Patents

Literature

82results about How to "Increase leakage inductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

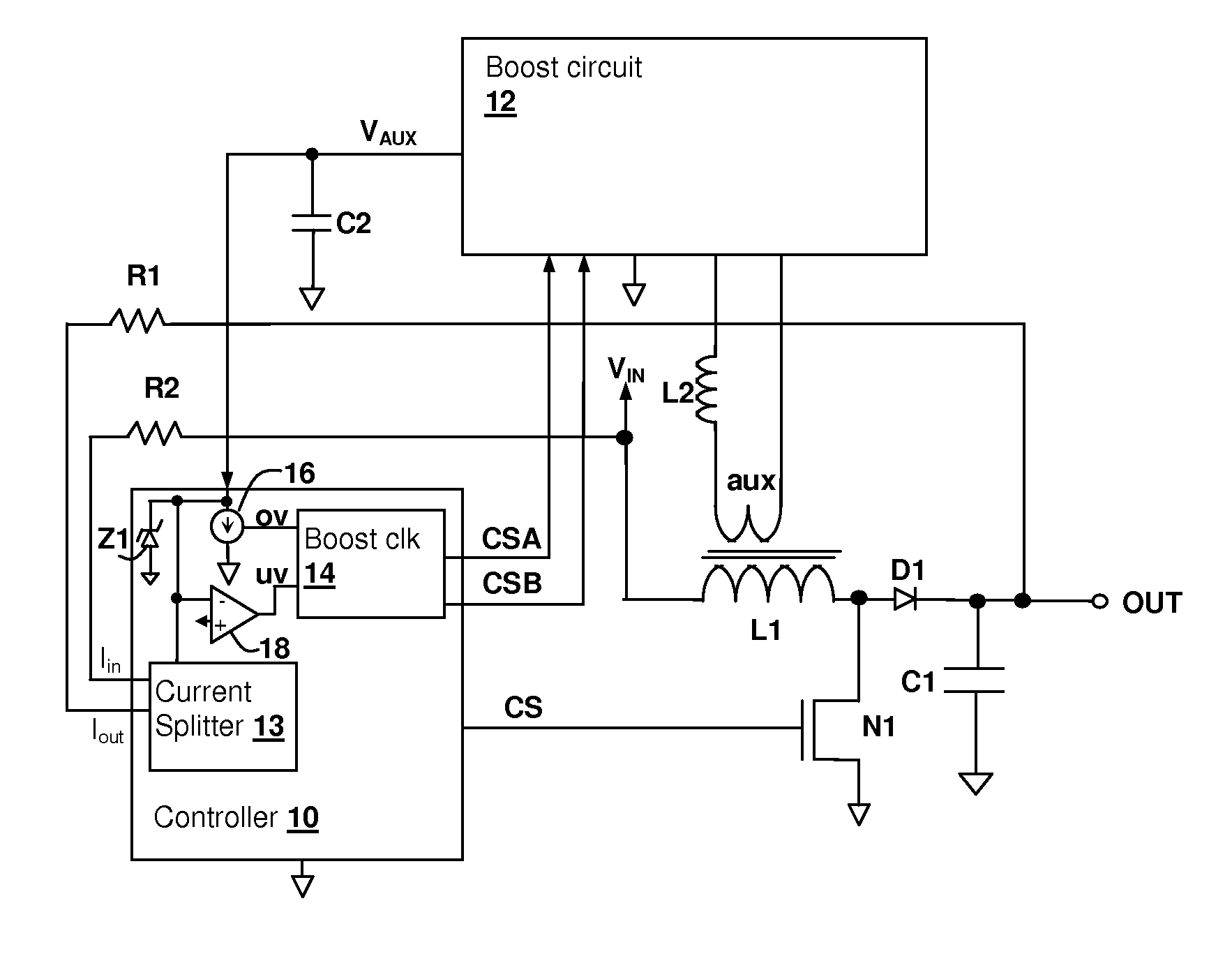

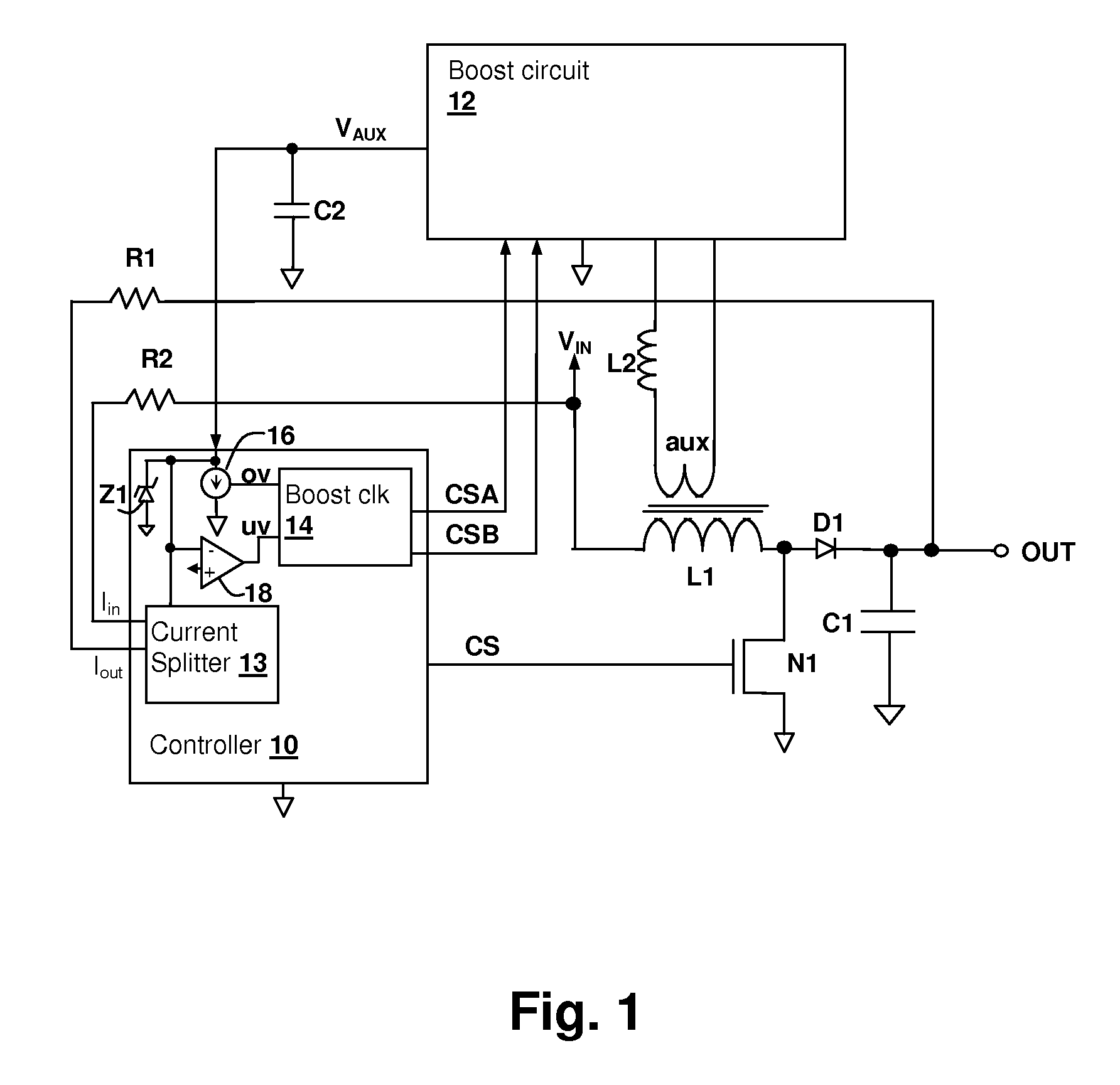

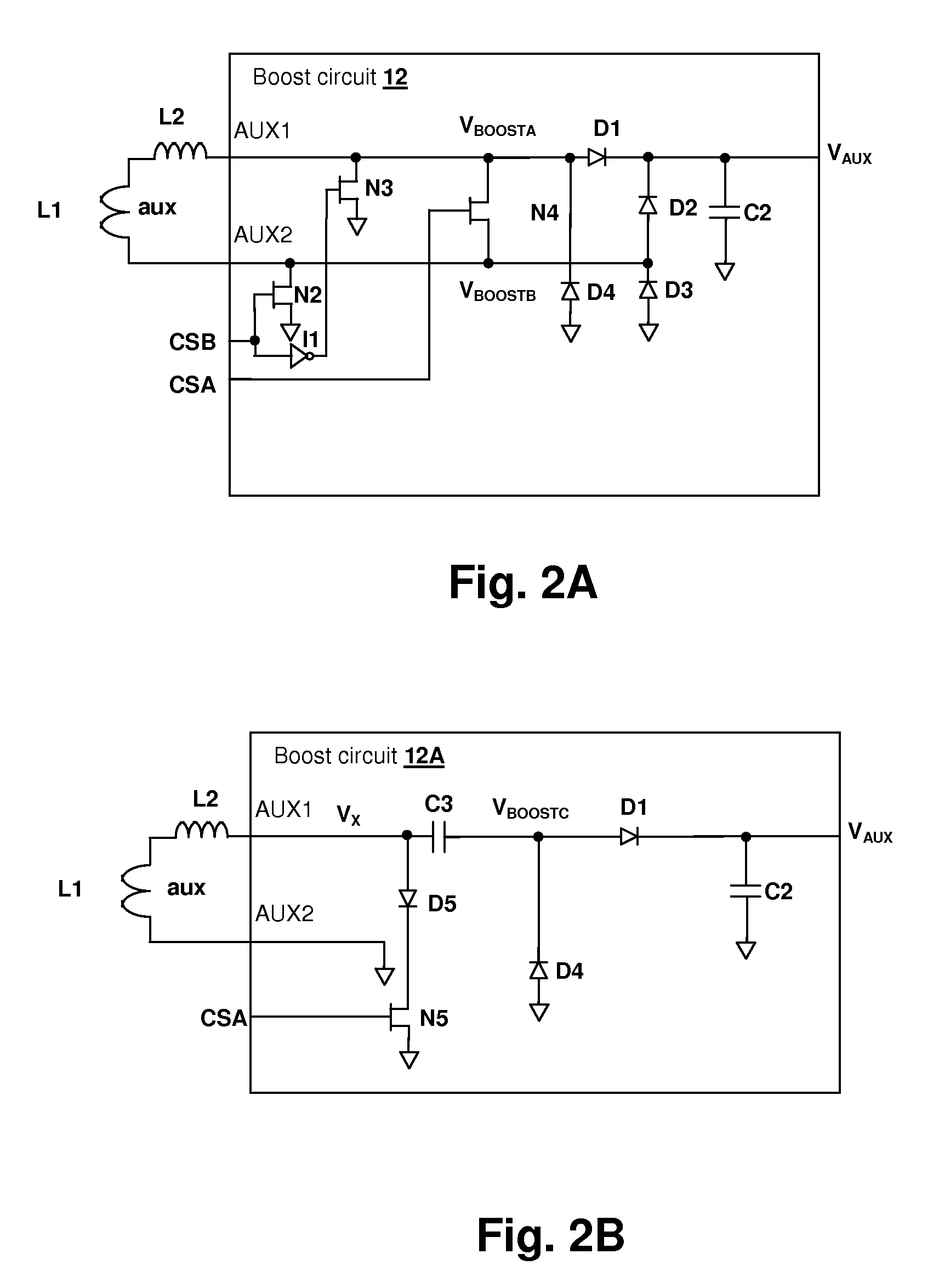

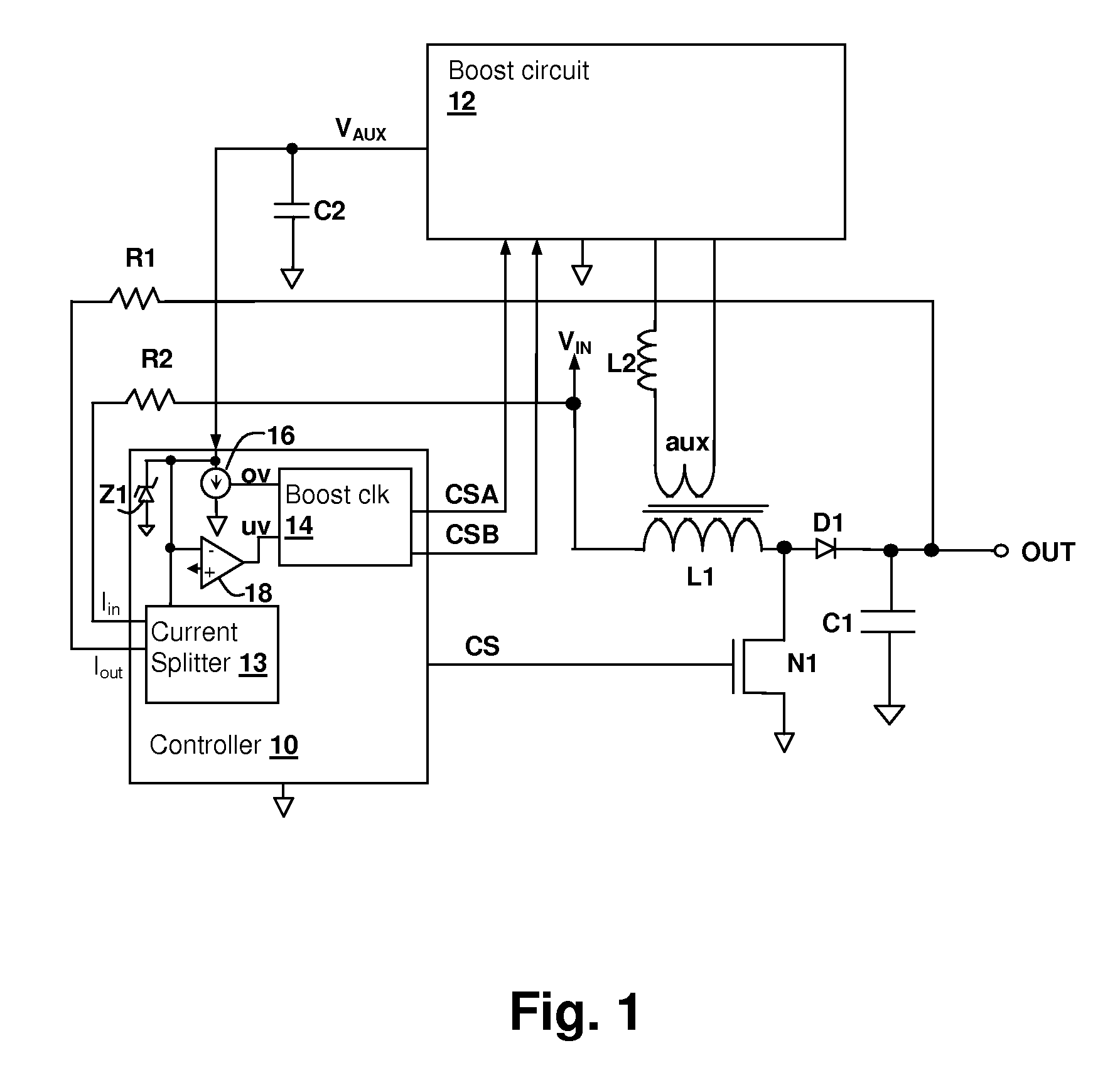

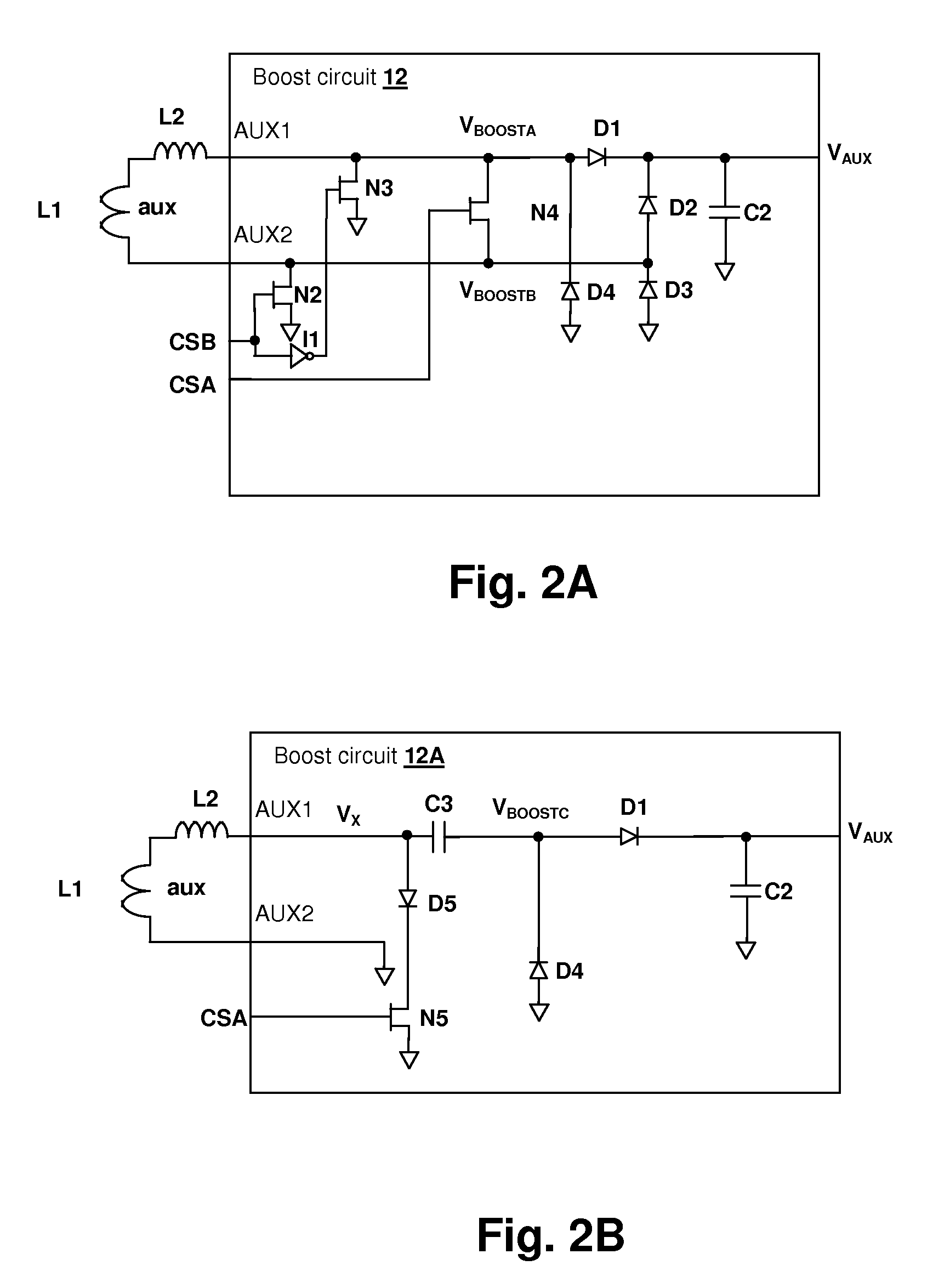

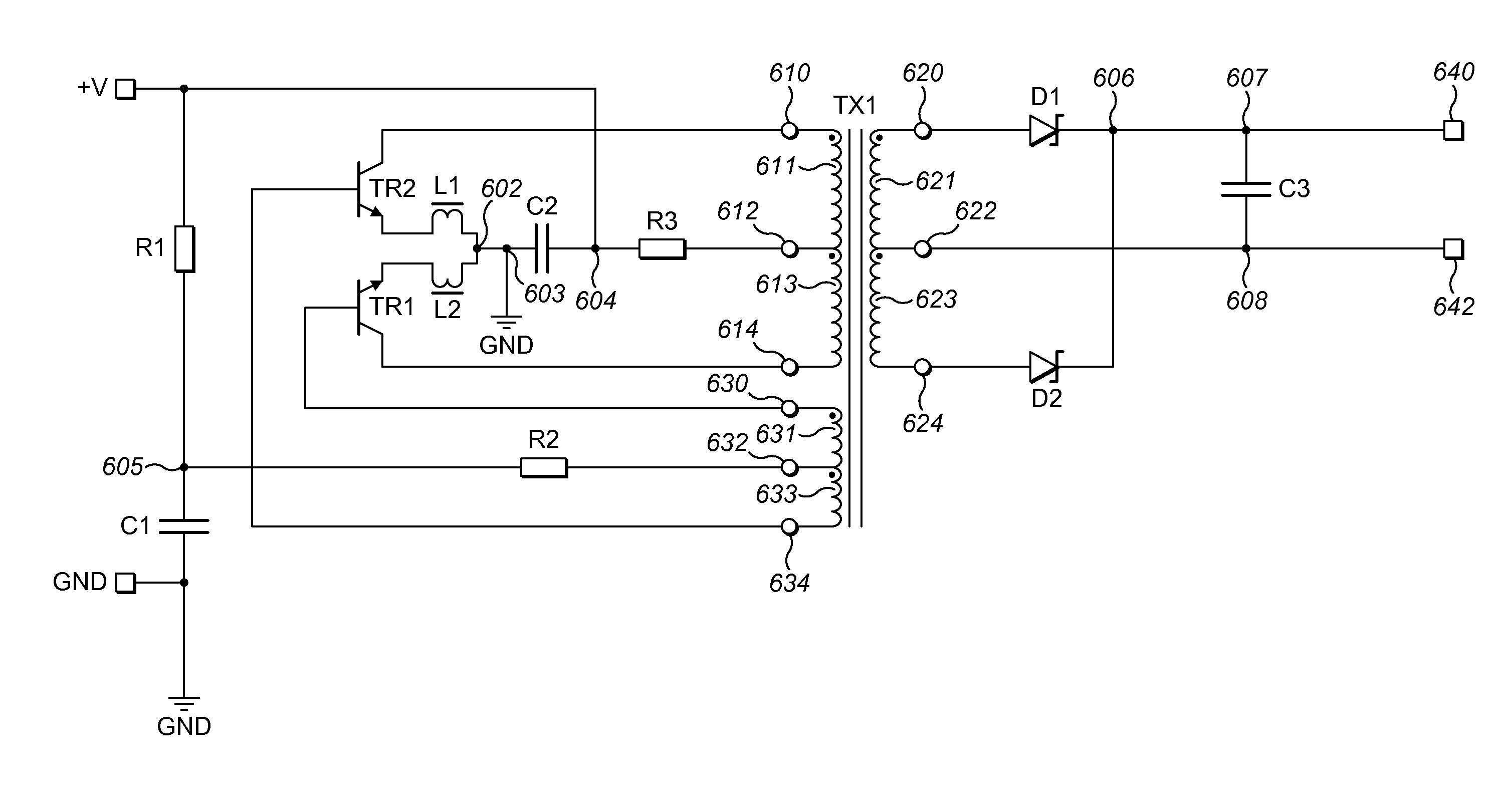

Switching regulator with boosted auxiliary winding supply

InactiveUS20090190379A1Increase leakage inductanceDc-dc conversionPower supply linesTransverterElectrical polarity

A boosted auxiliary winding power supply for a switched-power converter circuit provides operating voltage for control and other circuits early in the start-up phase of converter operation. A boost circuit has an input coupled to the auxiliary winding to boost the voltage available from the auxiliary winding at least during start-up of the switched-power converter. The boost thereby provides a voltage that is greater than the voltage across the auxiliary winding during start-up of the switched-power converter. The boost circuit may be actively switched at a rate higher than a switching rate of the switched-power converter, to increase a rate of rise of the operating voltage. Polarity information, which may be provided from the switched-power converter control circuit, can be used to actively rectify the output of the auxiliary winding.

Owner:CIRRUS LOGIC INC

Switching regulator with boosted auxiliary winding supply

InactiveUS8008898B2Increase leakage inductanceDc-dc conversionPower supply linesElectrical polarityEngineering

A boosted auxiliary winding power supply for a switched-power converter circuit provides operating voltage for control and other circuits early in the start-up phase of converter operation. A boost circuit has an input coupled to the auxiliary winding to boost the voltage available from the auxiliary winding at least during start-up of the switched-power converter. The boost thereby provides a voltage that is greater than the voltage across the auxiliary winding during start-up of the switched-power converter. The boost circuit may be actively switched at a rate higher than a switching rate of the switched-power converter, to increase a rate of rise of the operating voltage. Polarity information, which may be provided from the switched-power converter control circuit, can be used to actively rectify the output of the auxiliary winding.

