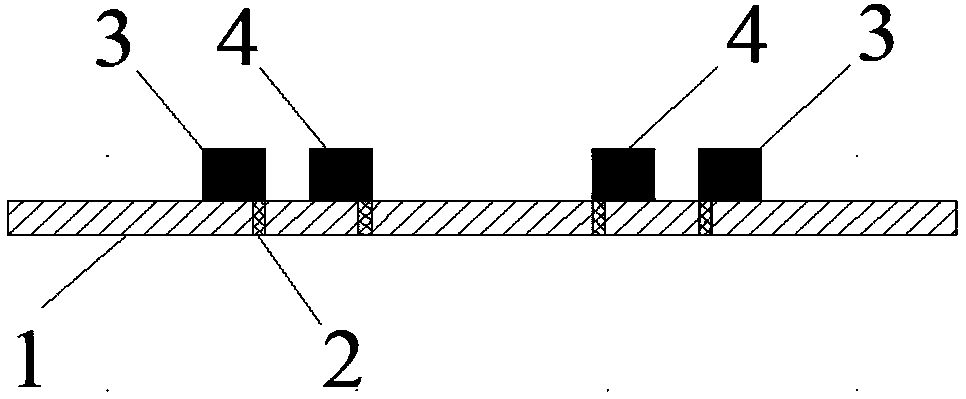

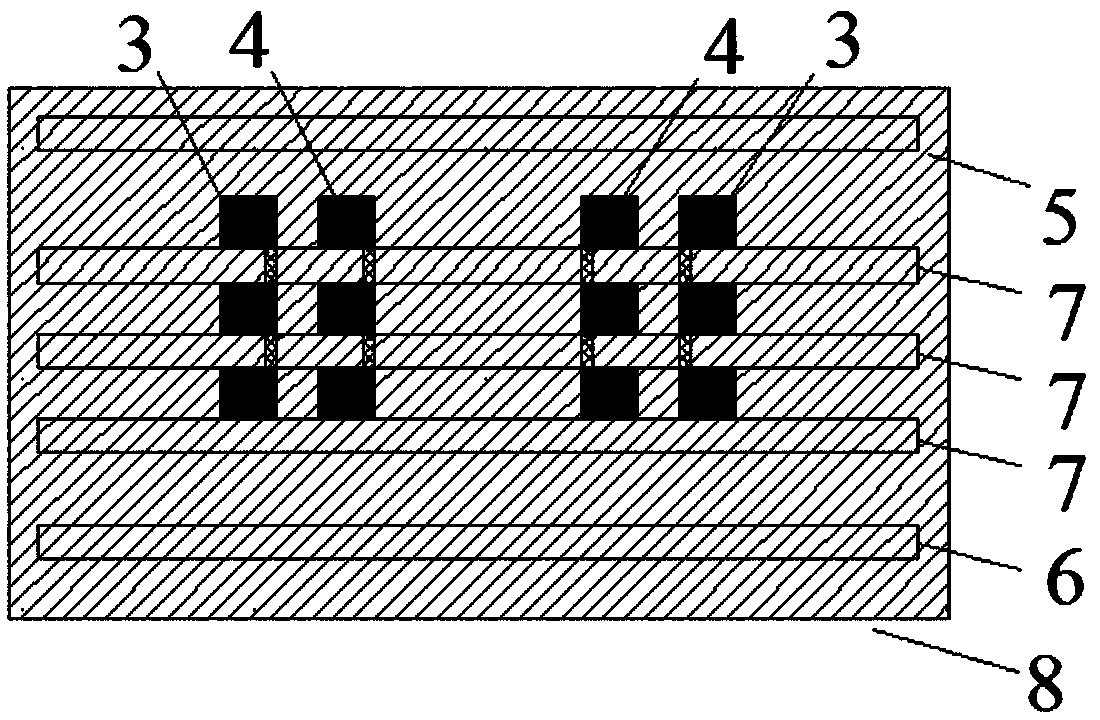

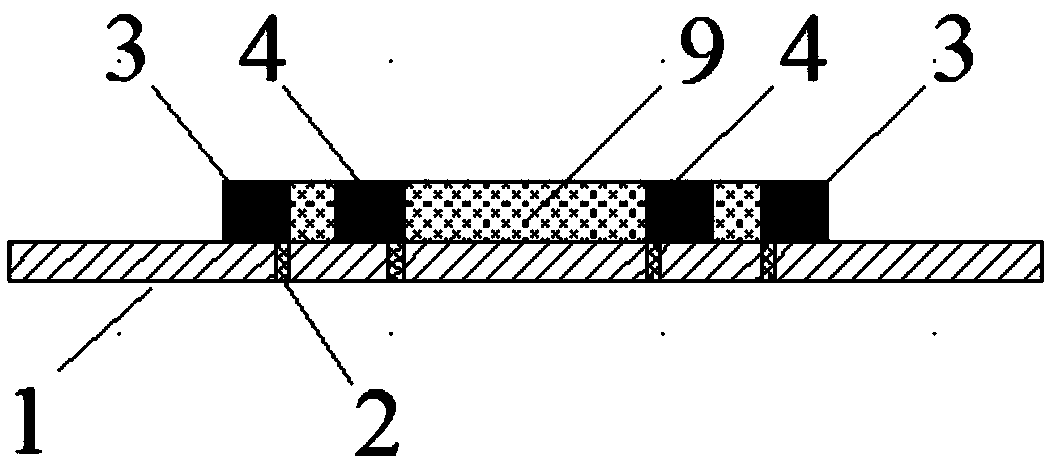

LTCC-based planar transformer and manufacturing method thereof

A technology for planar transformers and manufacturing methods, applied in transformers, inductance/transformer/magnet manufacturing, fixed transformers, etc., can solve the problems of limiting the performance development of planar transformers, low coupling coefficient, and inefficient flux linkage, etc., and achieve magnetic permeability improvement , high coupling coefficient, and the effect of reducing magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0052] The following is an example of the LTCC planar transformer prepared by combining two LTCC materials, HP30 (permeability 30) and GTN4 (permeability 200), printed and filled by the company, and a single permeability material (HP30) LTCC planar transformer. , further verify the implementation method and conclusion of the present invention by more specific examples.

[0053] The single-permeability material LTCC planar transformer and the LTCC planar transformer of the embodiment of the present invention were respectively prepared through the above process flow, and their electrical properties were tested and compared. Its inductance and leakage inductance parameters are shown in the table below:

[0054]

[0055] It can be seen from the table that the filling of high magnetic permeability materials increases the inductance of the planar transformer by 10%-15%, and the leakage inductance is significantly improved by about 20%. Under the same inductance requirement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com