High-frequency high-voltage transformer structure

A high-frequency, high-voltage, transformer technology, applied in the direction of fixed transformer or mutual inductance, transformer/inductor core, transformer/inductor coil/winding/connection, etc. Distributed capacitance, the effect of reducing the voltage between slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

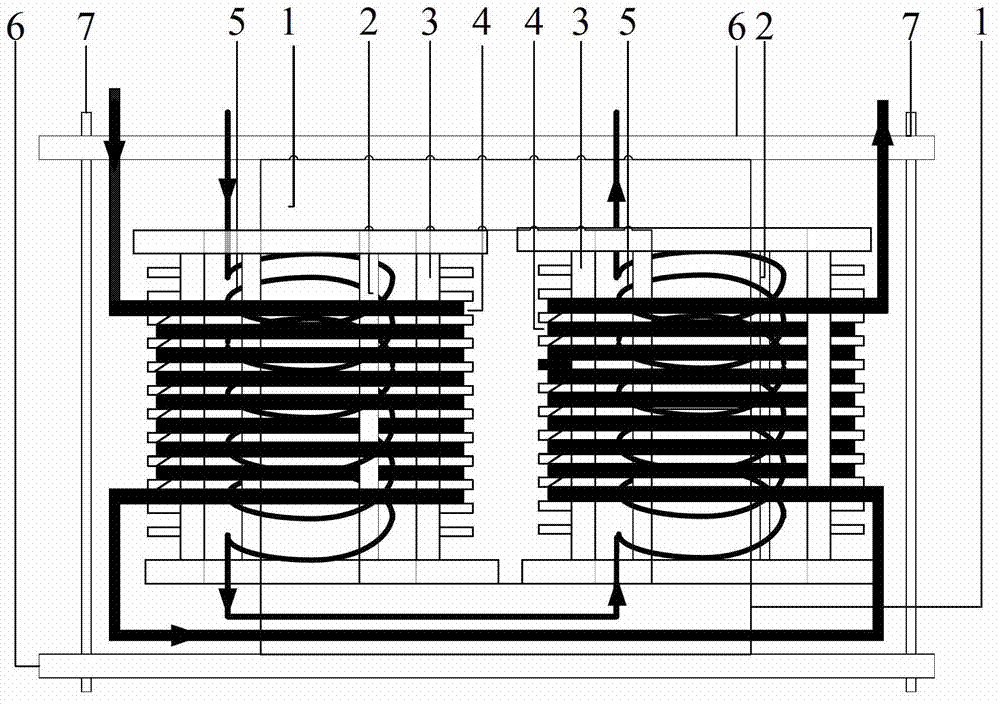

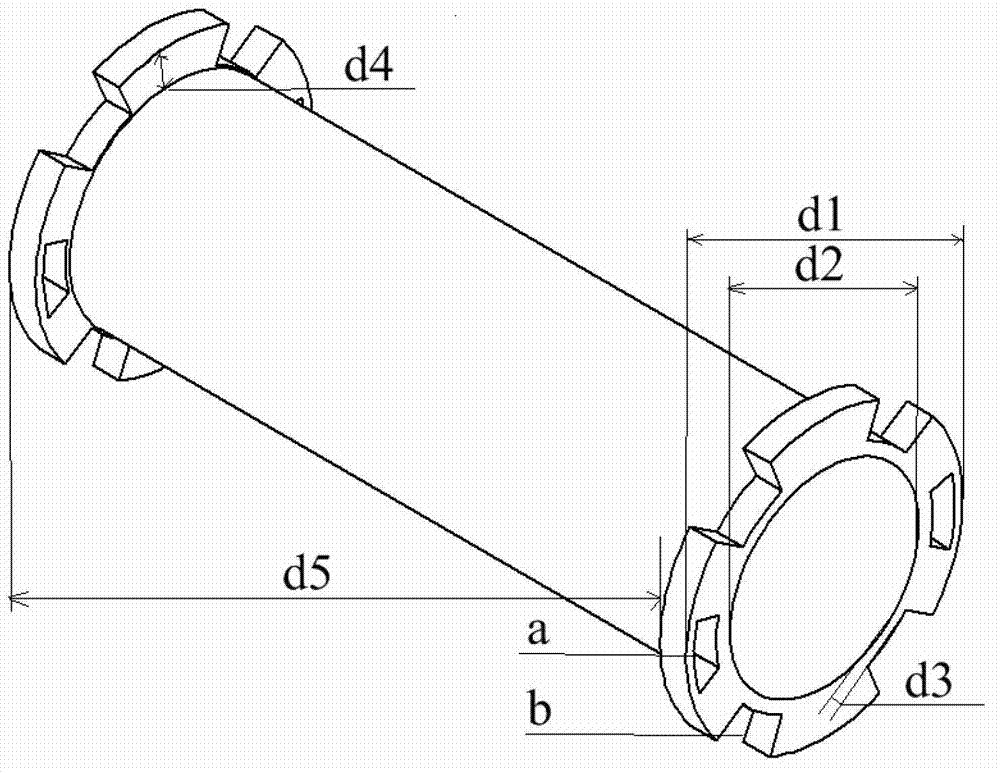

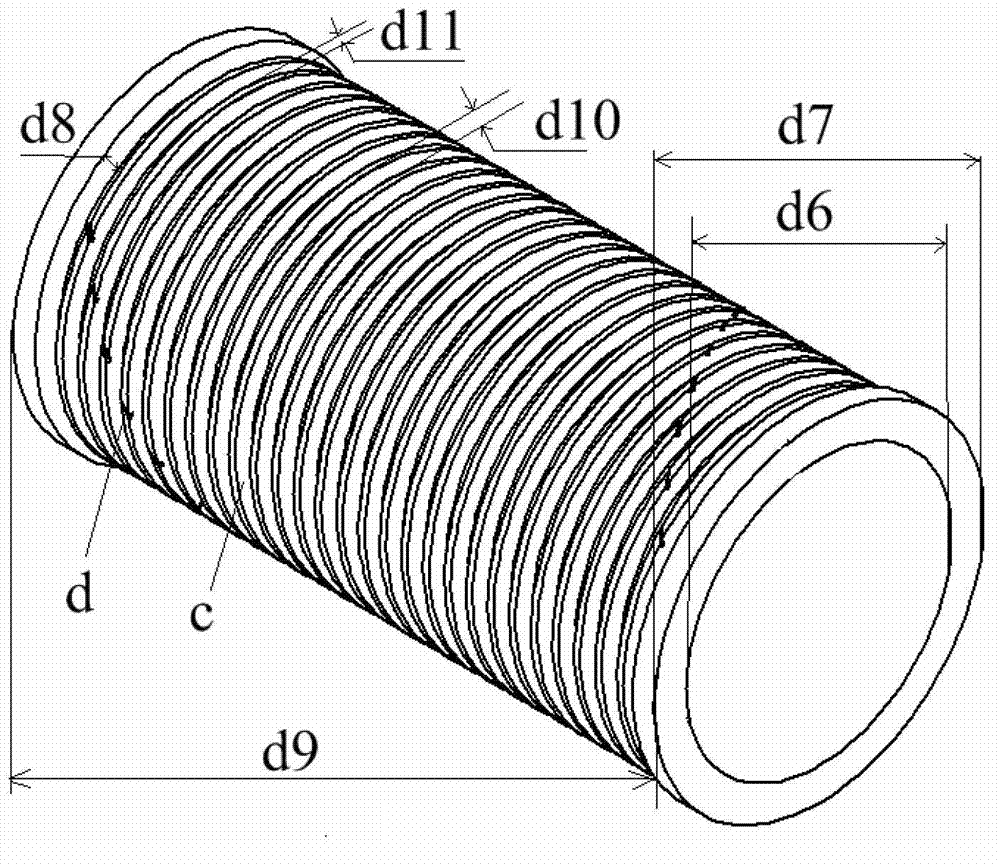

[0015] like figure 1 As shown, the present invention includes two transformer U-shaped magnetic cores 1, two transformer secondary winding bobbins 2, two transformer primary winding bobbins 3, two transformer secondary windings 4, two transformer primary windings 5, and A set of transformer fastening fixtures consists of six components. The transformer core adopts two U-shaped cores that can be connected. The material of the U-shaped core depends on the operating frequency of the designed transformer. Usually, high-frequency transformers can choose ferrite cores, amorphous cores or nanocrystalline cores. Class magnetic core. The purpose of using two U-shaped magnetic cores that can be connected is to easily remove and replace the primary and secondary windings; the primary and secondary winding frames of the transformer are made of insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com