Low-noise high efficiency power supply apparatus

A power supply device, high-efficiency technology, applied in the direction of output power conversion device, electrical components, adjustment of electrical variables, etc., can solve the problems of increasing parasitic capacitance, increasing noise coupling, etc., to reduce parasitic capacitance, reduce common mode noise, The effect of reducing common mode current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

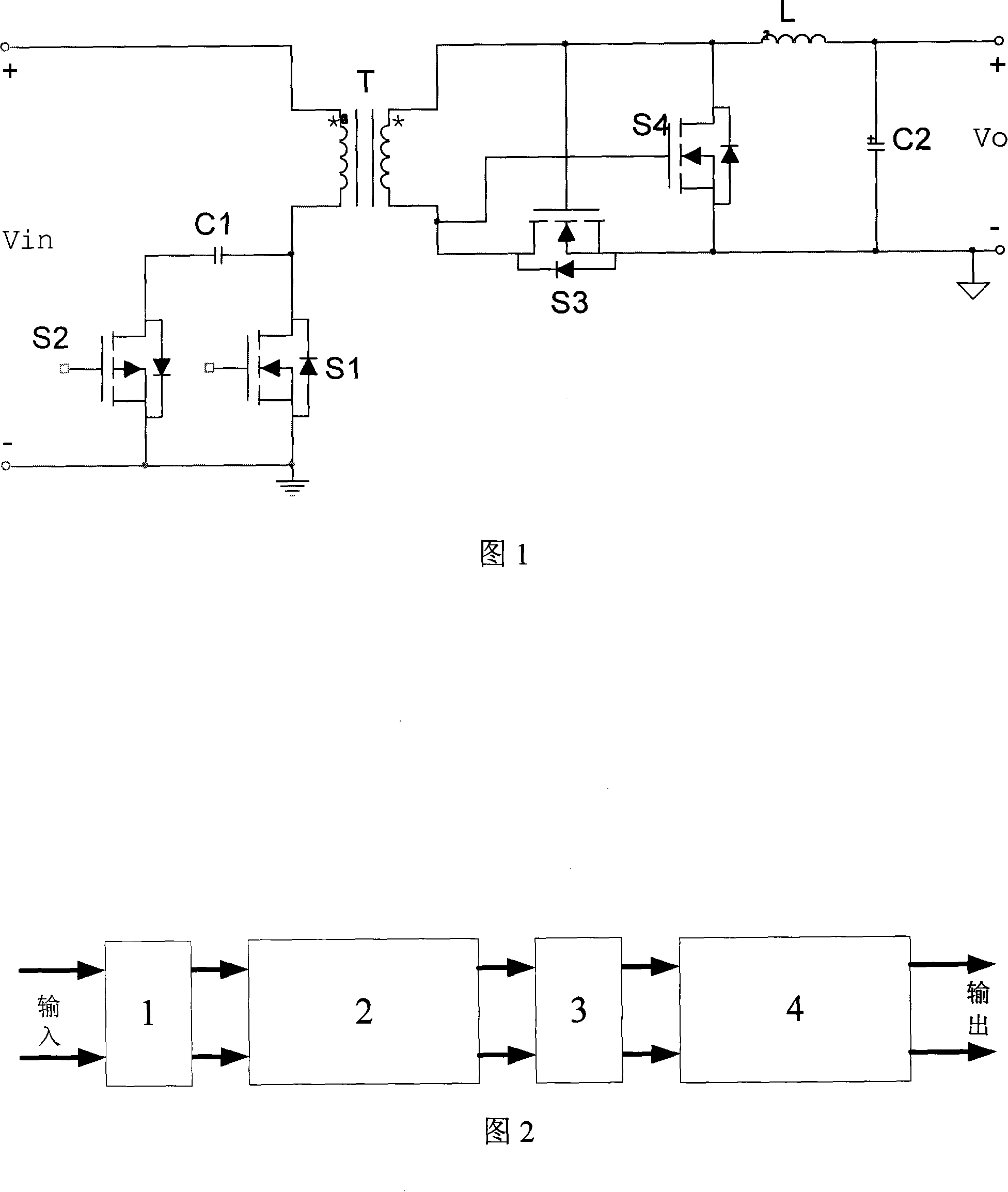

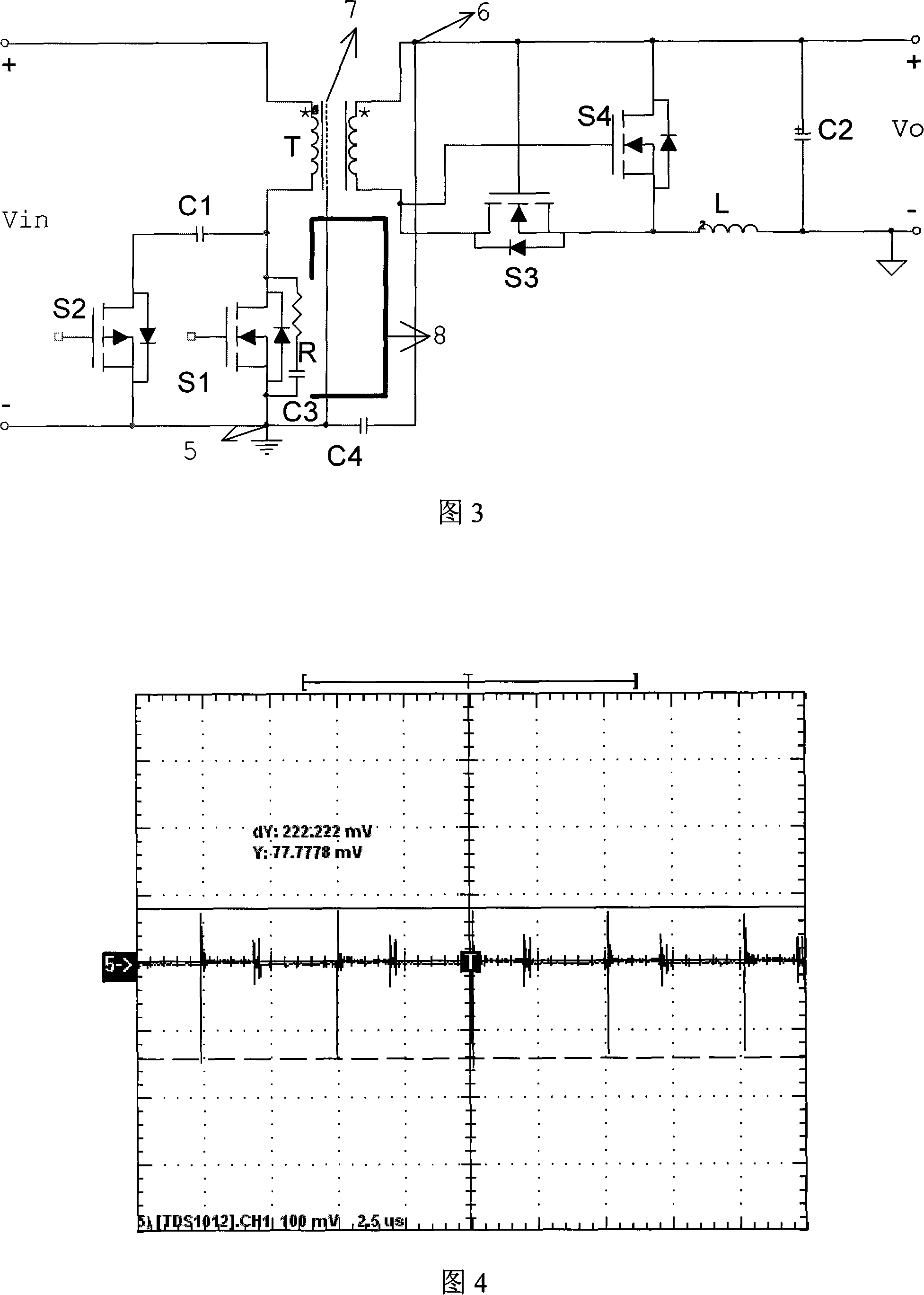

[0024] Referring to Fig. 2, a low-noise and high-efficiency power supply device includes an input common-mode filter 1, an active-clamp forward converter 2 with a self-driven synchronous rectification function, an output common-mode filter 3 and a low-dropout linear converter 4 , the input terminal of the active clamp forward converter 2 is connected to the input common-mode filter 1, the output terminal of the active clamp forward converter 2 is connected to the output common-mode filter 3, and the output terminal of the output common-mode filter 3 Connect the low dropout linear converter 4.