Owner:CIRRUS LOGIC INC

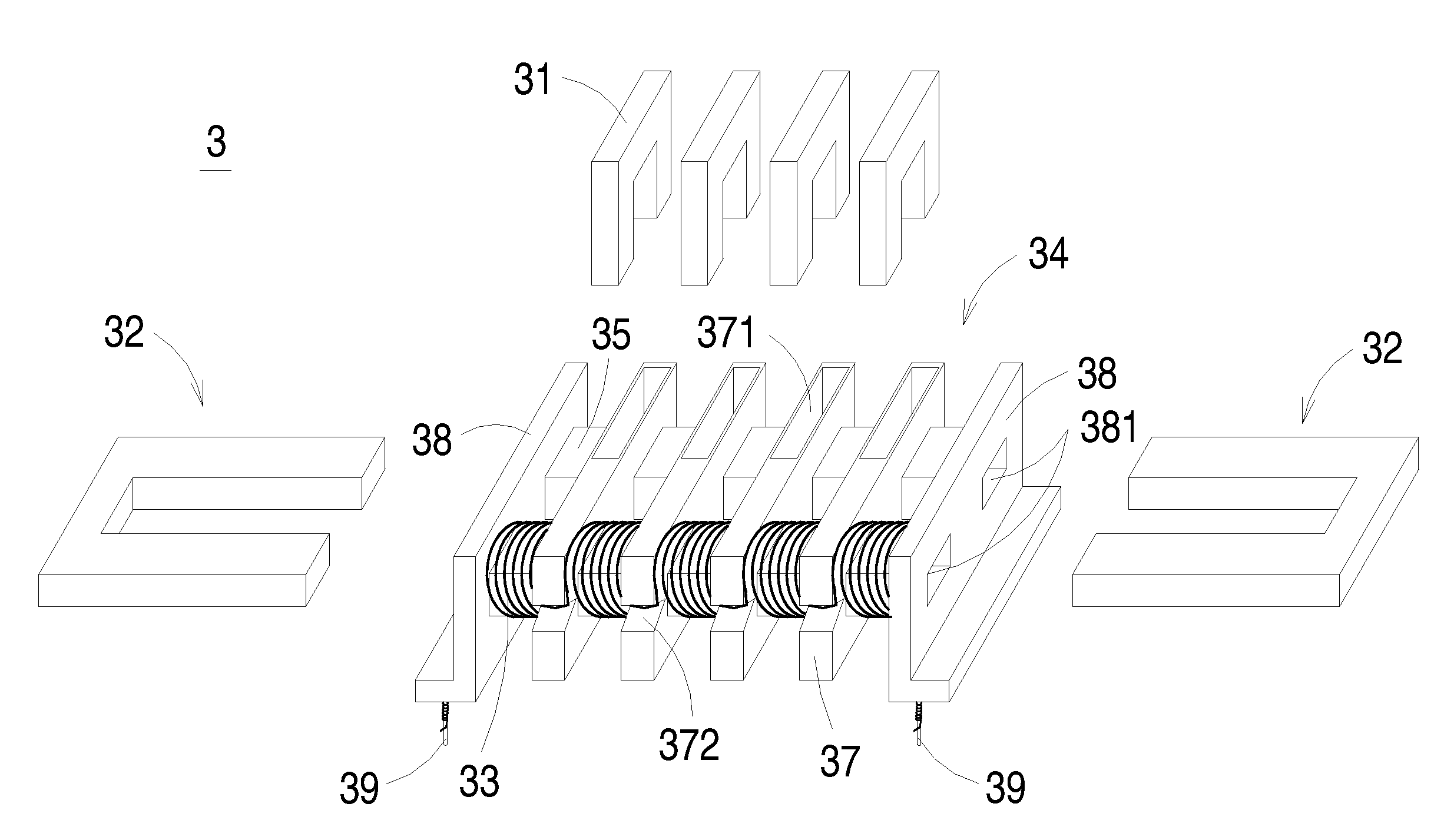

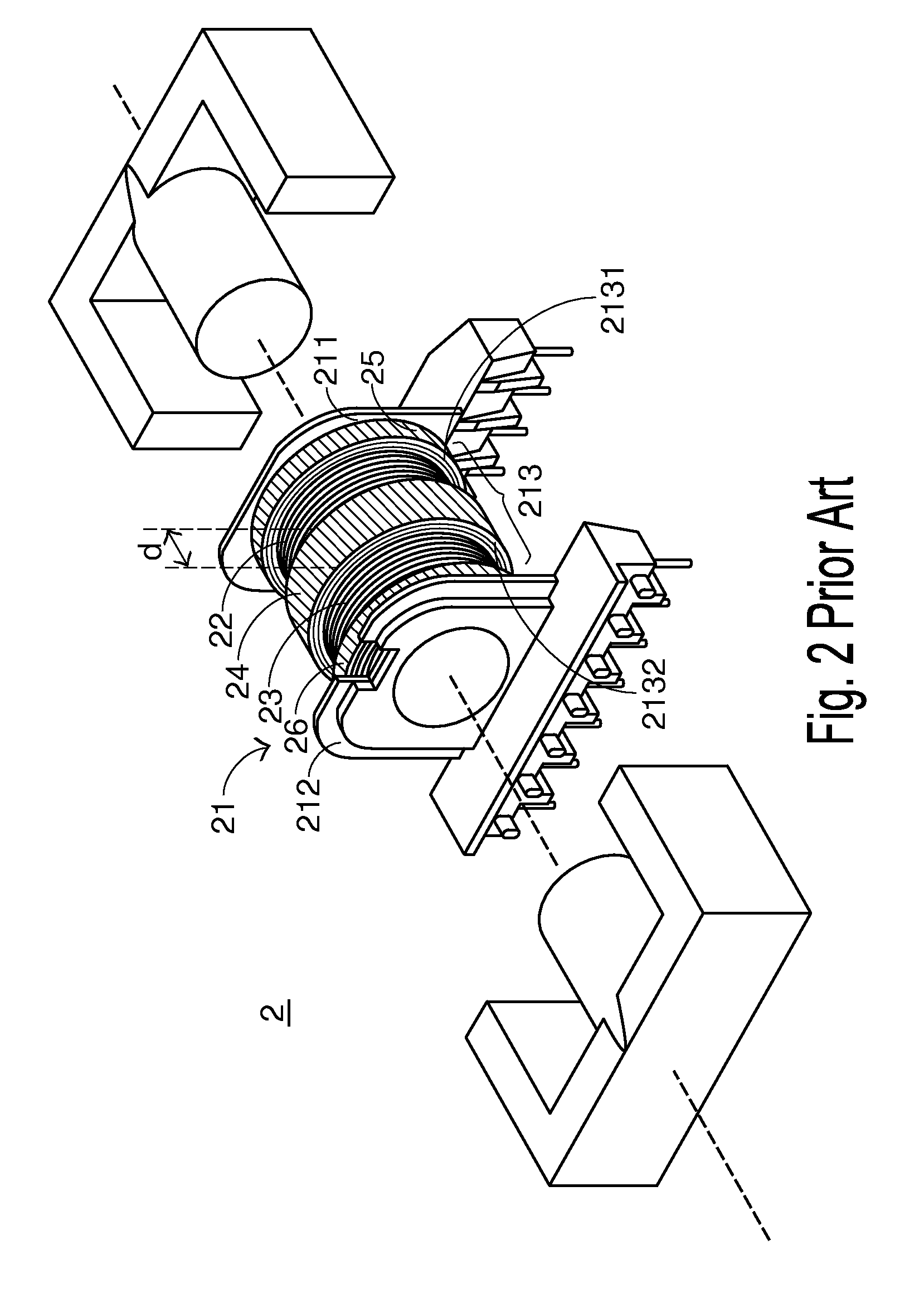

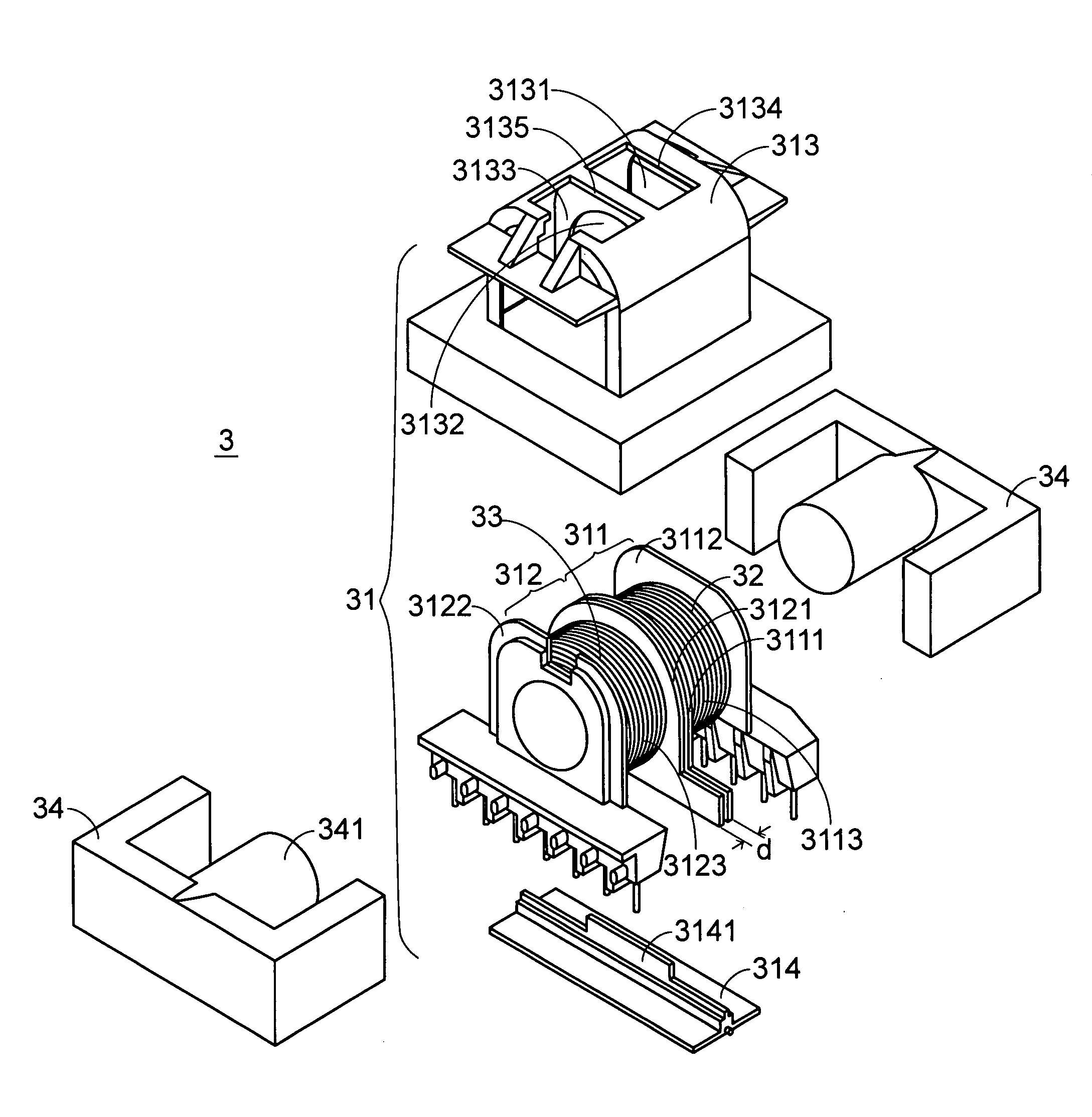

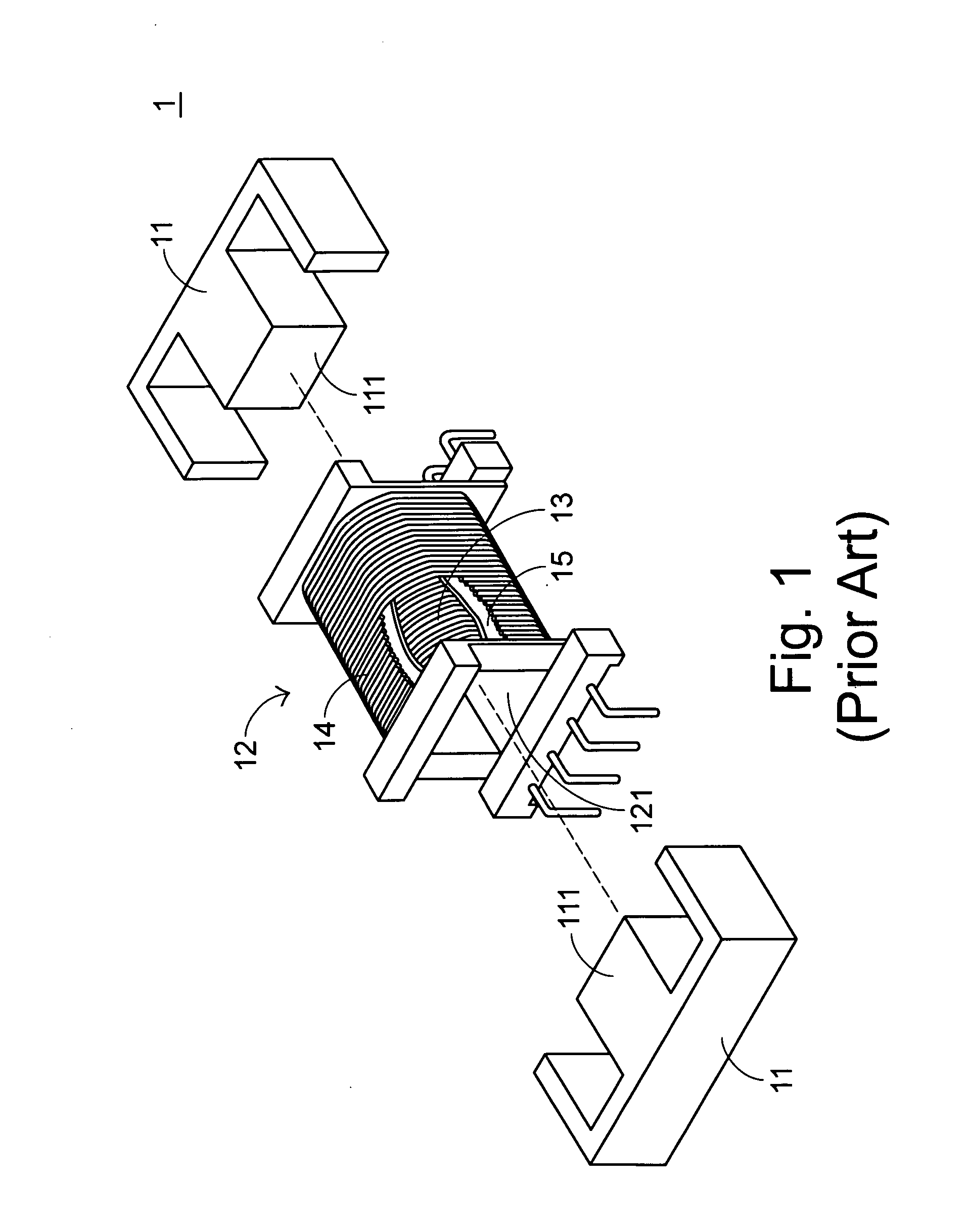

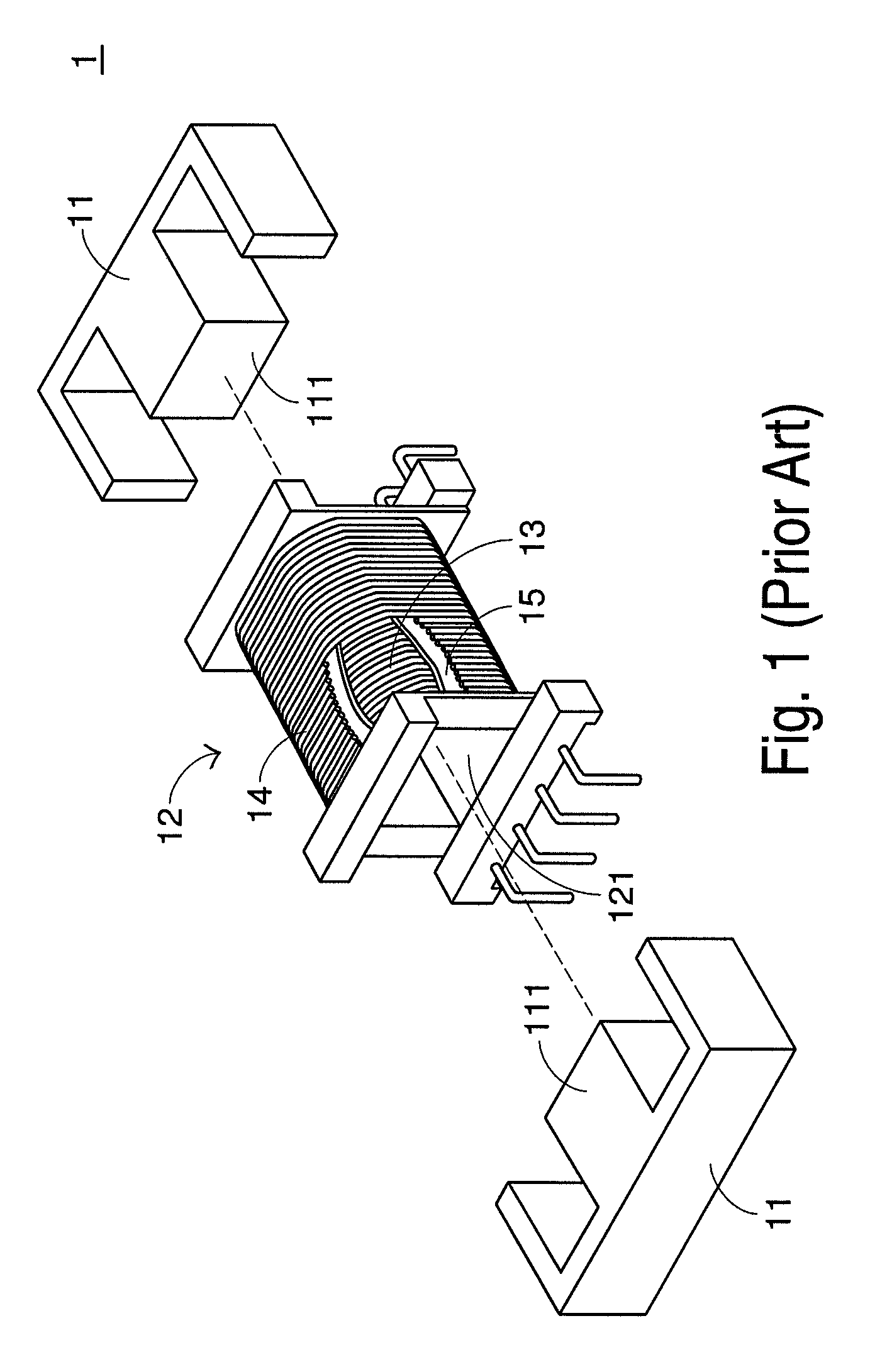

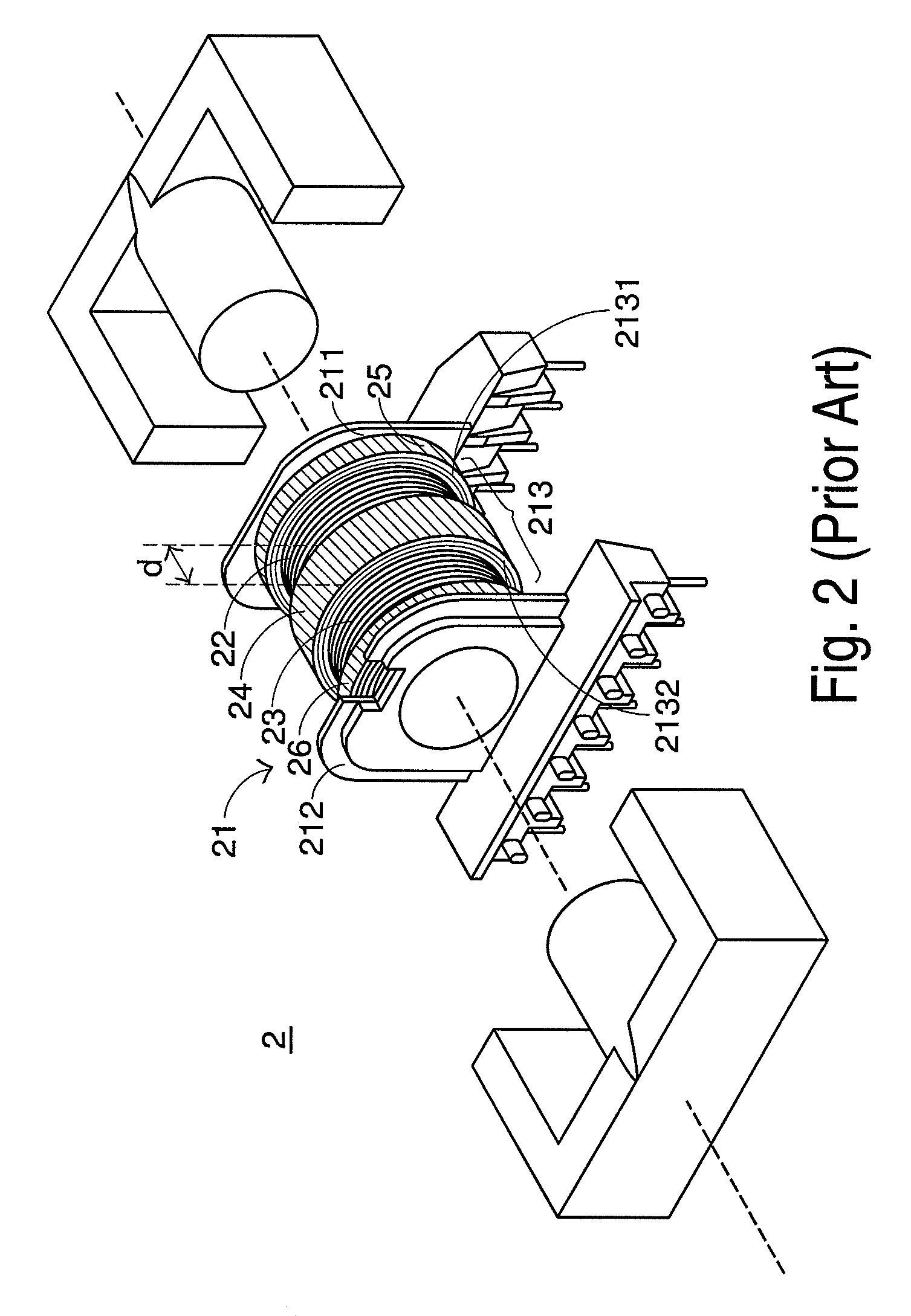

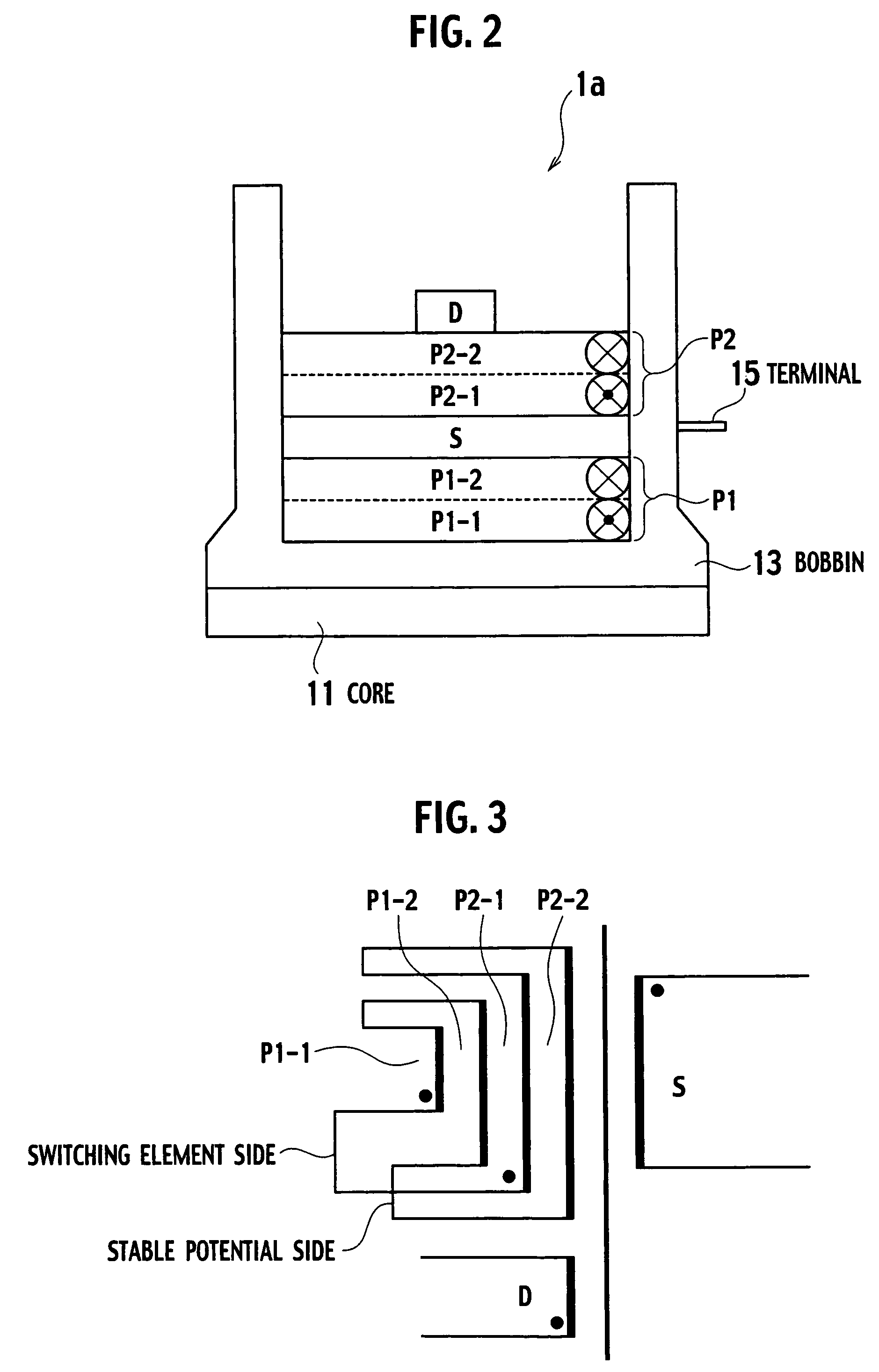

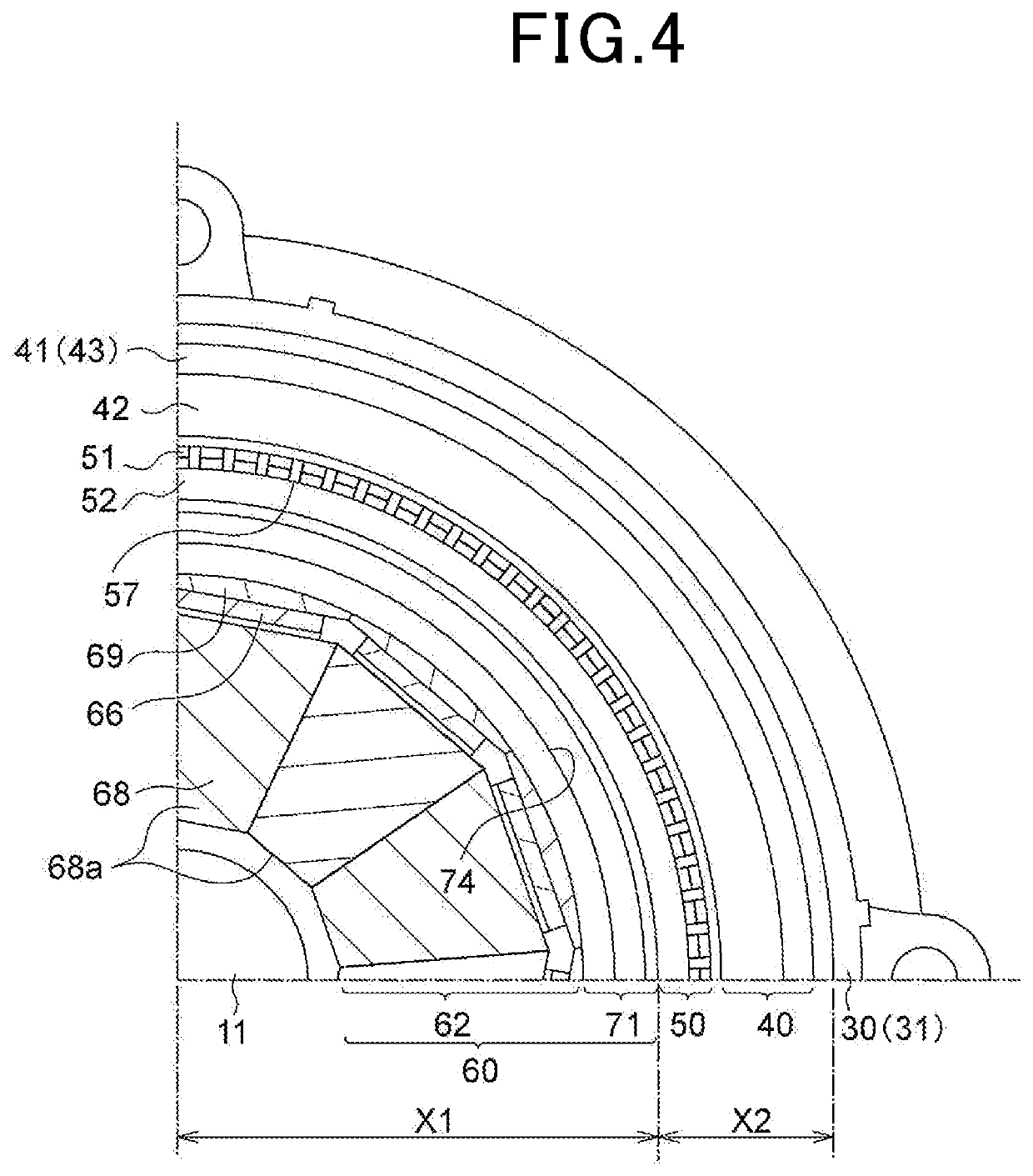

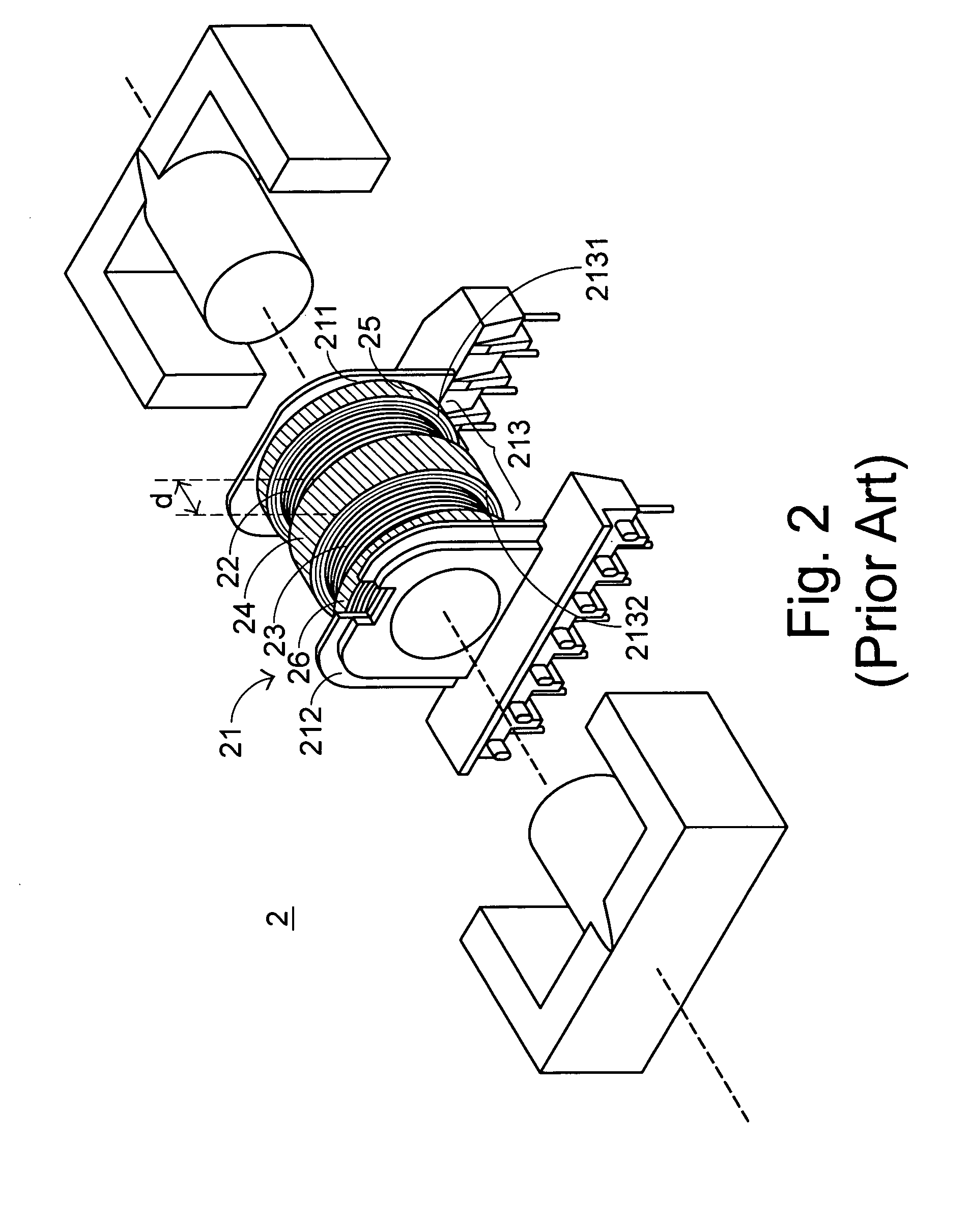

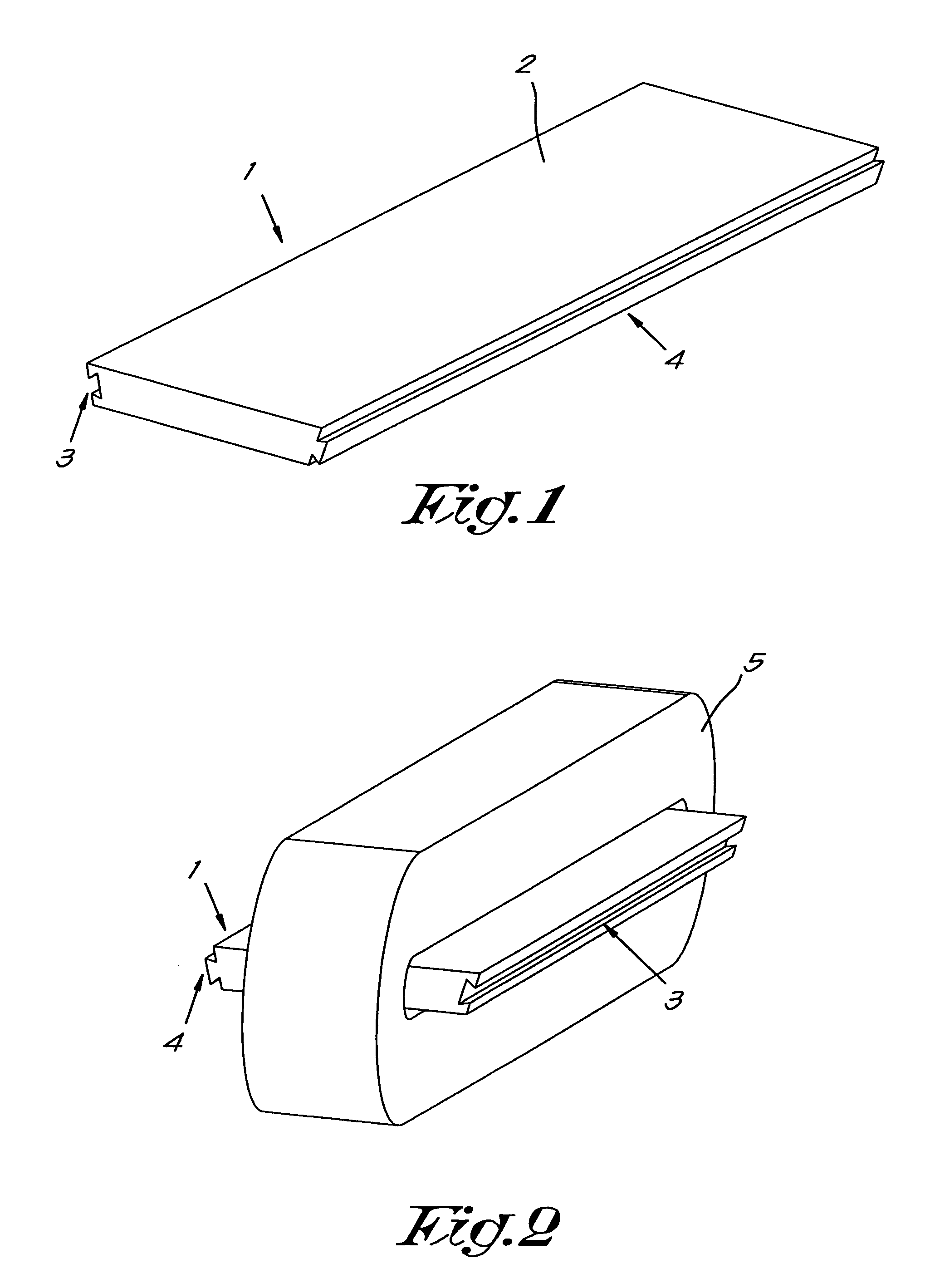

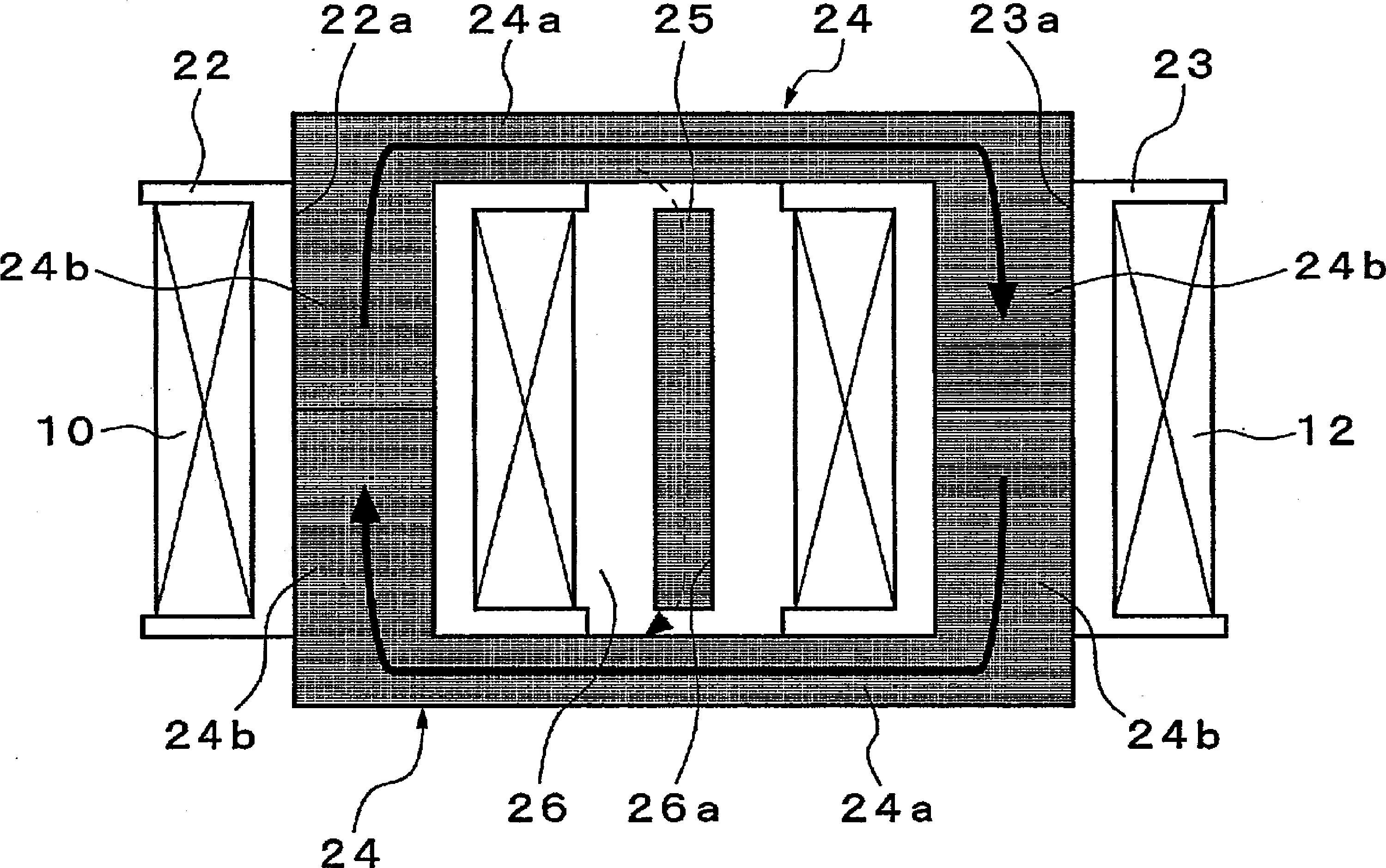

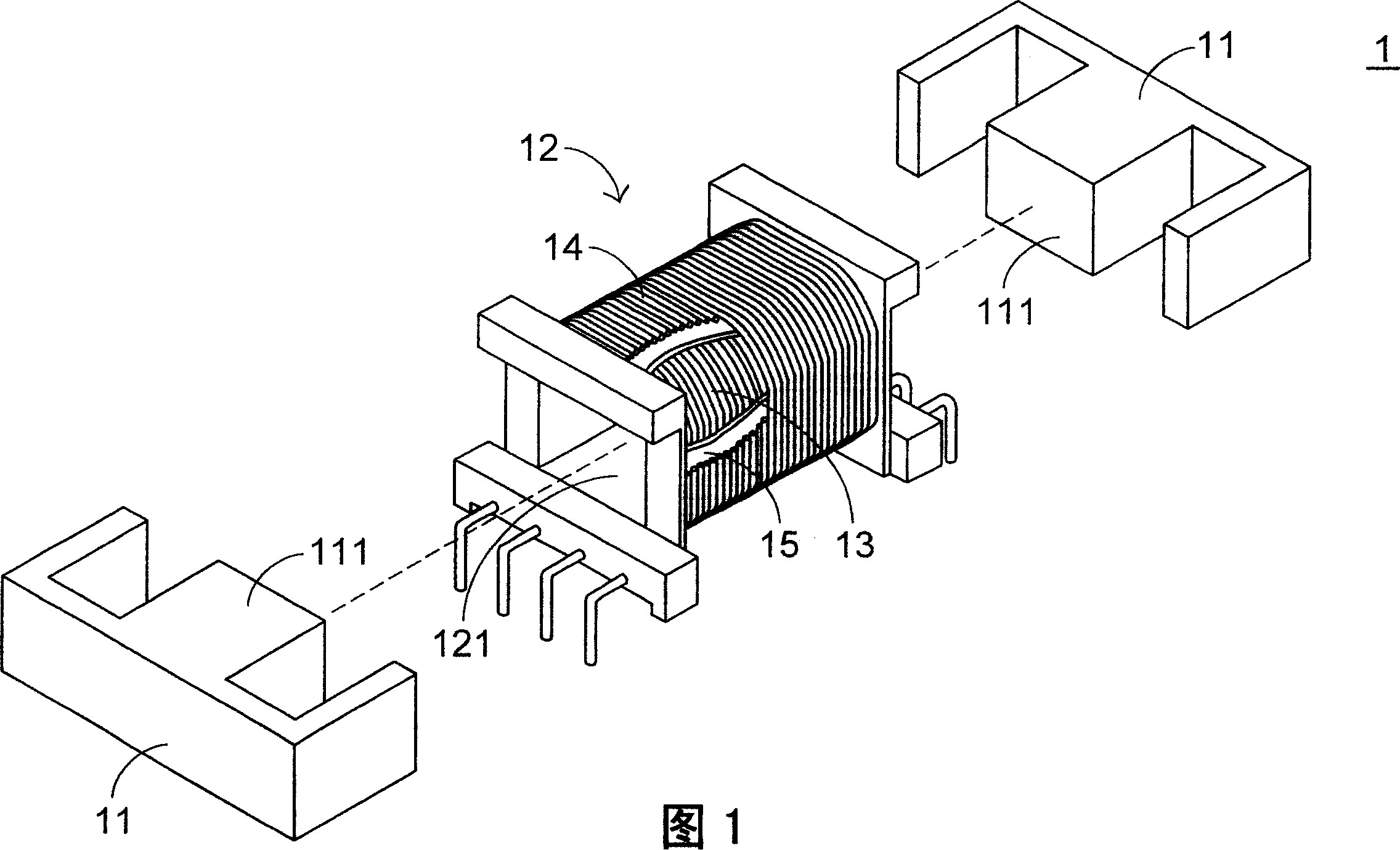

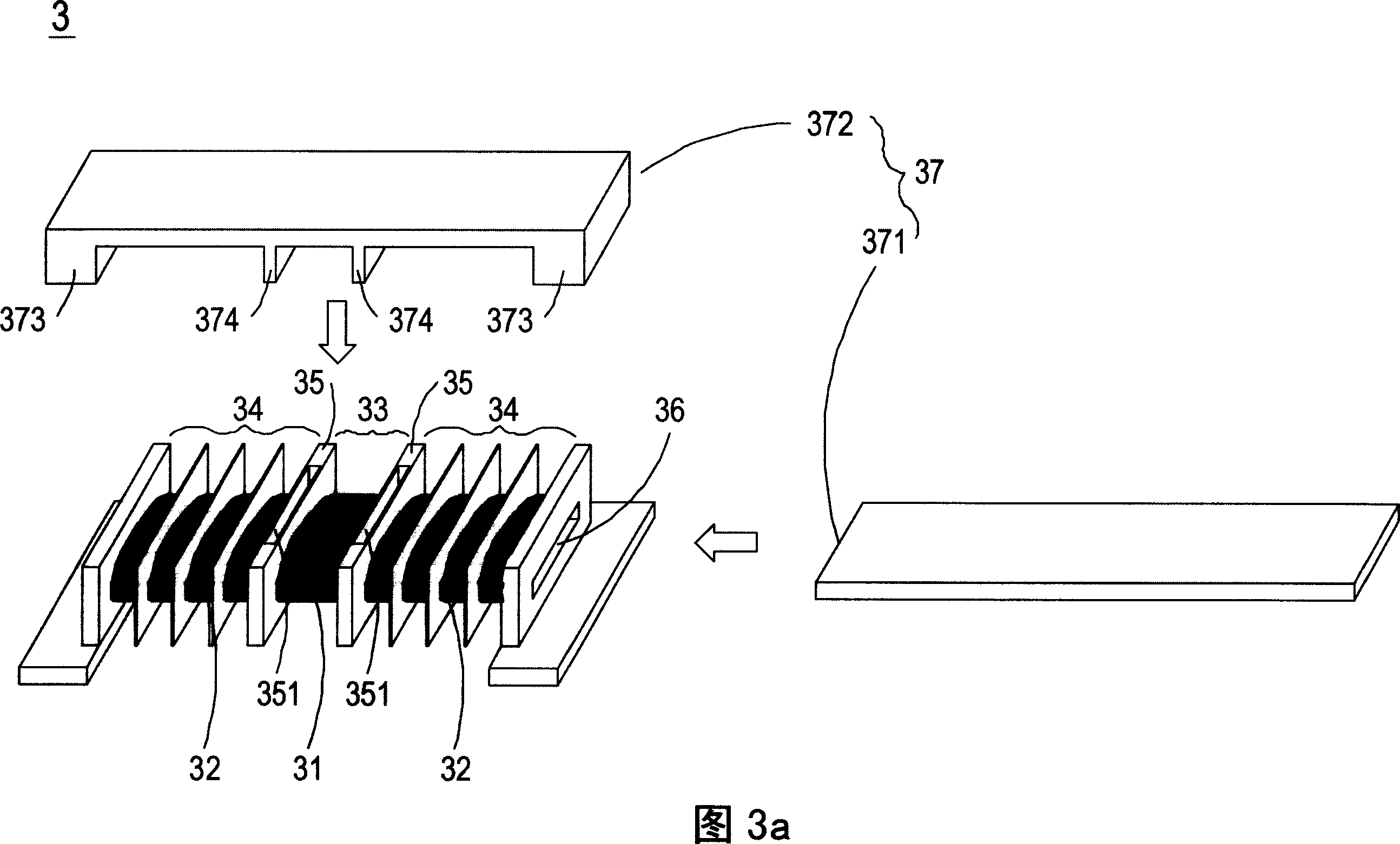

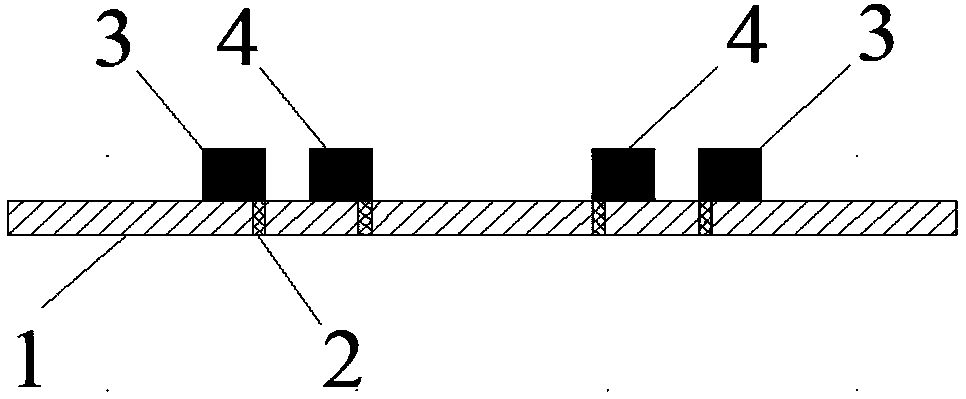

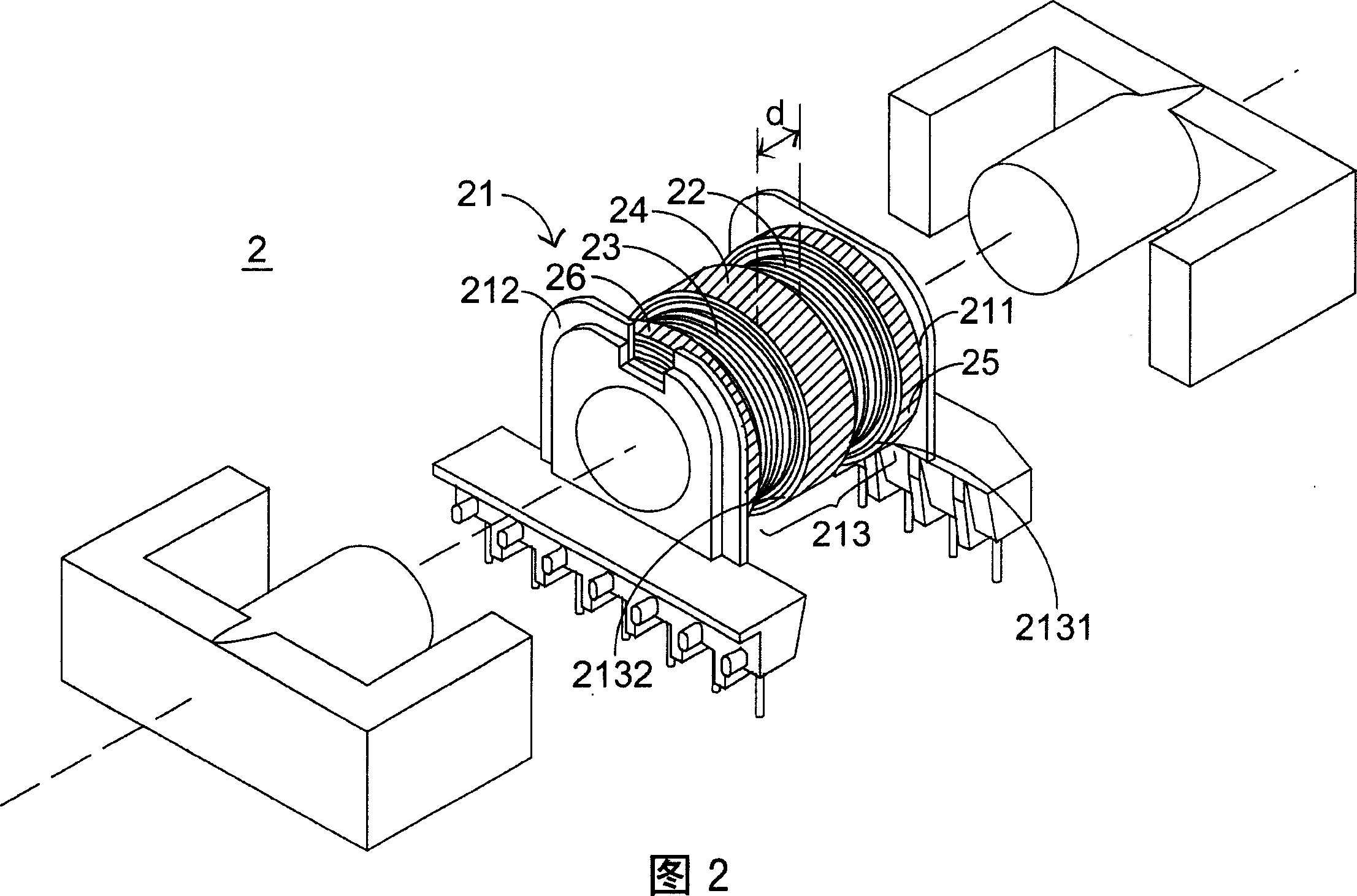

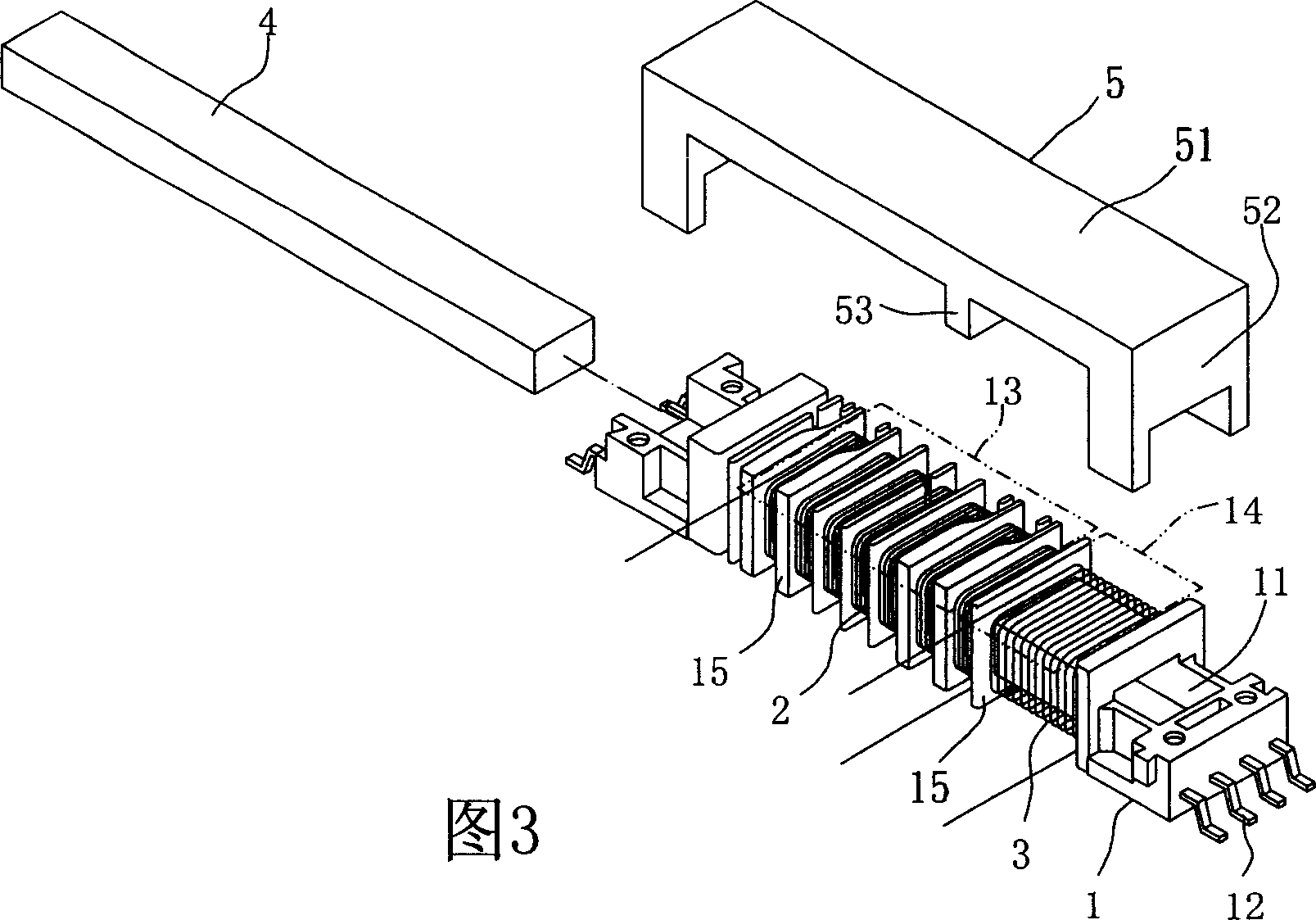

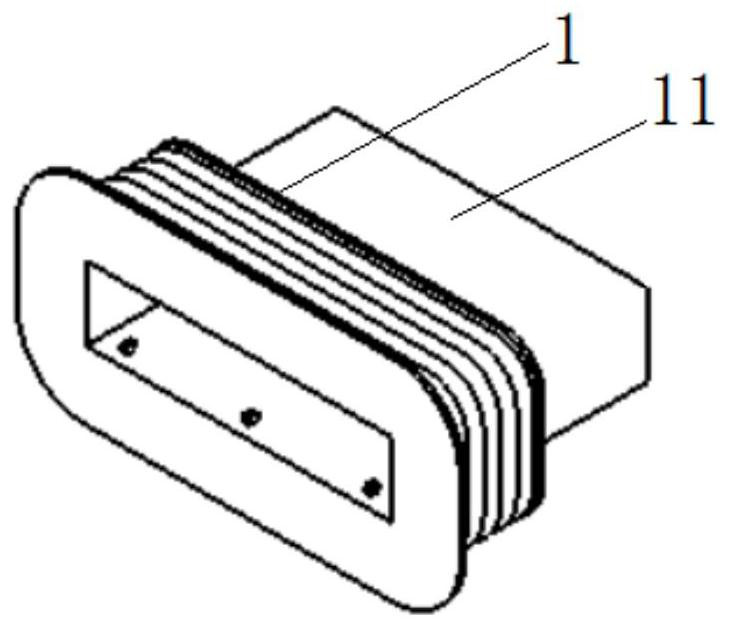

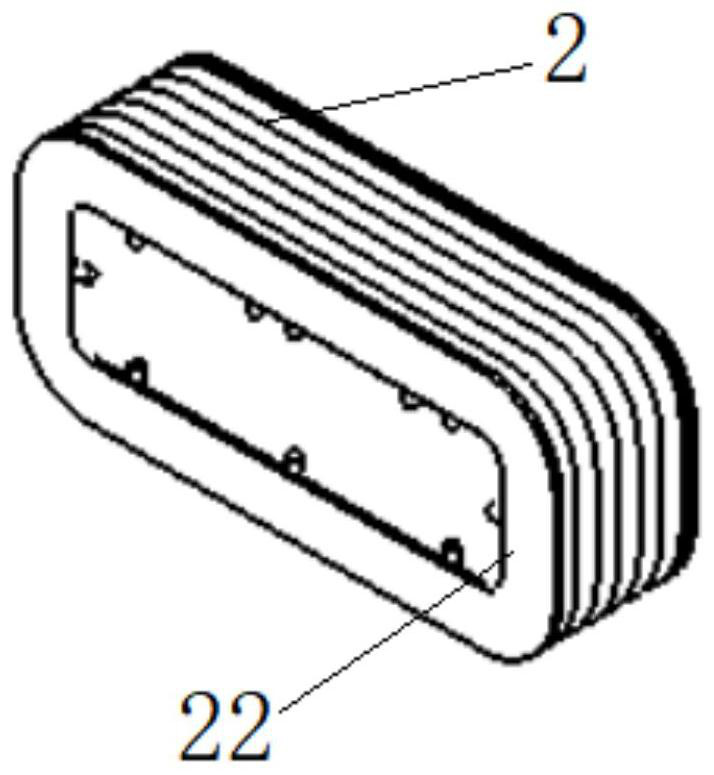

Structure of transformer

InactiveUS7218199B1Effective controlEffectively increasing leakage inductanceTransformersTransformers/inductances coils/windings/connectionsBobbinTransformer

A transformer includes a primary winding coil, a plurality of electrically-conductive sheets, a bobbin and a magnetic core assembly. The bobbin includes a first tube member, a second tube member and plural partition plates. The first tube member and the second tube member have a first channel and a second channel therein, respectively. Each partition plate is sheathed around the first tube member and the second tube member and includes a receptacle for accommodating respective electrically-conductive sheet, and the primary winding coil is wound around the second tube member.

Owner:DELTA ELECTRONICS INC

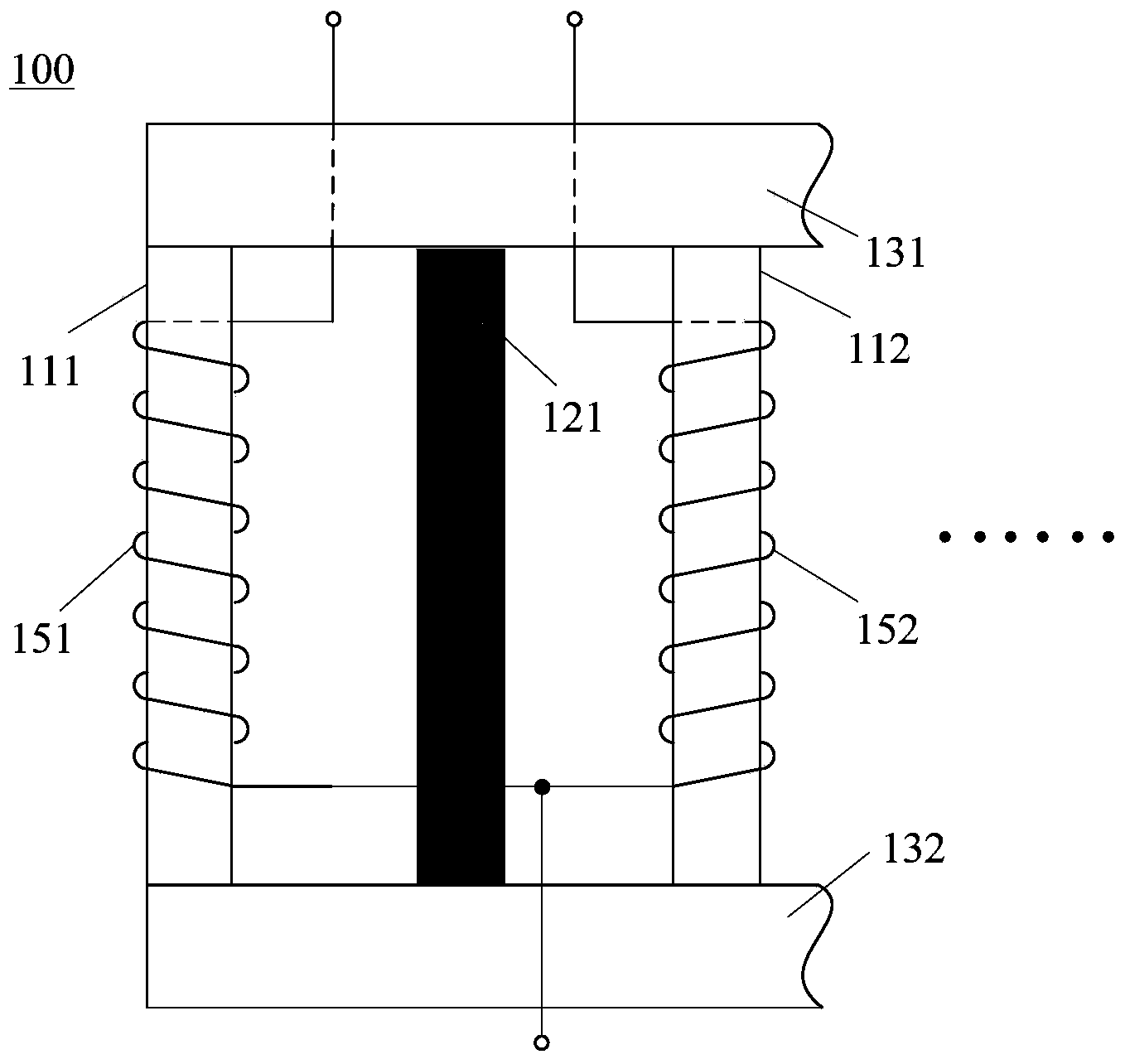

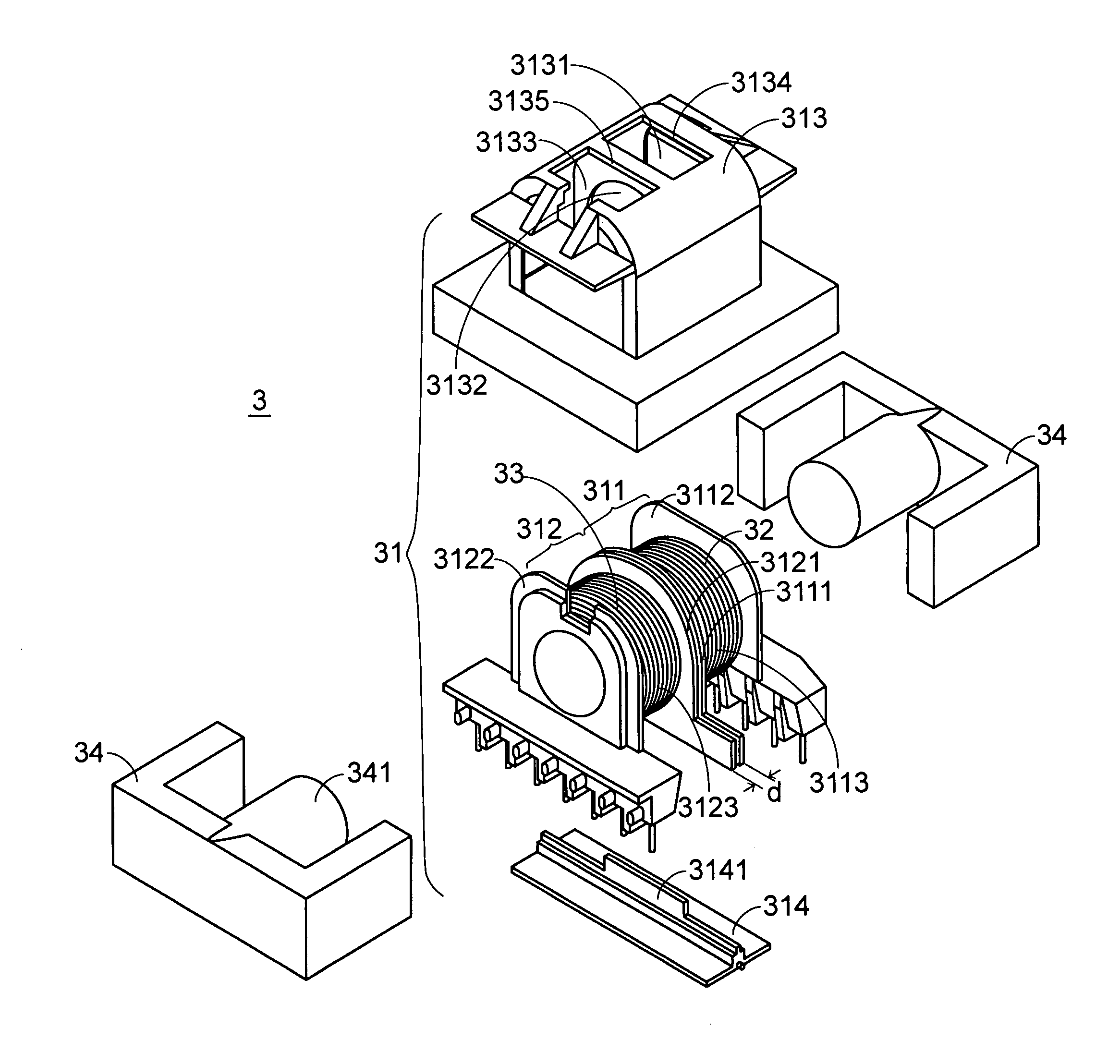

Coupling inductor and power converter

ActiveCN104021920AIncrease leakage inductanceImprove performanceTransformersInorganic material magnetismSystem stabilityLeakage inductance

The invention provides a coupling inductor and a power converter. The coupling inductor comprises a magnetic core and at least two windings. The magnetic core comprises at least two first magnetic columns, at least one second magnetic column and two opposite magnet yokes. The at least two first magnetic columns and the at least one second magnetic column are arranged between the two opposite magnet yokes. The at least two windings are wound on the at least two first magnetic columns respectively. The at least two windings and the at least two first magnetic columns correspond in a one-to-one mode. According to the coupling inductor, by adding the second magnetic column between the two opposite magnet yokes, the leakage inductance of the coupling inductor is increased, and accordingly the requirement for system stability is met when the coupling inductor is connected into the power converter.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

