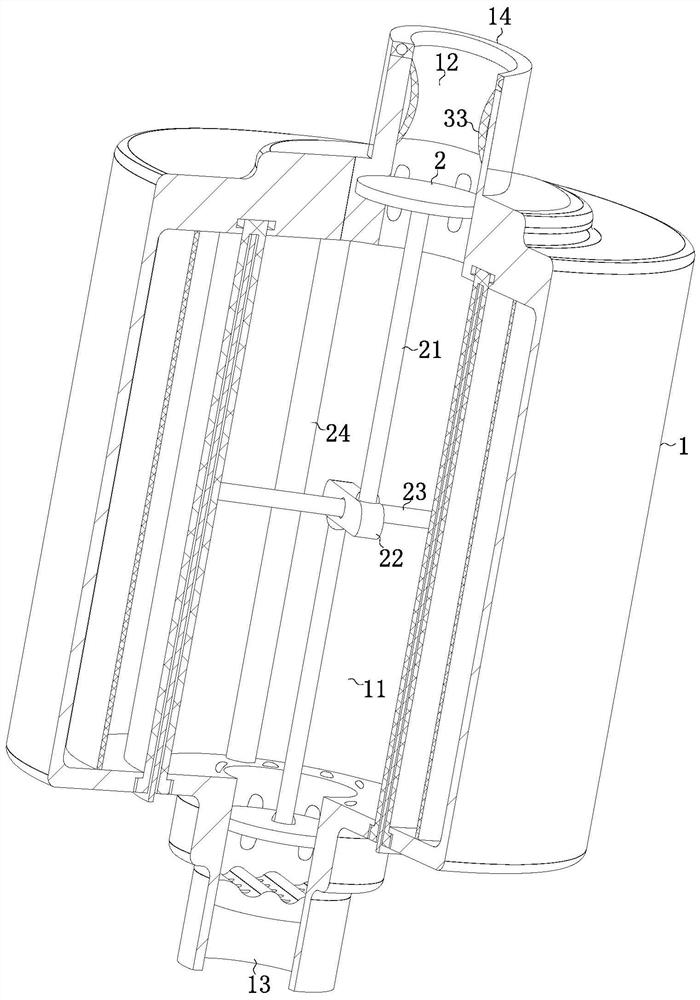

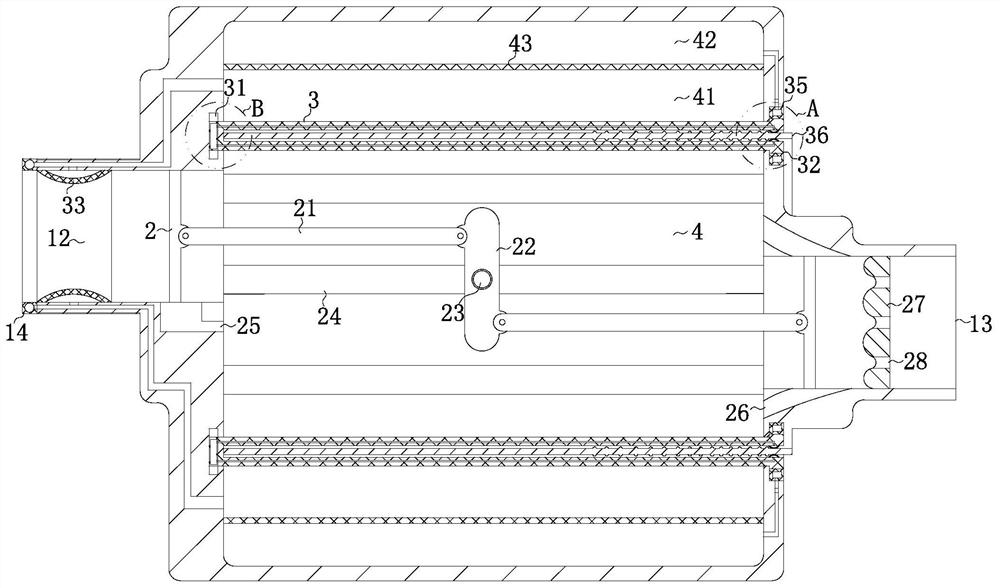

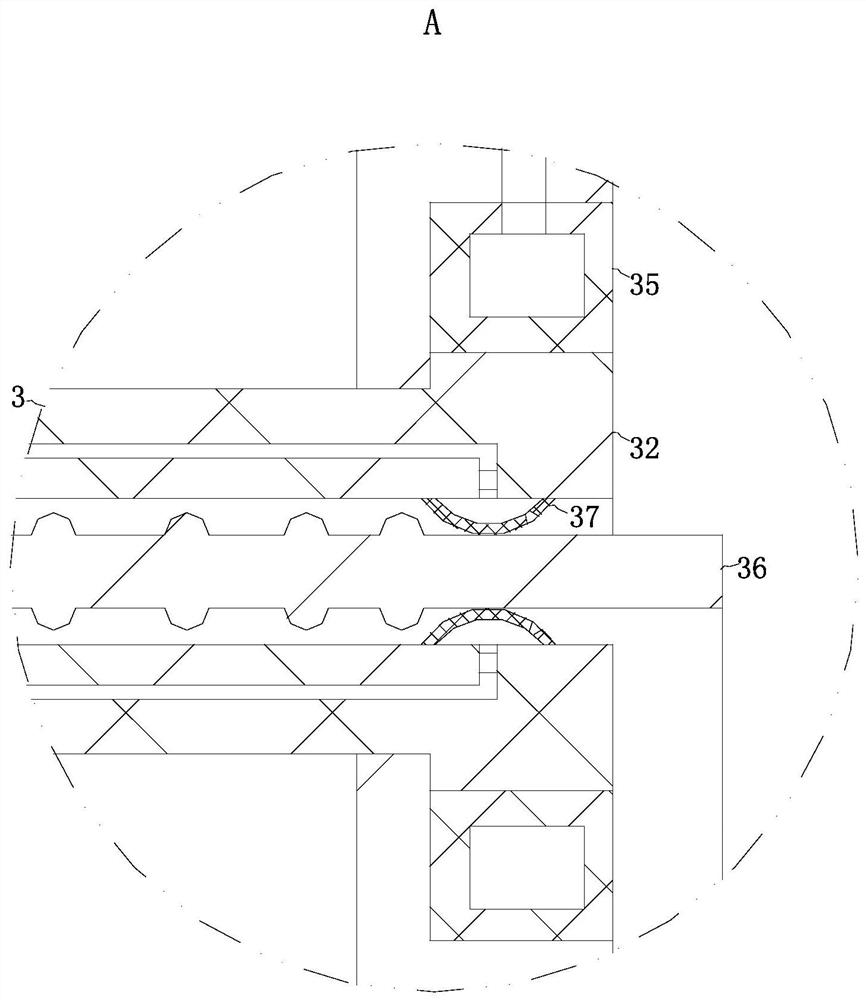

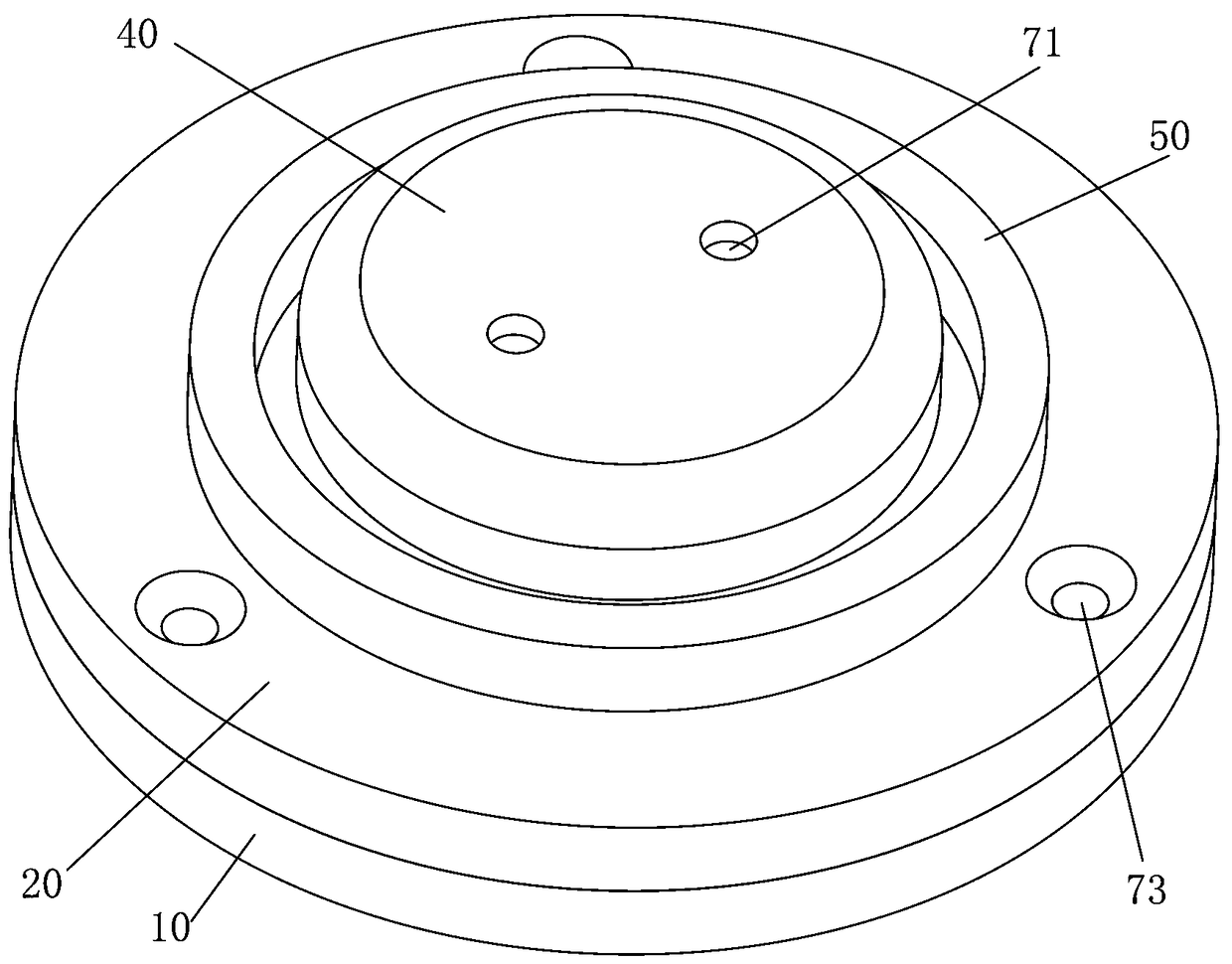

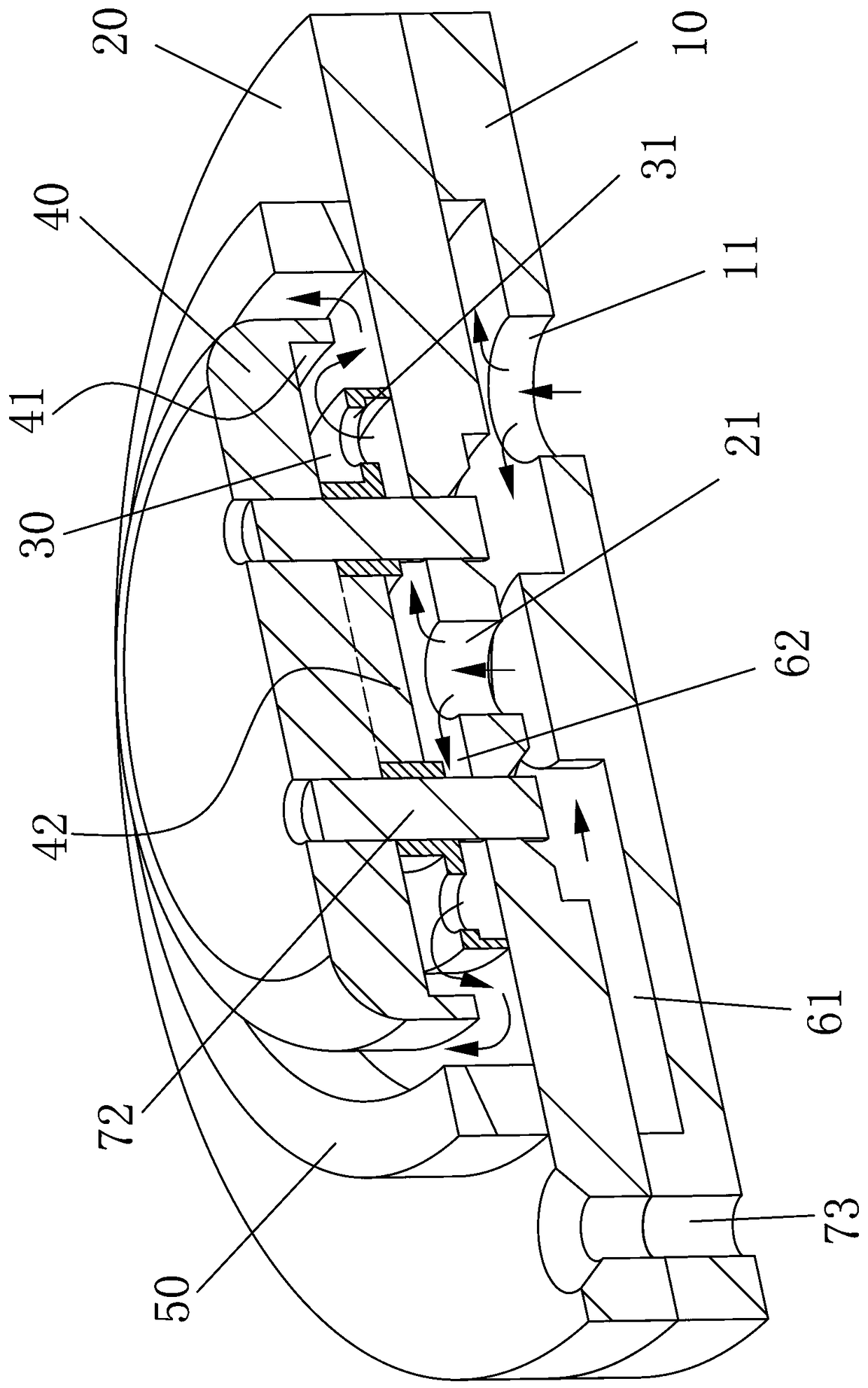

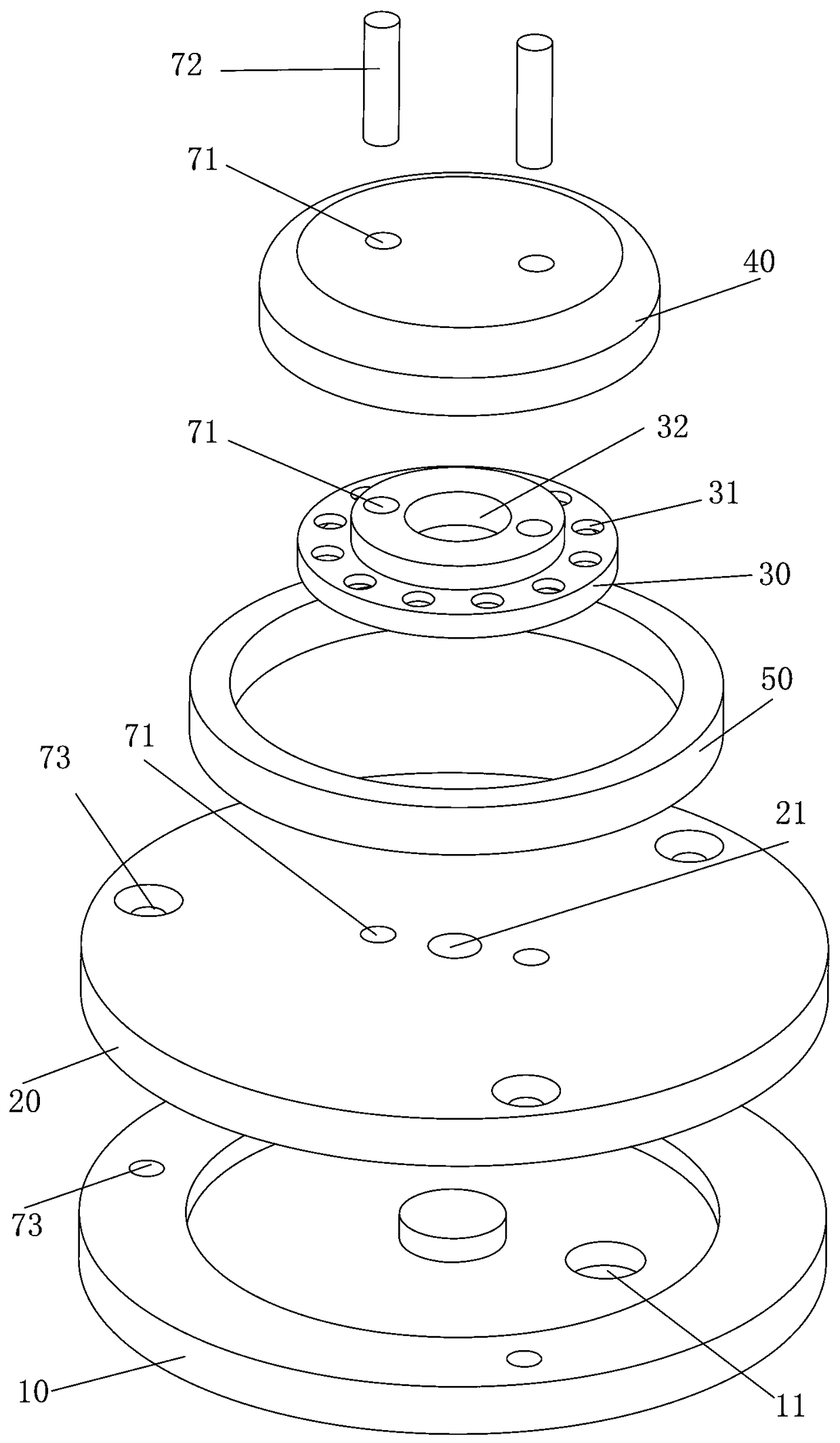

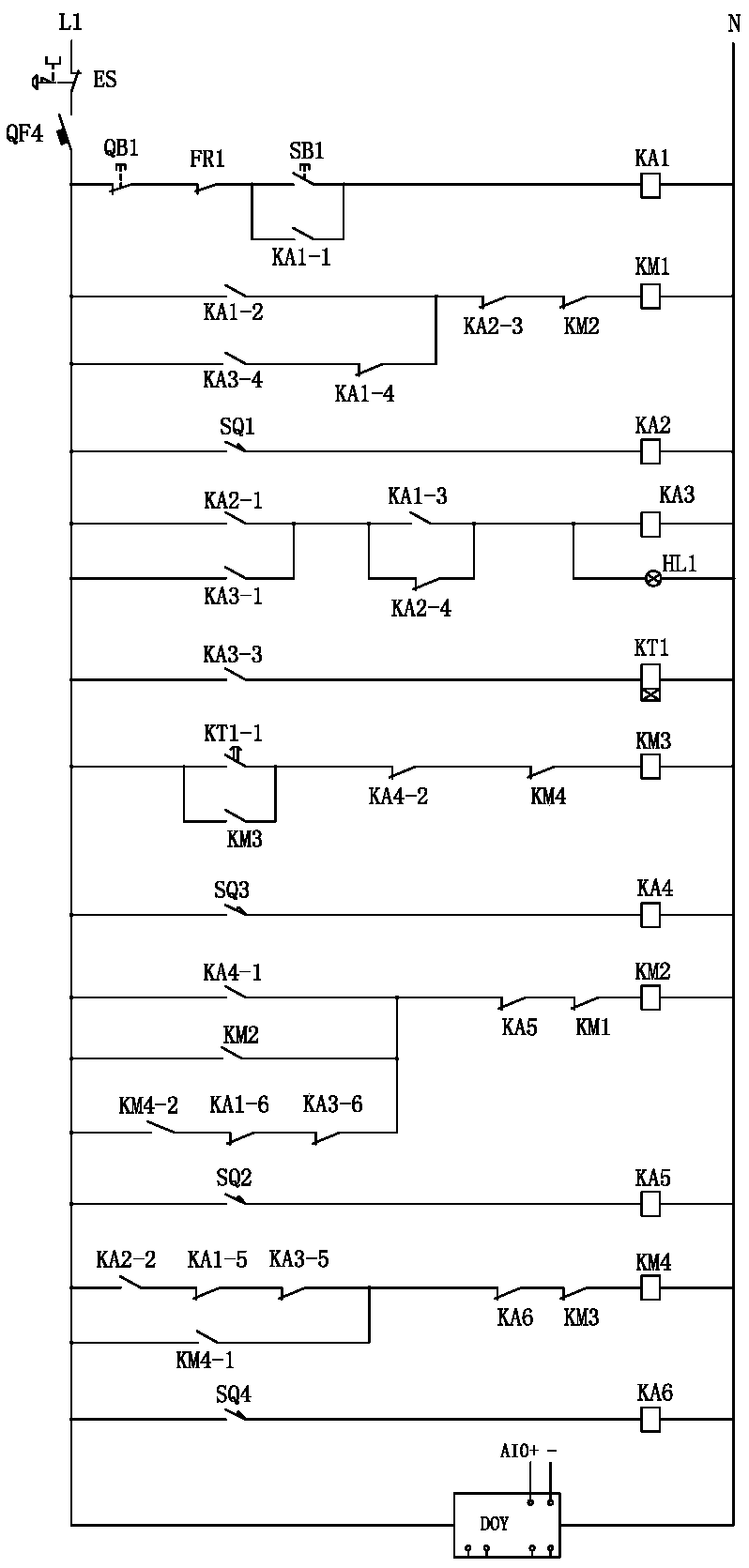

A gas pressure reducing valve

ActiveCN110553071BGood voltage stabilization effectEvenly ventedEqualizing valvesSafety valvesPistonVALVE PORT

