Combined unloading valve for commercial vehicles

A combined, commercial vehicle technology, applied in multi-way valves, valve devices, brake components, etc., can solve problems such as insufficient condensation and water separation, poor integrity and strength of unloading valves, and affecting the service life of brake components. , to reduce impact, improve service life, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

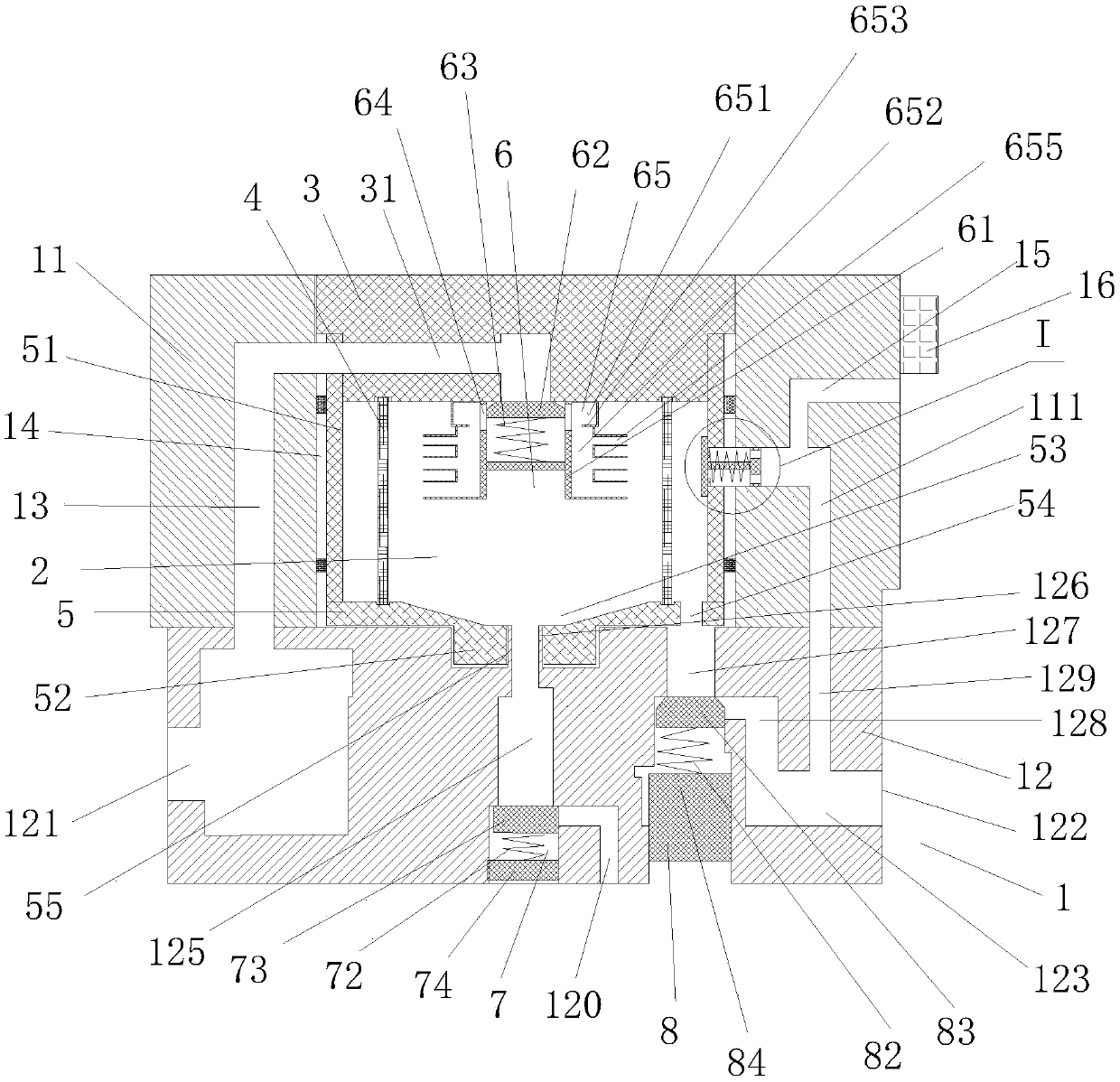

[0027] Such as figure 1 and figure 2 As shown, the commercial vehicle combined unloading valve includes a valve body 1, and a filter 2 is arranged in the valve body 1. The valve body 1 includes an upper valve body 11 and a lower valve body 12 connected up and down, and the side of the lower valve body 12 is provided with The air inlet port 121, the air outlet port 122 and the air outlet cavity 123 connected to the air outlet port 122, the upper valve body 11 is provided with a first air inlet passage 13, and the upper end surface of the upper valve body 11 is provided with an installation cavity 14 that runs through its lower end surface, The filter 2 is installed in the installation cavity 14, and the filter 2 includes an upper installation end cover 3, a molecular sieve filter 4 and a base 5;

