Full-automatic production equipment for brushes

A kind of production equipment and fully automatic technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of low efficiency, low work efficiency, low production cost, etc., to avoid waste of resources, improve production efficiency, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

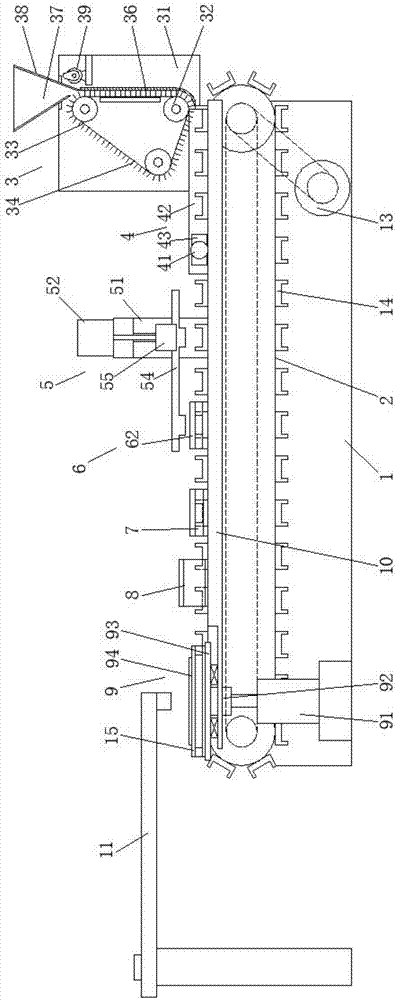

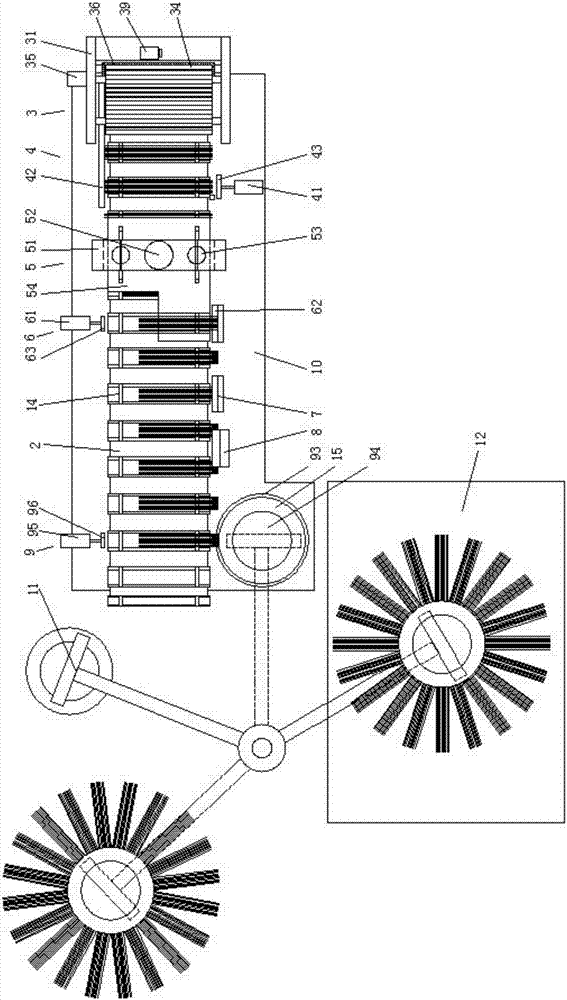

[0017] Referring to the accompanying drawings, a fully automatic brush production equipment includes a frame 1, a conveyor belt 2, a substrate 10, a manipulator 11, and a stamping and forming device 12. The conveyor belt 2 is arranged on the frame 1, and the conveyor belt 2 is driven by a chain. Plate conveyor structure, the base plate 10 is fixed on the frame 1, and its top surface is attached to the inner bottom surface of the upper part of the conveyor belt 2, the manipulator 11 is located outside the output end of the conveyor belt 2, and the stamping and forming equipment 12 is located on the frame 1 and the manipulator 11, the bottom of the frame 1 is provided with a drive motor 13, the drive motor 13 is connected to the input shaft of the conveyor belt 2 through a chain, and the outer surface of the conveyor belt 2 is fixedly connected with a number of equidistant fixed slots 14, The fixing groove 14 and the conveyor belt 2 are fixedly connected by screws, and the base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com