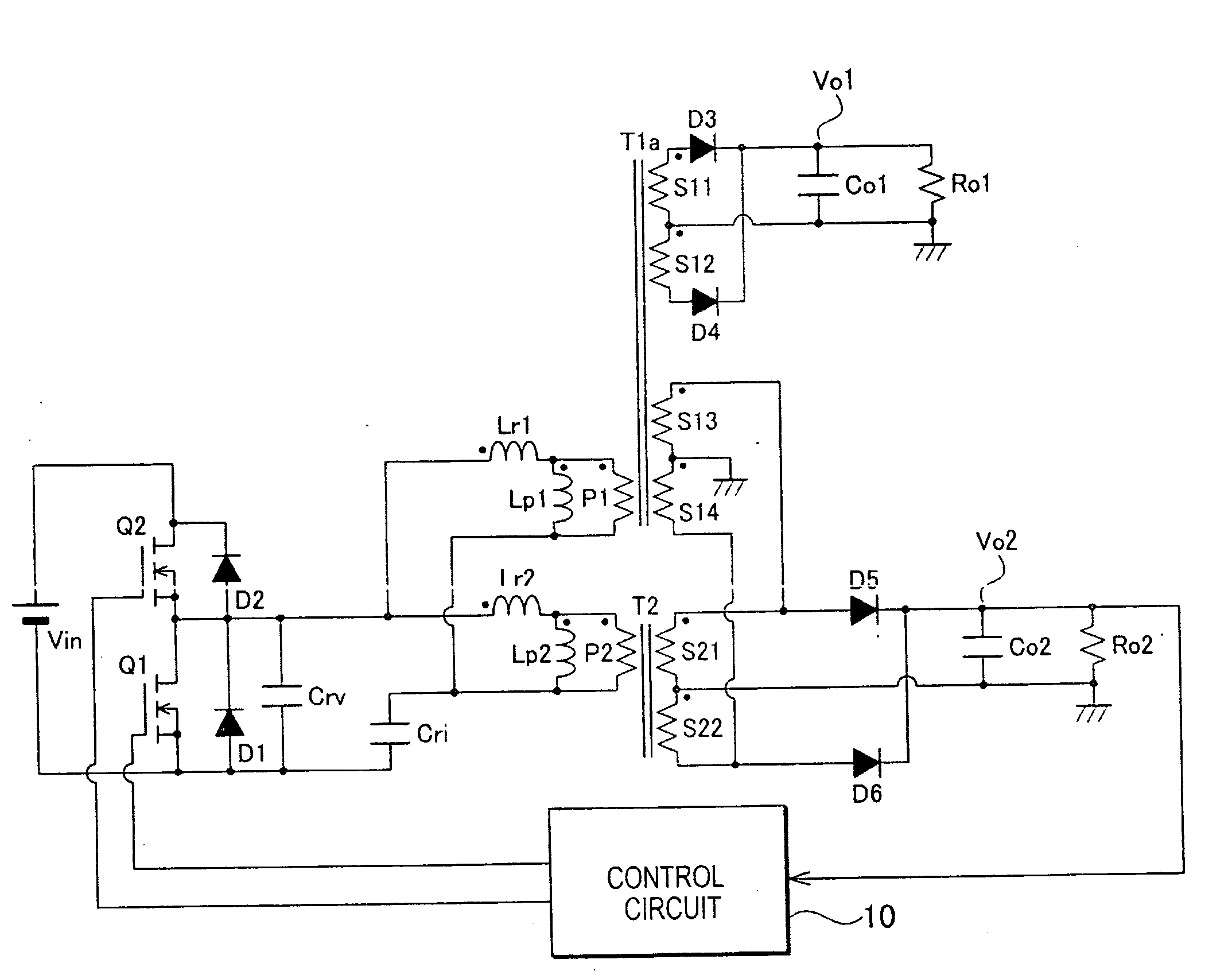

DC conversion apparatus

ActiveUS20090201700A1Reduce the number of turnsIncrease the resistance valueEfficient power electronics conversionConversion with intermediate conversion to dcEngineeringConductor Coil

A DC conversion apparatus comprises a first transformer, a second transformer, a parallel circuit having series circuits connected in parallel, one of the series circuits including a reactor and a primary winding of the first transformer, the other series circuit including a reactor and a primary winding of the second transformer, a conversion circuit converting a DC voltage of a DC power source into an AC voltage and outputting it to the parallel circuit, a first rectifying-smoothing circuit rectifying and smoothing a first voltage generated by a first secondary windings of the first transformer into a first DC output, and a second rectifying-smoothing circuit rectifying and smoothing a second voltage generated by a first secondary windings of the second transformer into a second DC output that is different from the first voltage. The second secondary windings of the first transformer are connected in parallel with the first secondary windings of the second transformer.

Owner:SANKEN ELECTRIC CO LTD

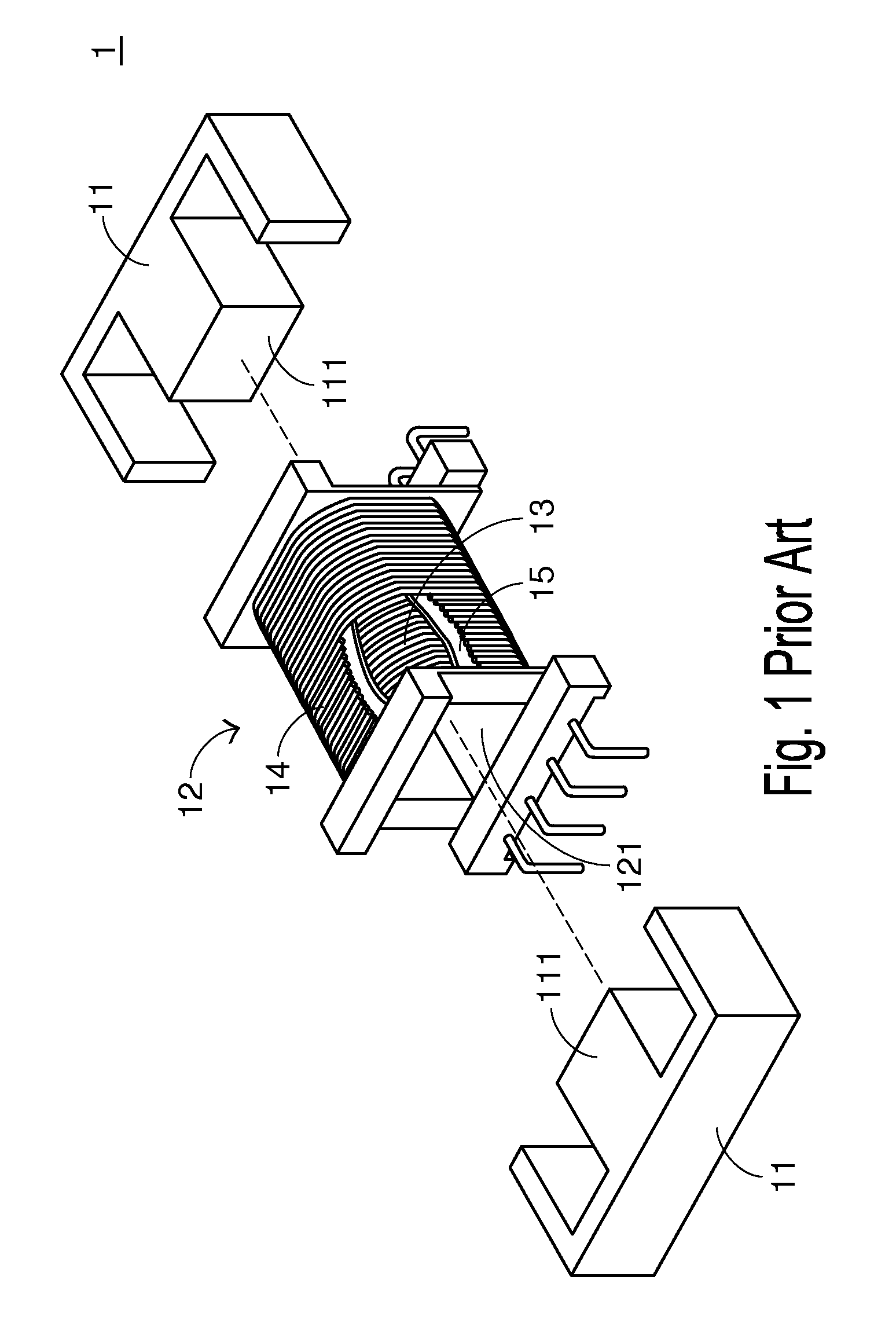

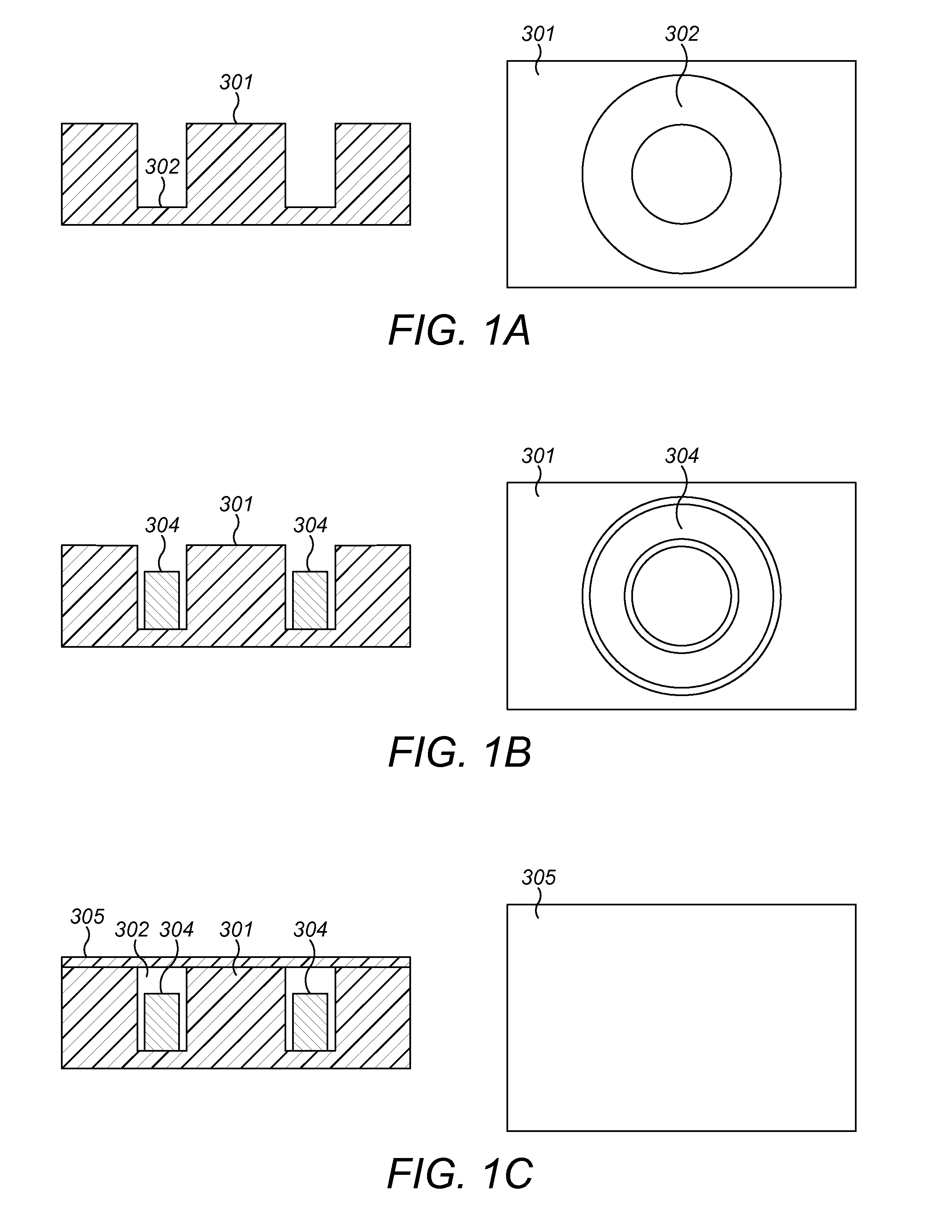

Transformer structure

ActiveUS20050140485A1Reduce the coupling coefficientIncrease leakage inductanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinEngineering

A transformer structure is proposed herein which includes a primary winding coil, a secondary winding coil, a bobbin module, and a magnetic core assembly. The magnetic core assembly is mounted within the bobbin module. The bobbin module includes a first winding window portion and a second winding window portion in which the first winding window portion allows the primary winding coil to be wound thereupon and the second winding window portion allows the secondary winding coil to be wound thereupon. Both of first winding window portion and the second winding window portion include a first lateral plate, and each couples or separate with each other by the first lateral plate, such that the primary winding coil and the secondary winding coil are separated with each other and the leakage inductance, and the safe distance of electrical security for the transformer is increased accordingly.

