Automatic welding machine of gold sample tube

An automatic welding machine and sample tube technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of scrapped samples, no higher than 80%, high technical requirements for operators, etc., and the time to achieve welding is short , smooth weld seam, high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

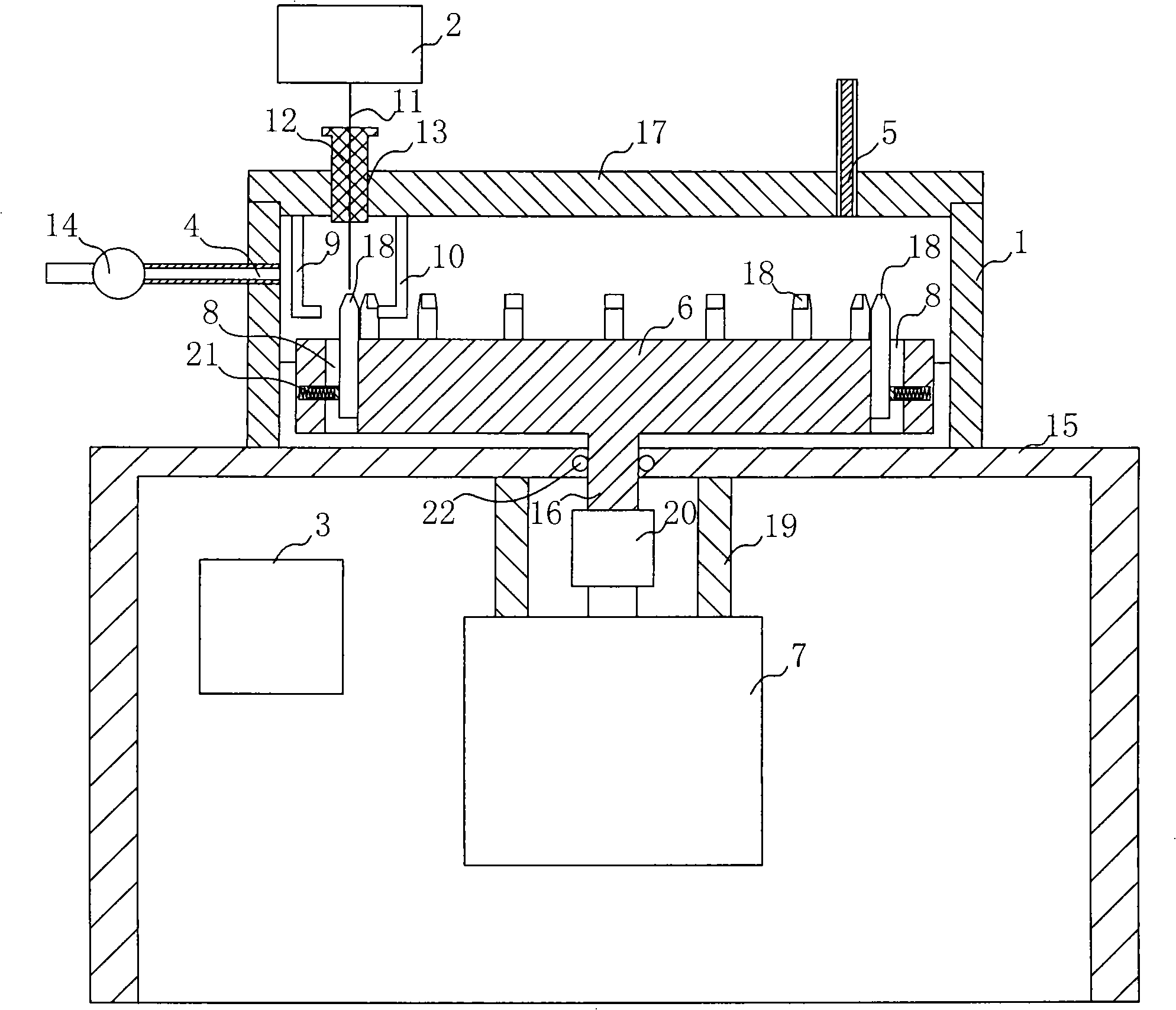

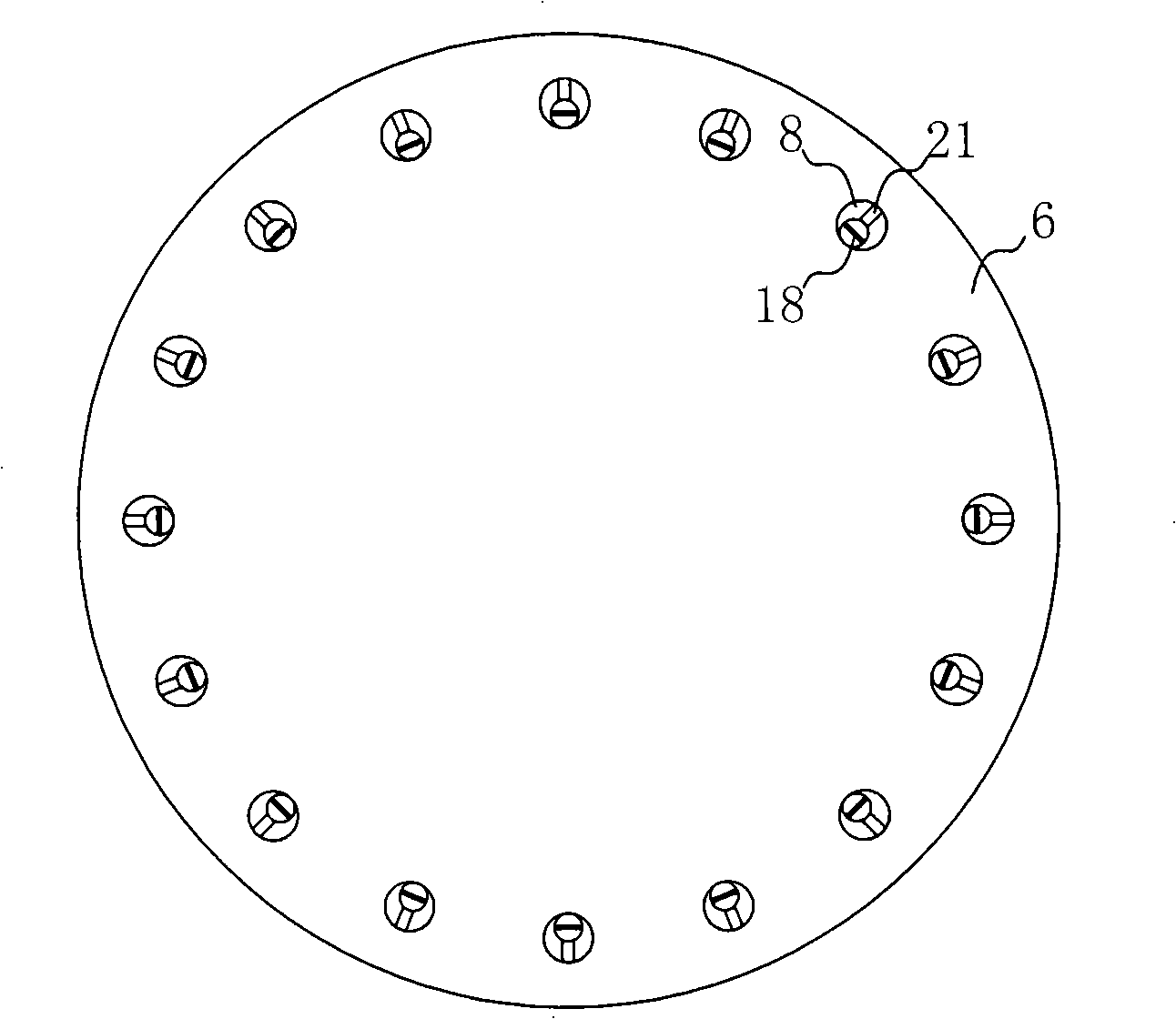

[0010] Such as figure 1 and figure 2 As shown, the gold sample tube automatic welding machine of the present invention includes an argon chamber 1 , an argon arc welding machine 2 , and a program controller 3 . The argon chamber 1 is provided with an air inlet 4 and an air outlet 5, the air inlet 4 is connected to an argon source, and the air outlet 5 is connected to the atmosphere. The argon chamber 1 is provided with a turntable 6, the turntable 6 is made of metal and is disc-shaped, the turntable 6 is connected with a drive motor 7, the drive motor 7 can be a geared motor, and the drive motor 7 can drive the turntable when it is working. 6 turn. Sixteen gold tube positioning holes 8 are provided on the top of the rotating disk 6, and the number can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com