Anti-magnetic shielding apparatus for repairing welding of electrolytic tank horizontal bus in strong magnetic field environment

A horizontal busbar and anti-magnetic shielding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as large transportation costs, labor costs for building workshops, prolonged busbar welding and repair periods, and large electrolytic tanks. , to avoid the increase of current density, improve the shielding of magnetic field waves, and reduce the investment of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

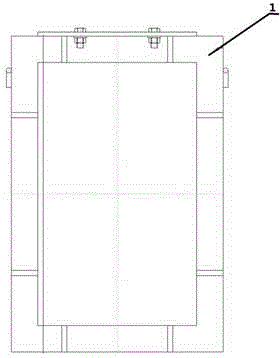

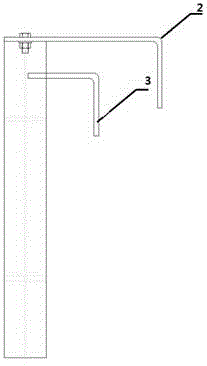

[0019] An anti-magnetic shielding device for repairing and welding the horizontal busbar of an electrolytic cell in a strong magnetic field environment, such as figure 1 and 2 As shown: the device includes a complete and continuous shielding magnetic shield 1 that is made of good magnetic permeability materials and is matched with the welding part and the welding machine. A detachable current guide is equipped at the rear end of each shielding magnetic shield 1. plate 2.

[0020] On both sides of the shielding magnetic shield 1, there are hooks 3 connected to the welding parts.

[0021] The shielding magnetic shield 1 is double-layered, and its material is electrical silicon steel or high carbon steel plate.

[0022] When in use, install a shielding magnetic shield on the surface to be welded, and at the same time seal the welder with a shield, adjust the welding parameters of the TRA-500 welding machine to one-way control, adjust the arc ending current to about 400A, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com