Owner:DELTA ELECTRONICS INC

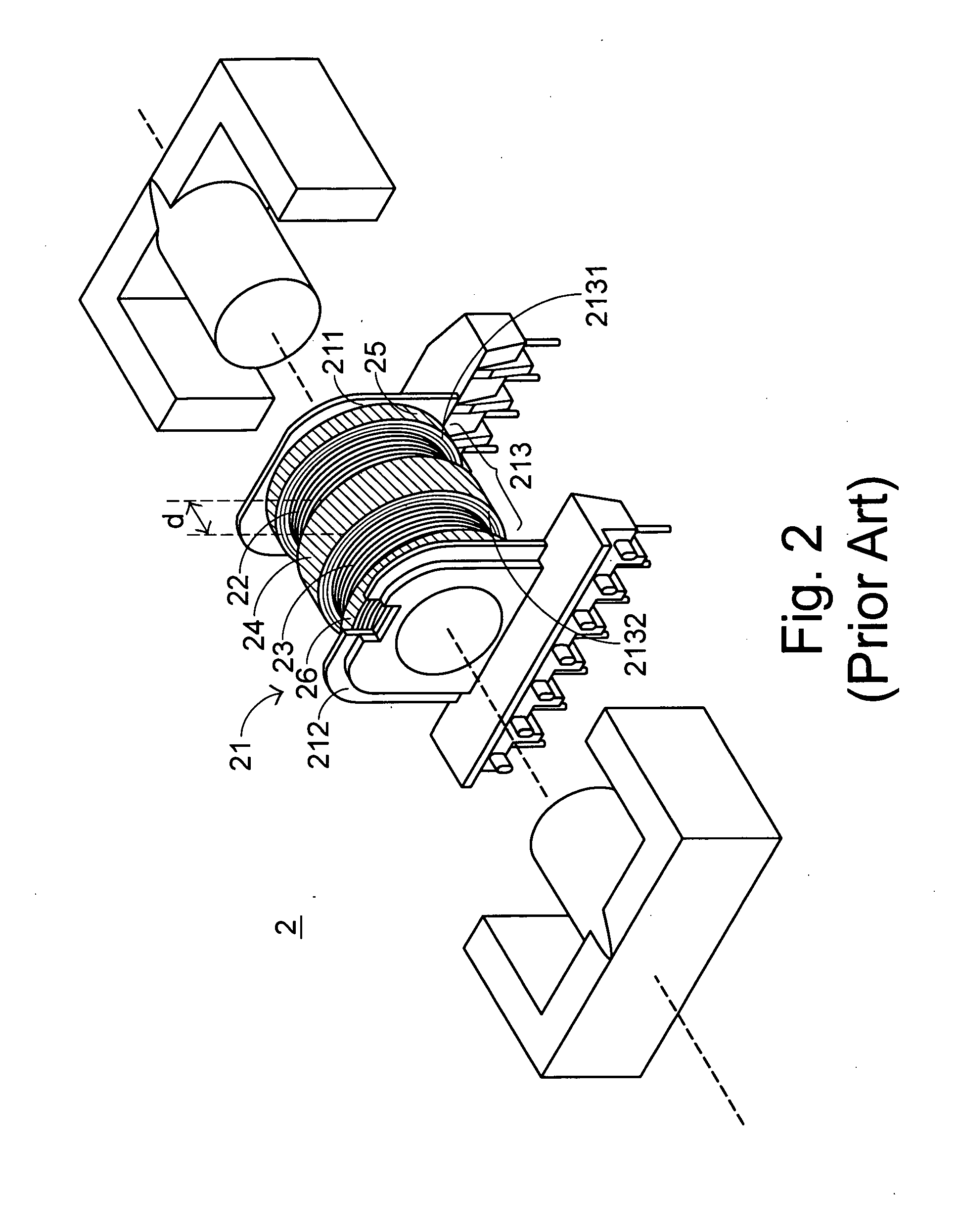

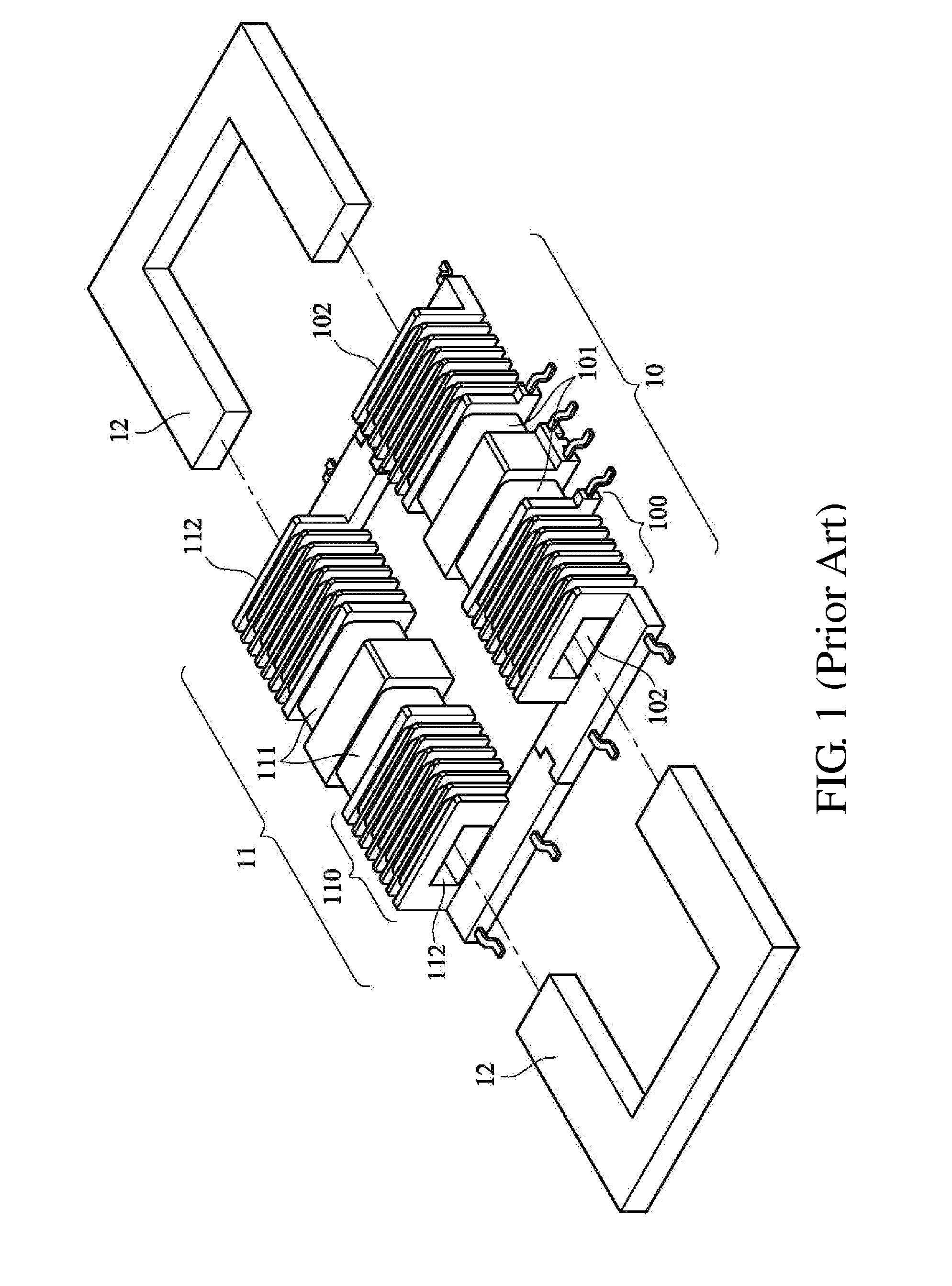

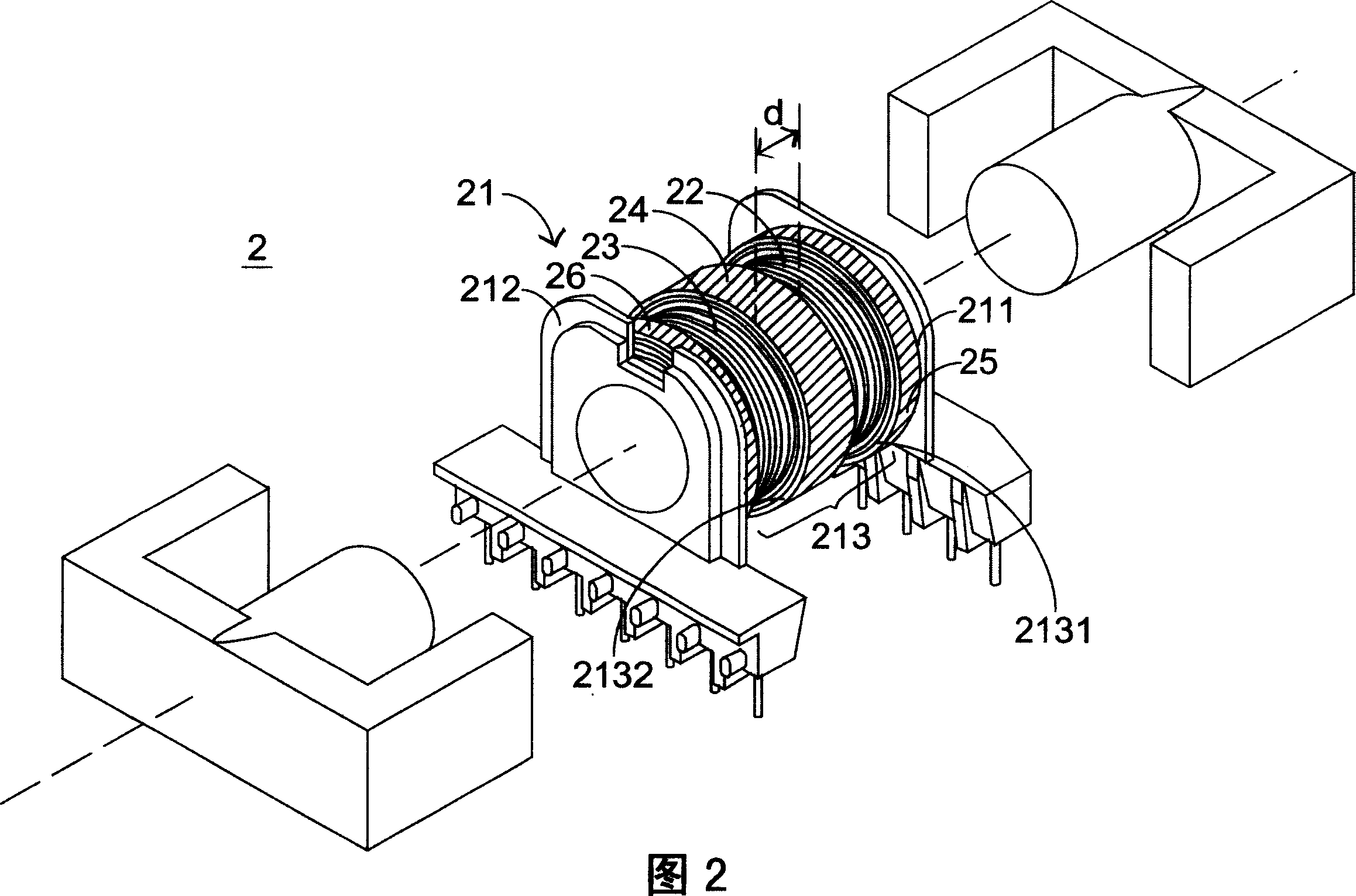

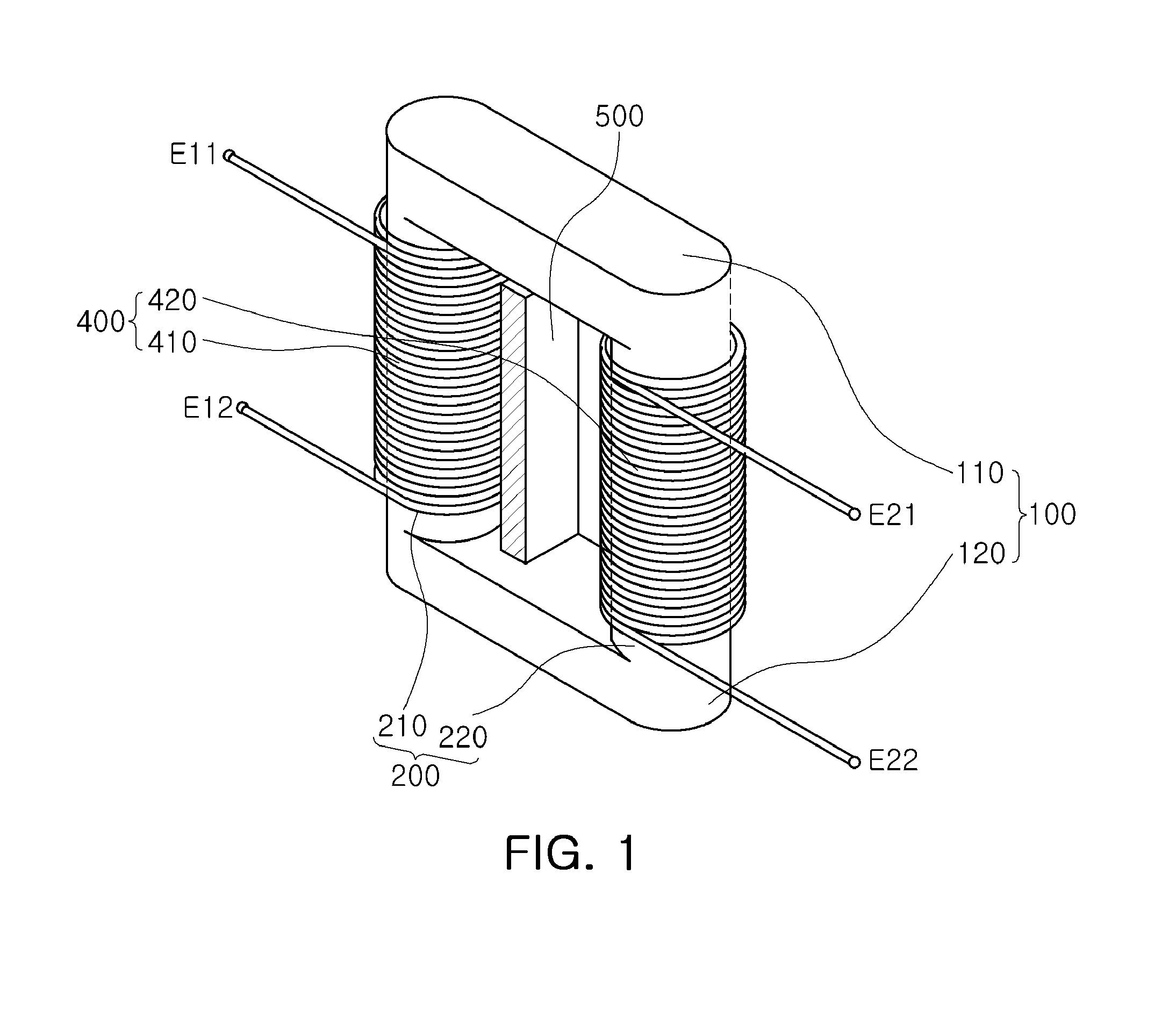

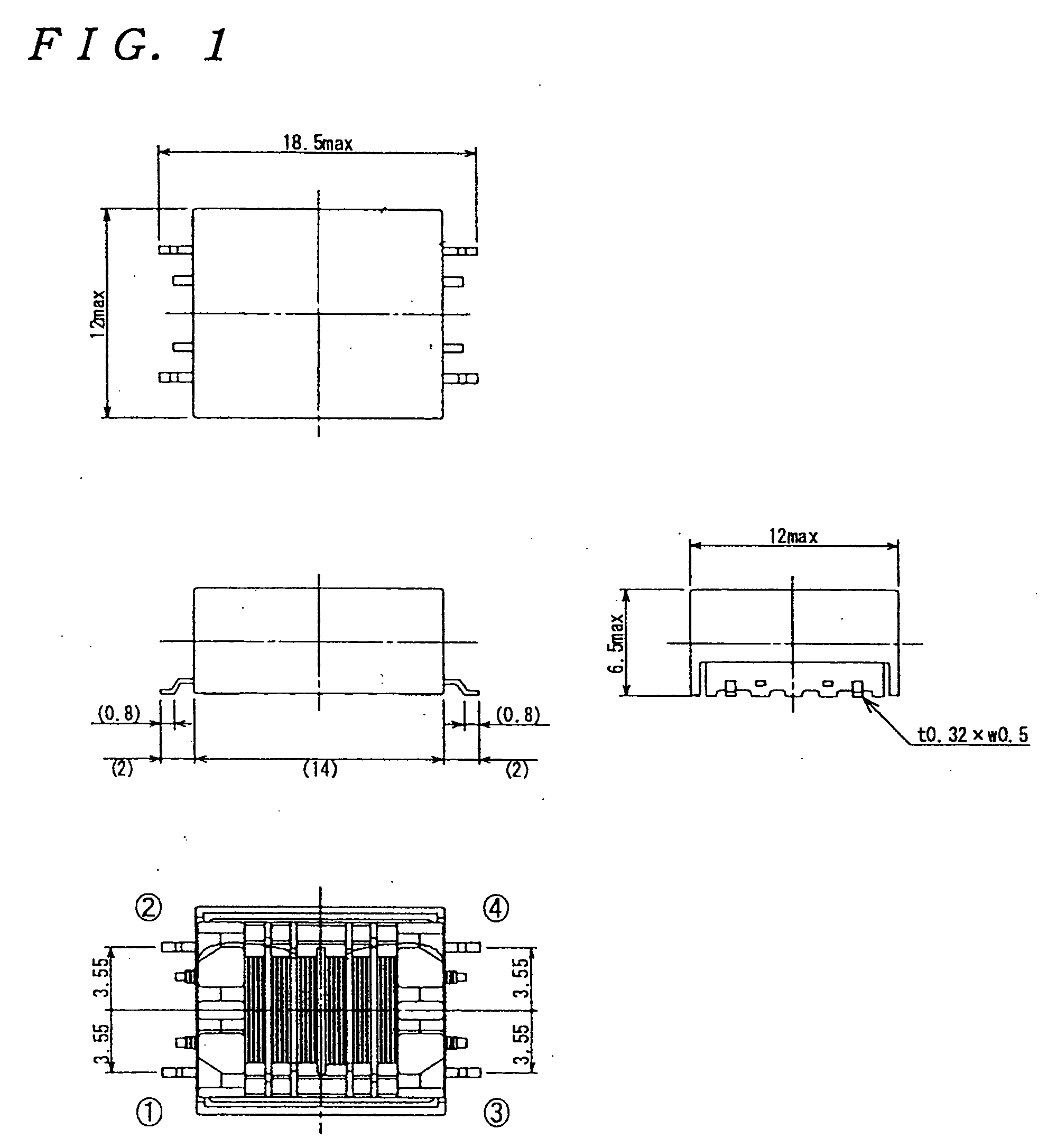

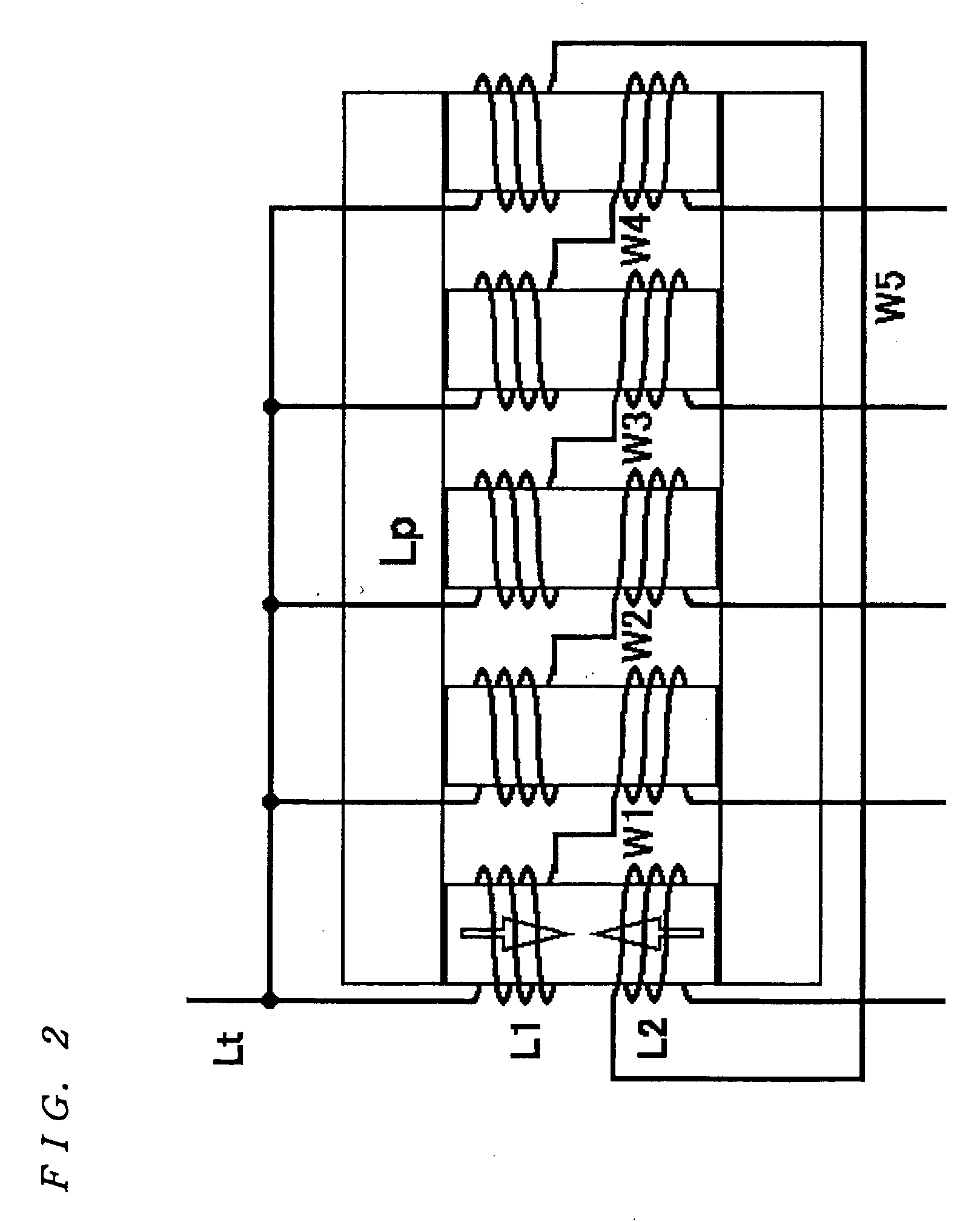

Transformer

ActiveUS7221252B1Increase distanceIncrease leakage inductanceTransformersTransformers/inductances magnetic coresLeakage inductanceConductor Coil

A transformer structure is disclosed. The transformer comprises a primary winding coil, plural secondary winding coils, a first winding portion, plural second winding portions, plural partition plates, a channel, and a magnetic core assembly. The first winding portion is used for winding the primary winding coil thereon, and the plural second winding portions are used for winding the secondary winding coils thereon and disposed at two sides of the first winding portion. The plural partition plates are disposed between the first winding portion and the second winding portions, respectively, and each the partition plate has a slot. The channel penetrates the first winding portion, the second winding portions and the partition plates. The magnetic core assembly comprises an I-shaped magnetic core and a U-shaped magnetic core. The I-shaped magnetic core is received in the channel and the U-shaped magnetic core has plural protrusions inserted into the slots of the partition plates. Thereby, a leakage inductance of the transformer is adjusted by a distance between the protrusions of the U-shaped magnetic core and the I-shaped magnetic core received in the channel.

Owner:DELTA ELECTRONICS INC

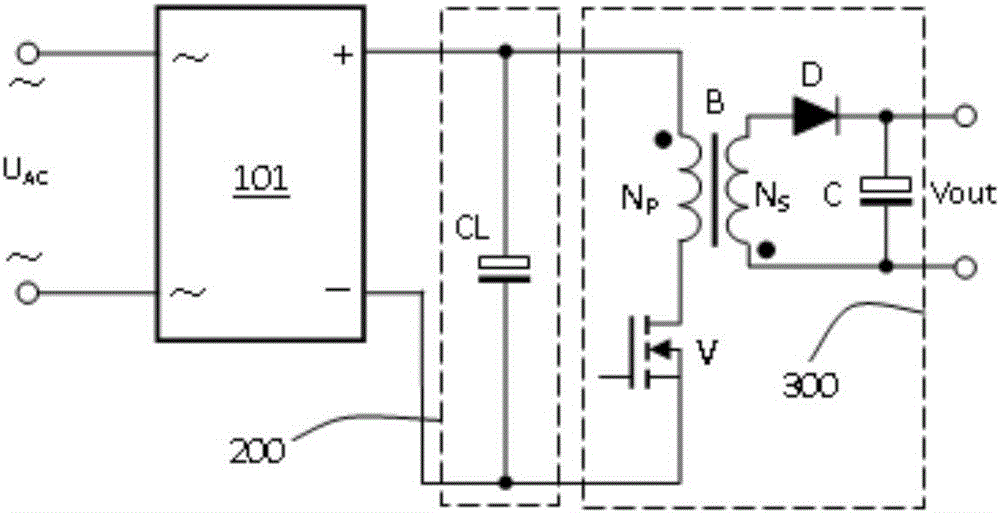

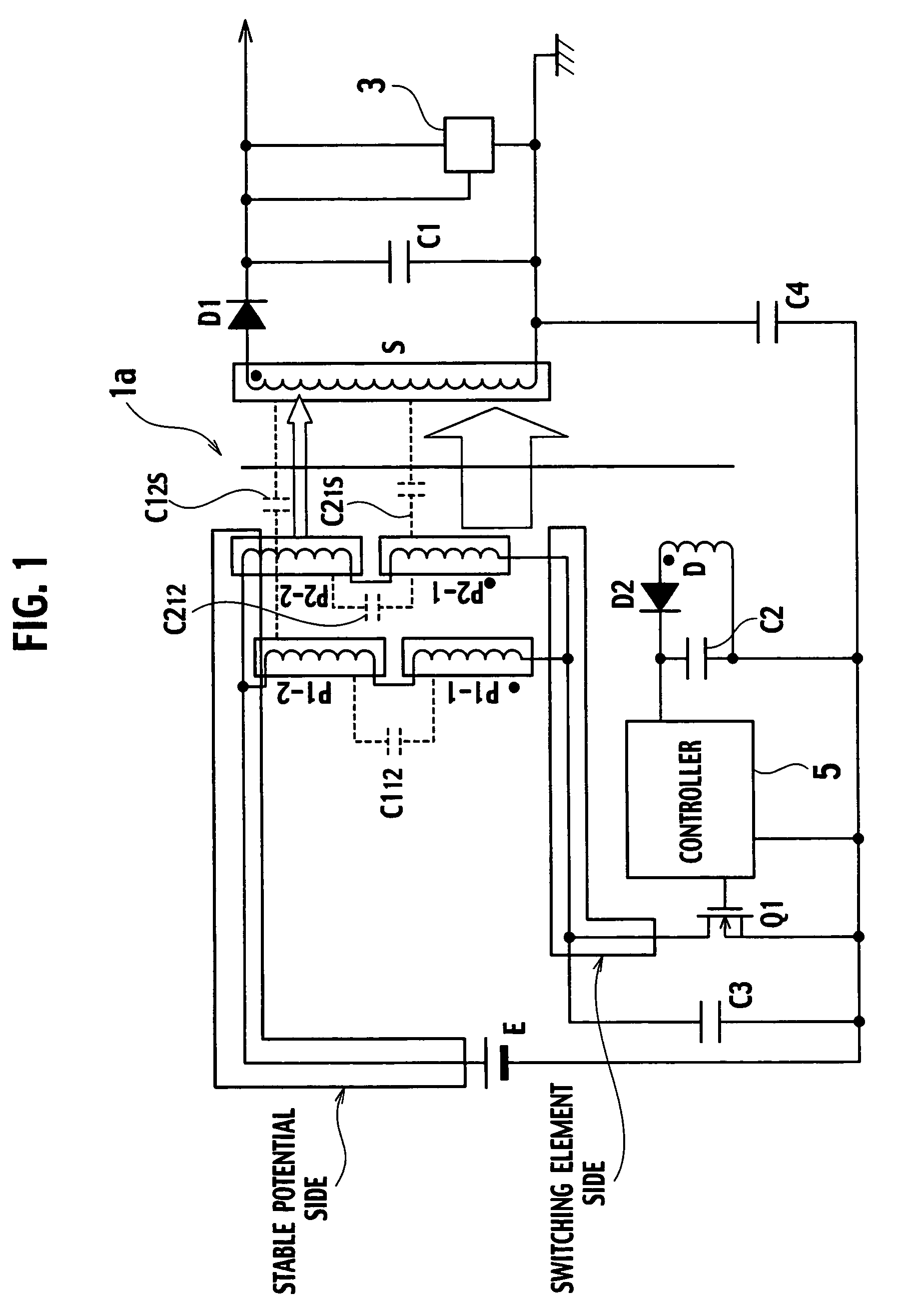

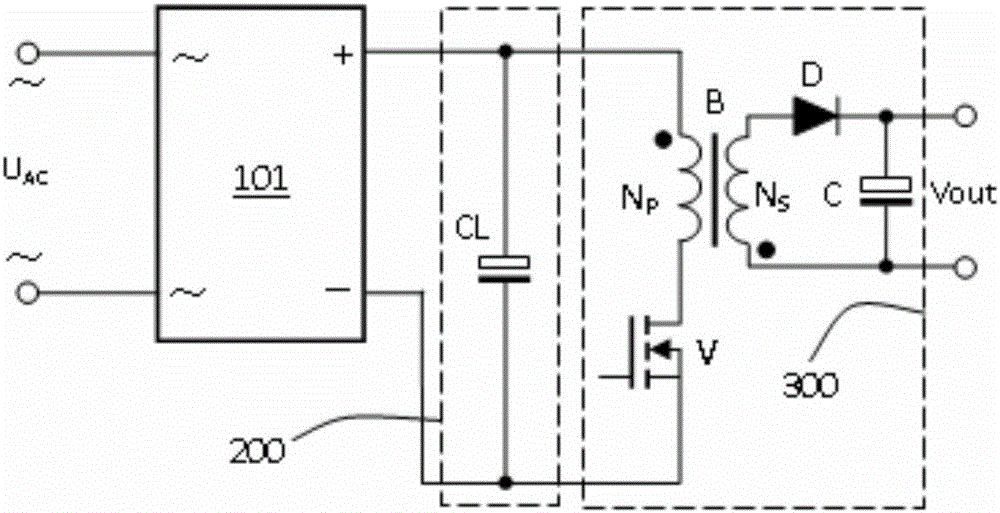

Flyback switching power supply

ActiveCN106655791AIncrease leakage inductanceImprove conversion efficiencyDc-dc conversionElectric variable regulationPower flowLow voltage

The invention discloses a flyback switching power supply. On the basis of a common three-winding absorption flyback converter, the dotted terminal of NP1 in a transformer B is connected to a power supply, the dotted terminal of NP2 of a second primary side winding is grounded, double-wire winding of NP1 and NP2 is guaranteed, one capacitor C1 is added, one end of C1 is connected with the heteronymous terminal of NP1, and the other end of C1 is connected with the heteronymous terminal of NP2, so that NP1 and NP2 are excited when Q1 is conducted in a saturated manner, energy is output from secondary side NS when Q1 is disconnected, and energy of leakage inductance is losslessly adsorbed through D1; the flyback switching power supply is suitable for working under low voltage, and the utilization rate and current density of primary side winding are improved, so that the power density is large, relatively large leakage inductance between primary side and secondary side is permitted, and the conversion efficiency is high.

Owner:MORNSUN GUANGZHOU SCI & TECH

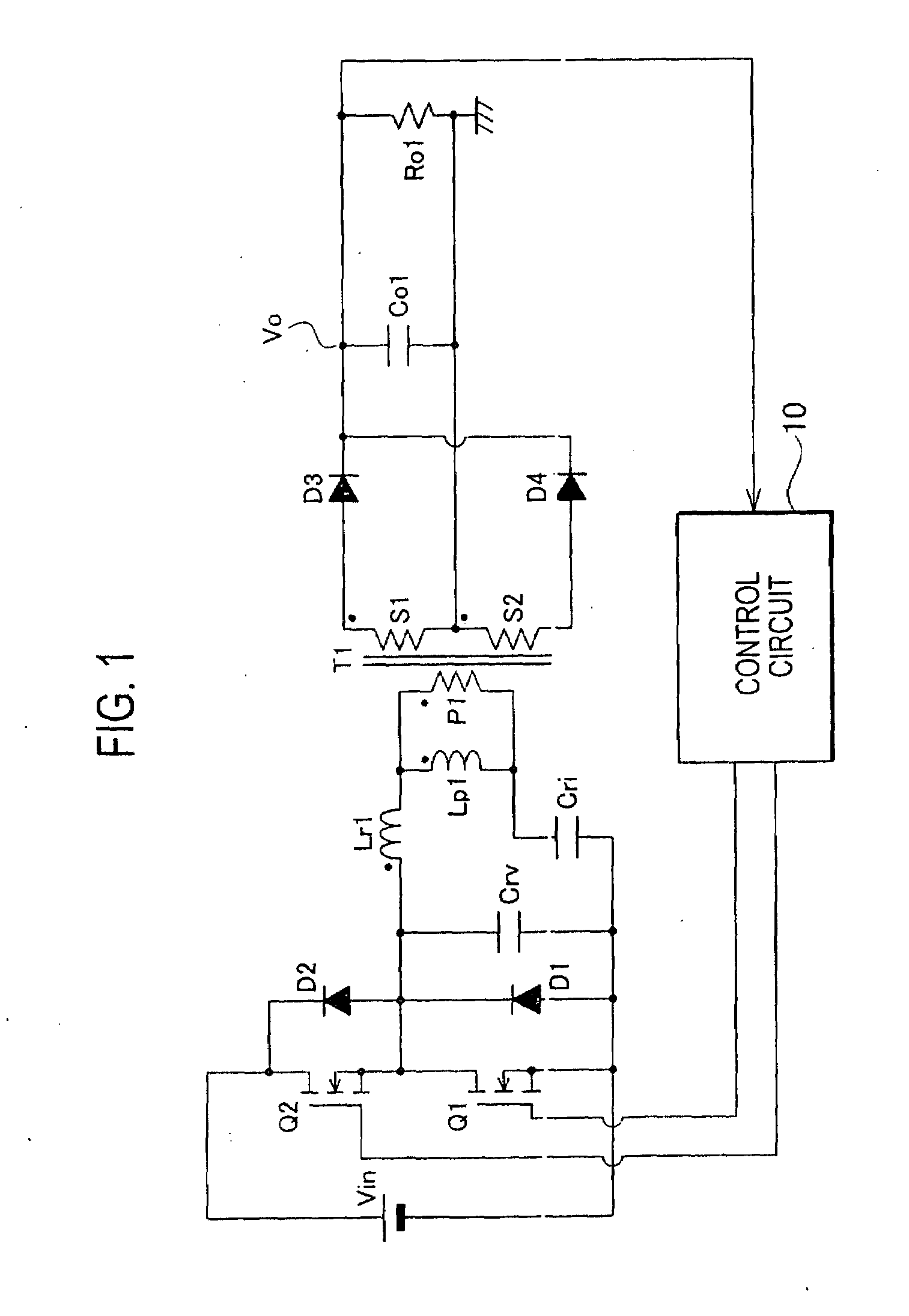

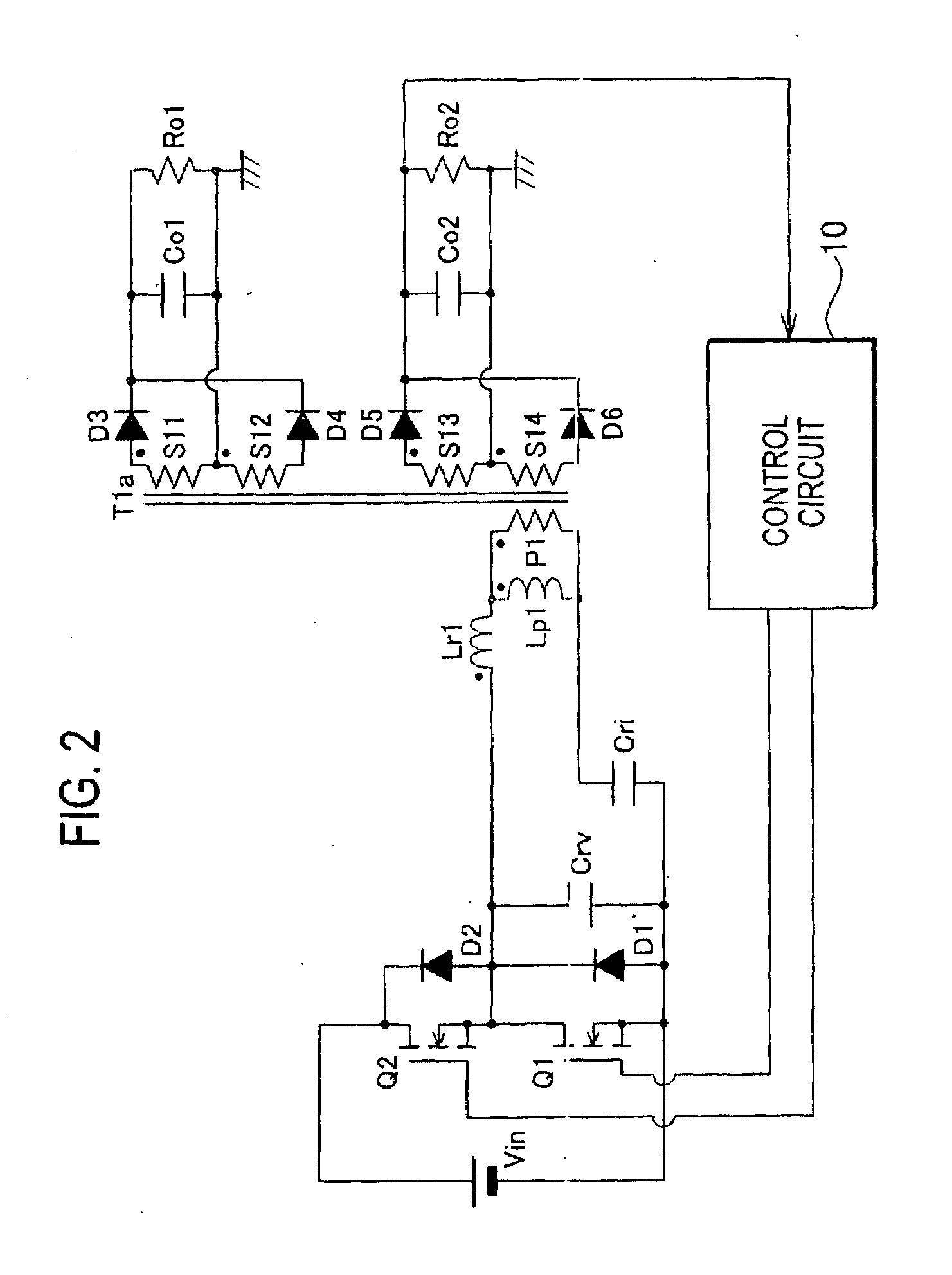

DC power source apparatus

ActiveUS7145784B2Reduce parasitic capacitanceComplex structureTransformersDc-dc conversionHigh frequency powerTransformer

Owner:SANKEN ELECTRIC CO LTD

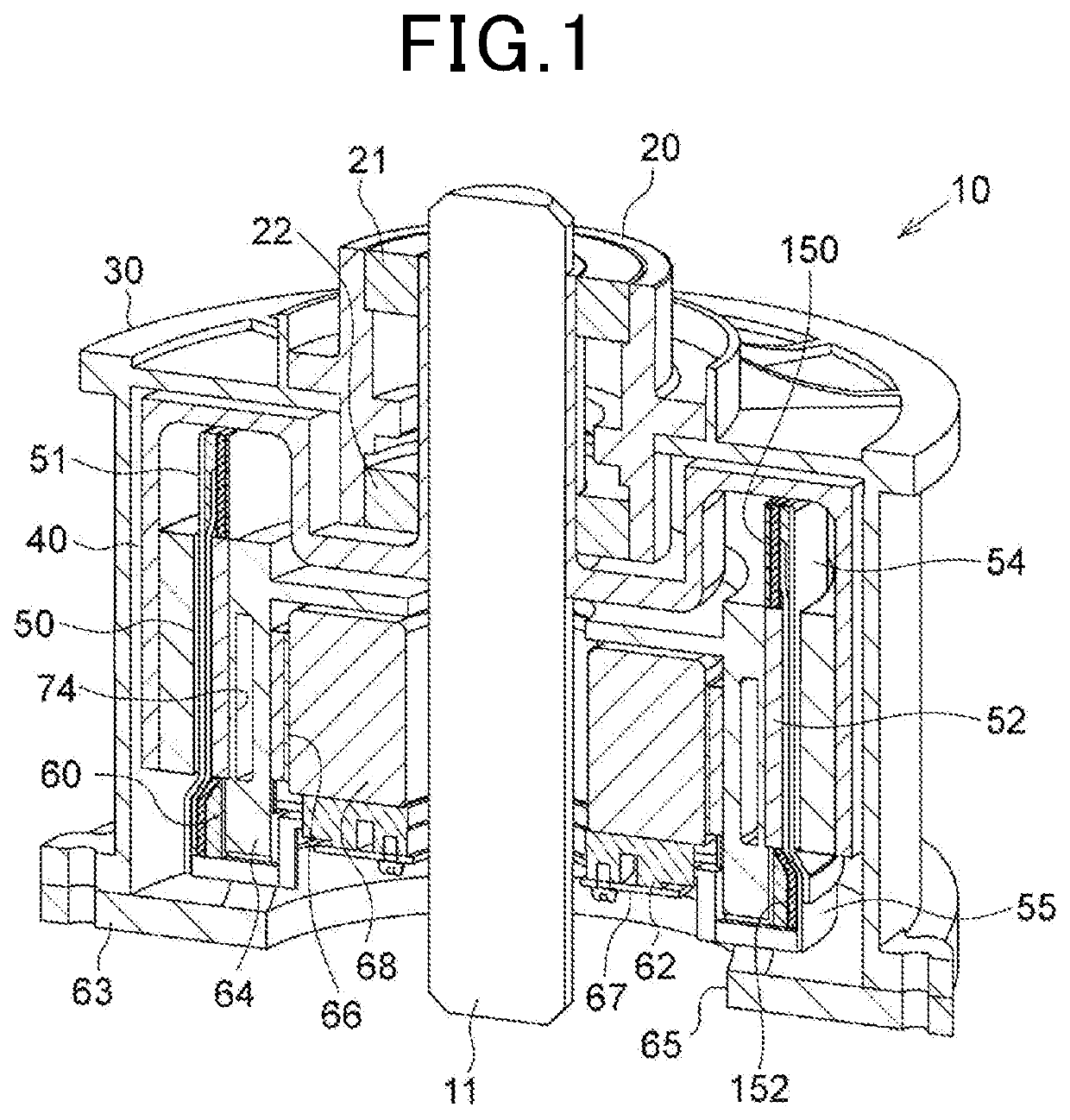

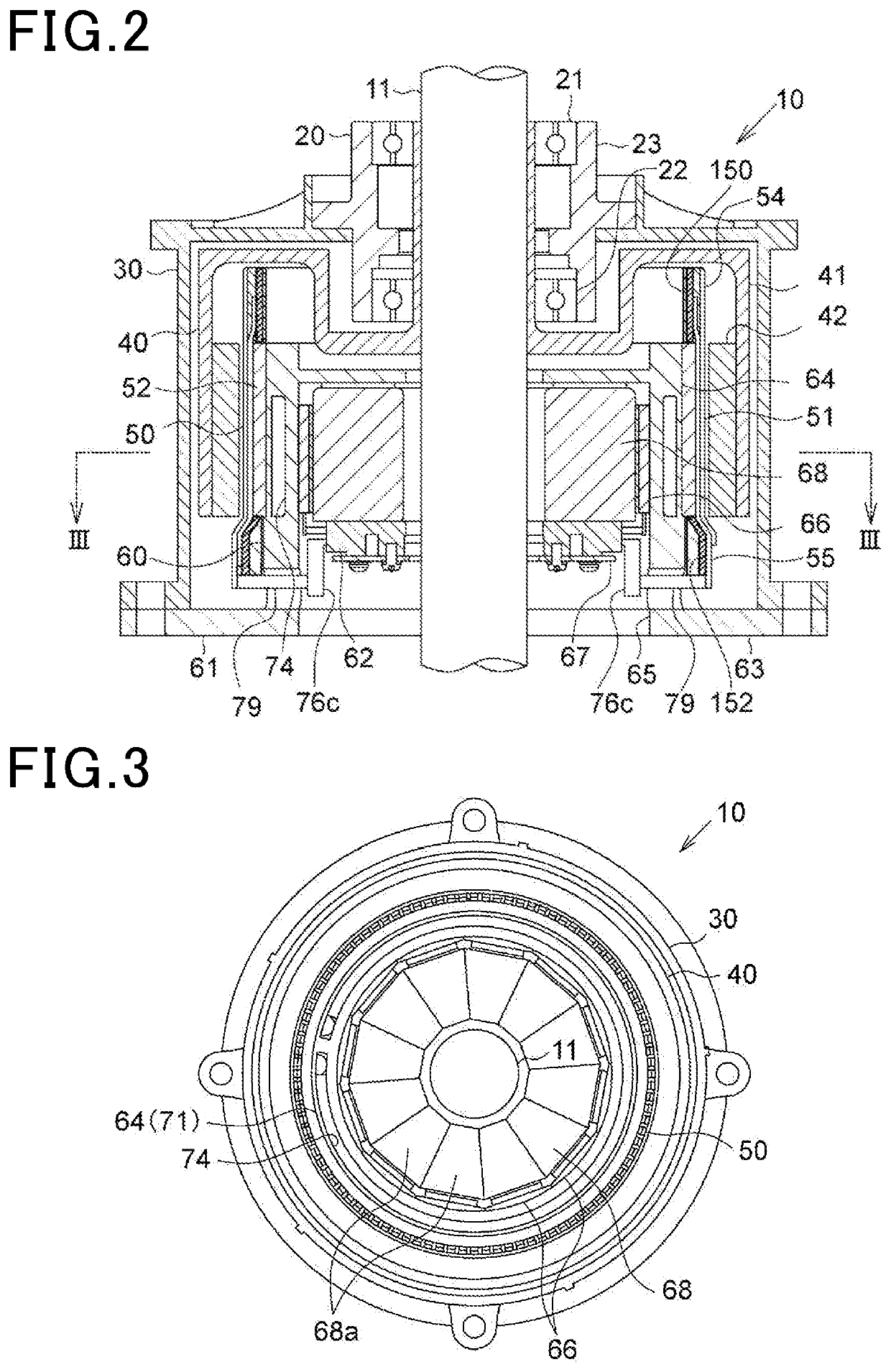

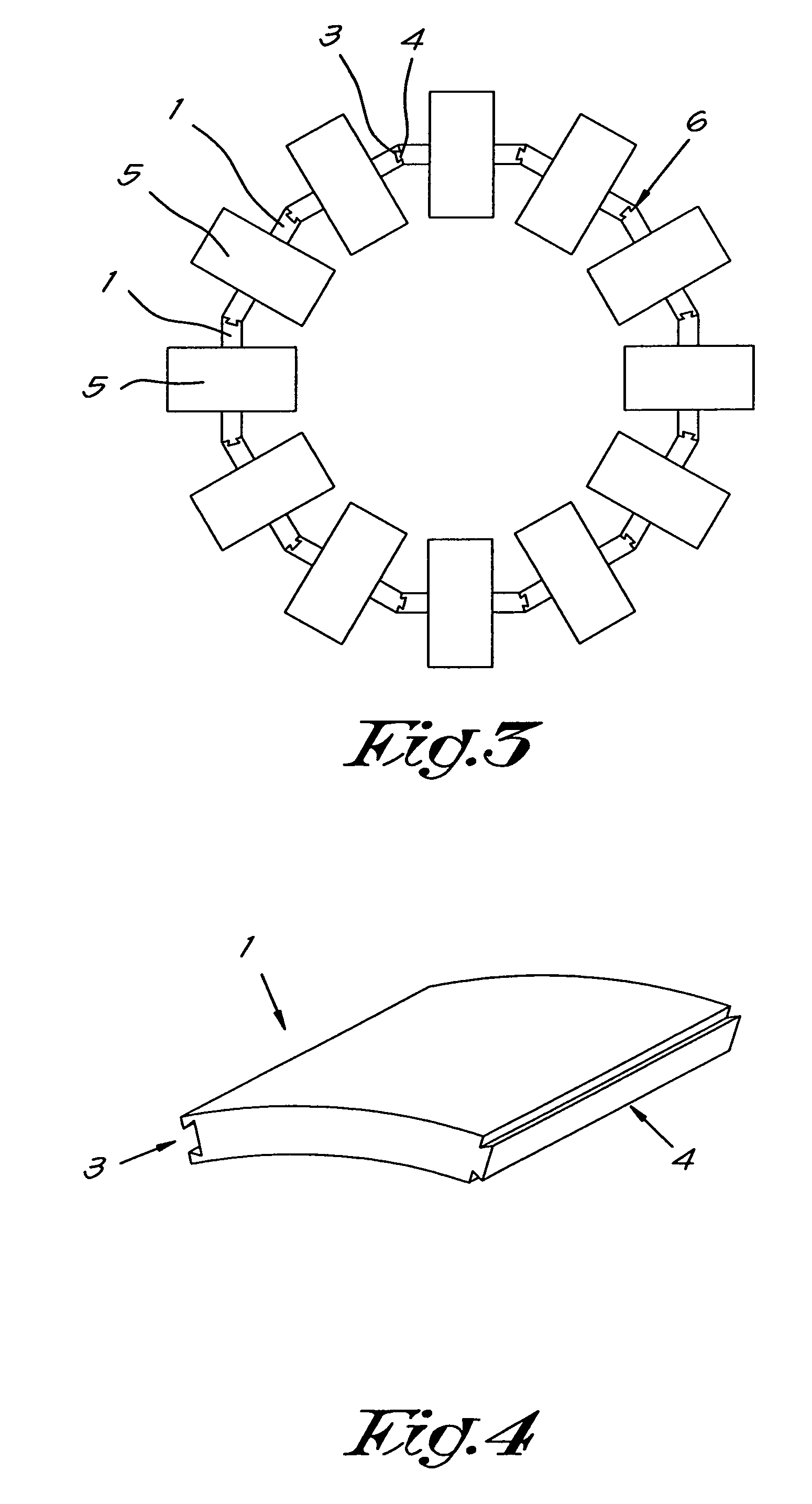

Rotating electric machine

PendingUS20210234415A1Increase first-order lag elementSuppress fluctuationsAssociation with control/drive circuitsMagnetic circuit rotating partsElectrical conductorElectric machine

A rotating electric machine includes a rotor and a stator. The rotor includes a magnet section constituted of permanent magnets. The stator is arranged coaxially with the rotor and includes a stator coil and a stator coil holder. The stator coil is formed of electrical conductors arranged in a circumferential direction of the stator. The stator coil holder is configured to hold the stator coil. In the stator, there are provided inter-conductor members between the electrical conductors in the circumferential direction or no inter-conductor members are provided between the electrical conductors in the circumferential direction. Moreover, the inter-conductor members are formed of a magnetic material satisfying a predetermined relationship or formed of a nonmagnetic material. The stator coil has a coil end part protruding from an axial end of the stator coil holder. A soft-magnetic member is provided on at least part of a surface of the coil end part.

