Method for manufacturing holographic mother board by using laser welding imposition

A laser welding and holographic technology, applied in the field of holography, can solve the problems of difficult cutting and splicing precision, large influence of human factors, long imposition cycle, etc., and achieve the effects of small thermal deformation, high cutting precision and high splicing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Example: Make large-size holographic master of cigarette carton hologram by laser welding imposition

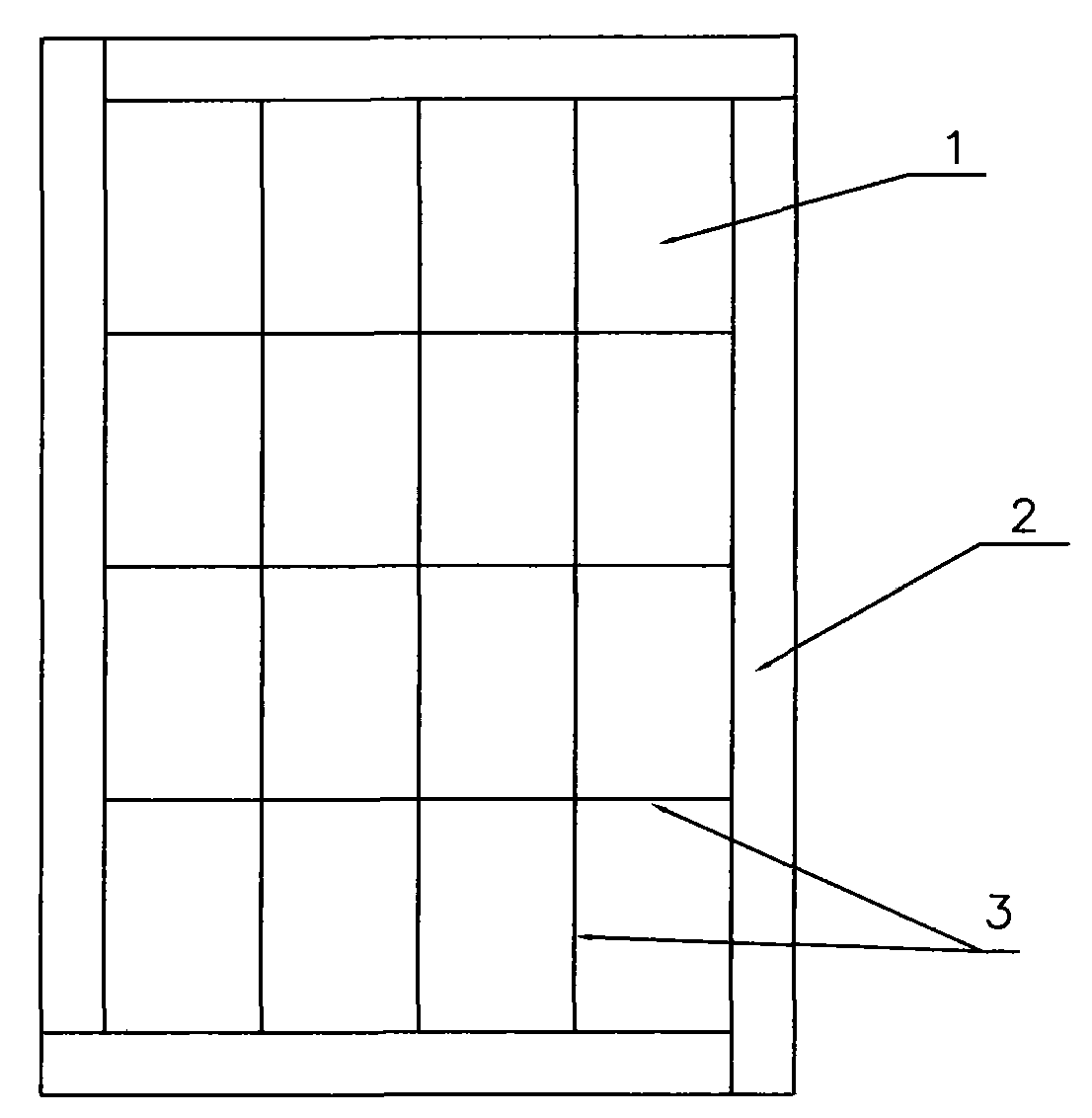

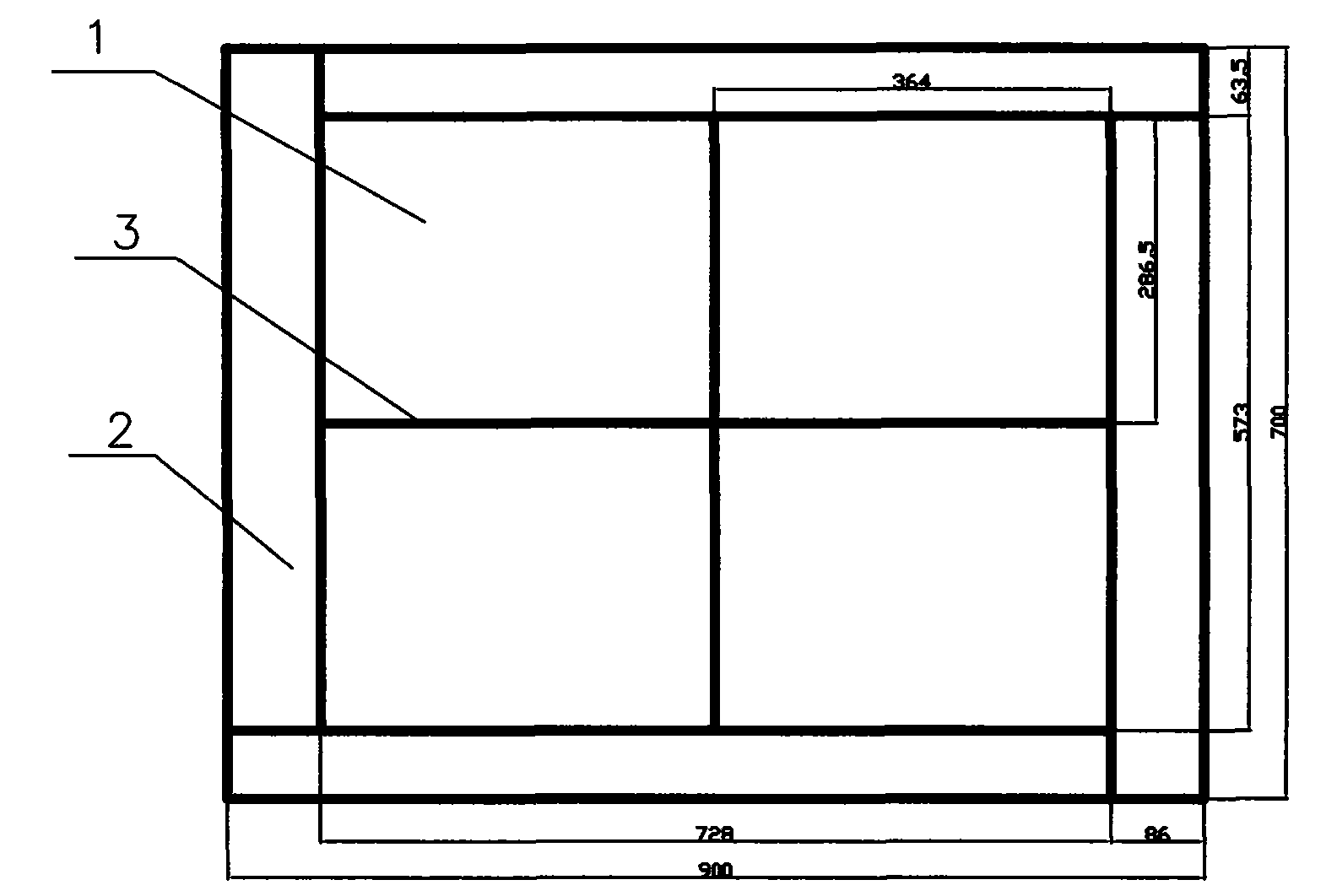

[0025] Task requirements: It is required that the effective molding area of the spliced master plate is 728×573mm, and the size of each unit hologram (i.e. cigarette carton) is 364×286.5mm, a total of 4 unit holograms, forming a 2×2 Matrix of unit holograms; after adding the frame, the master size is 900×700mm.

[0026] The manufacturing method is:

[0027] 1. Duplicate 4 pieces of holographic patterns (i.e. unit holographic patterns) of cigarette cartons by electroforming, that is, copy 4 nickel plates with holographic patterns of cigarette cartons, and the thickness of nickel plates can be selected about 80 microns (more The electroforming imposition is slightly thicker), but the thickness difference between the nickel plates should be controlled within ±5 microns (thickness and thickness error can be achieved by controlling the electroforming parameters);

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com