Transformer and iron core set thereof

A technology of transformers and iron cores, used in transformers, transformer/inductor cores, variable transformers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

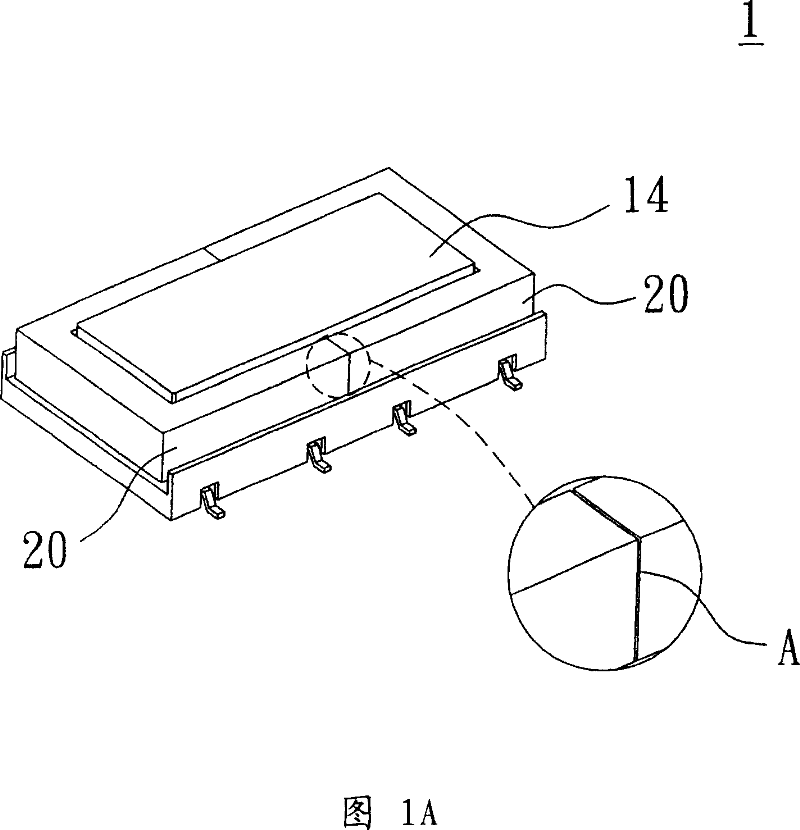

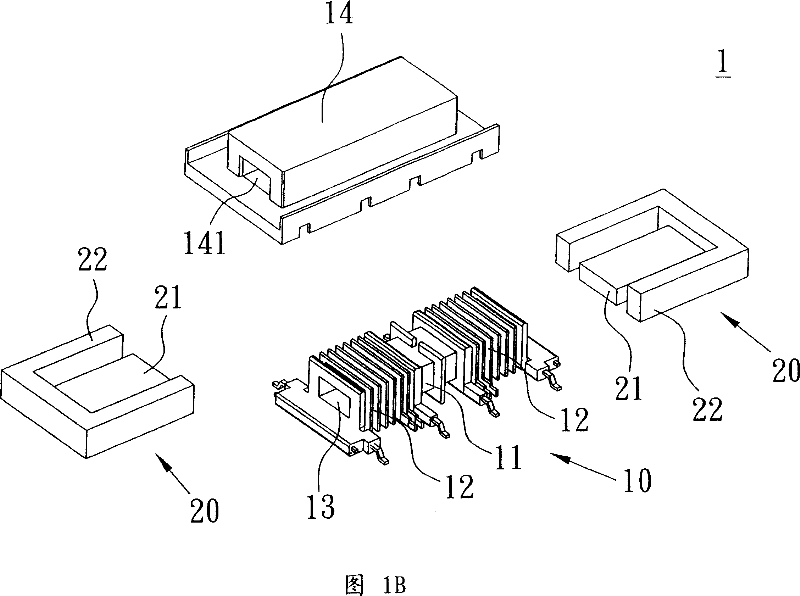

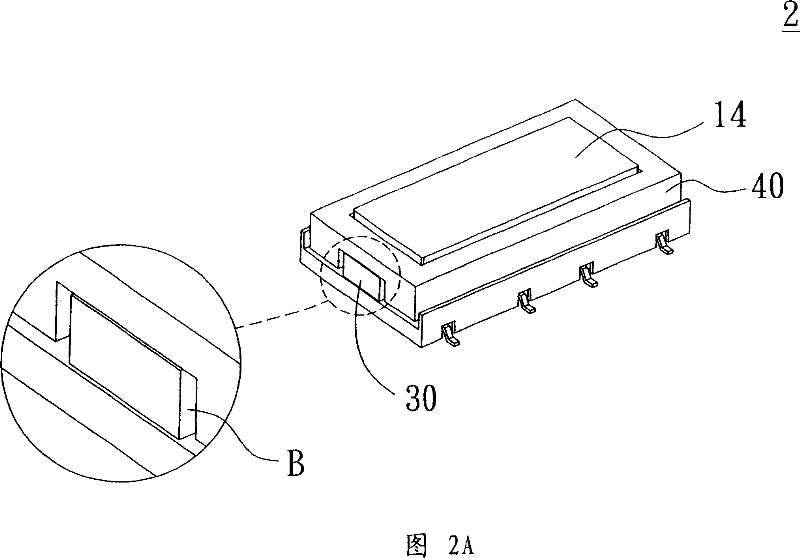

Image

Examples

Embodiment Construction

[0045] Please refer to Fig. 3A and shown in Fig. 3B, it is the first preferred embodiment of the transformer of the present invention, wherein the transformer 3 is made up of a bobbin 10 and an iron core group, wherein the iron core group also includes a first An iron core 30 and a second iron core 50 . The winding frame 10 has a primary winding area 11 and two secondary winding areas 12, the primary winding area 11 is located in the middle section of the winding frame 10, and the two secondary winding areas 12 are located in the On both sides of the primary winding area 11, the primary winding area 11 can be wound by one or two sets of primary coils (not shown in the figure), and the secondary winding areas 12 can respectively provide a set of secondary coils ( not shown in the figure), in addition, the winding frame 10 is axially provided with a perforation 13; the first iron core 30 is I-shaped and penetrates the perforation 13 of the winding frame 10; the second iron core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com