Owner:DENSO CORP

Transformer structure

ActiveUS7142079B2Reduction factorIncrease leakage inductanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinLeakage inductance

Owner:DELTA ELECTRONICS INC

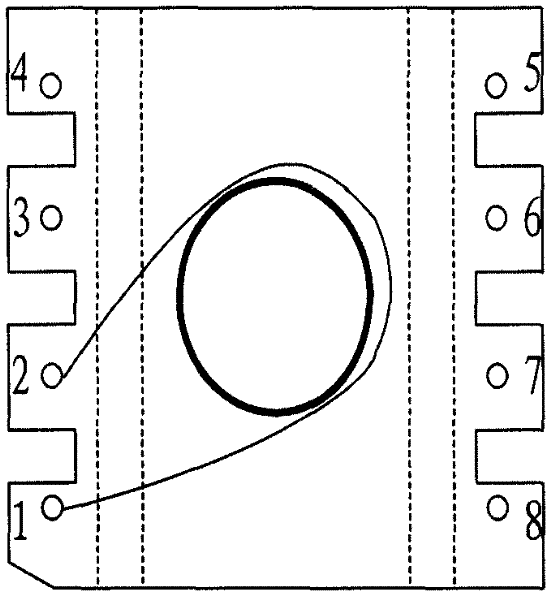

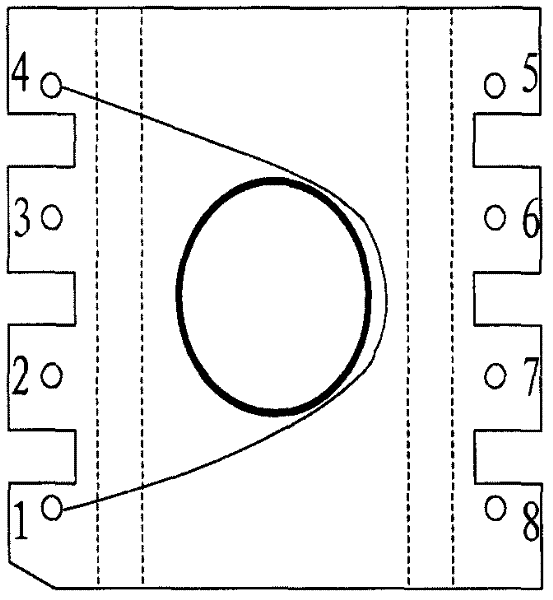

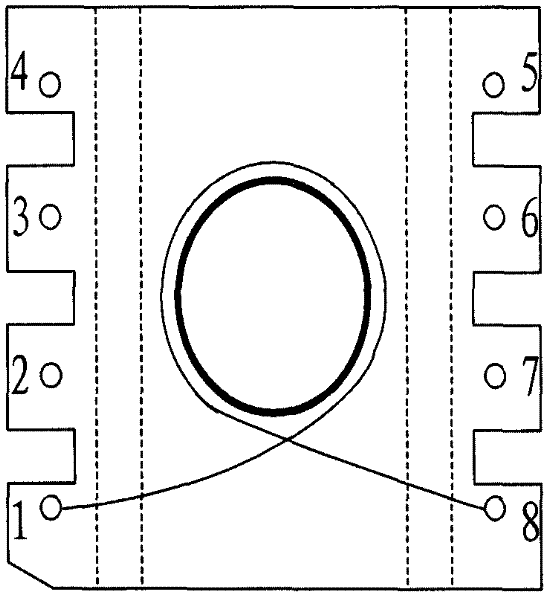

Transformer and winding method of transformer

InactiveCN102403120AImprove cross adjustmentIncrease leakage inductanceTransformers/inductances coils/windings/connectionsCoils manufactureLeakage inductanceConductor Coil

The invention provides a transformer and a winding method of transformer. The theoretical turns ratio of the secondary coil is determined according to the multi-path rated output voltages and the integer number of turns of the secondary coil is determined according to the theoretical turns ratio of the secondary coil, wherein the integer number of turns is the turn ratio of one circle of the transformer skeleton; the number of decimal turns of the secondary coil is adjusted so that the voltage value outputted by each path of the multi-path secondary coils is close to the rated output voltage value; said decimal turns ratio is the number of turns by taking any two different pins as the starting point and the terminal point and winding the transformer skeleton for not more than one circle. The embodiment of the invention provides a designing method of the decimal turns of the transformer to obviously improve the cross adjusting rate of the multi-path output switch powers. The winding process is used via a lead-out pin of the transformer so as to obtain the needed decimal turns. The decimal turns can realize the precise turns ratio and adjust the outputted secondary leakage inductance.

Owner:ANHUI TATFOOK TECH CO LTD

Electric motor having segmented stator windings

A turbocompressor system including a high speed motor (10) including a rotor (12) mounted in a rotative manner relative to the stator, wherein on the rotor (12) one or more impellers (11) are directly fixed, the stator including active motor structures and a shell (7), including a ferromagnetic stator core (6) and a winding being constructed as toroidally wound coils (5), the shell (7) is constructed in such a manner as to create additional open space between the stator core (6) and the shell (7), constituting a cooling channel (15) through which process gas is passed axially for directly cooling the active motor structures and the rotor (12), prior to compression by the one or more impellers (11).

Owner:ATLAS COPCO AIRPOWER NV

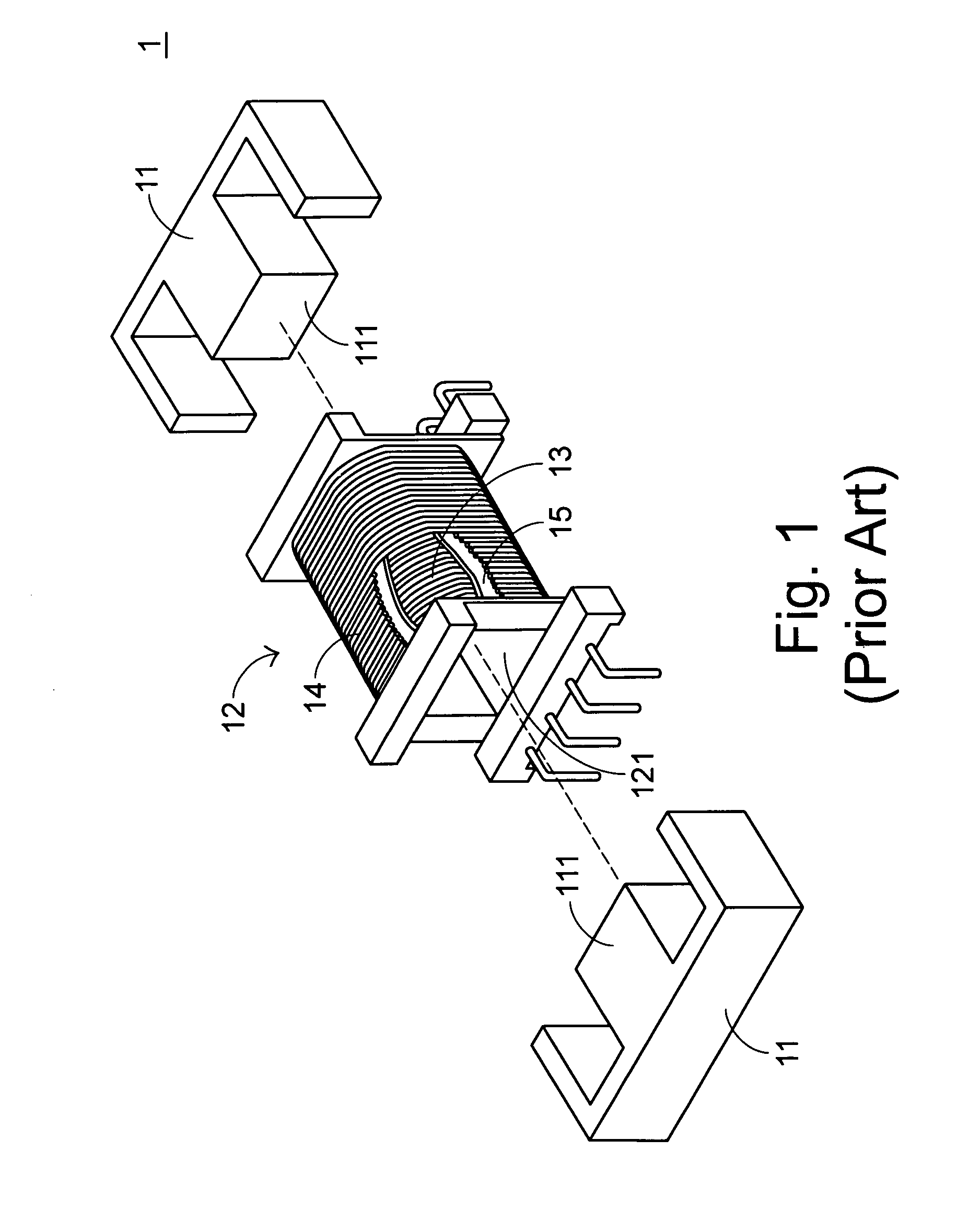

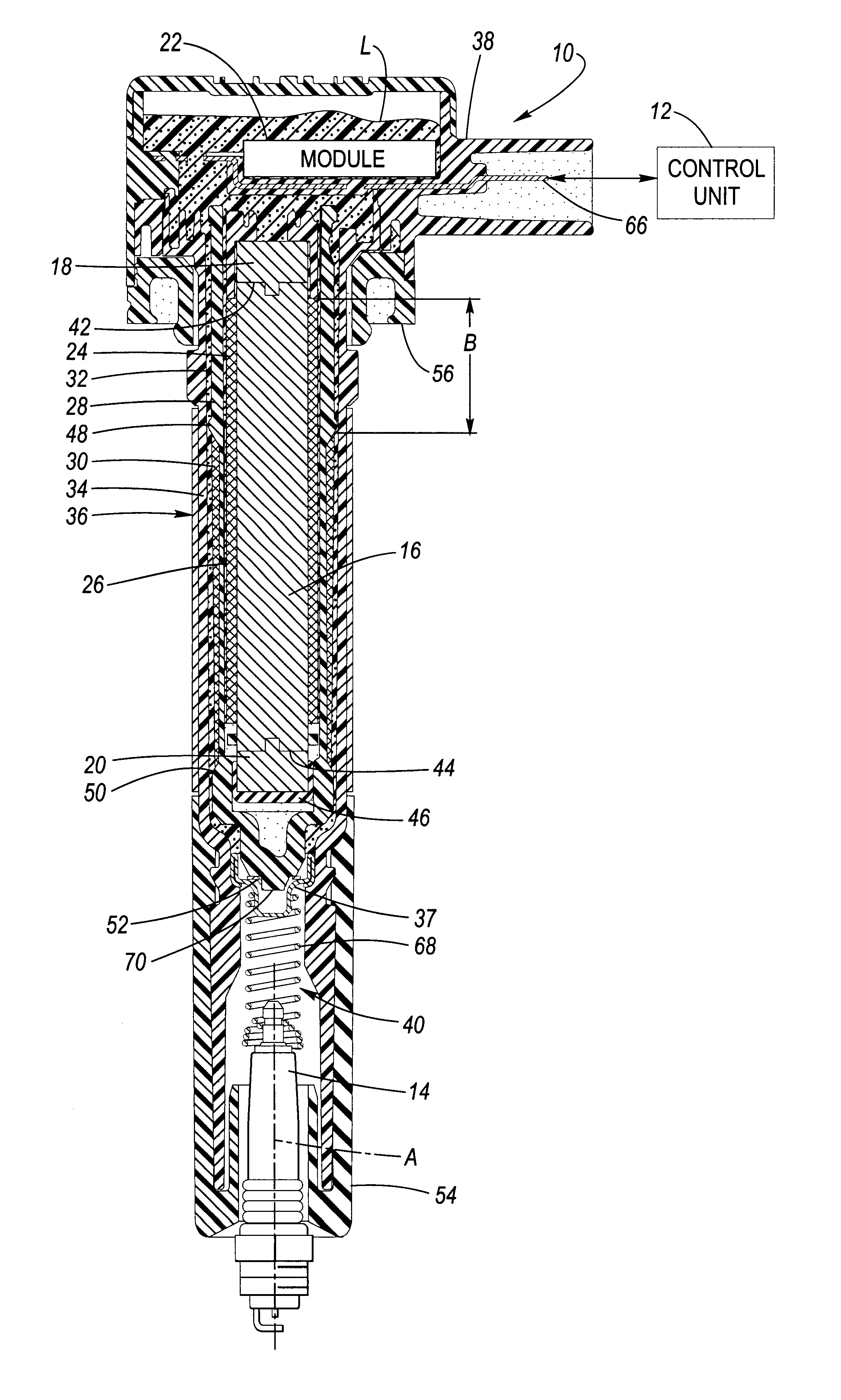

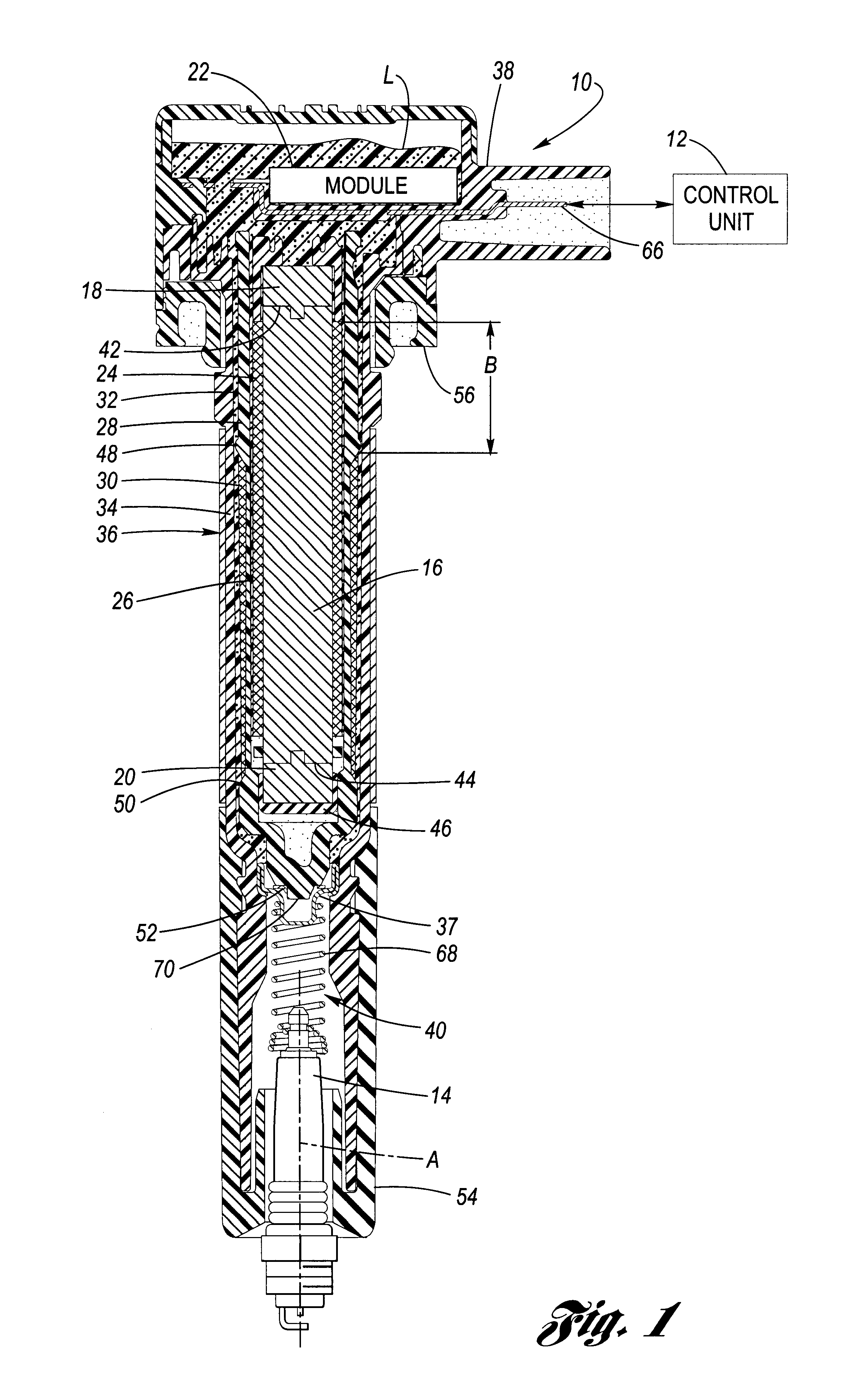

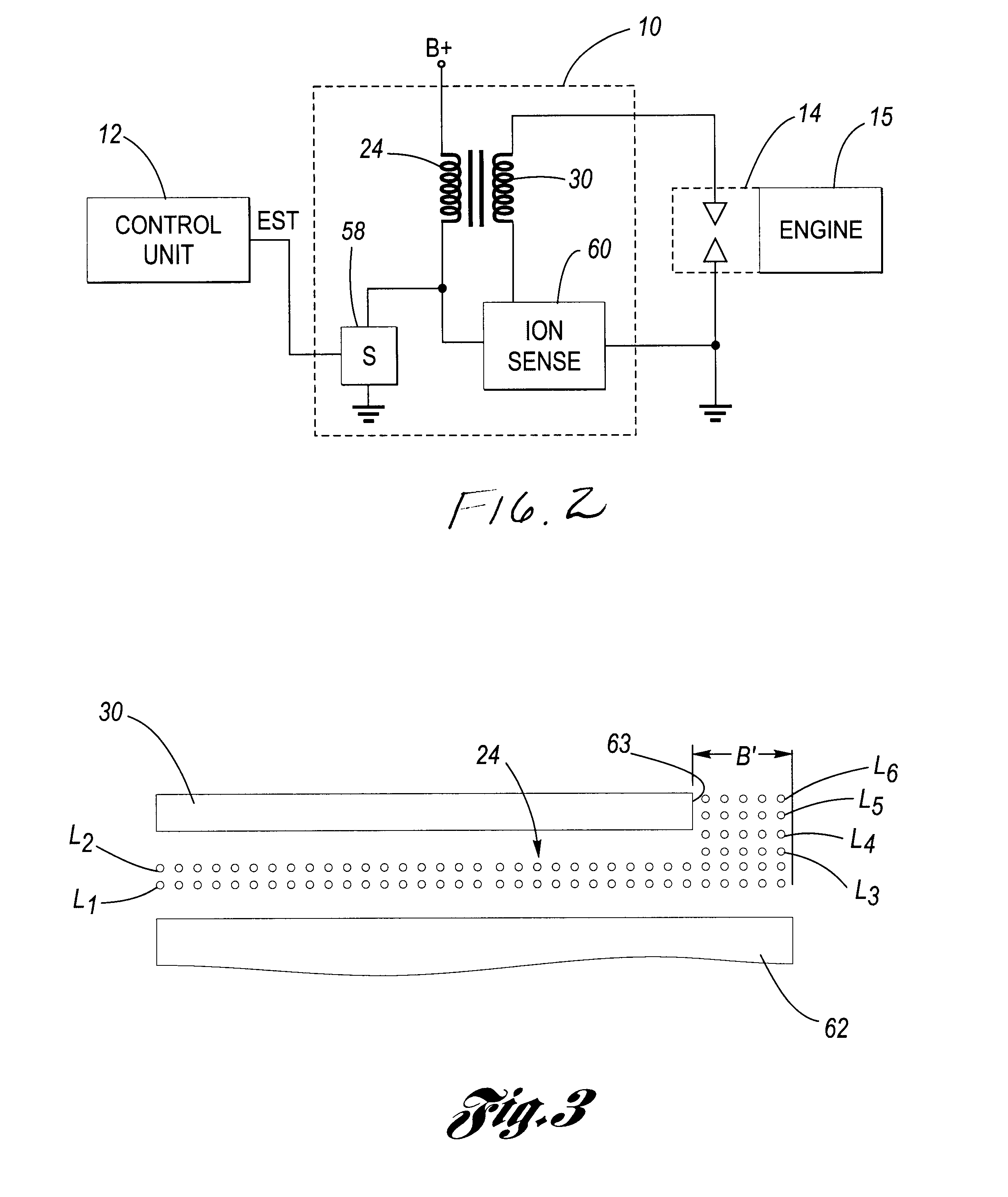

Ignition apparatus having increased leakage to charge ion sense system

InactiveUS6700470B2Reduce couplingIncrease leakage inductanceTransformersTransformers/inductances casingsLow voltageLeakage inductance

An ignition apparatus includes a central core extending along a main axis, and a primary winding disposed radially outwardly thereof. The ignition apparatus further includes a secondary winding. The primary winding has a greater axial length than the secondary winding, this additional axial length being implemented on the low-voltage axial end of the ignition apparatus, relative to the main axis. The extended primary winding provides an increased leakage inductance spike, which may be used by an ion sense system to (i) obtain increased bias voltages, and, (ii) increase the effective turns ratio, thereby reducing the amount of wire required for the secondary winding.

Owner:DELPHI TECH INC

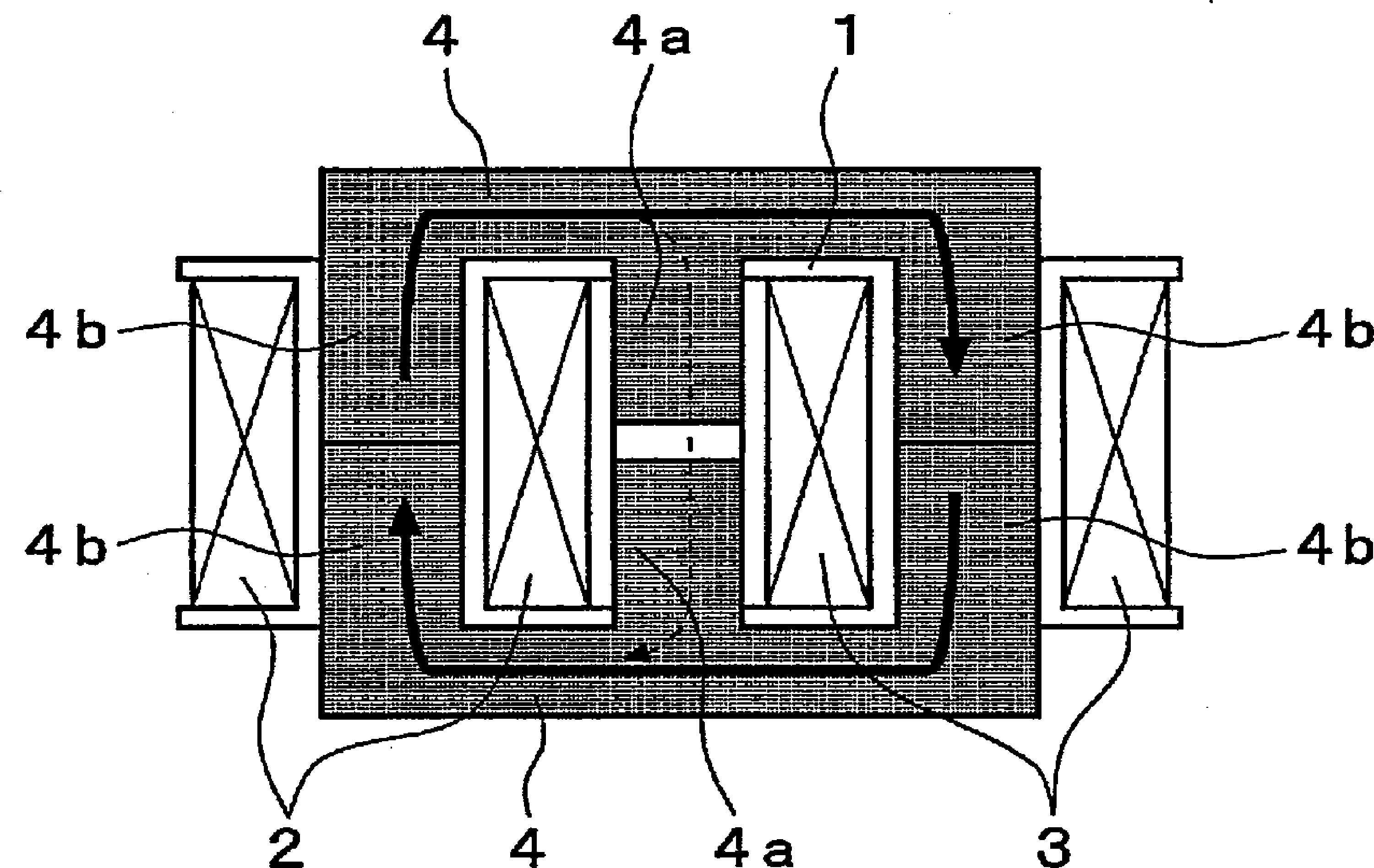

Transformer

InactiveCN104115243AIncrease leakage inductancePursuing miniaturization and thinningTransformersTransformers/inductances coils/windings/connectionsTransformerEngineering

Provided is a transformer for which leak inductance can be adjusted as desired and machining is simple, it being possible to significantly reduce the size of the transformer. A transformer provided with a primary coil (10), a secondary coil (12), and a core (14) forming a ring-shaped closed magnetic circuit by being disposed between the primary coil and the secondary coil, wherein a magnetic body (15) having a sectional area smaller than the sectional area of the core is disposed between the primary coil (10) and the secondary coil (12) such that a shortcut in the ring-shaped closed magnetic circuit is formed across a gap between both ends of the magnetic body (15) and the core.

