Ball valve with all-welded valve bodies and welding method of ball valve

An all-welding, valve body technology, applied in welding equipment, high-frequency current welding equipment, valve details, etc., can solve the problems of fast heating speed, unfavorable welding quality, shortening valve service life, etc. Control, avoid the effect of poor sealing performance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

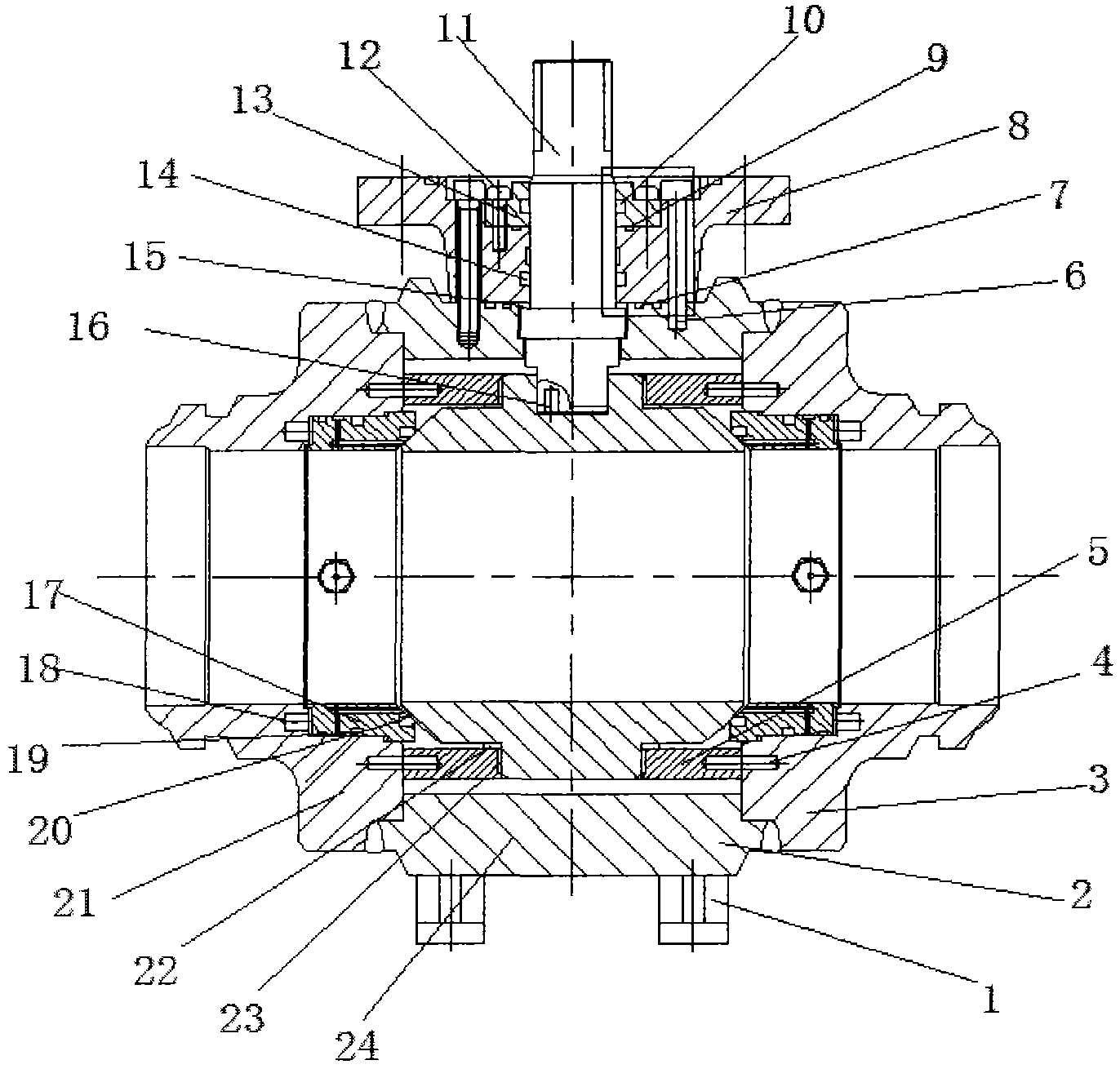

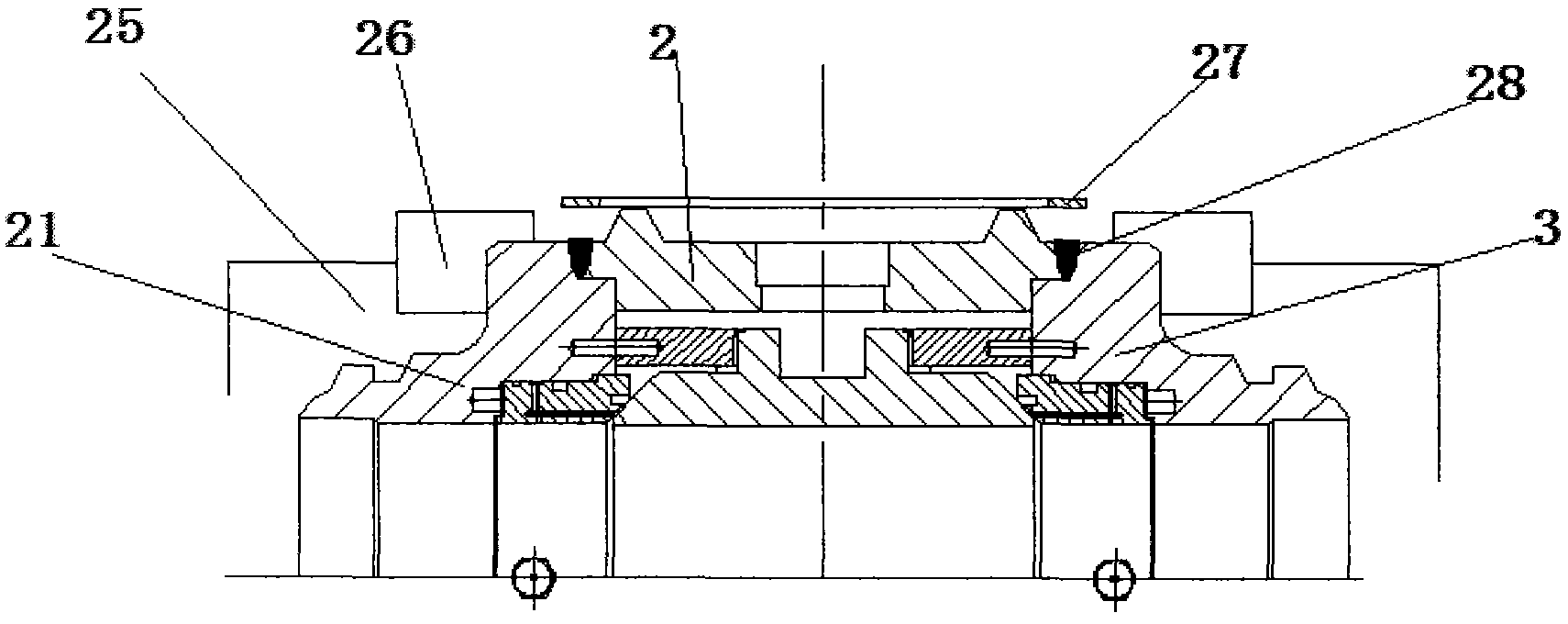

[0020] Such as figure 1 As shown, a ball valve with a fully welded valve body includes a tripod (1), a middle valve body (2), a right valve body (3), a cylindrical pin (4), a lining plate (5), a first inner hexagon Screw (6), first O-ring (7), connecting disc (8), second O-ring (9), third O-ring (10), valve stem (11), second inner Hex screw (12), gland (13), fourth O-ring (14), gasket (15), static spring (16), valve seat support ring (17), spring (18), fifth O Type sealing ring (19), valve seat (20), left valve body (21), thrust washer (22), sliding bearing (23), ball valve core (24); the tripod (1) is fixed by screw connection Below the middle valve body (2), the right valve body (3) and the left valve body (21) are respectively fixed on the left and right sides of the middle valve body (2) by welding, and the ball valve core (24) is fixed by the lining plate (5) And positioned in the spherical cavity formed inside the middle valve body (2), a thrust washer (22) and a slidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com