Owner:盘锦云飞石油设备有限公司

Magnetic-conductive guiding structure of Hall ion source

PendingCN108735562AHigh densityIncrease the magnetic field strengthIon beam tubesMagnetic susceptibilityEngineering

The invention provides a magnetic-conductive guiding structure of a Hall ion source, comprising an air inlet insulating bowl, an air venting magnetic-conductive disk and an air outlet magnetic-conductive bowl arranged in order from bottom to top, wherein a lower chamber is disposed between the air inlet insulating bowl and the air venting magnetic-conductive disk, and an upper chamber is disposedbetween the air venting magnetic-conductive disk and the air outlet magnetic-conductive bowl; the air inlet insulating bowl is provided with an air inlet hole communicated with the lower chamber, theair venting magnetic-conductive disk is provided with an air venting hole communicating the upper and lower chambers, and the air outlet magnetic-conductive bowl is provided with an air outlet hole communicated with the upper chamber; the air enters the lower chamber from the air inlet hole, enters the upper chamber through the air venting hole, and finally exits from the air outlet hole. In the invention, an upper chamber is disposed between the air venting magnetic-conductive disk and the air outlet magnetic-conductive bowl, so that the magnetic sensing line is partially restrained within the upper chamber to increasing the magnetic susceptibility of the upper chamber, thereby increasing the magnetic field strength of the upper chamber. The invention is simple in structure and low in production cost.

