Mechanical welding seam tracking device

A tracking device and mechanical technology, applied in the field of weld seam tracking, can solve the problems of large deformation before welding, high manufacturing and maintenance costs, poor flexibility, etc., and achieve the effect of smooth welding, simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

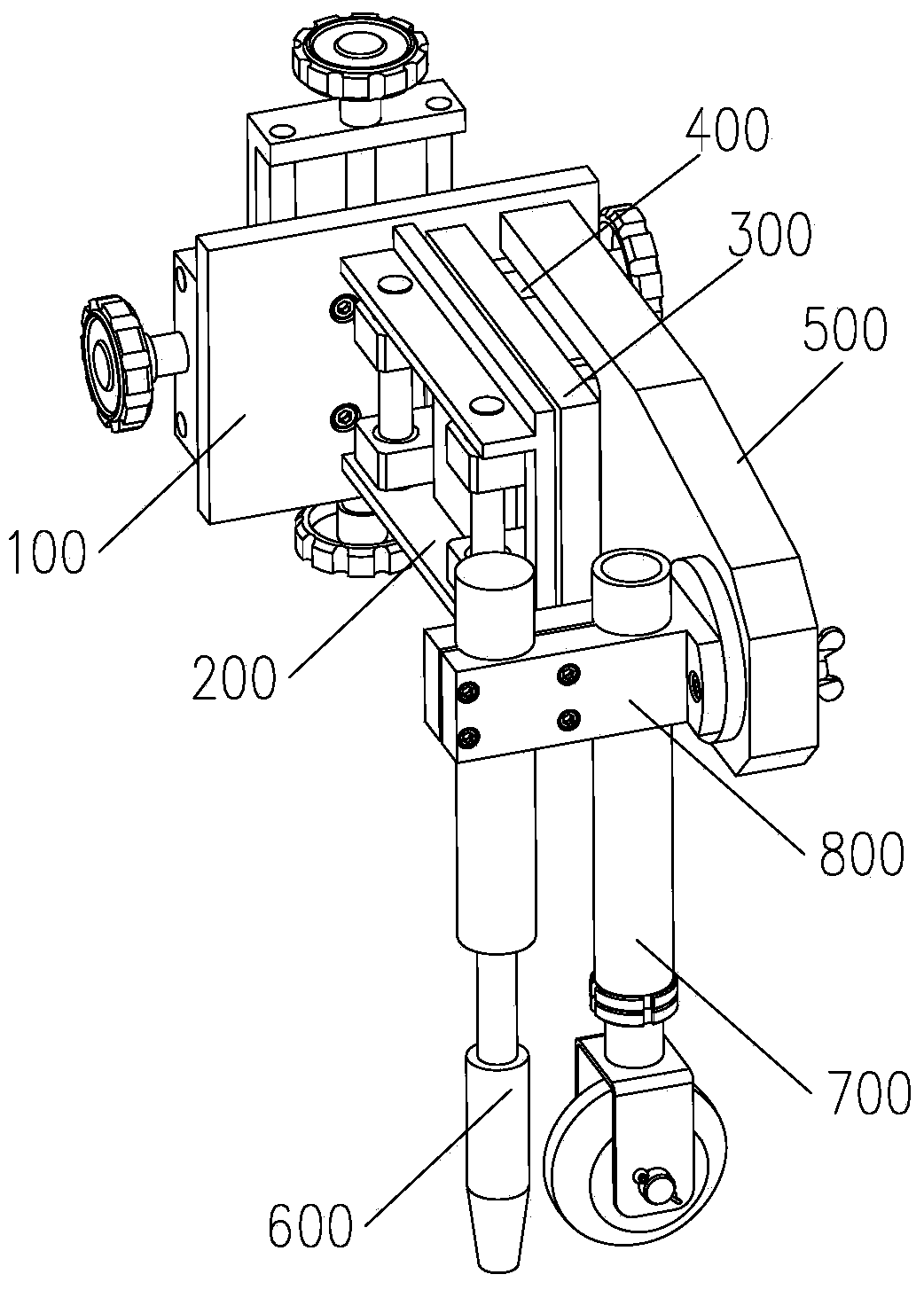

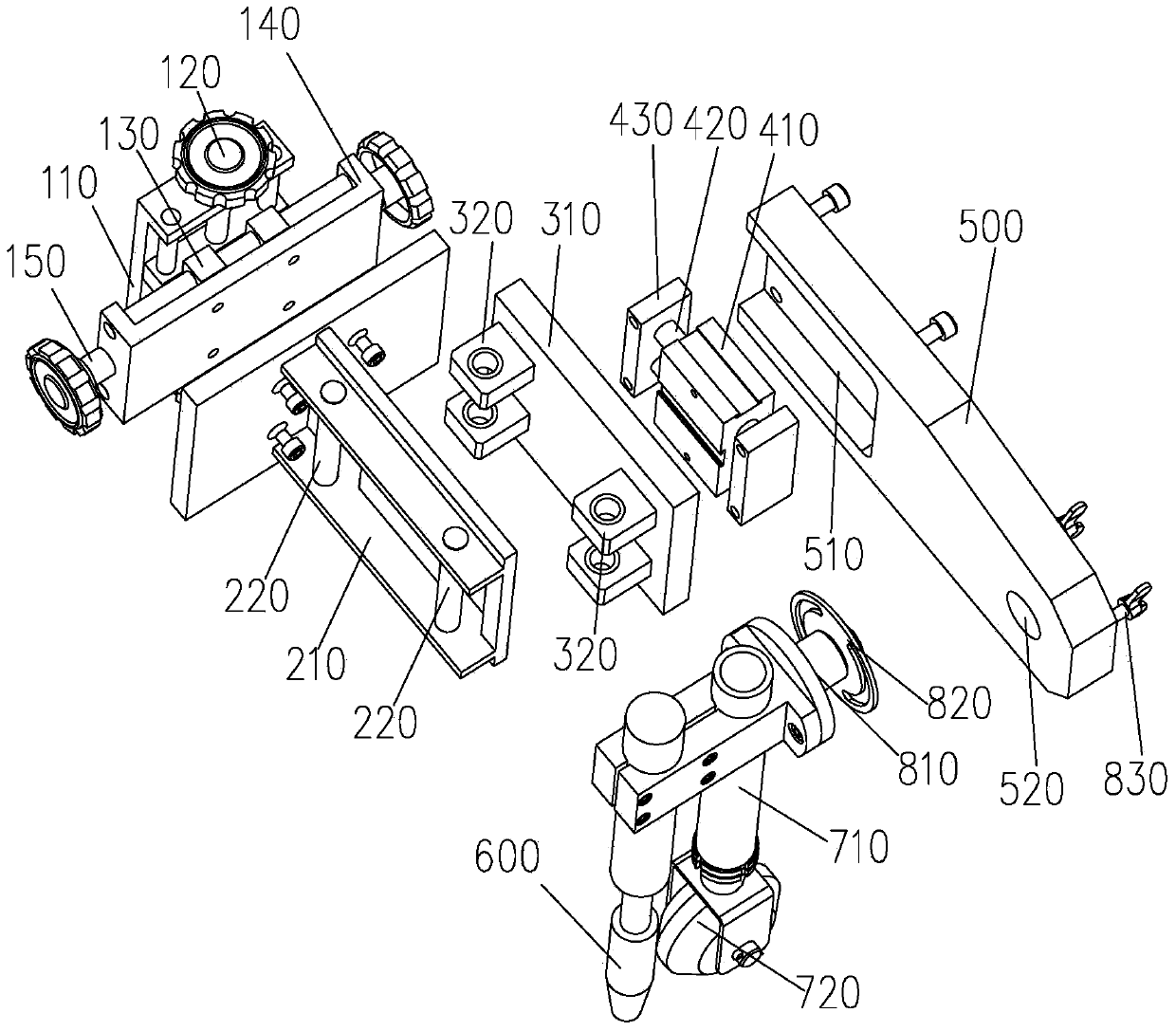

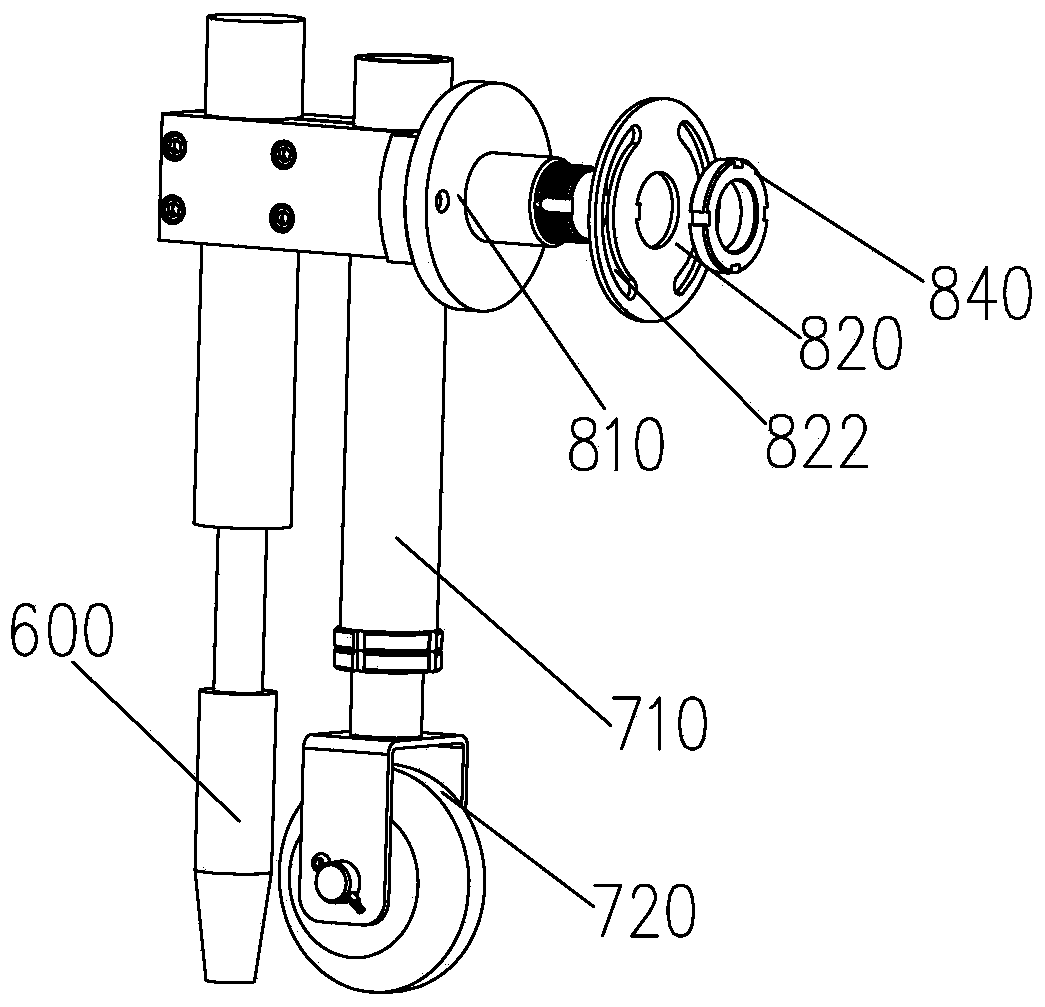

[0022] Such as figure 1 As shown, a mechanical seam tracking device includes a fine-tuning mechanism 100, a guide rod mechanism 200, a guide plate mechanism 300, a horizontal drive mechanism 400, a connecting plate 500, a welding torch 600, a tracking assembly 700, and a steering gear 800. The fine-tuning mechanism 100, the guide plate mechanism 300 is respectively connected with the guide rod mechanism 200, and the guide plate mechanism 300 can move up and down relative to the guide rod mechanism 200, the horizontal drive mechanism 400 is respectively connected with the connecting plate 500, the guide plate mechanism 300, the welding torch 600 and the tracking assembly 700 are installed on the diverter 800 respectively, and the diverter 800 is installed on the connecting plate 500 .

[0023] The mechanical seam tracking device described in this embodiment ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com