Owner:FDK CORP

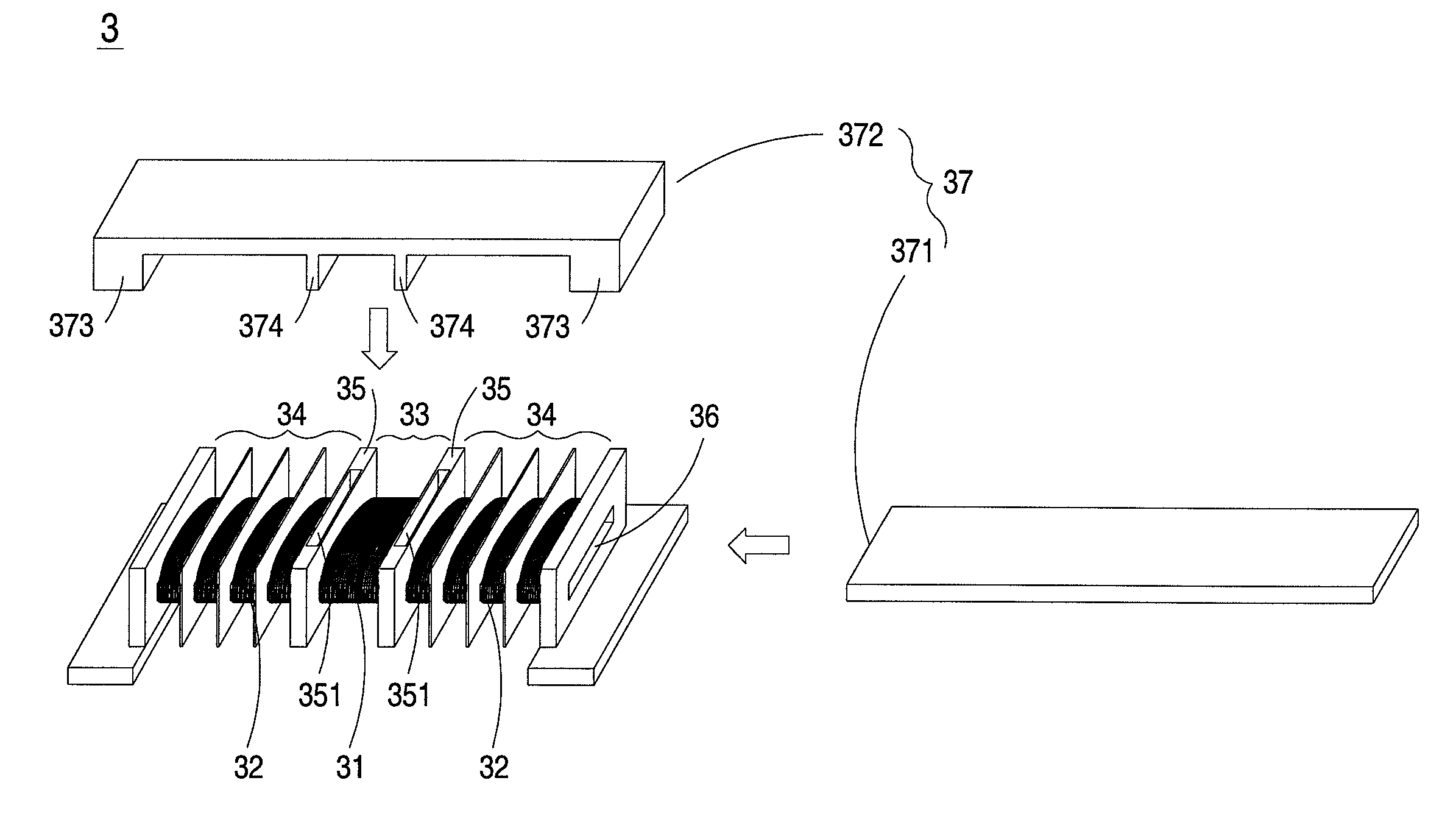

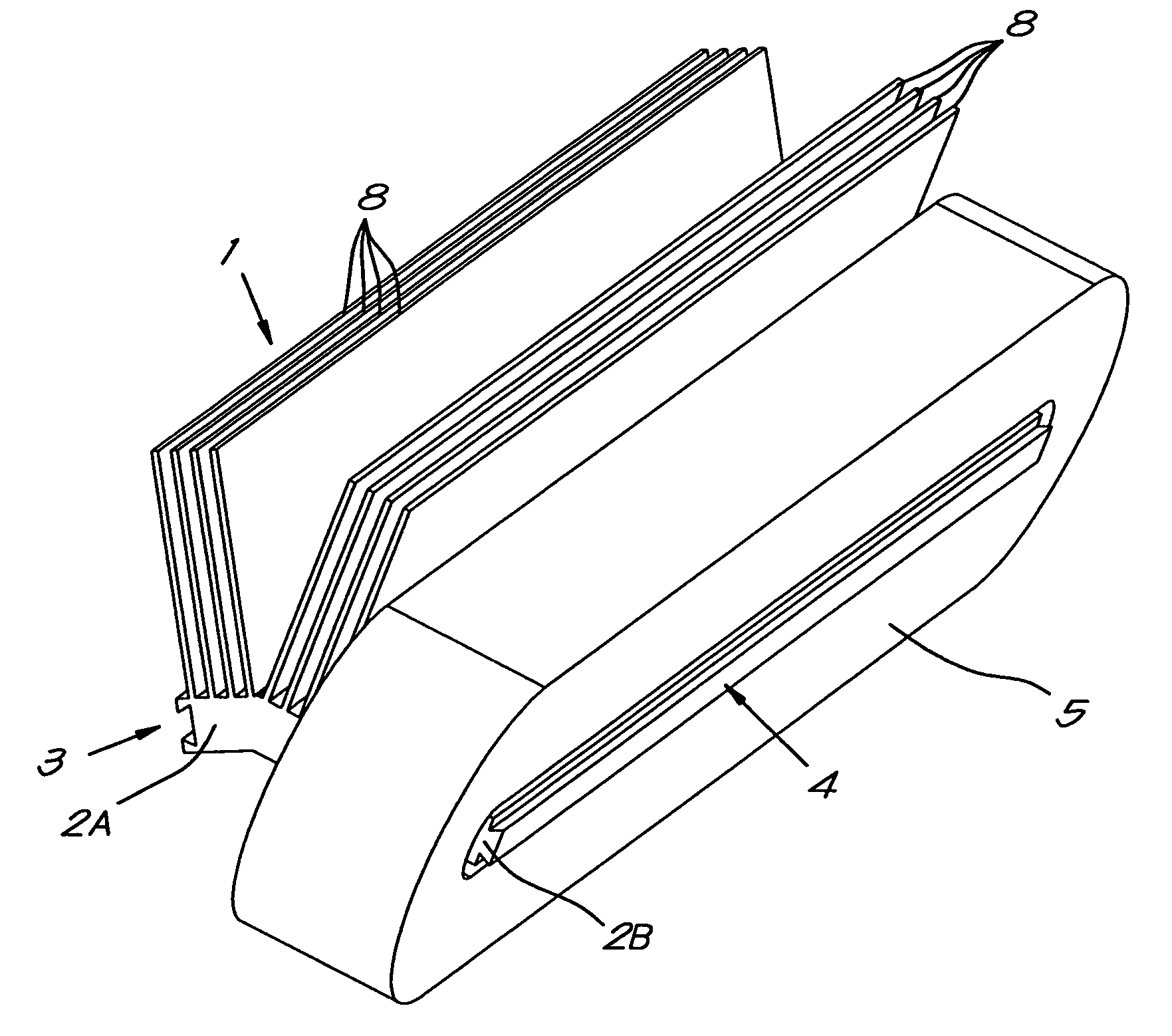

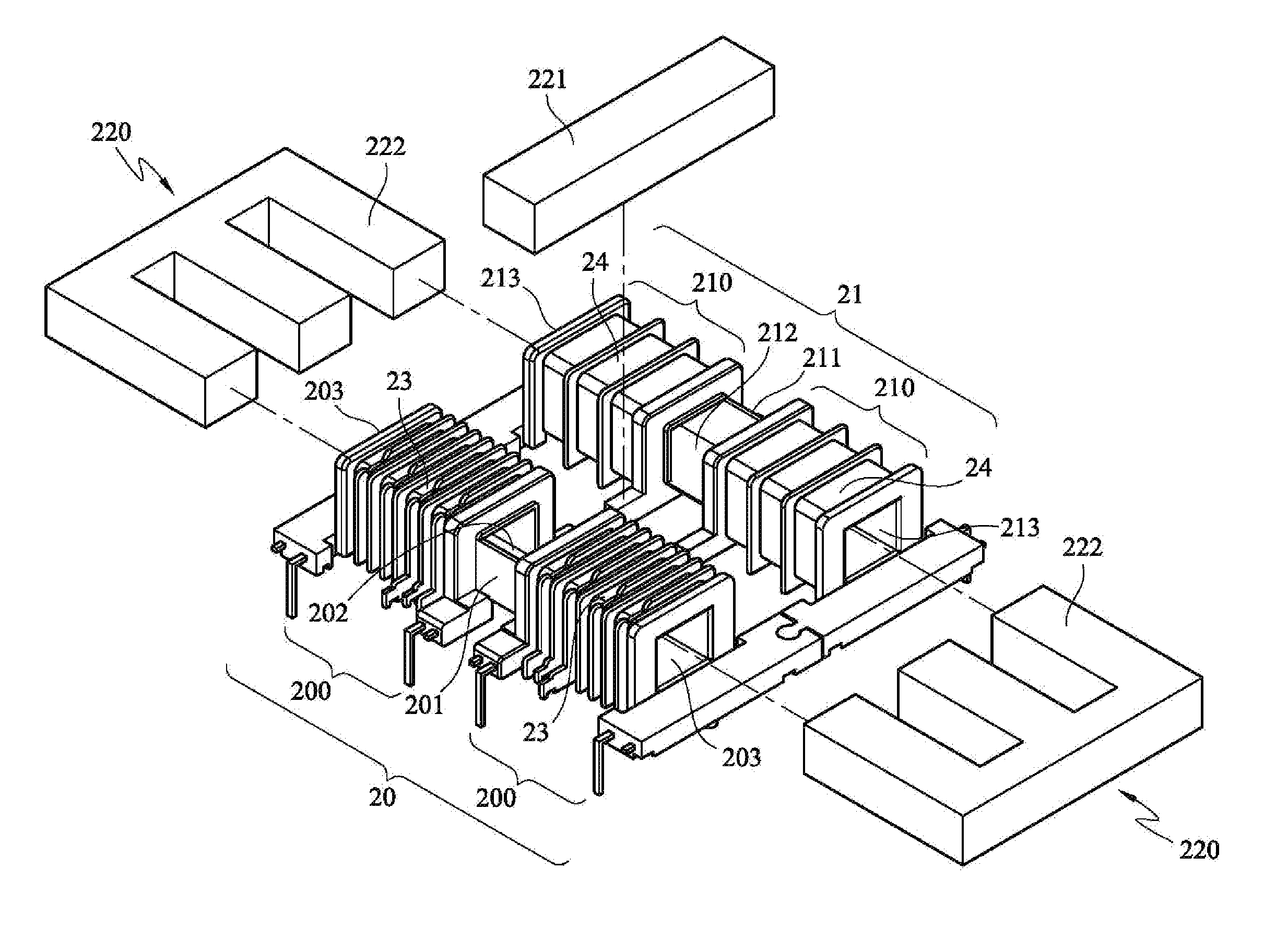

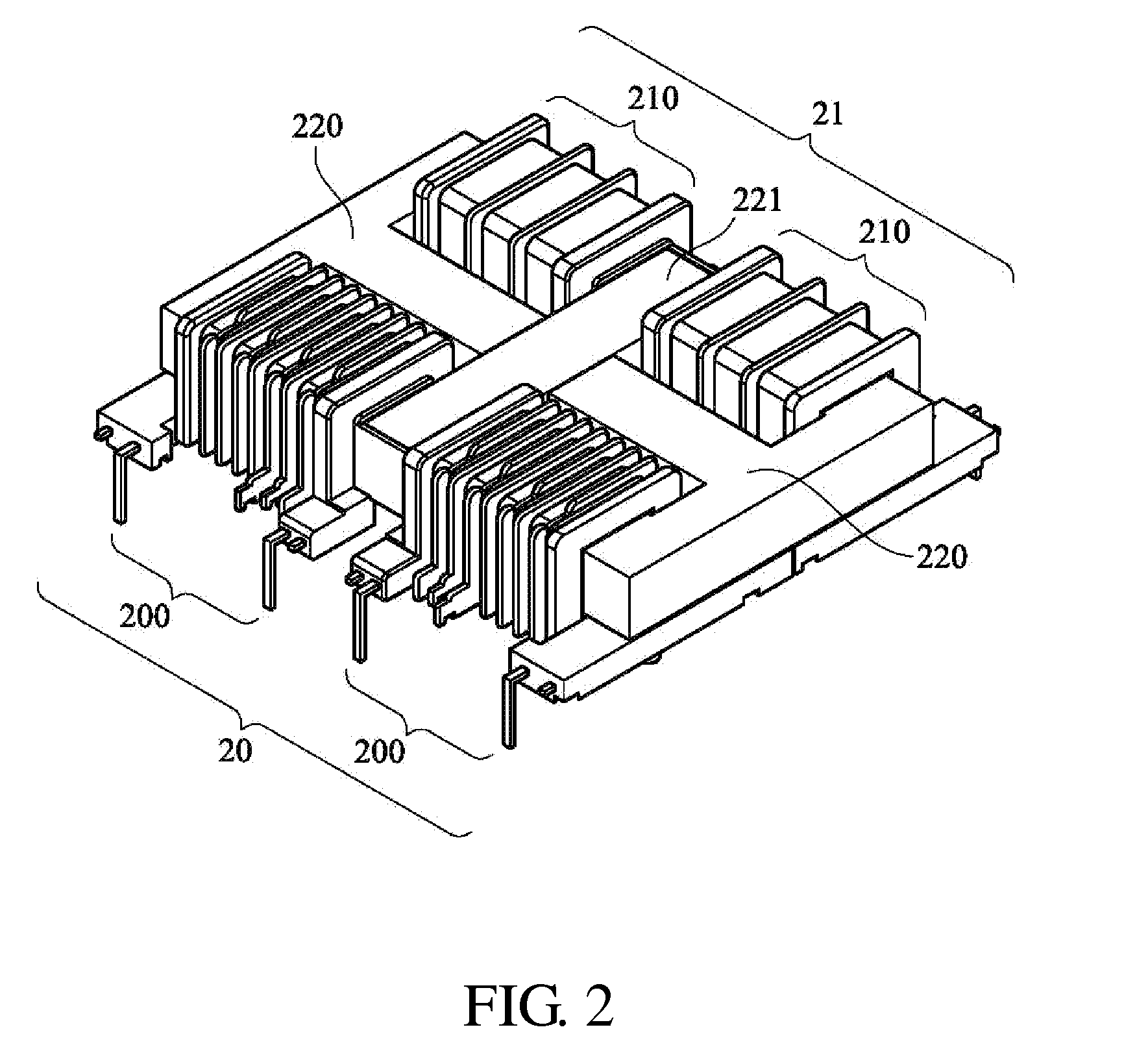

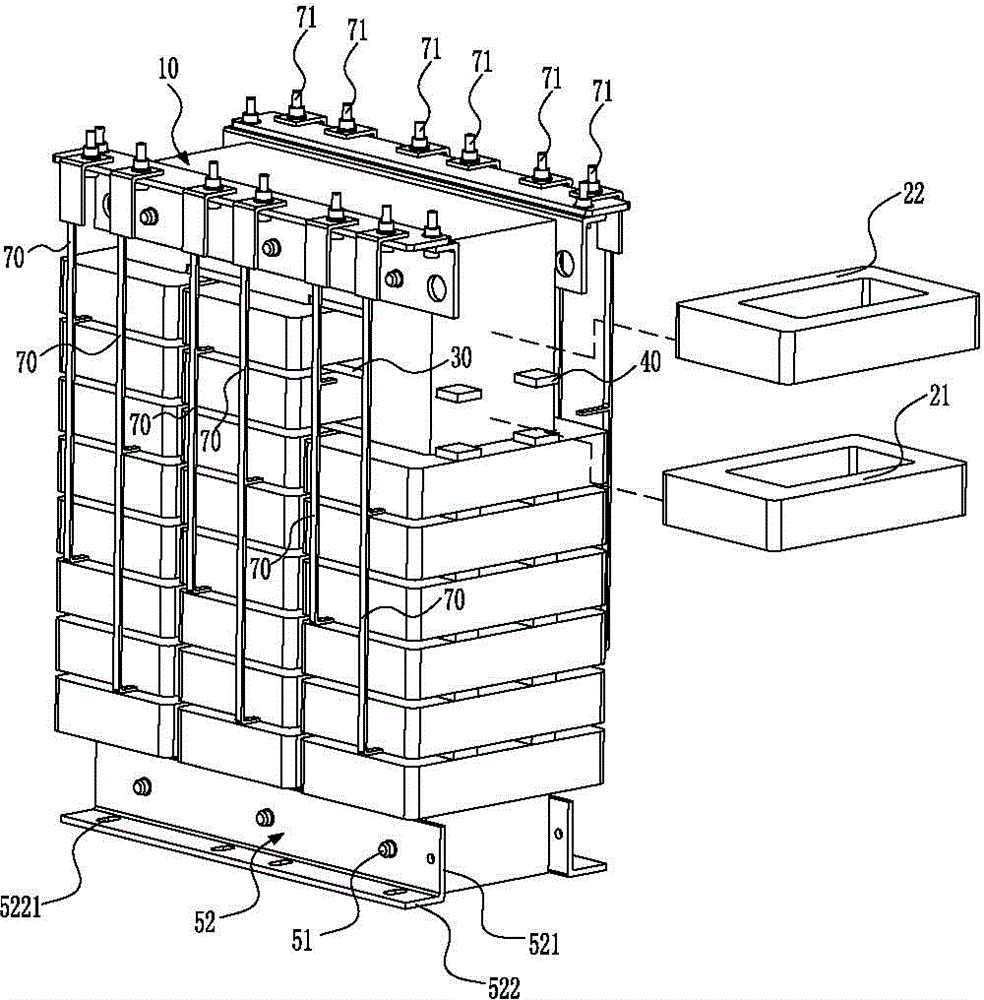

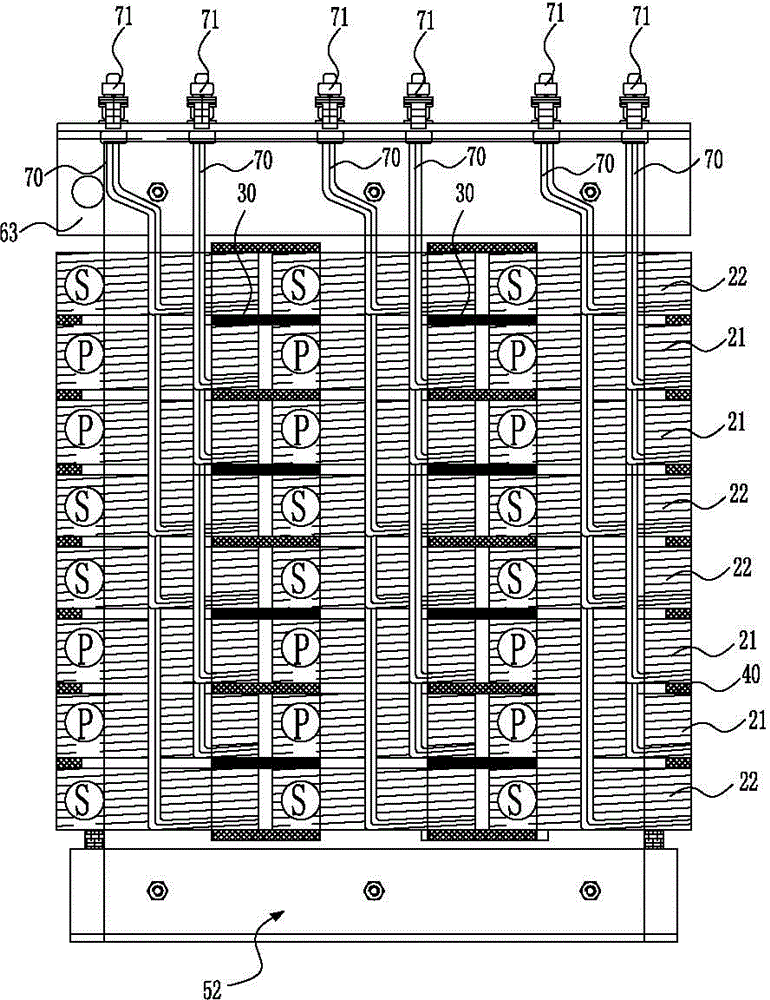

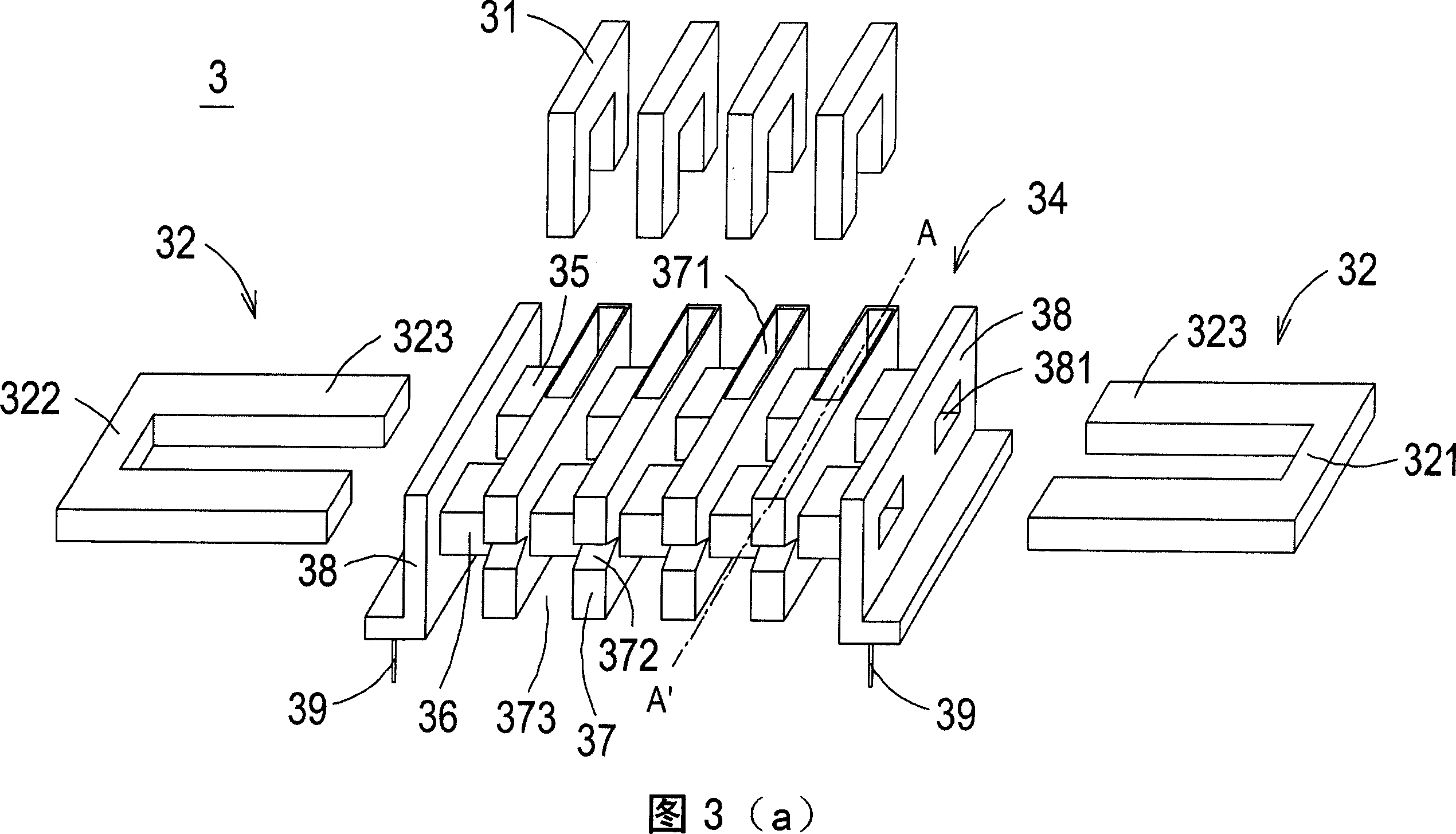

Transformer Structure

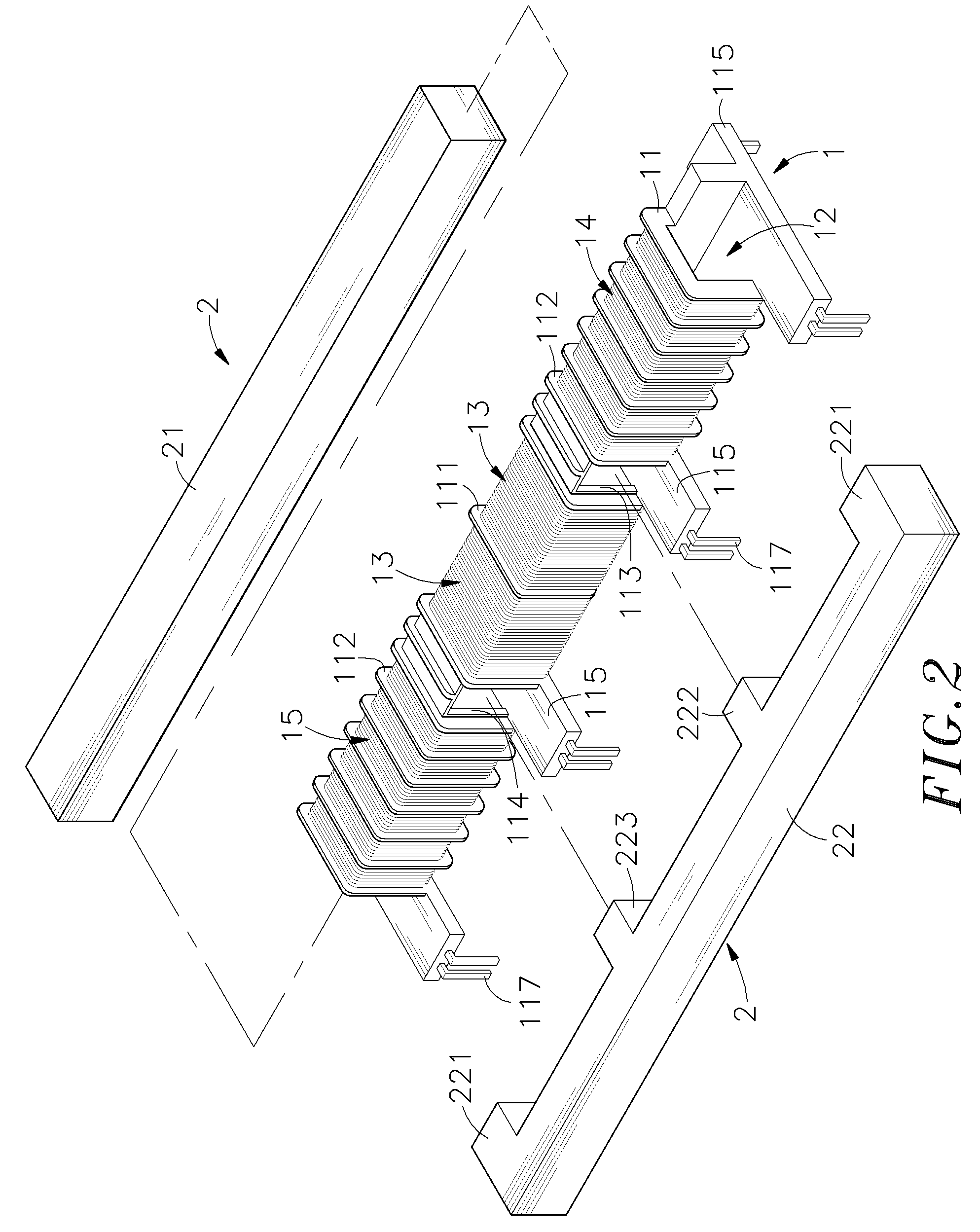

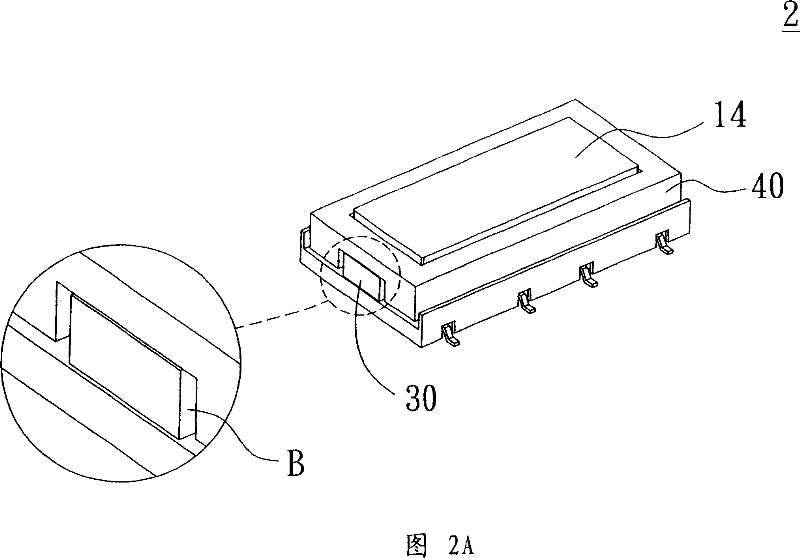

InactiveUS20090066459A1Increase leakage inductanceFulfil requirementsTransformersTransformers/inductances coils/windings/connectionsTransformerConductor Coil

A transformer structure is provided. The transformer structure comprises at least one first winding frame, at least one second winding frame, a plurality of primary coil assemblies which are wound around the at least one first winding frame, a plurality of secondary coil assemblies which are wound around the at least one secondary winding frame, and an iron core assembly which is placed in the jacks of the at least one first winding frame and the at least one second winding frame. The at least one first winding frame has a plurality of primary coil areas, around which the primary coil assemblies are wound. The at least one second winding frame has a plurality of secondary coil areas, around which the secondary coil assemblies are wound.

Owner:DELTA ELECTRONICS INC

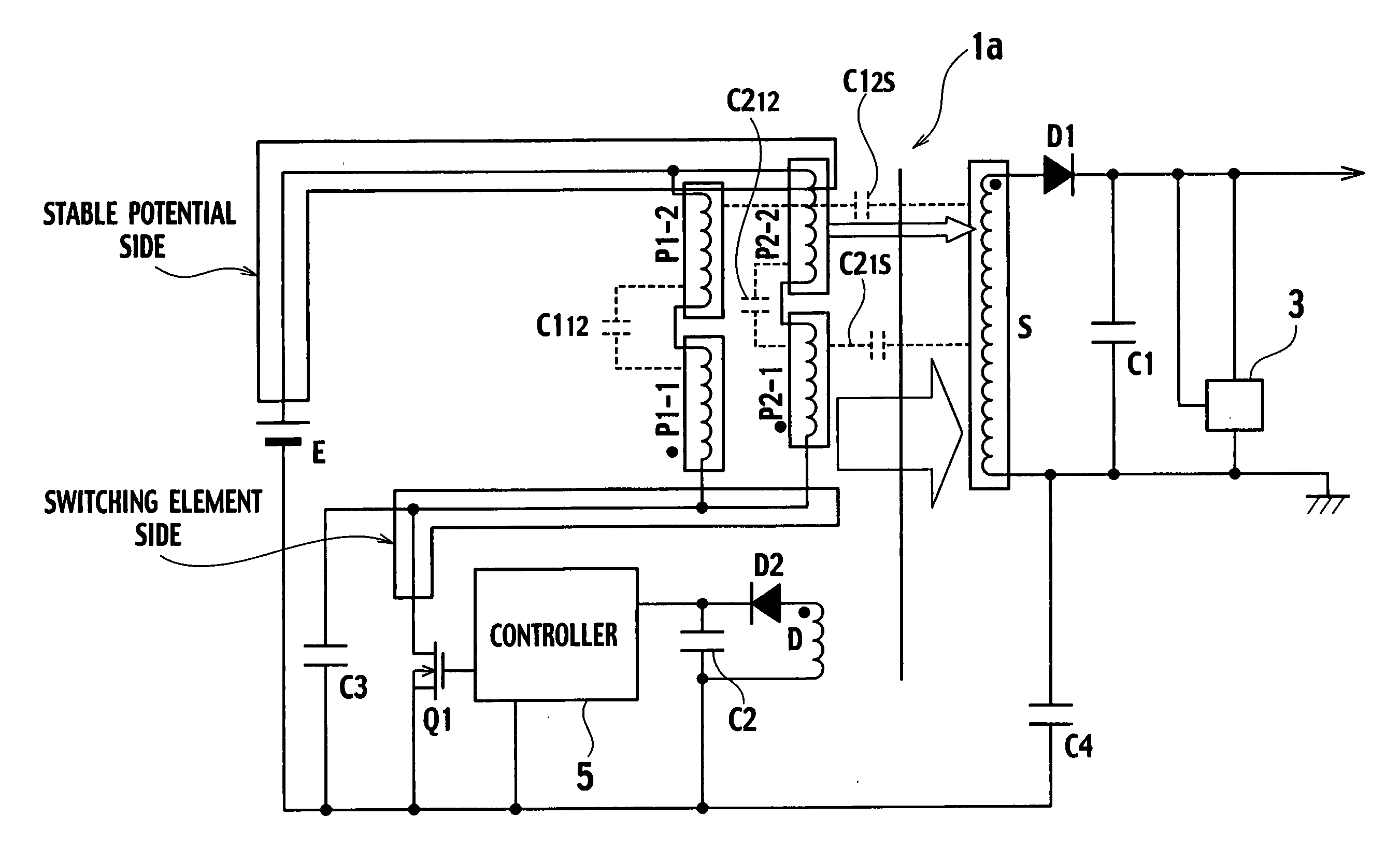

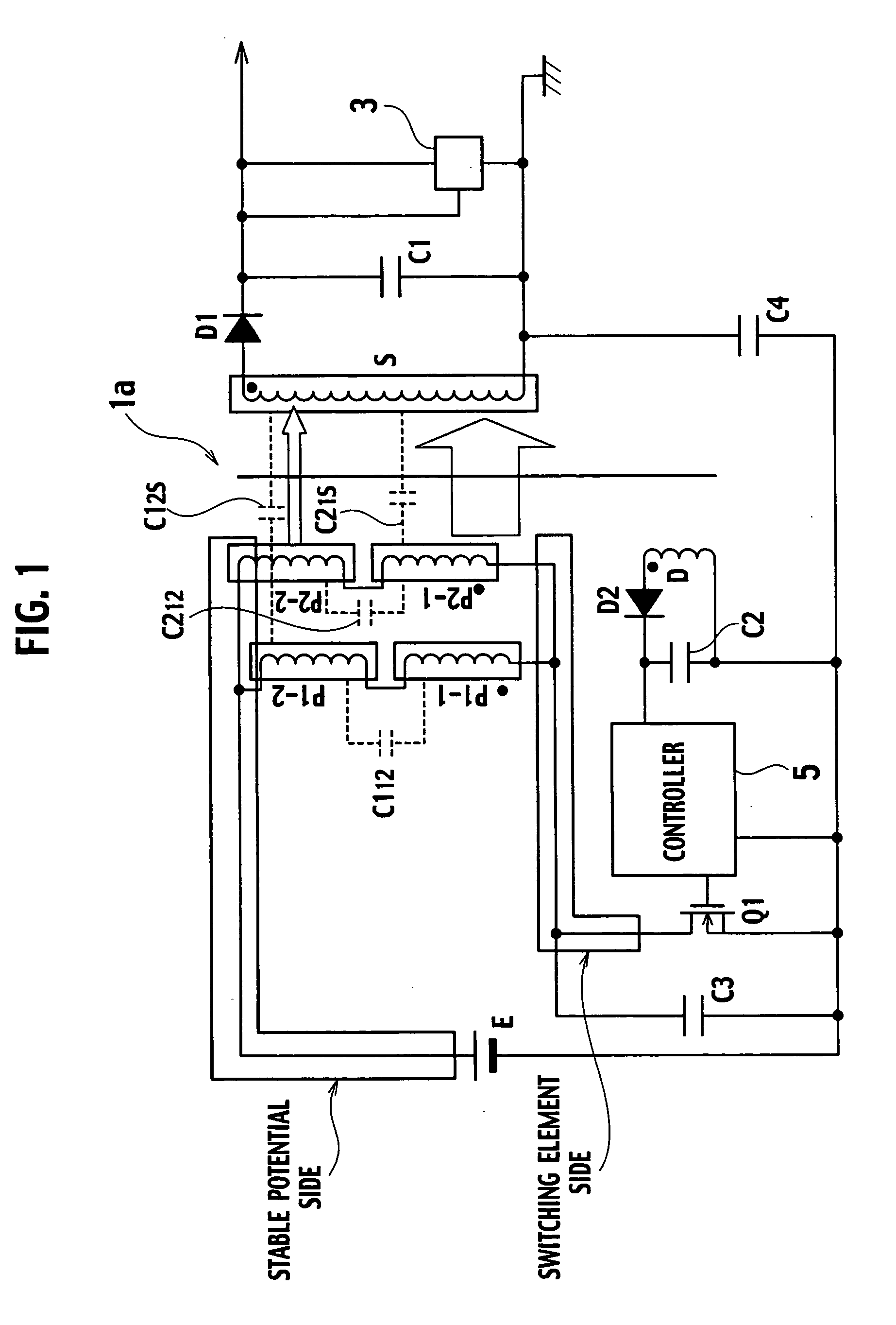

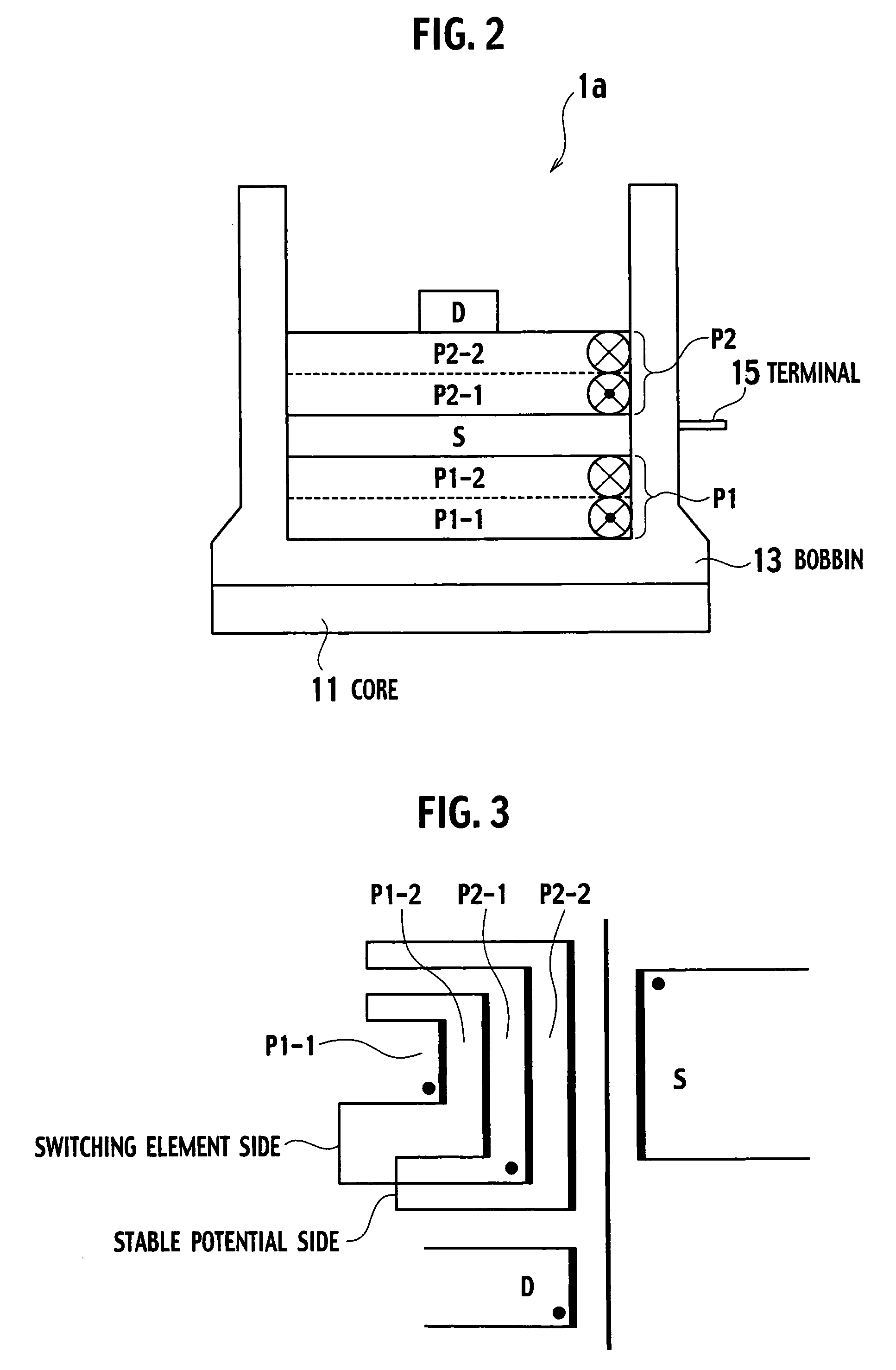

DC power source apparatus

ActiveUS20060044844A1Reduce parasitic capacitanceComplex structureTransformersDc-dc conversionHigh frequency powerTransformer

A DC power source apparatus has a DC power source for supplying a DC voltage, a transformer, and a switching element connected to a primary winding of the transformer. The switching element carries out ON / OFF operations to convert the DC voltage from the DC power source into high-frequency power, which is transferred to a secondary winding of the transformer and is converted into a DC output voltage. The primary winding of the transformer consists of a first primary winding made of a plurality of winding layers and a second primary winding made of a plurality of winding layers. The first and second primary windings are connected in parallel. The first primary winding is arranged on an inner side of the secondary winding, and the second primary winding is arranged on an outer side of the secondary winding. A terminal of a winding layer farthest from the secondary winding among the winding layers of each of the first and second primary windings is connected to the switching element.

Owner:SANKEN ELECTRIC CO LTD

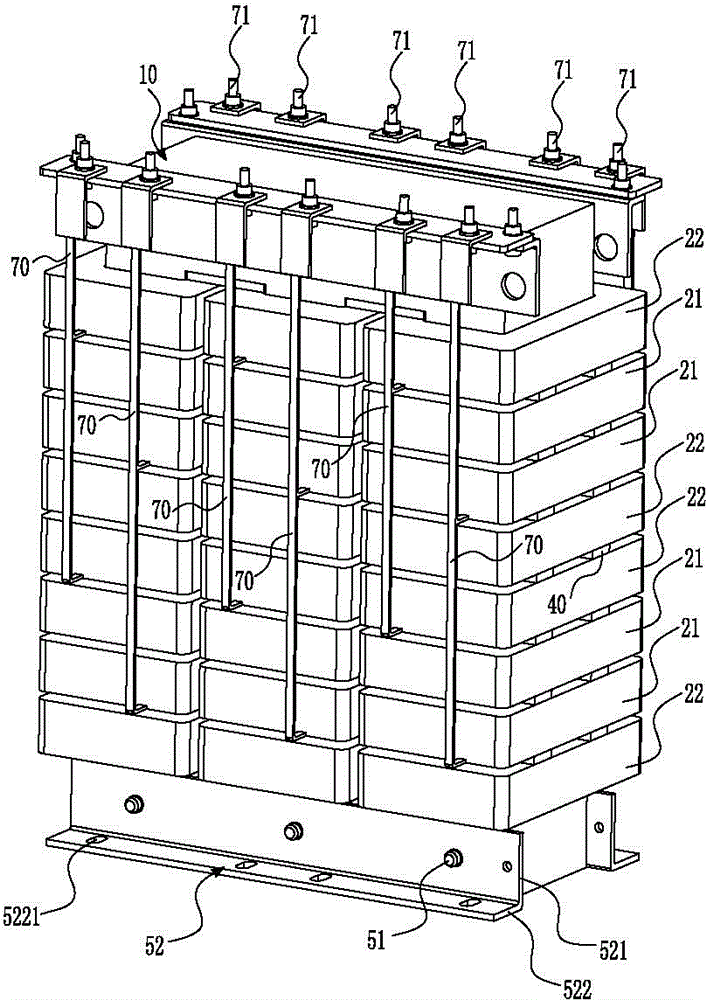

Pancake coil wound three-phase transformer

InactiveCN102982979AEasy to ventilate and dissipate heatSmall diameterTransformers/inductances coils/windings/connectionsFixed transformersLeakage inductanceEngineering

The invention discloses a pancake coil wound three-phase transformer, which comprises an iron core and windings, wherein each winding comprises a primary winding and a secondary winding; the primary winding of each winding comprises a plurality of pancake primary coils; the secondary winding of each winding comprises a plurality of pancake secondary coils which are the same as the pancake primary coils of each winding in number; each single pancake secondary coil of each winding is adjacent to the corresponding single pancake primary coil to form a branch winding; and the pancake primary coils of the branch windings of each winding are adjacent to one another. The pancake coils are superposed, a clearance is formed between each two adjacent pancake coils, and a magnetic leakage sheet is clamped between the pancake secondary coil and the pancake primary coil of each branch winding. Therefore, the pancake coil of the pancake coil wound three-phase transformer has the characteristics of small intermediate diameter, material conservation and the like, effectively improves electric density, shortens the whole volume, and has good ventilation and heat dissipation performance; and furthermore, the leakage inductance is adjusted by the magnetic leakage sheet, so that the process is convenient to operate and easy to control and a relatively large leakage inductance is obtained by a relatively small magnetic branch.

Owner:DONGGUAN GUANGHUA IND

Transformer structure

ActiveCN101022054AIncrease leakage inductanceIncrease distanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLeakage inductanceCore set

This invention relates to a transformer structure including: a primary winding, a secondary winding, a first winding part for winding the primary winding, a second winding part for winding the secondary winding, a spacing board set between the two winding parts and having a holding part, a through part passing through the first, the second parts and the spacing board, a iron core set including type-1 core and type-U core, multiple projection parts are set between two sides of type-U core, part of the 1-type core is set in the through part, the projection parts are plugged in the holding part of the spacing board to regulate the leakage inductance by the distance between the projection part and the 1-type core plugged in the through part.