Owner:DONGGUAN CHANGYI PHOTOELECTRIC CO LTD

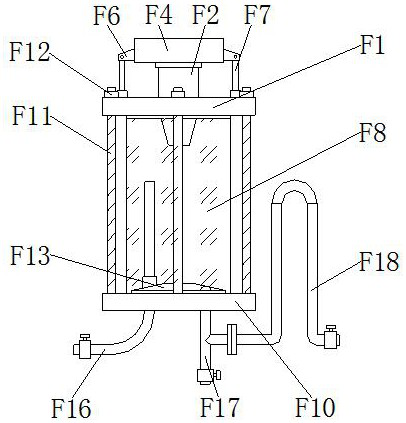

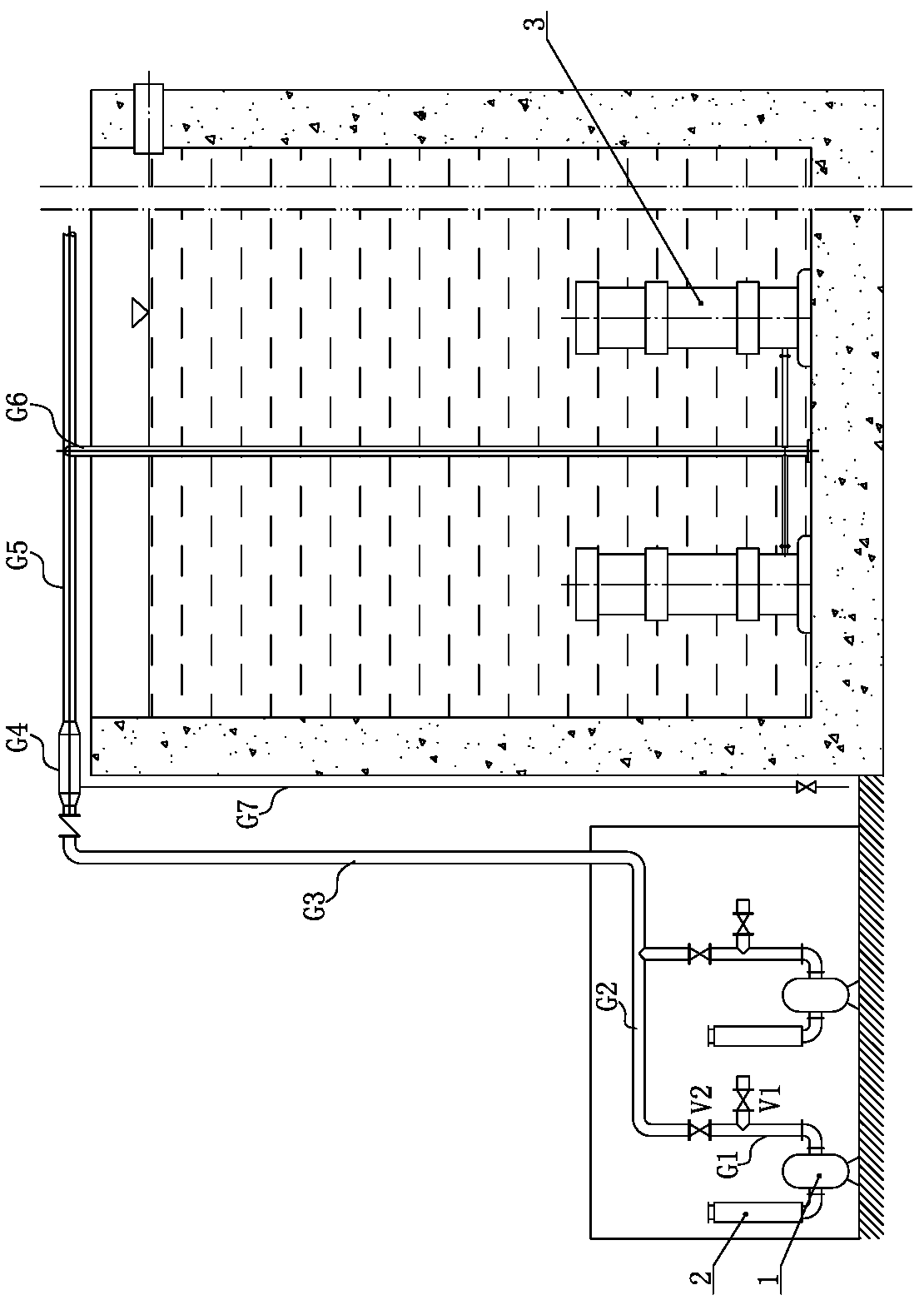

Pool aeration system and aeration method thereof

ActiveCN108640264AAvoid enteringPrevent affecting operationWater contaminantsSustainable biological treatmentAeration systemMoisture

The invention relates to a pool aeration system and a aeration method thereof. The blower fan outlet pipes are respectively arranged at outlets of roots blower fans, an air supply valve is arranged atthe top of the blower fan outlet pipe, the outlet of the air supply valve and an air feed standpipe and the upwardly extended air feed standpipe are connected, the top of the air feed standpipe is connected with an air feed transverse pipe with horizontal extending along the top of the pool, several air feed branch pipes extending to the bottom of the pool are connected with the air feed transverse pipe, and the lower end of the air feed branch pipe is respectively connected with an air intake of a corresponding aeration head; a horizontally extended escape pipe is connected with a middle section of the blower fan outlet pipe, and an emptying valve is arranged at the outlet of the escape pipe. When aeration is carried out on the pool, the emptying valve is opened before starting, a blowerfan is turned on, after the blower fan is operated with a full speed, the air supply valve is opened, the emptying valve is closed and air is supplied to the pool, the emptying valve is opened for pressure relieving while shutdown, the blower fan is stopped, and the air supply valve and the emptying valve are closed. The aeration system and the aeration method realize zero-load starting and unloading of the blower fan, can avoid moisture erosion, and have long usage life.