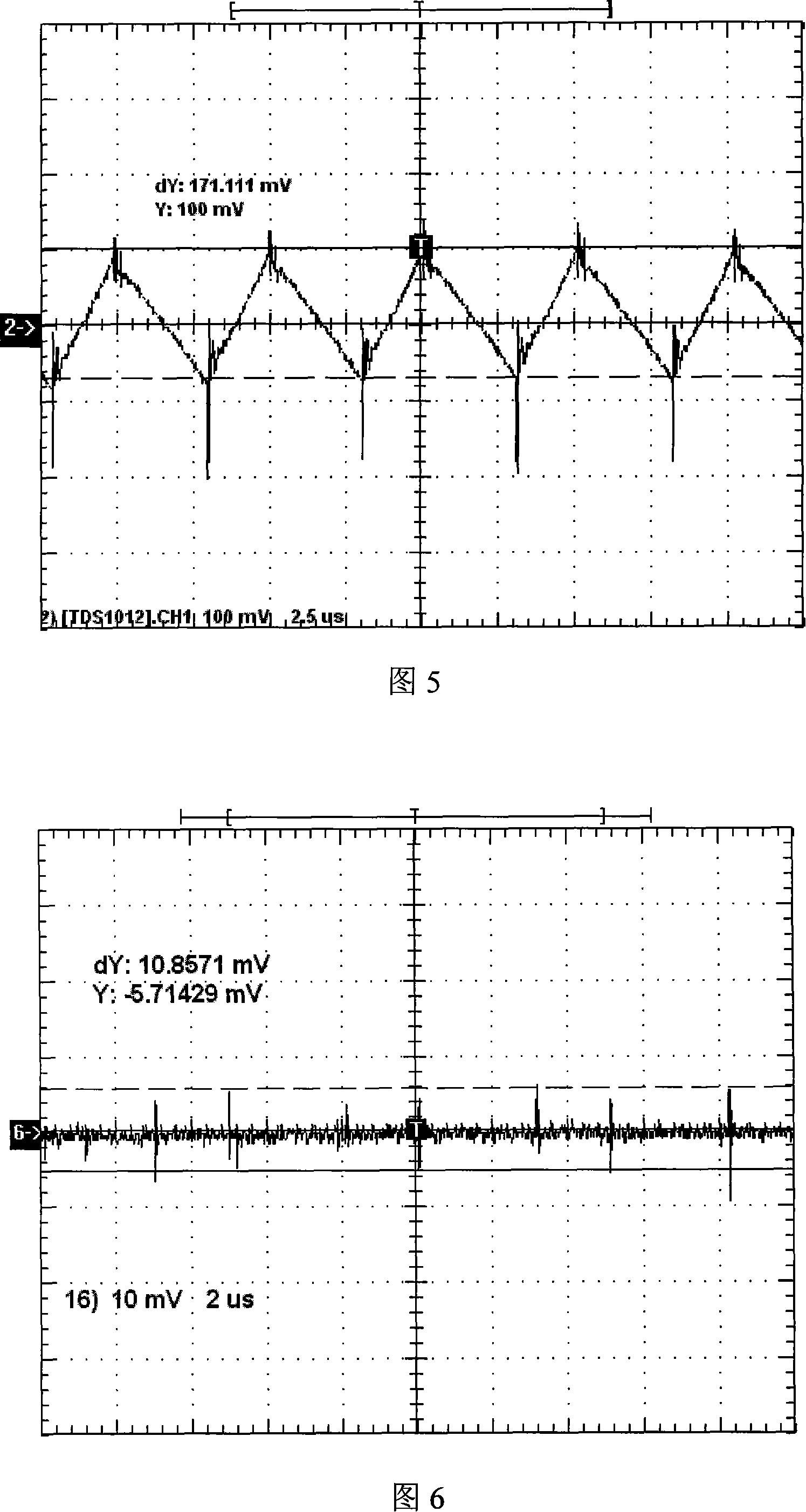

[0025] The input voltage first passes through the input common-mode filter 1 to filter the common-mode noise, and then passes through the active clamp forward converter 2 with self-driven synchronous rectification function to convert the input voltage to a voltage slightly higher than the required voltage It is sent to the output common-mode filter 3, which reduces the output common-mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com