Owner:DELTA ELECTRONICS INC

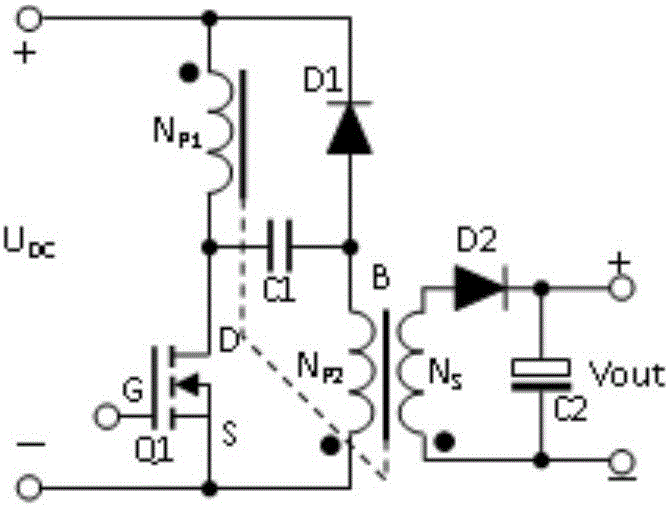

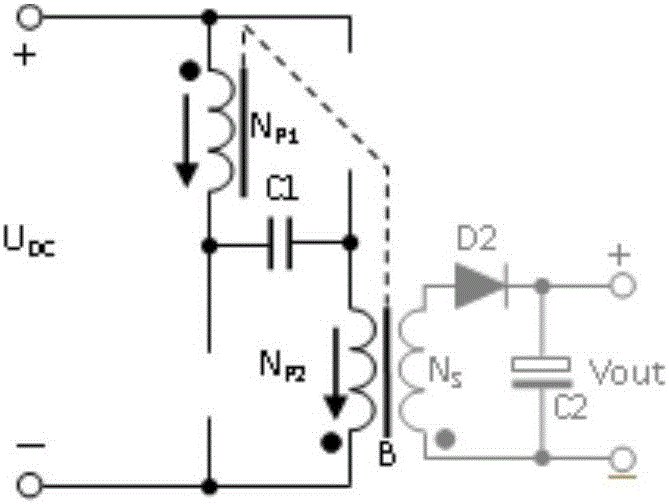

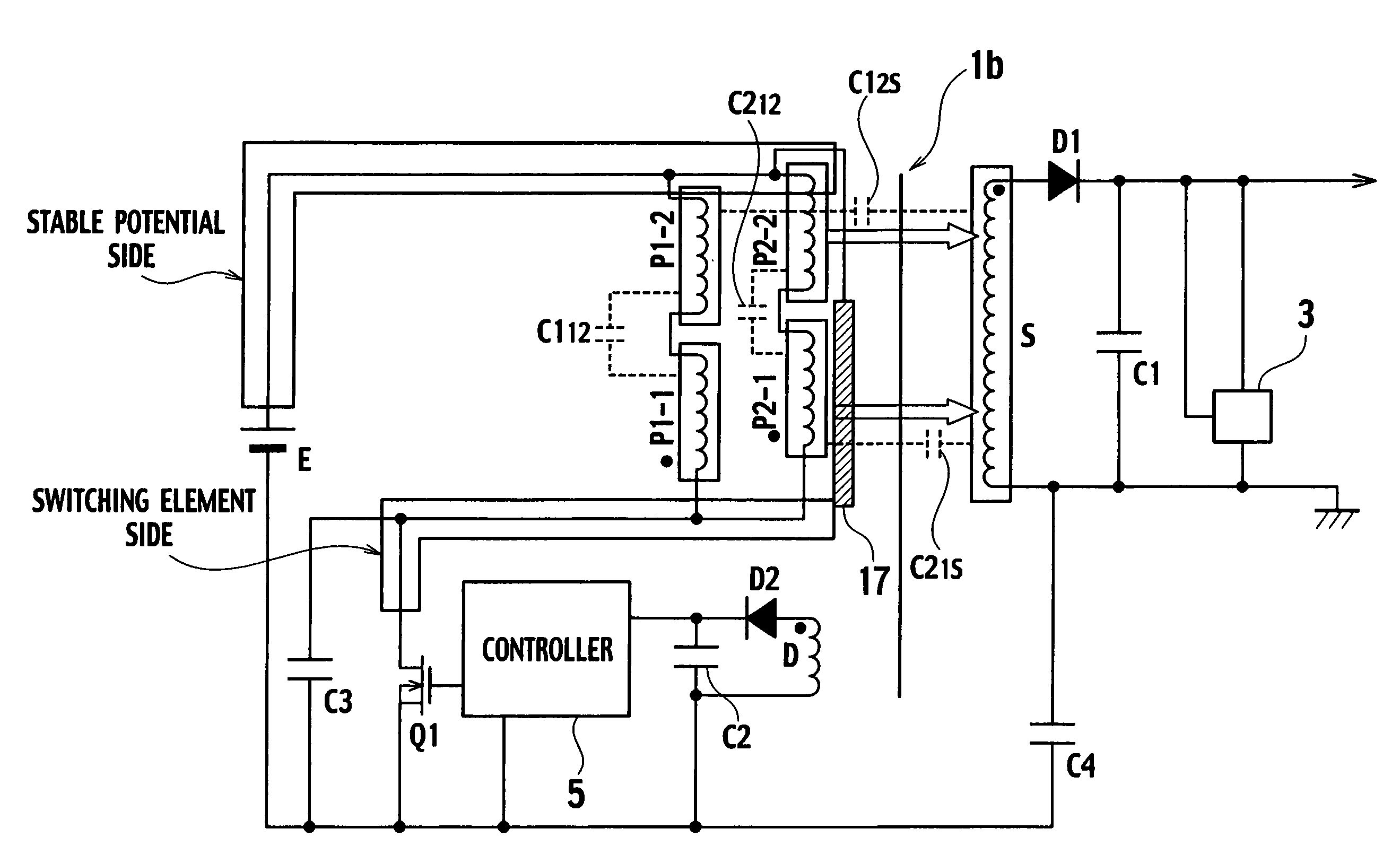

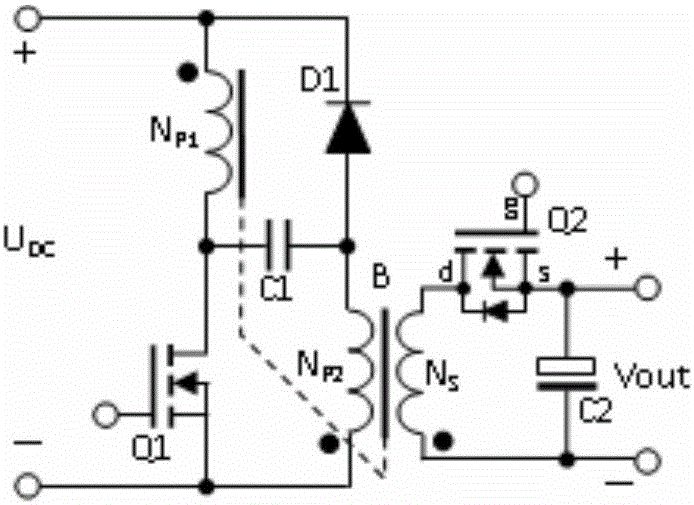

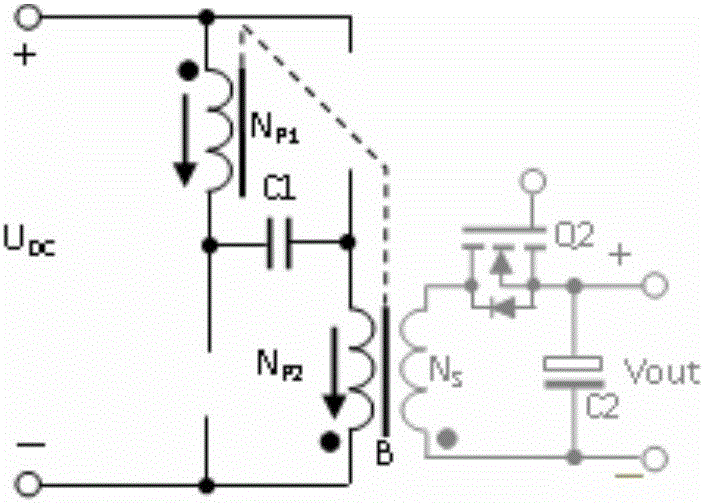

Fly-back type switching power supply

ActiveCN106849670AIncrease leakage inductanceImprove conversion efficiencyDc-dc conversionElectric variable regulationPower flowLow voltage

The invention provides a fly-back type switching power supply. On the basis of a common three-winding absorption fly-back type switching power supply, an NP1 dotted terminal in a transformer B is connected with the power supply; an NP2 dotted terminal of a secondary primary edge winding is grounded; an NP1 and an NP2 are bifilar windings and a capacitor C1 is increased; one end of the C1 is connected with an NP1 heteronymous terminal and the other end of the C1 is connected with an NP2 heteronymous terminal; a secondary edge adopts a Q2 of an opposite connection method to the prior art and is controlled by PWM (Pulse-Width Modulation) signal controlled by the other path of output voltage, so that when Q1 is conducted, the NP1 and the NP2 are excited and energy is abundant; when the Q1 is switched off, a secondary edge NS realizes rectification output voltage through the Q2 according to requirements on an output load, and lossless absorption of leakage inductance and surplus energy is realized by the NP2 through a D1, so that the fly-back type switching power supply is suitable for working under low voltage, the utilization rate and current density of the primary edge winding are improved and the power density is great; the leakage inductance between the primary edge and the secondary edge is allowable to be relatively great and the conversion efficiency is high; EMI (Electromagnetic Interference) is great; the bandwidth of the power supply is very wide and loop response is good.

Owner:MORNSUN GUANGZHOU SCI & TECH

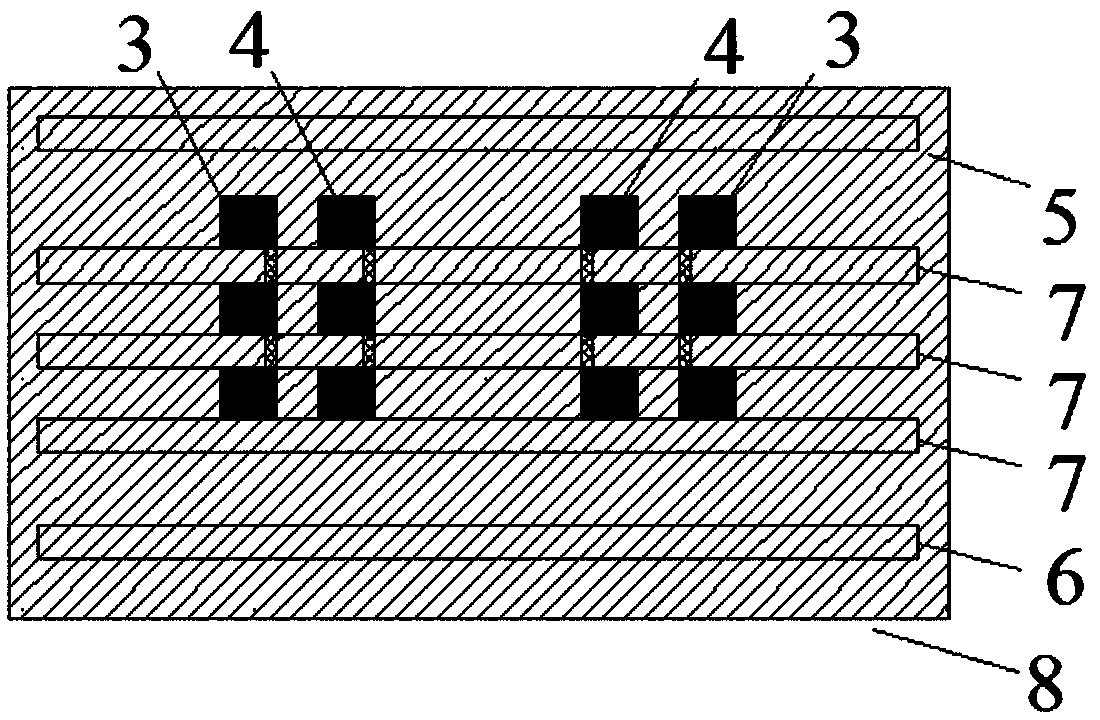

LTCC-based planar transformer and manufacturing method thereof

InactiveCN109545532AIncrease fluxGood inductance and other electrical propertiesInductances/transformers/magnets manufactureFixed transformersEngineeringLeakage inductance

The invention discloses a LTCC-based planar transformer and a manufacturing method thereof. The method comprises the following steps: S1, preparing an upper substrate, a lower substrate and a plurality of middle substrates, which all employ an LTCC (Low Temperature Co-Fired Ceramic) material raw ceramic chip with the first magnetic conductivity; S2, forming a hole in at least one middle substrate;S3, manufacturing primary and secondary electrode patterns on the plurality of middle substrates, and performing the filling of the holes to form a plurality of electrode layers; S4, putting an LTCCmaterial with second magnetic conductivity in areas where the primary electrodes and the secondary electrodes of the plurality of electrode layers are mutually inducted and overlapped to form a plurality of filling electrode layers, wherein the second magnetic conductivity is greater than the first magnetic conductivity; S5, laminating the plurality of filling electrode layers, the upper substrateand the lower substrate, and carrying out glue discharging and sintering to form the LTCC planar transformer, in which the LTCC material with the first magnetic conductivity and the LTCC material with the second magnetic conductivity are co-fired and then tightly combined to form an intermediate magnetic conductivity material with the magnetic conductivity being between the first magnetic conductivity and the second magnetic conductivity. The coupling coefficient of a planar transformer can be effectively improved, and the primary leakage inductance and the secondary leakage inductance of theplanar transformer are reduced.

Owner:SHENZHEN SUNLORD ELECTRONICS

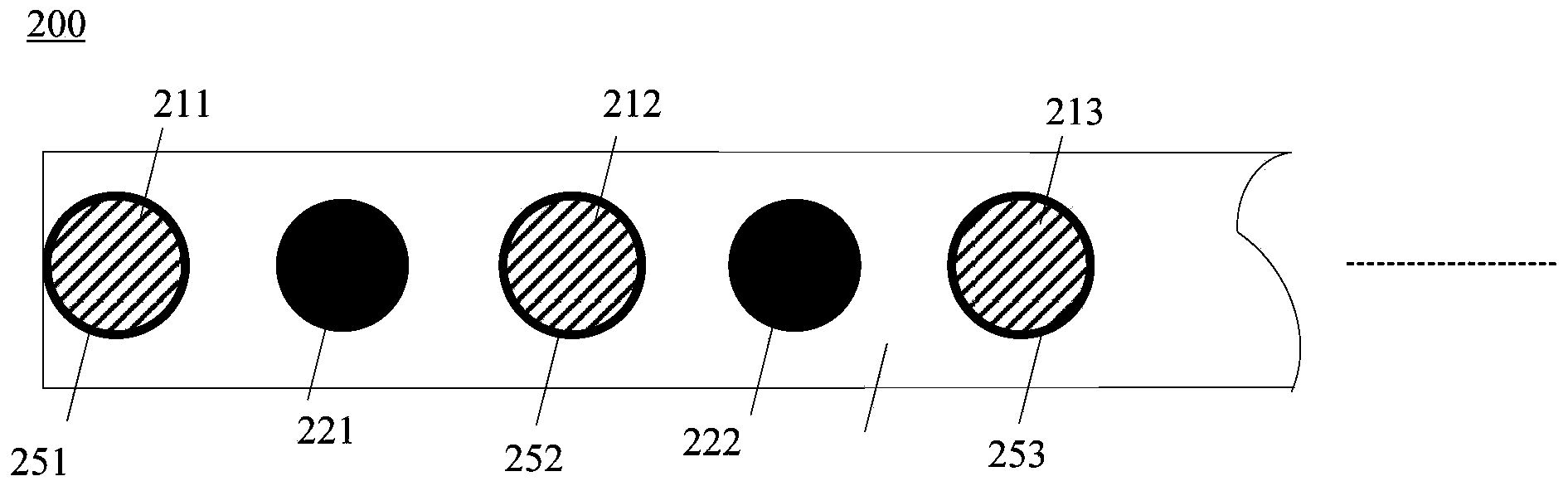

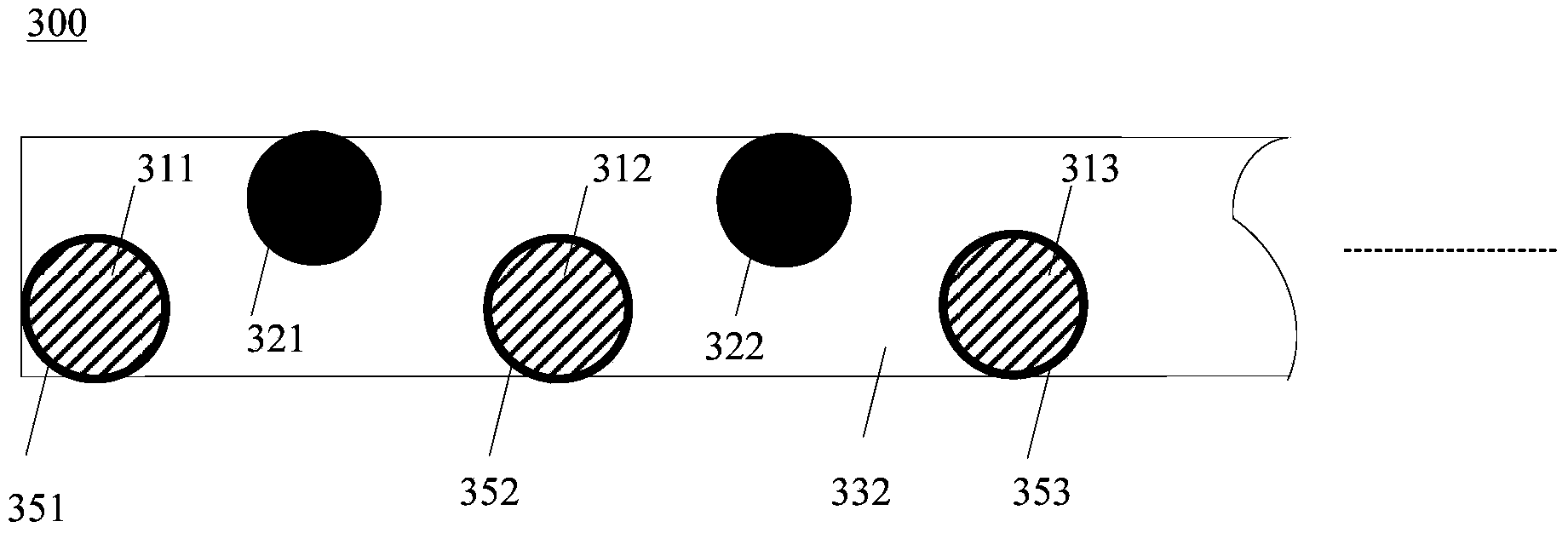

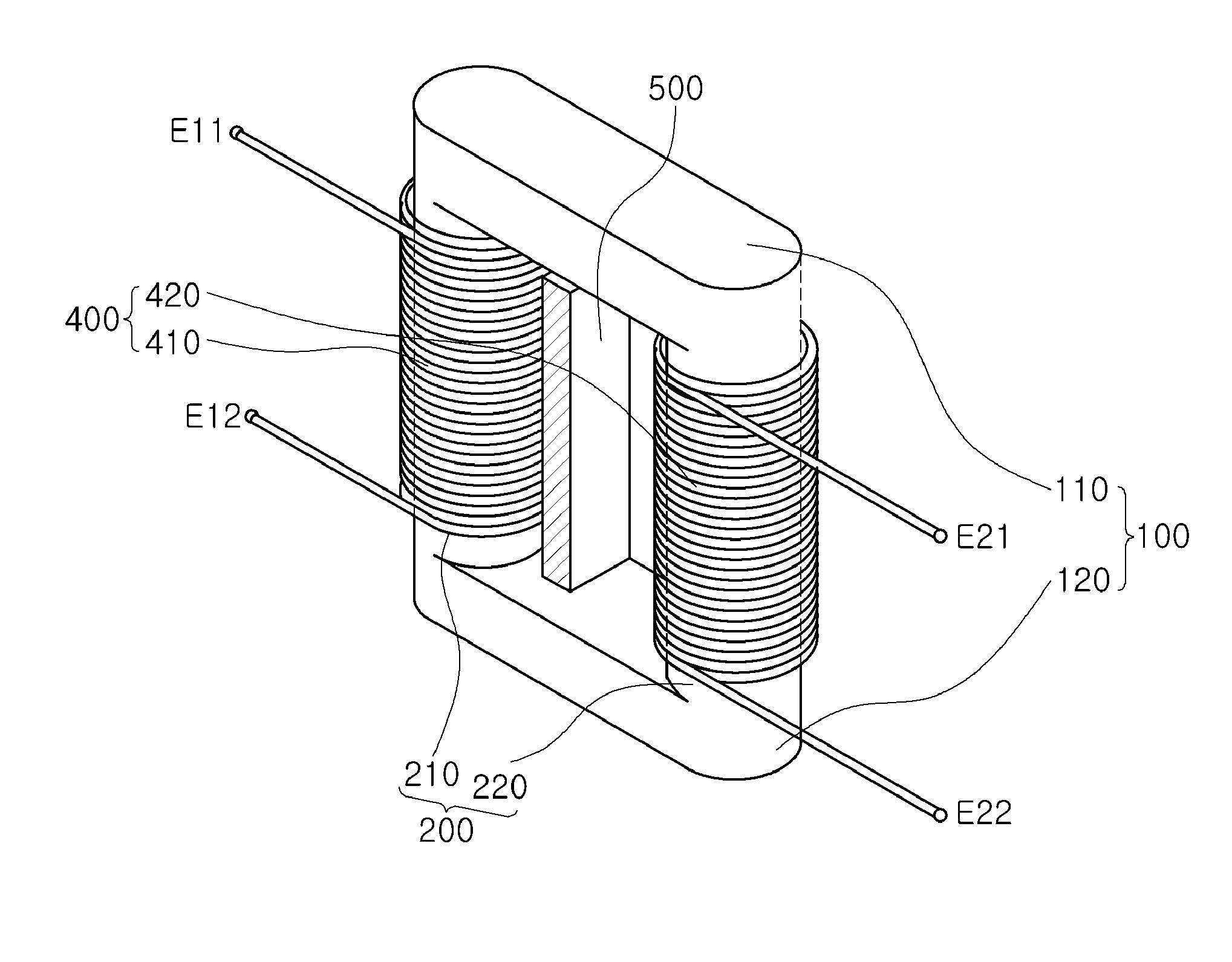

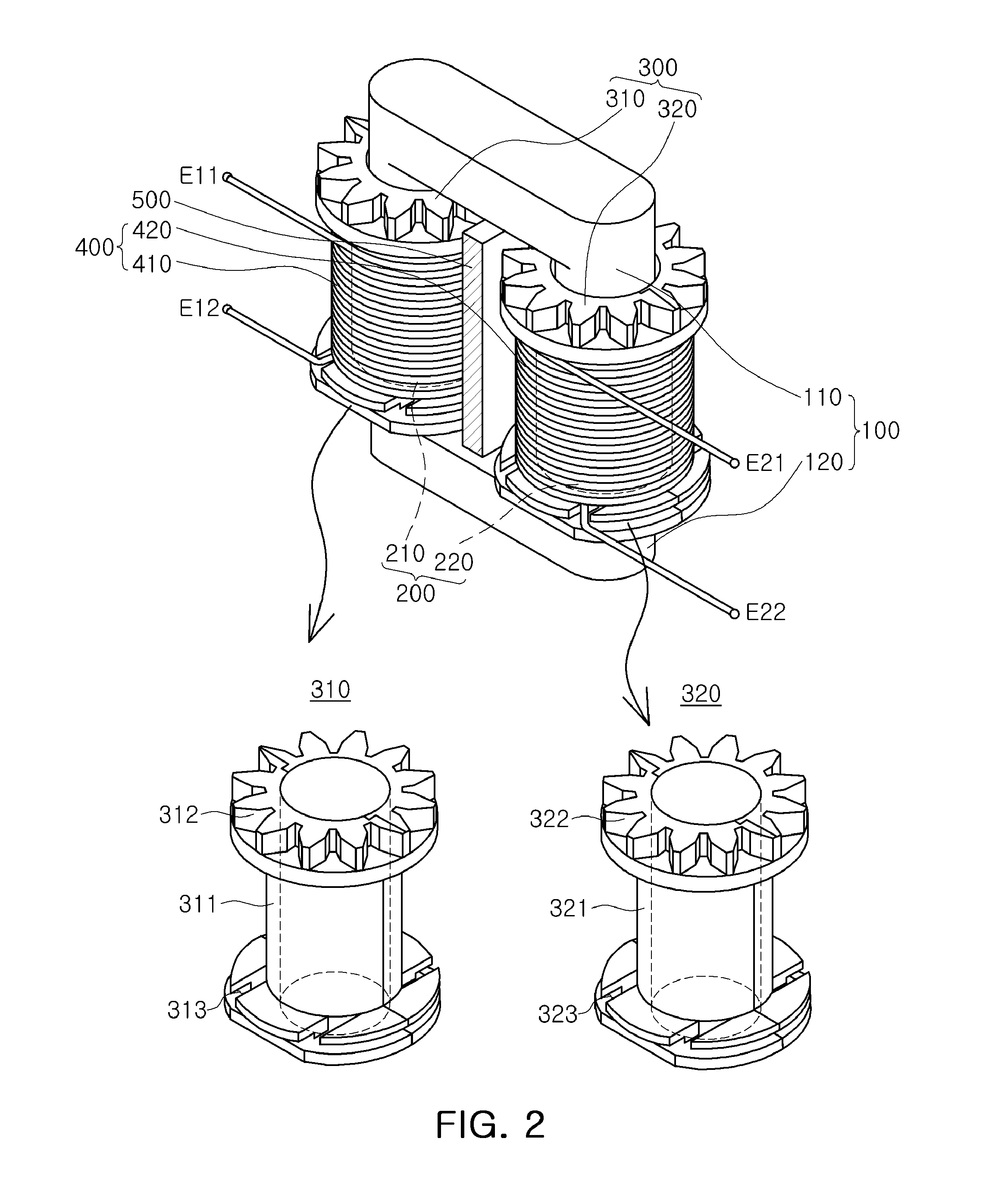

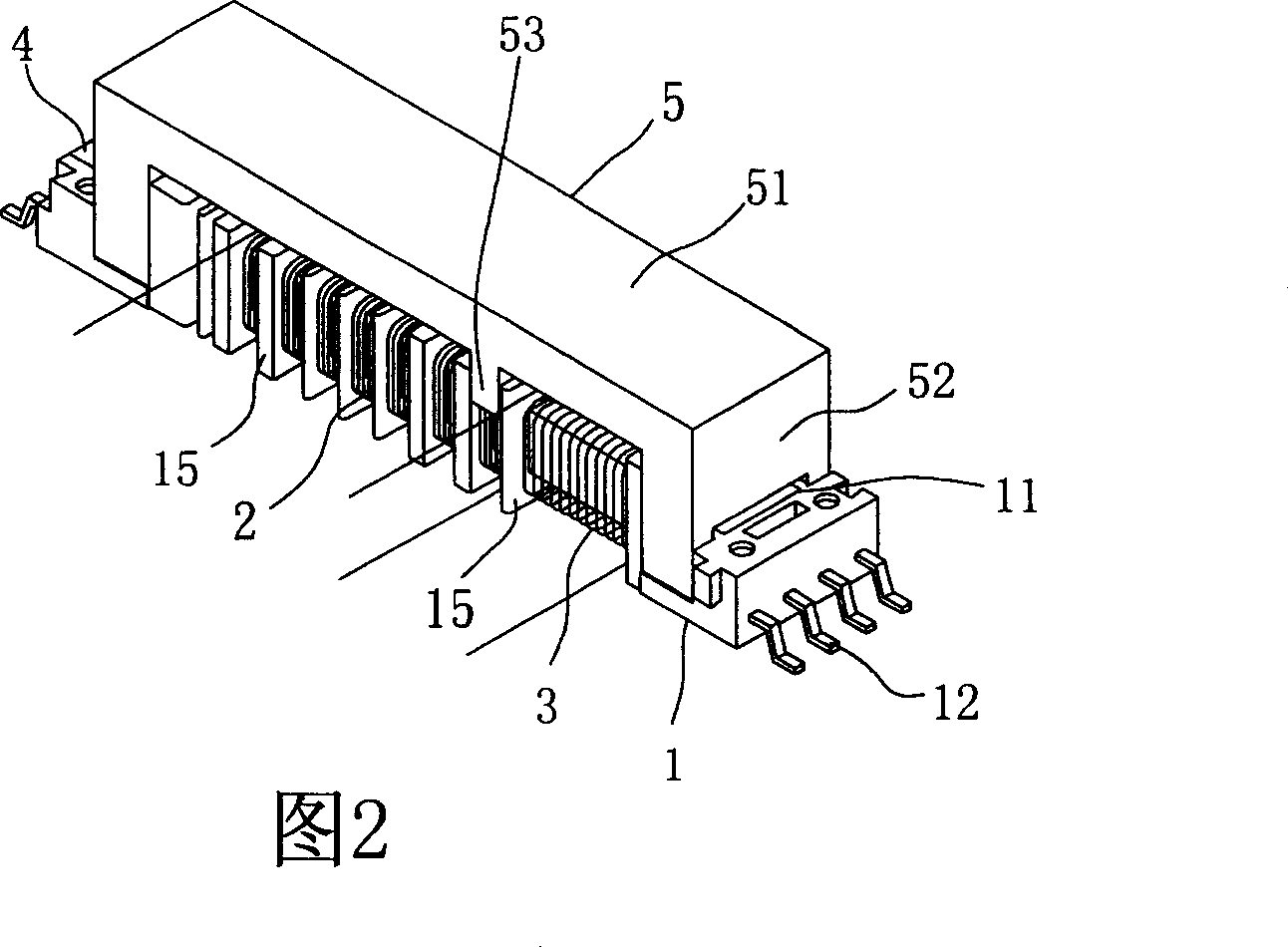

Electromagnetic interference filter and method of manufacturing the same

InactiveUS20140176289A1Increase leakage inductanceMultiple-port networksTransformers/inductances magnetic coresElectromagnetic interferenceEngineering

There are provided an electromagnetic interference filter and a method of manufacturing the same. The electromagnetic interference filter includes a base core including a first base core and a second base core facing the first base core, a leg core including first and second leg cores disposed between the first base core and the second base core, the first and second leg cores facing each other, a winding coil part including first and second winding coils wound around the first and second leg cores, respectively, and connected to a power supply, the first and second winding coils respectively providing magnetizing inductance and leakage inductance, and a central core disposed between the first and second cores to provide an inductance leakage path between the first and second base cores.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

High voltage transformer with high magnetic leakage and dual high voltage output

InactiveUS7646278B2Reduce coupling effectIncrease creepage distanceTransformers/reacts mounting/support/suspensionTransformersEngineeringHigh pressure

The present invention relates to a high voltage transformer with high magnetic leakage and dual high voltage output, comprising a base and a core set, wherein the base contains a hollow support into which a first core of the core set pierces, and primary coils are wound on both sides of the hollow support, while a plurality of isolation channels is installed for winding first and second secondary coils on external sides of primary coils. First and second slots are opened between the primary coils and the first and second secondary coils respectively, and both slots cut into an internal through hole. When a second core of the core set is placed at one end of the hollow support, extensions at both ends of the second core go through both sides of the first core, together with first and second protrusive parts between the two extensions that are installed within the first and second slots and combined with the first core to form multiple magnetic paths.

Owner:TAIPEI MULTIPOWER ELECTRONICS

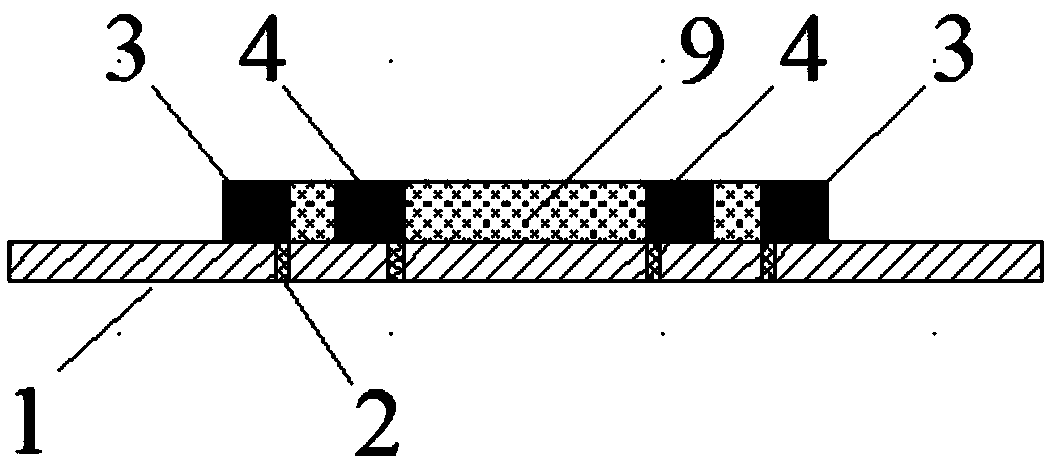

Transformer and iron core set thereof

InactiveCN101042958AOptimize volumeChange quantityVariable inductancesTransformers/inductances magnetic coresBobbinTransformer

The invention provides a transformer that mainly comprises a bobbin, the first iron core and the second iron core, the bobbin possesses a primary coiling area and a secondary coiling area, the first iron core is set through the bobbin, the second iron core is mounted on the bobbin, and the second iron core possesses the first protruding part which bestraddles the bobbin, and the second protruding part which is formed integrally on the second iron core and between the first protruding part, and the second protruding part is between the primary coiling area and a secondary coiling area.

Owner:DELTA ELECTRONICS INC

Embedded magnetic component transformer device

ActiveUS20160111965A1Increase leakage inductanceEfficient power electronics conversionTransformers/inductances coils/windings/connectionsLC circuitConductor Coil

An embedded transformer device includes first, second, and auxiliary windings, defined in an insulating substrate by conductive vias joined together by conductive traces. The positions of the conductive vias are arranged to optimize the isolation properties of the transformer and to reduce the coupling of the transformer by increasing the leakage inductance. The embedded transformer device provides better isolation between input side and output side windings, and allows an oscillating LC circuit to be set up in the case of a short circuit, preventing high power from extending between the input and output terminals and thereby avoiding damage to the connected electrical components.