Owner:扬州奔宇环保科技有限公司

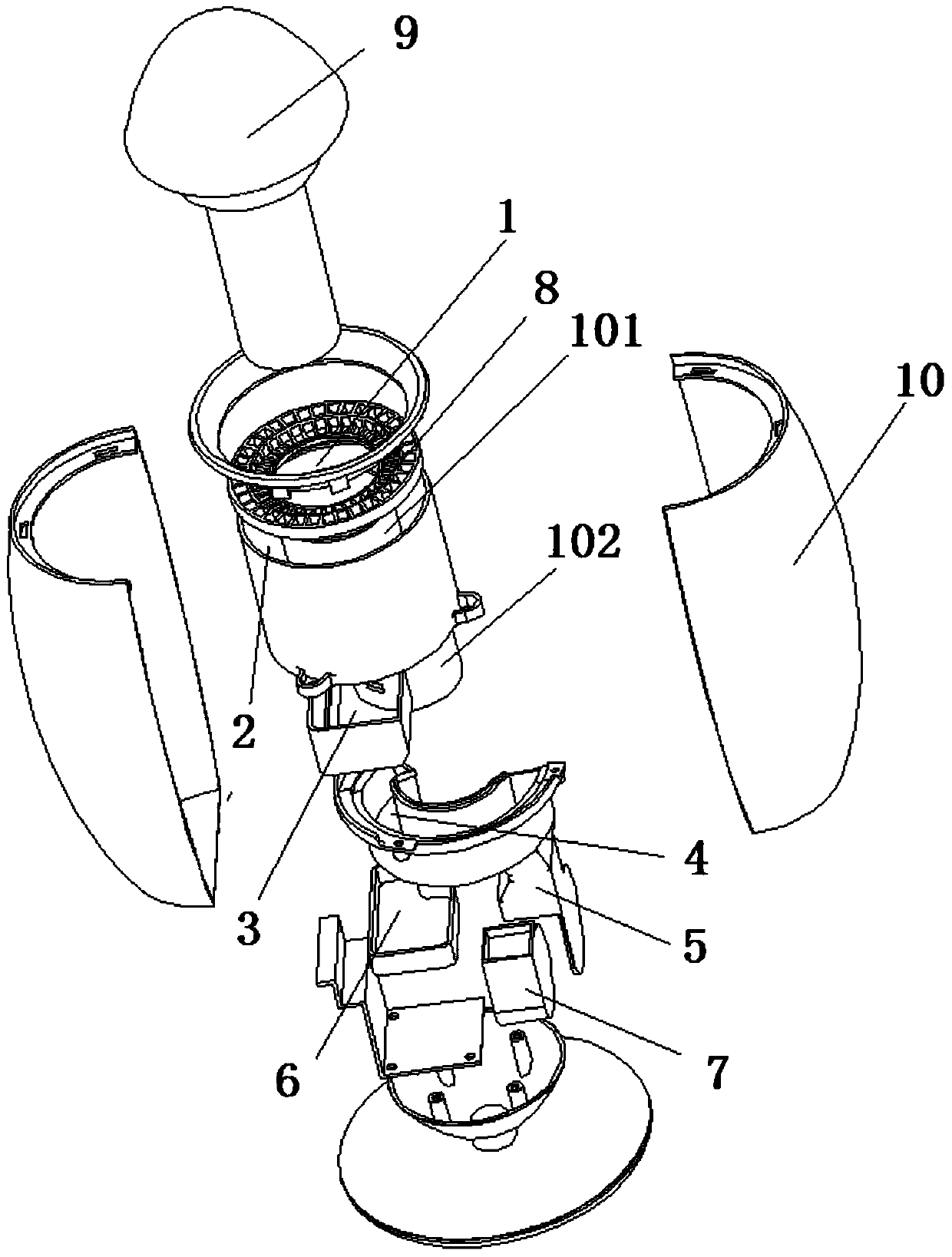

An air sterilizer structure

ActiveCN105457070BRealize disinfection and sterilizationAchieve humidificationLighting and heating apparatusAtomized substancesInlet channelEngineering

The invention relates to a structure of an air disinfector. The structure comprises a water inlet channel, a mist channel, an ionization device, a mist uniform distribution device, an atomization device and a draught fan; the water inlet channel is vertically arranged and comprises a water inlet section and a slow flow section which are sequentially connected and communicated from top to bottom, and the slow flow section is located on one side of the lower end of the water inlet section; the mist channel is arranged on the outer side of the water inlet section in a surrounding mode, and the slow flow section penetrates out of the lower end of the mist channel; the ionization device is installed on the outer side wall of the lower portion of the slow flow section and communicated with the slow flow section; the mist uniform distribution device is arranged on the outer side of the slow flow section arranged above the ionization device in a surrounding mode, the upper end of the mist uniform distribution device is fixedly connected with the lower end of the mist channel, and one side of the lower end of the mist uniform distribution device is communicated with a vertically-arranged mist generation channel; the atomization device is installed in the mist generation device and communicated with the ionization device; the draught fan is located at the lower end of the mist generation channel. The structure of the air disinfector is compact in structure and not only can disinfect and sterilize air, but also can humidify the air.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

