Welding pipe groove grinding device

A technology for welding pipes and grooves, which is used in grinding machines, grinding workpiece supports, grinding/polishing equipment, etc. Convenient, even sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

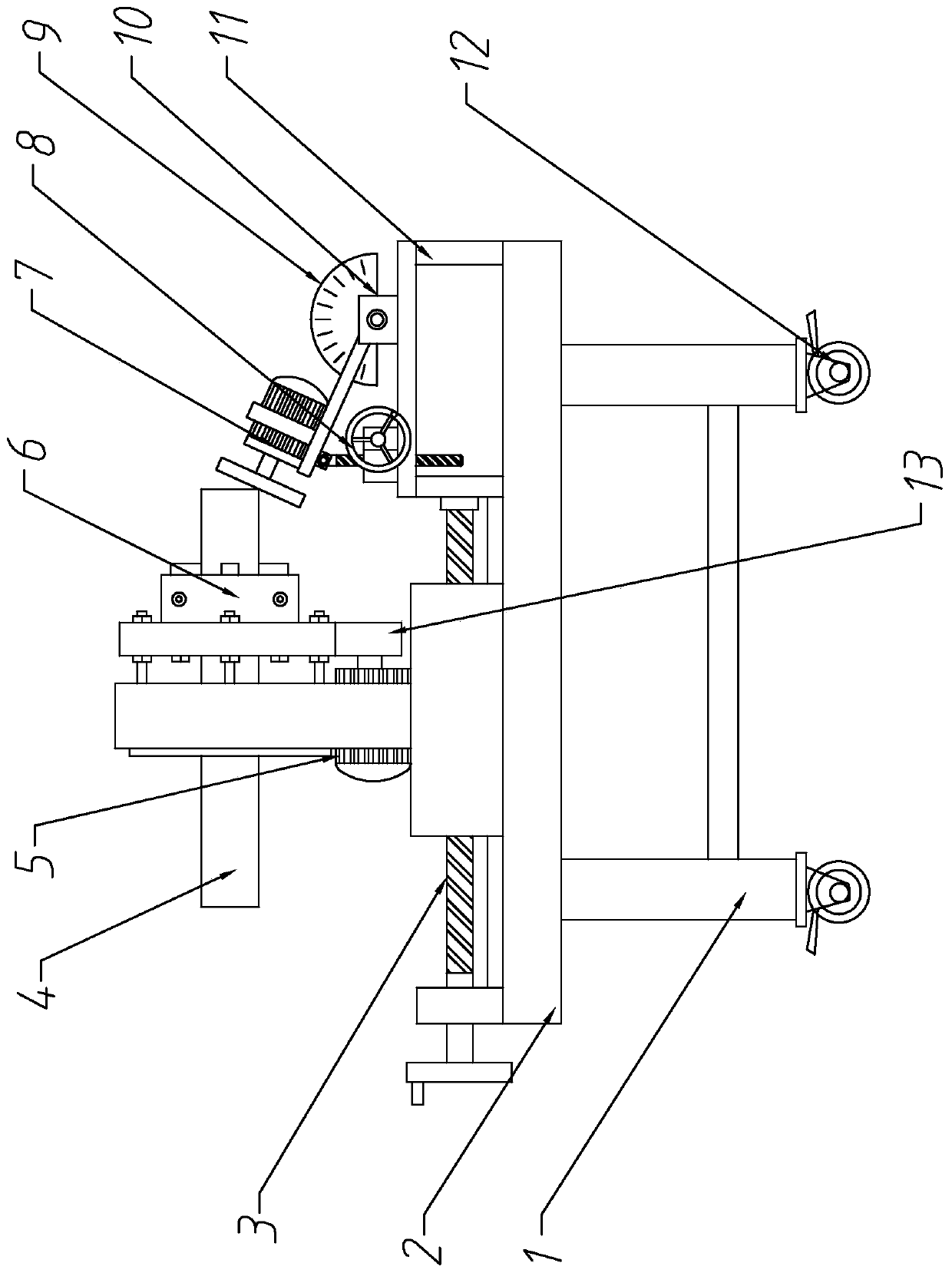

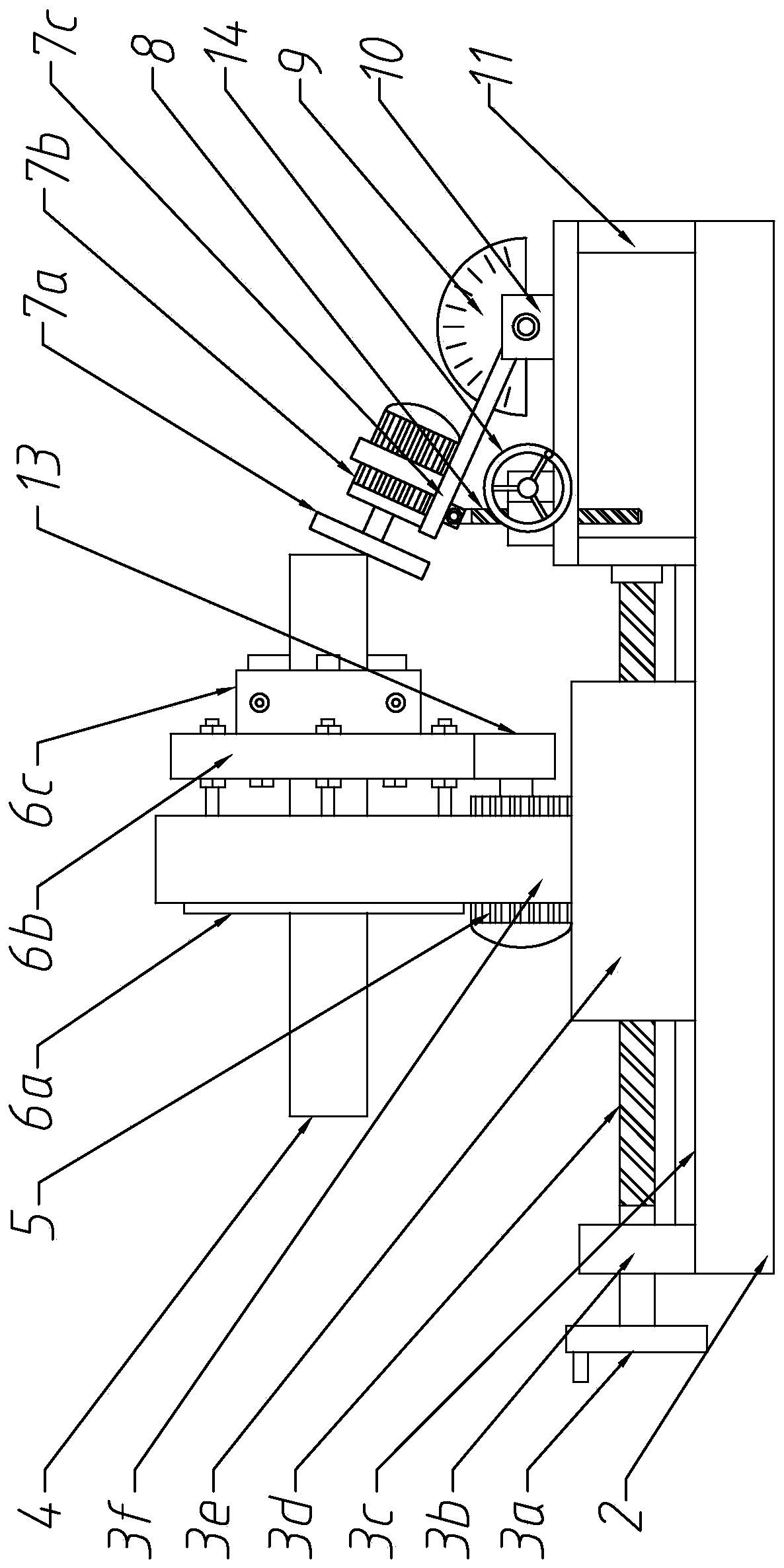

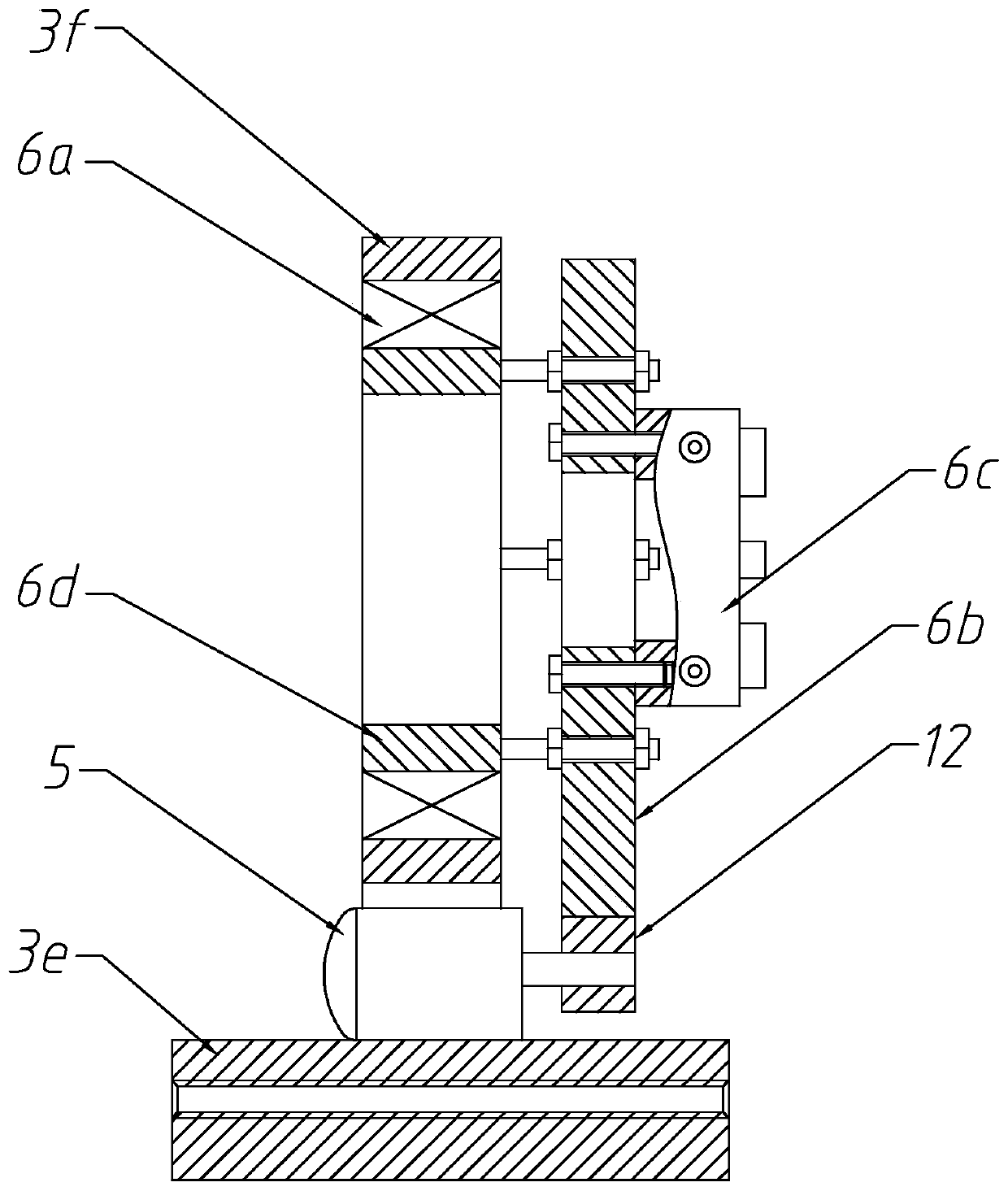

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] see Figure 1-6 , this embodiment provides a welded pipe bevel grinding device, including a support table 2 and a welded pipe 4, the lower end of the support table 2 is fixed with a leg 1, the lower end of the support leg 1 is fixed with a caster 12, and the support table 2 is set There is a propulsion mechanism 3, and the propulsion mechanism 3 includes a first hand wheel 3a, a bearing seat 3b, a slide rail 3c, a first screw mandrel 3d, a sliding support 3e, a support plate 3f and a support 11, and the bearing seat 3b is fixed on the support table 2. One end, the bracket 11 is fixed on the other end of the support table 2, one end of the first screw mandrel 3d is connected to the bracket 11 through the bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com