Owner:MURATA MFG CO LTD

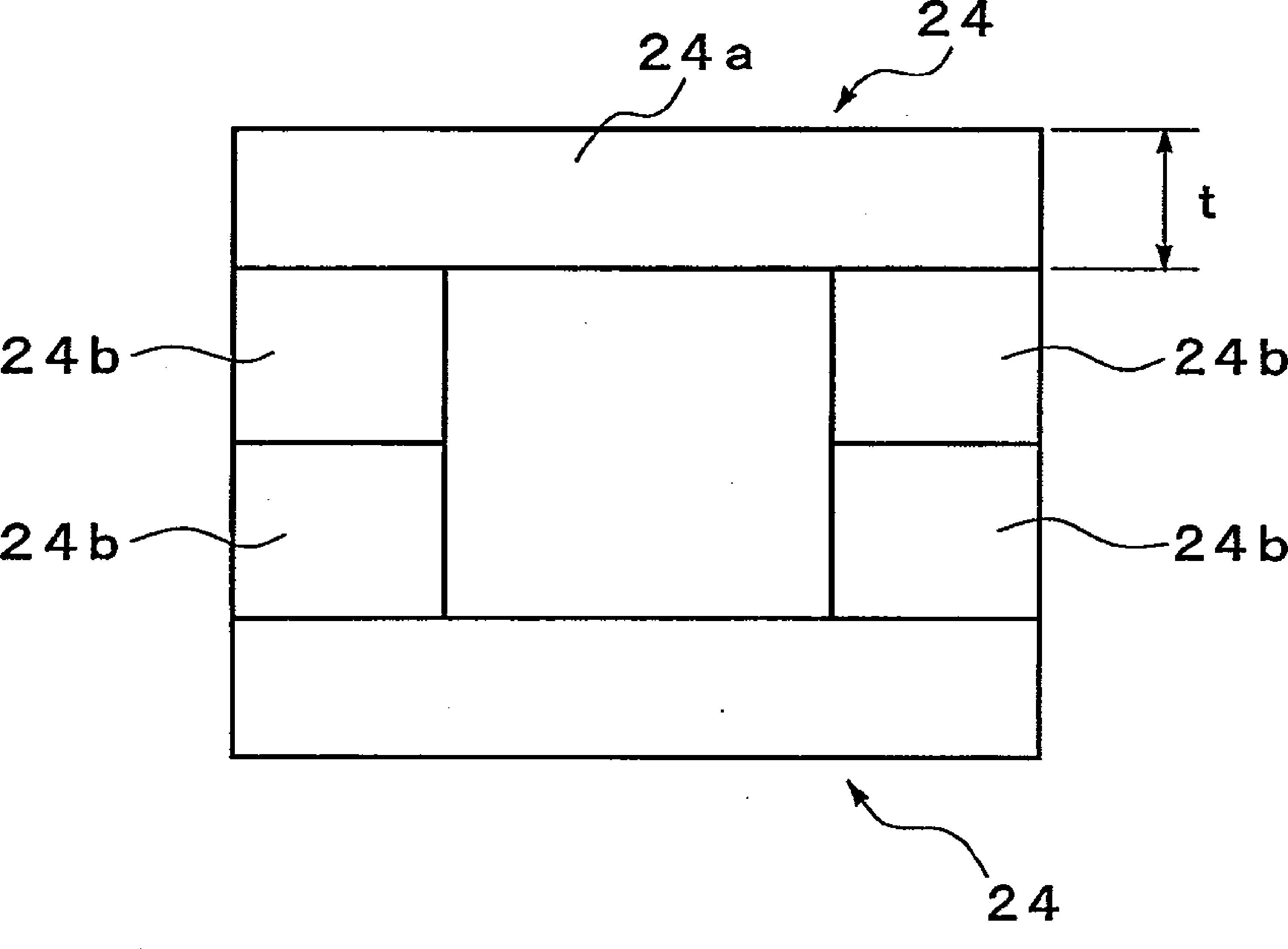

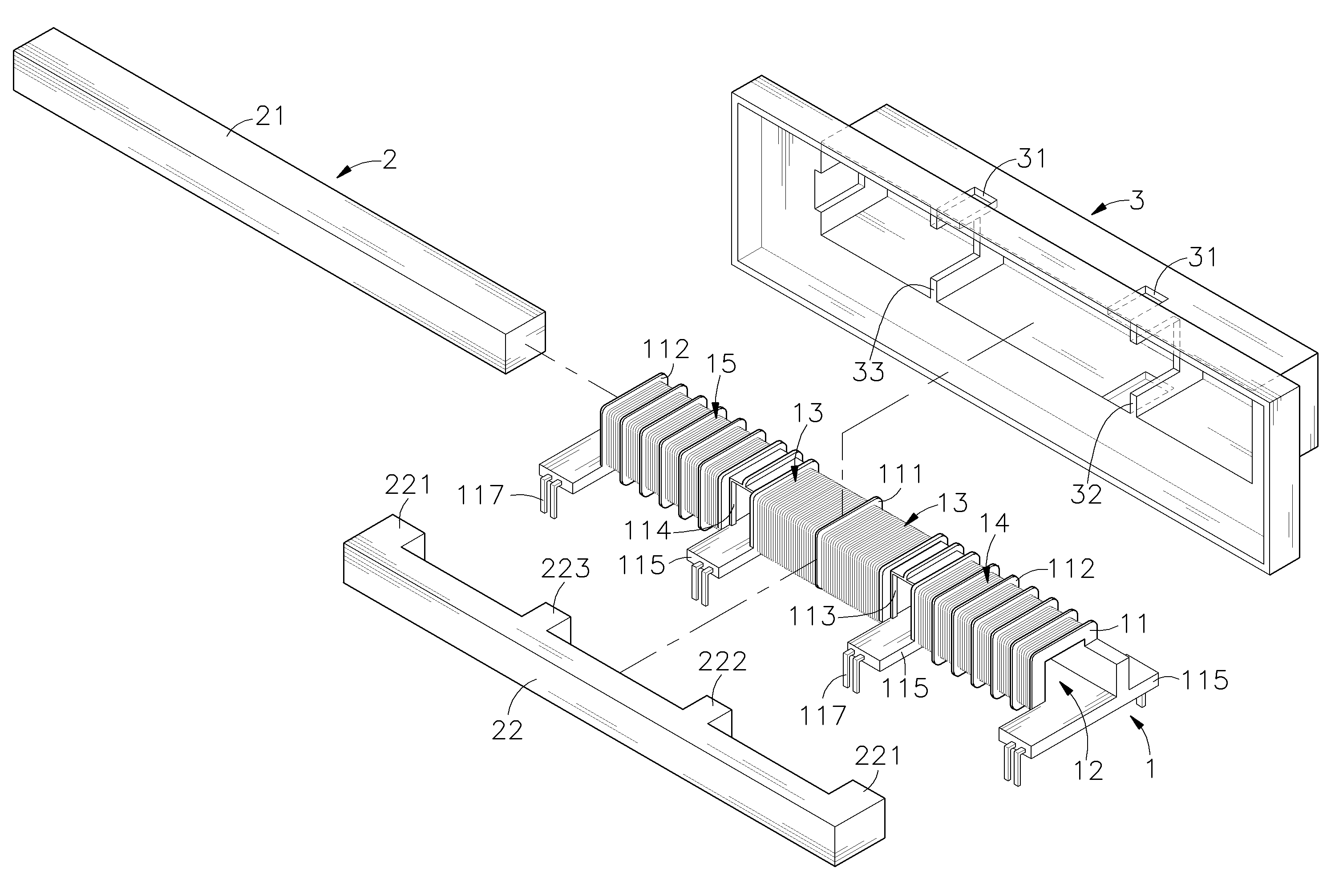

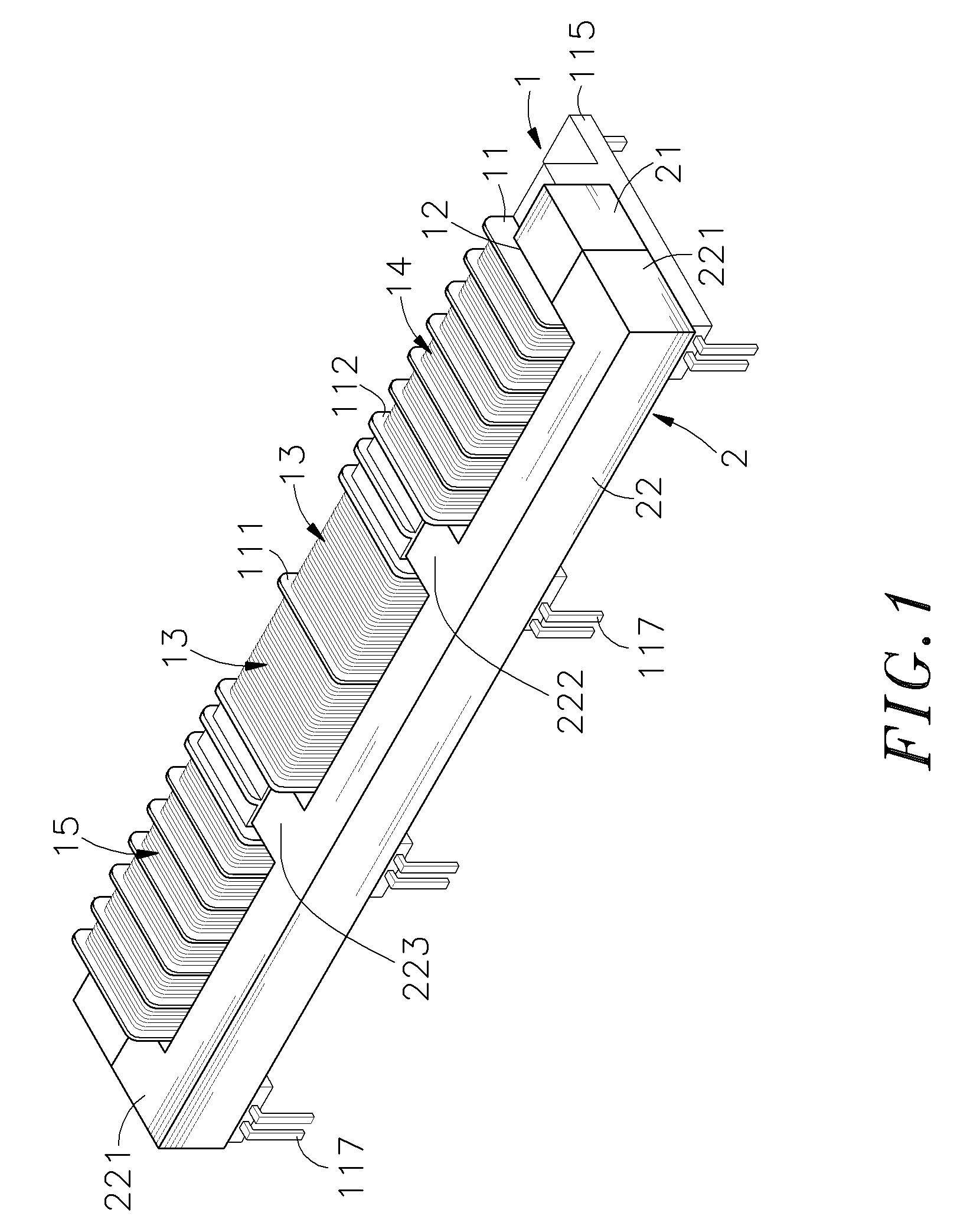

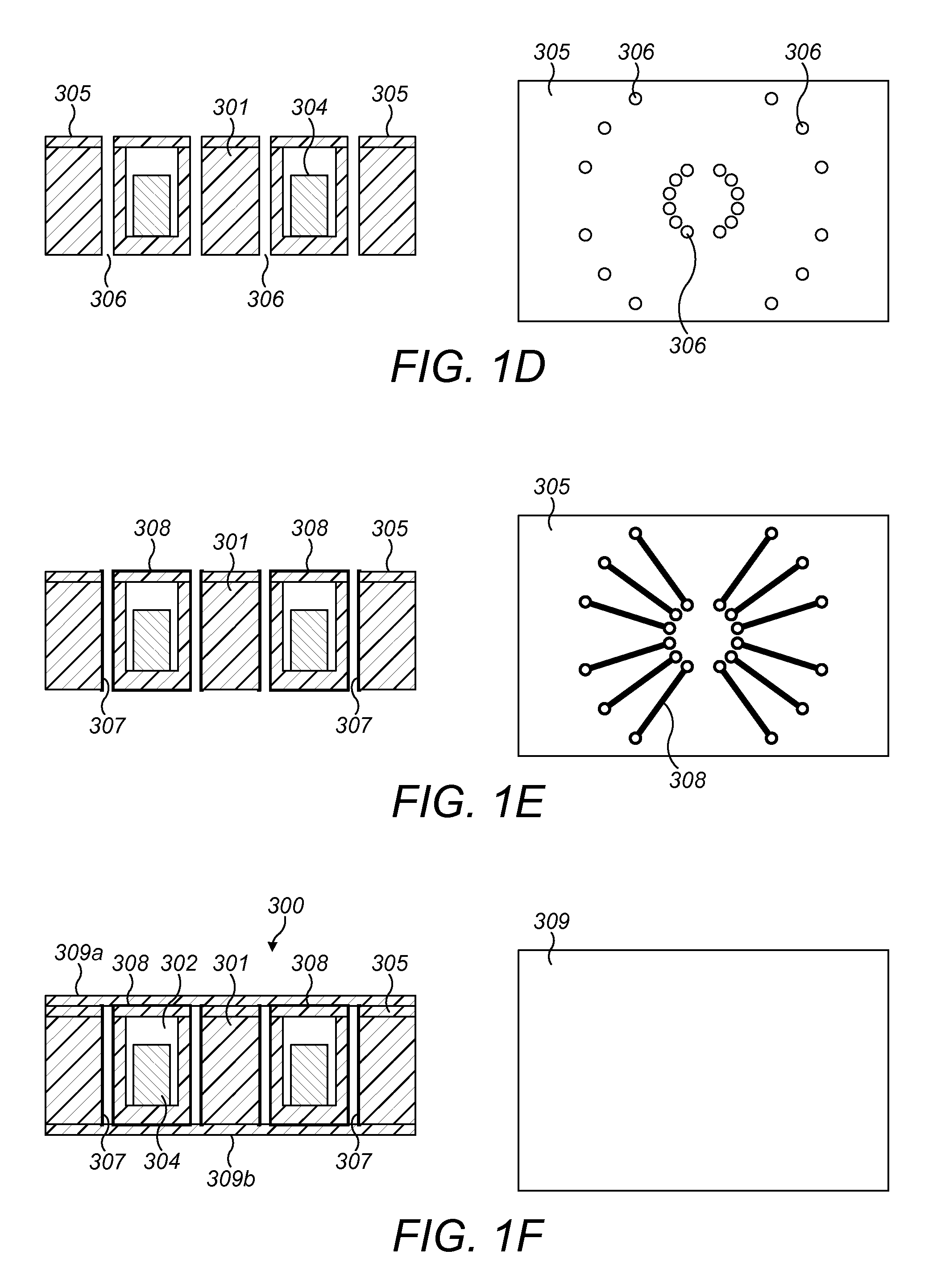

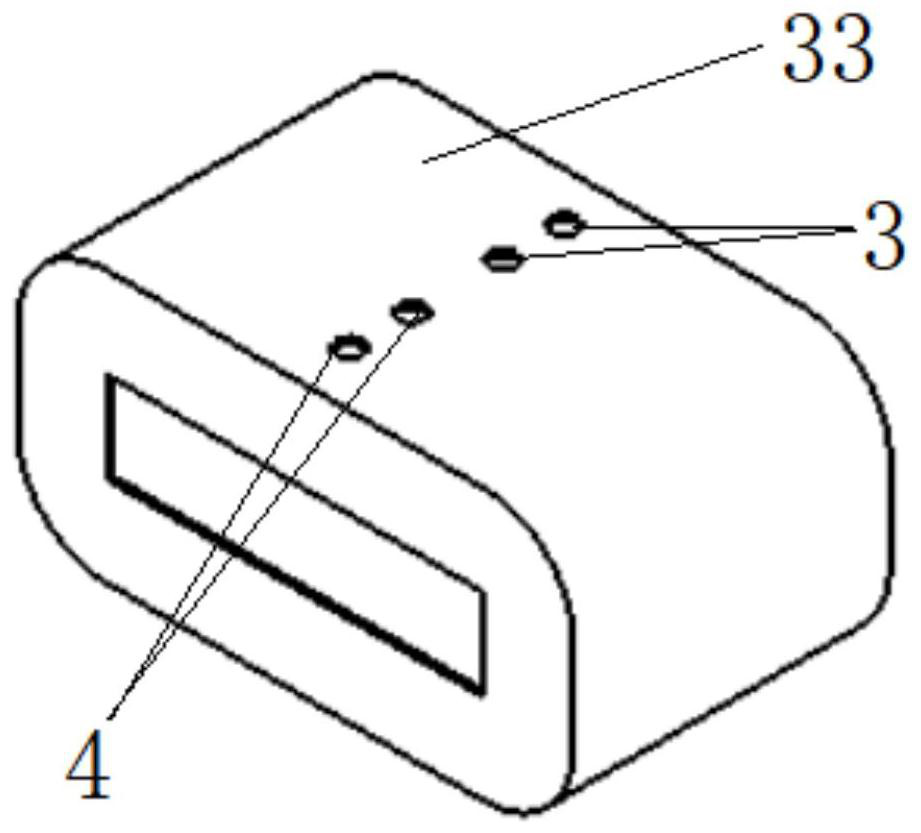

Transformer

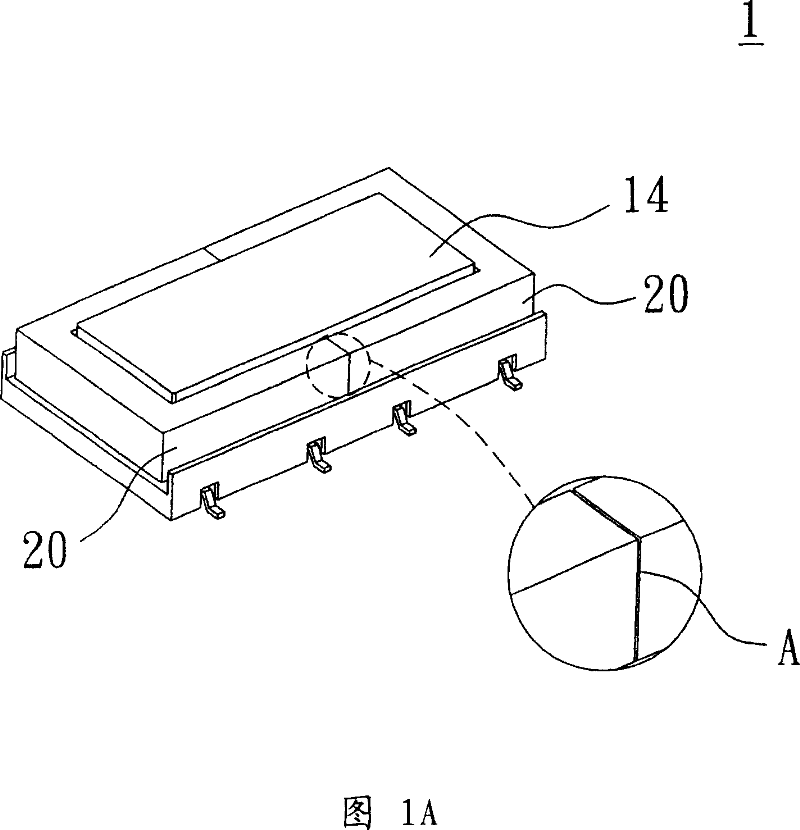

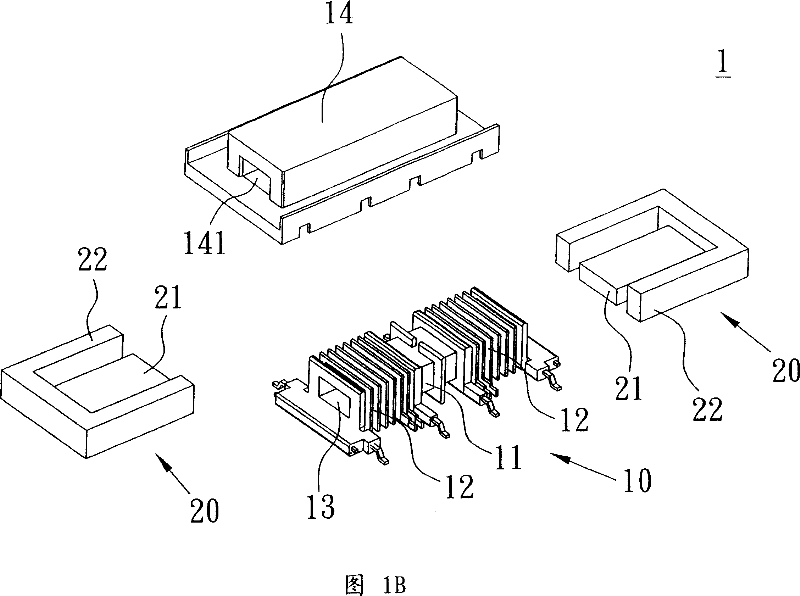

InactiveCN101060028ASimplify the assembly processIncrease output powerTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

The related transformer comprises: a primary winding, multiple conductive sheets, a winding base with two hollow plates and some baffle plates, and an iron core assembly, wherein every hollow plate has one throughout path, every baffle plates is set on the first plate and has an accommodation slot for the conductive sheet, and the iron core assembly are set in two paths partially. This invention simplifies assembly process, increases output power and heat dispersion capacity, and improves the electric security.

Owner:DELTA ELECTRONICS INC

High voltage transformer for controlling the leakage inductance

InactiveCN101055789AIncrease leakage inductanceConsider sizeTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionLow voltageDetent

A high voltage transformer controlling leakage inductance is used in a multi-lamp driving system, the transformer comprises: at least a line frame, a first winding, a second winding, a first magnetic unit and a second magnetic unit; wherein the line frame is provided with a receiving space for receiving the first magnetic unit, and provided with a first area and a second area on a surface, the first winding, the second winding are corresponding to the first area and the second area of the line frame respectively, the second magnetic unit covers the line frame side ends, and a trabecules beam extending from a proper position of a bottom of the second magnetic unit is provided between the first area and the second area; with the structure, the trabecules beam extending from the second magnetic unit is inserted into an inserting-detent portion, so that a low voltage magnetic passage generated by the first magnetic unit being effected by the first winding and the second winding respectively, and an alternating piezomagnetic passage are completely separated.

Owner:LIEN CHANG ELECTRONICS ENTERPRISE

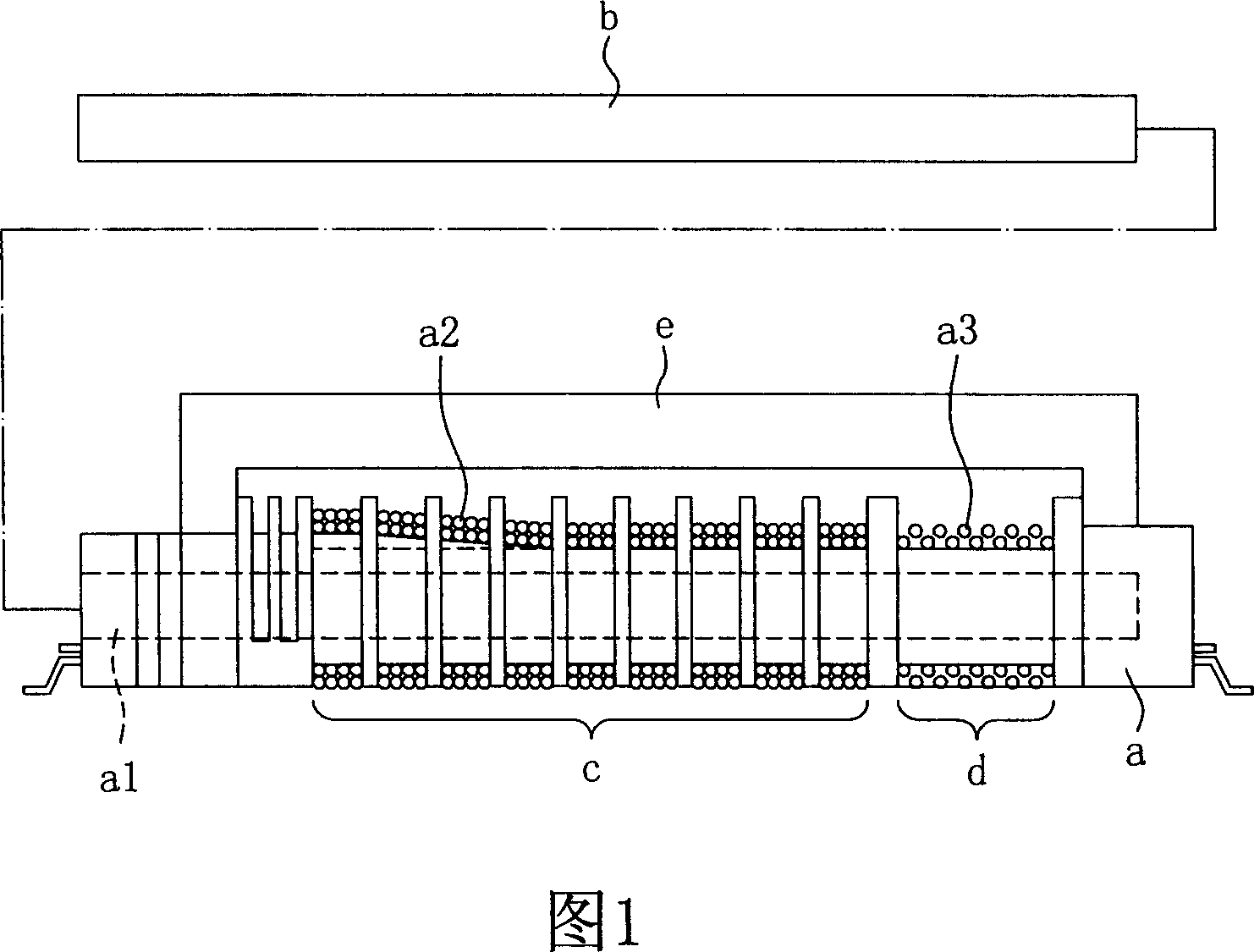

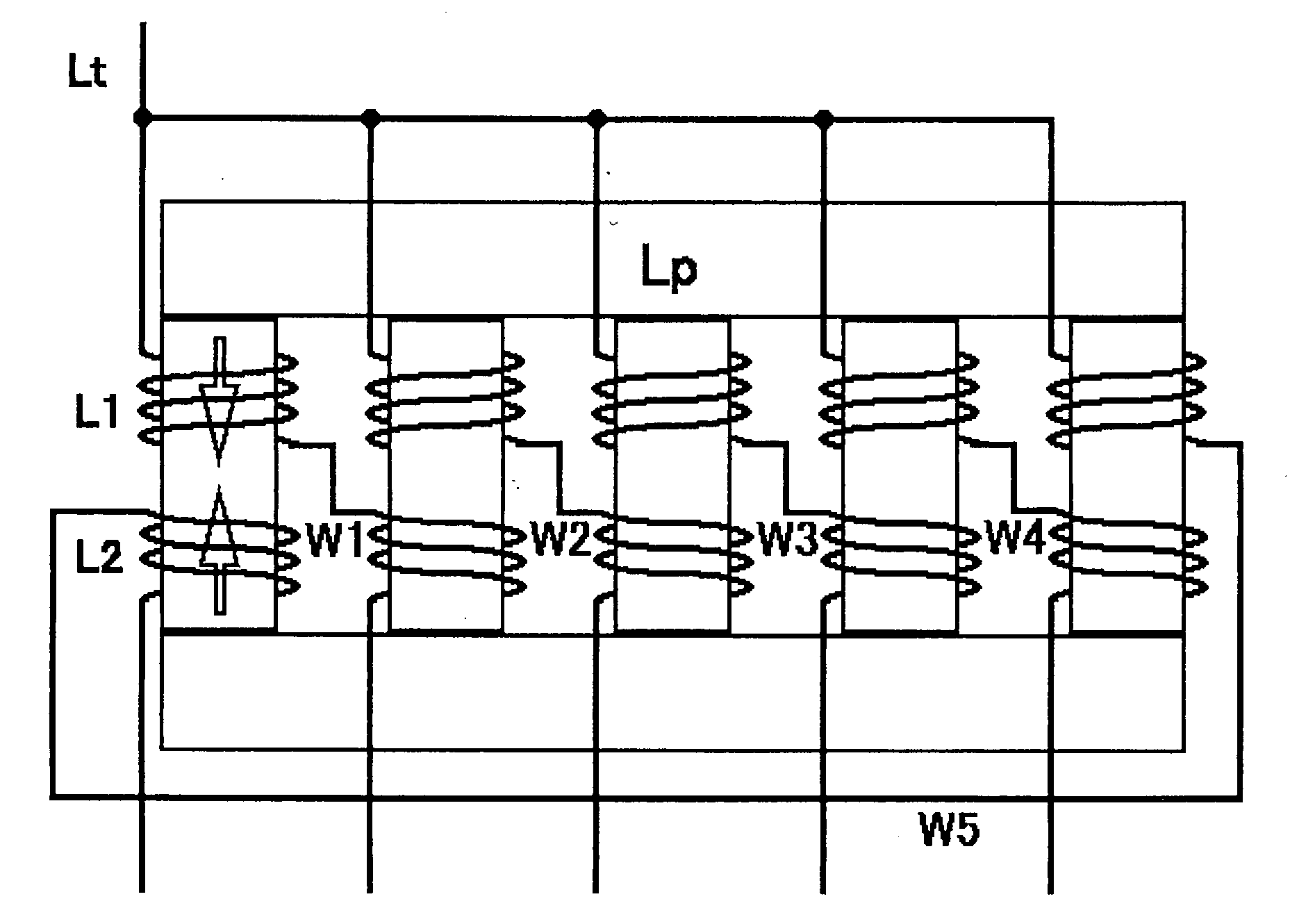

Module for parallel lighting and balancer coil for discharge lamp

InactiveUS20060055338A1Made tallerReduce the coupling coefficientElectric discharge tubesElectric light circuit arrangementElectrical conductorEffect light

A small balancer coil for cold-cathode florescent lamps having sufficient shunt / balance effects, comprises a discharge lamp, a conductor located close to the discharge lamp, and two coils whose magnetic fluxes face each other. The magnetic fluxes generated in the coils face and cancel each other. Lamp currents of the discharge lamps are balanced by making the sum of the reactances of the mutual inductance of the balancer coil larger than the negative resistance of the discharge lamp. Section winding is applied to each coil of the balancer coil so as to maintain shunt and balance effects even in a small / flat balancer coil by making self-resonance frequency of each of the coils higher.

Owner:HONG FEI CHEN +2

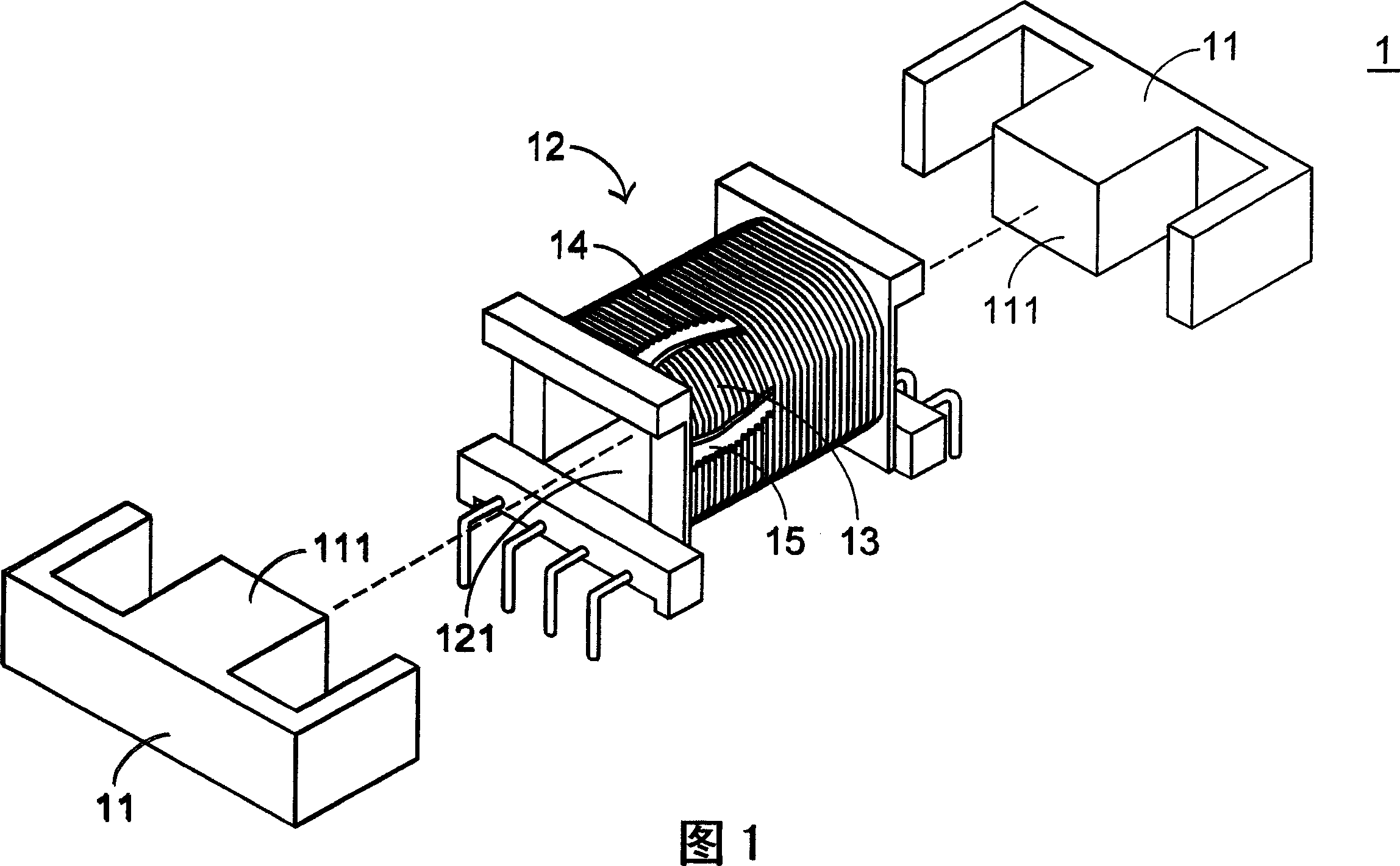

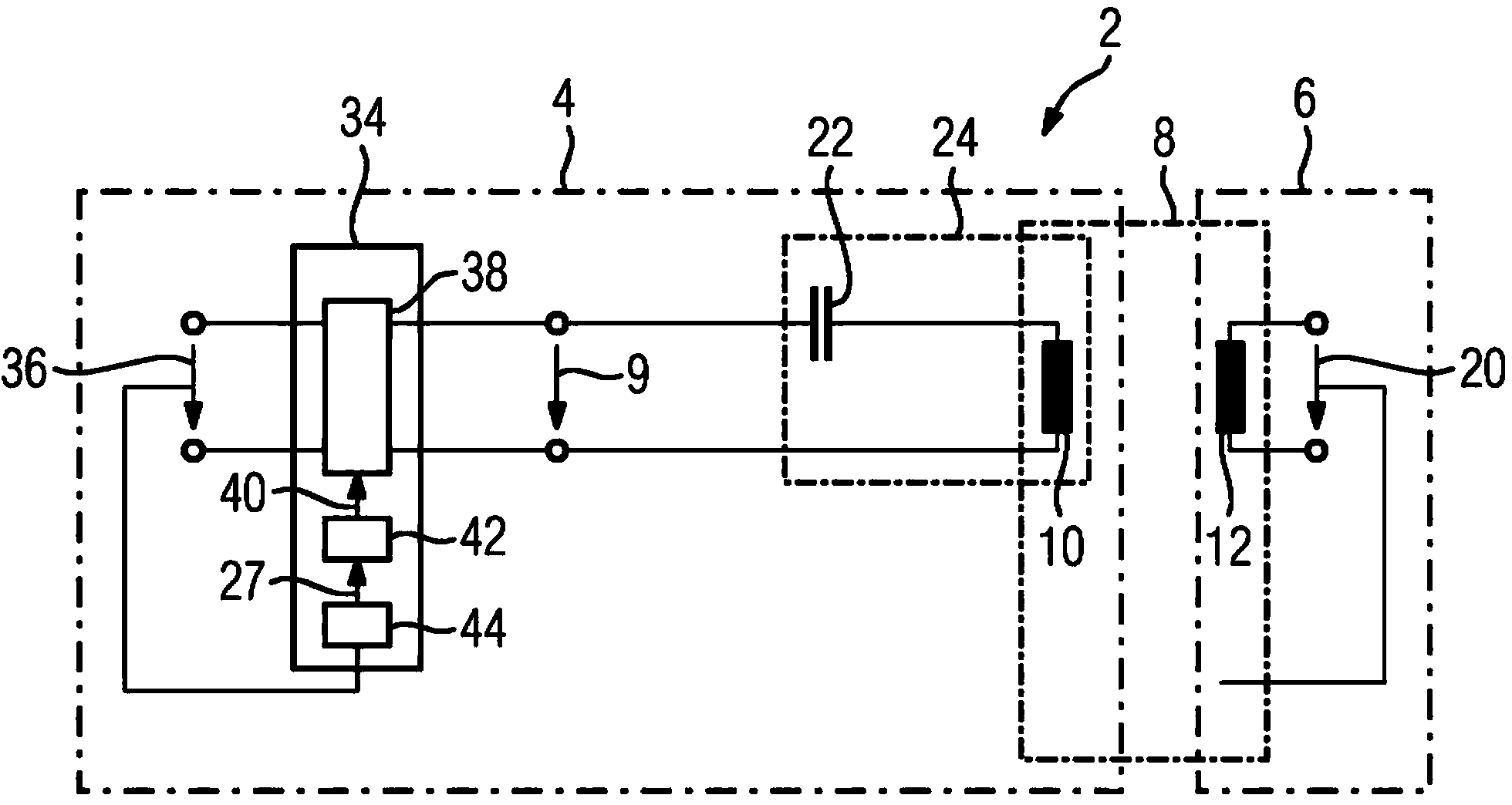

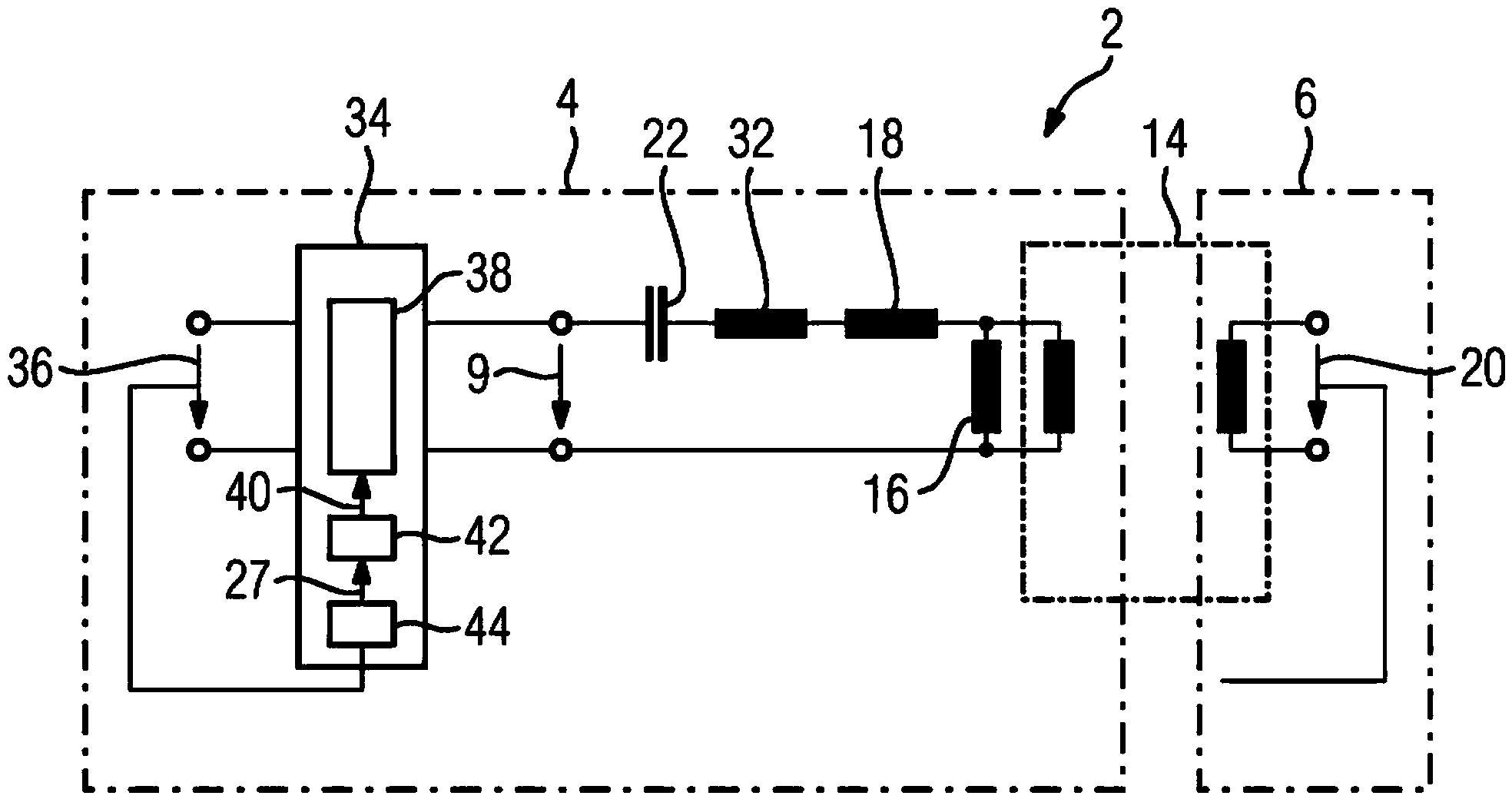

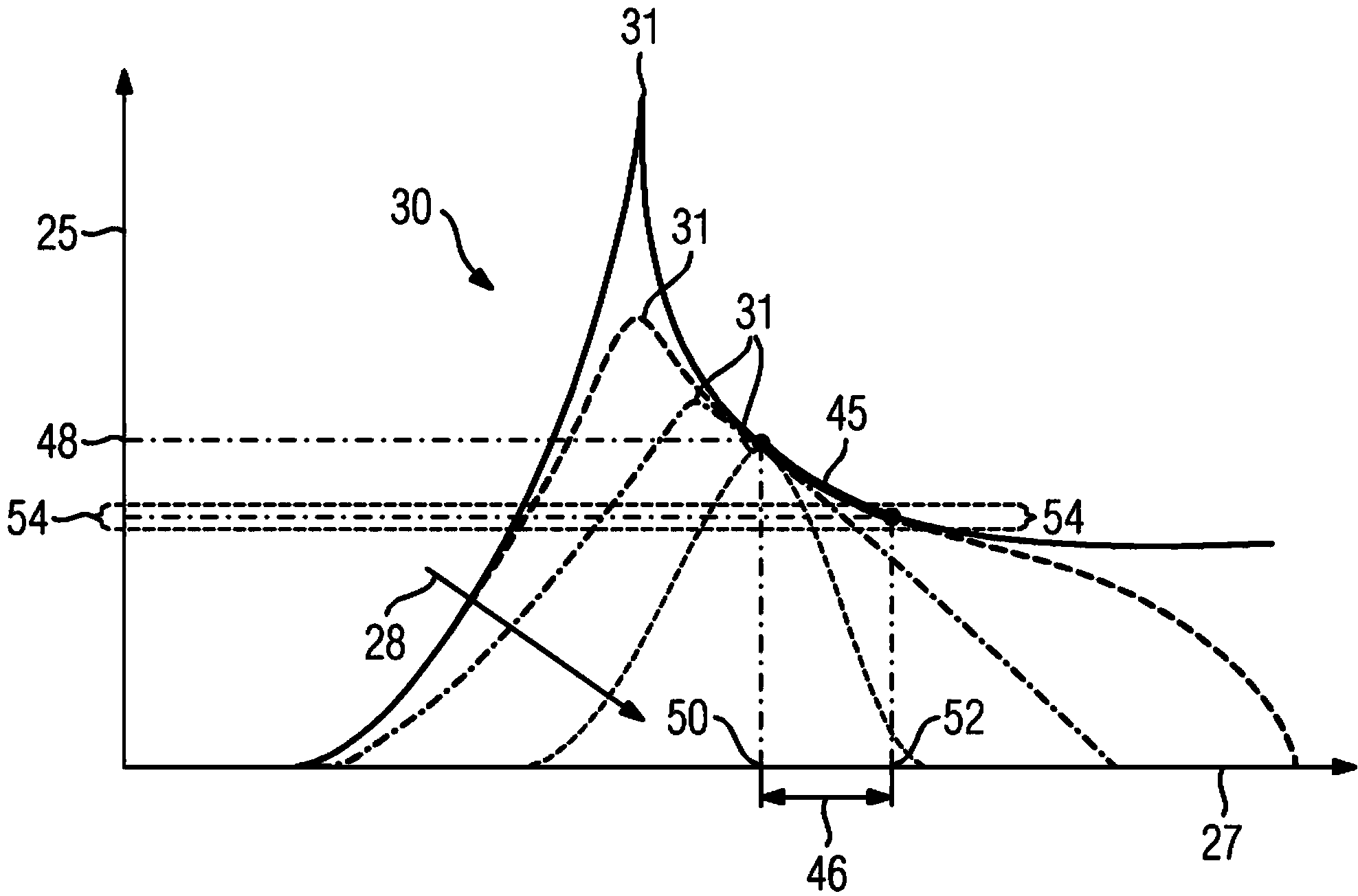

Open-loop control of a contactless energy transmission by means of a characteristic curve of a resonant circuit

ActiveCN103582996AEliminate closed-loop controlReduce complexityRadiation diagnosis data transmissionTransformersCapacitanceLoop control

The invention relates to a circuit for transmitting an input voltage (36) from an electrical energy source (64) in a stator (4, 55) to a load (70) within a device (6) movable relative to the stator (4, 55) comprising an control element (34) for converting an input voltage (36) into a transmission voltage (9), a resonant circuit (24) for receiving the transmission voltage (9), wherein the resonant circuit (24) contains a capacitor (22) and a primary winding (10) of a transformer (8) and the transformer (8) having the primary winding (10) and a secondary winding (12), wherein the primary winding (10) is provided for transmitting the transmission voltage (9) to the secondary winding (12) and the secondary winding (12) is provided for supplying the received transmission voltage (20) to the load (70). According to the invention, the actuator element (34) is provided for detecting the input voltage (36) and adjusting the frequency (27) of the transmission voltage (9) based on a control characteristic (45) in such a manner that the amplitude of the load voltage (20) dropping at the load (70) remains substantially constant, wherein in the control characteristic (45) the transmission ratio (25) of the resonant circuit (24) is plotted over the frequency (27) to be adjusted.

Owner:SIEMENS HEALTHCARE GMBH

Cake type solid insulation high-frequency transformer based on 3D printing

ActiveCN111952038AAchieve inductance matchingReduce volumeAdditive manufacturing apparatusTransformers/inductances coolingEngineeringLeakage inductance

The invention provides a cake-type solid insulation high-frequency transformer based on 3D printing, which is characterized in that a winding mold shell comprises a winding inner shell, a secondary winding shell and a winding outer shell, a primary winding is wound on the winding inner shell, a secondary winding is wound on the secondary winding shell, and the secondary winding shell is nested atone end of the winding inner shell to form an integrated structure; the primary side winding and the secondary side winding are of an upper-lower cake type winding structure; the winding shell is sleeved on the upper part of the integrated structure; a sealed space is formed between the primary winding, the secondary winding and the winding shell; the solid insulating material is loaded in the sealed space; the magnetic core is connected with the winding mold shell in an inserted mode, and the magnetic core is connected with the winding inner shell and the secondary winding shell in an inserted mode, so that the primary winding and the secondary winding sleeve the outer wall of the magnetic core. According to the invention, the matching problem of the leakage inductance and the main inductance in the resonant soft switching circuit is solved, the solid insulating material is difficult to apply, and the design goals of high power density, high efficiency and high insulating strength areachieved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com