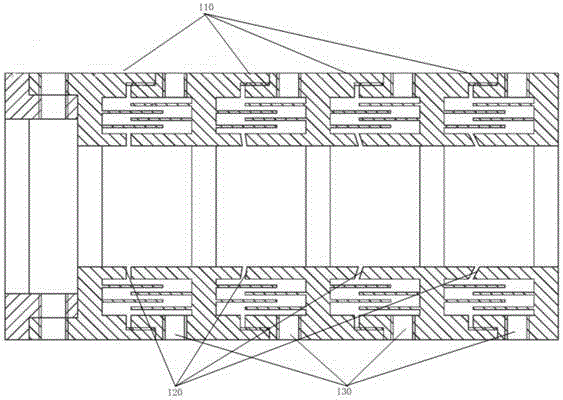

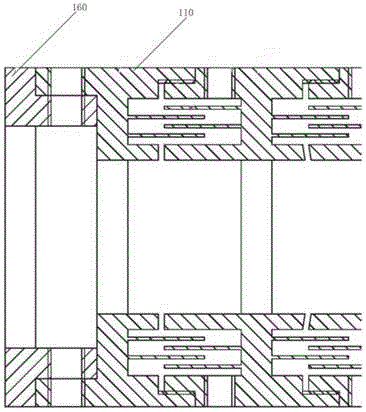

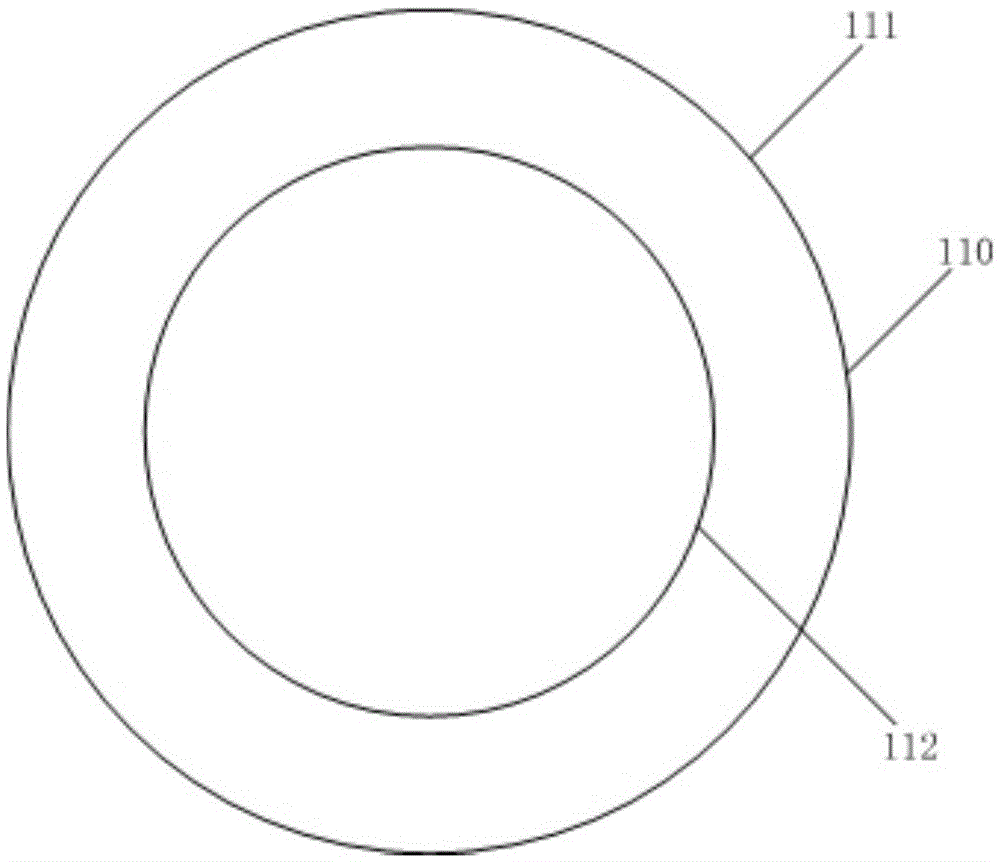

Annular extrusion air-cooling apparatus and pipe extrusion molding apparatus

The present invention discloses an annular extrusion air-cooling apparatus and a pipe extrusion molding apparatus. The annular extrusion air-cooling apparatus comprises an annular air hood, wherein the air hood comprises an outer circumferential housing and an inner circumferential housing; an air inlet arranged on the outer circumferential housing; an air outlet arranged on the inner circumferential housing; a cavity arranged in the annular air hood and communicated to the air inlet and the air outlet; and an air stabilizing grille arranged in the cavity.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com