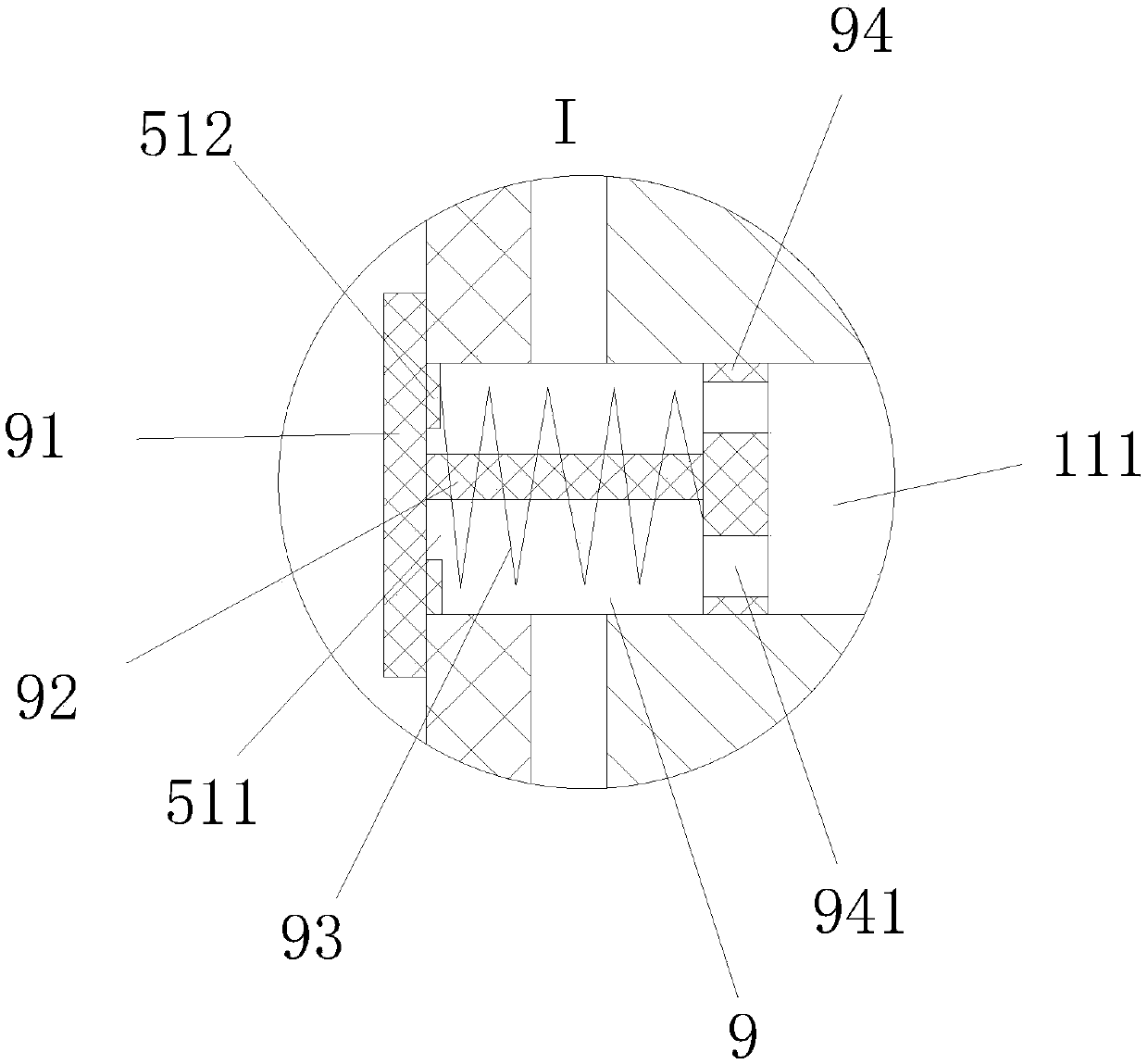

[0028] The upper end surface of base 5 is provided with sealing sleeve 51, and sealing sleeve 51 is positioned at the outside of molecular sieve filter screen 4; The shape is an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com