Hollow fiber ultrafiltration membrane of water purifier and preparation method for hollow fiber ultrafiltration membrane

An ultrafiltration membrane and water purifier technology, applied in the field of water purifier hollow fiber ultrafiltration membrane and its preparation, can solve the problems of low flux, poor hydrophilicity, poor toughness, etc. The effect of good performance and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

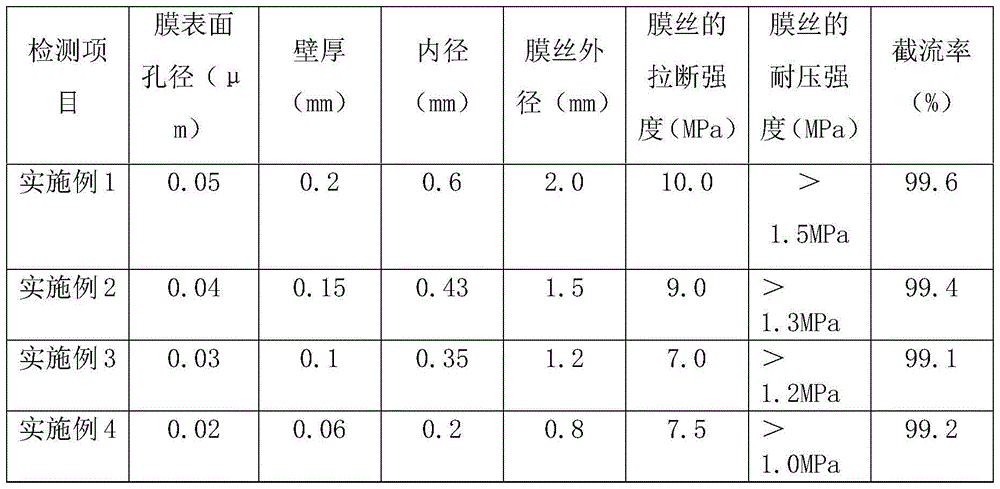

Examples

Embodiment 1

[0025] A water purifier hollow fiber ultrafiltration membrane is composed of the following components in mass percentage:

[0026] Polyethersulfone resin 20%

[0027] PVC 10%

[0028] Polar solvent 55%

[0029] Polar small molecule porogen 8%

[0030] Hydrophilic agent 7%

[0031] The specific method includes the following steps:

[0032] Step 1: Weigh each component according to the above formula, put each component into the spinning kettle, stir and dissolve at 95°C for 10 hours, and make a spinning casting solution that is evenly mixed, vacuum static defoaming and keep At the required spinning temperature of 95°C;

[0033] Step 2: The casting solution is spun into a vacuum fiber membrane through a spinning machine, and then immersed in a coagulation bath of deionized water at 60°C to obtain a hollow fiber ultrafiltration membrane; the hollow fiber ultrafiltration membrane is spun and stretched; the coagulation bath includes External coagulation liquid and internal coa...

Embodiment 2

[0036] A water purifier hollow fiber ultrafiltration membrane is composed of the following components in mass percentage:

[0037] Polyethersulfone resin 16%

[0038] PVC 8%

[0039] Polar solvents 54%

[0040] Polar small molecule porogen 12%

[0041] Hydrophilic agent 10%

[0042] Concrete preparation method comprises the following steps:

[0043] Step 1: Weigh each component according to the above formula, put each component into the spinning kettle, stir and dissolve at 80°C for 8 hours to make a uniformly mixed spinning casting solution, vacuum static defoaming and keep At the required spinning temperature of 80°C;

[0044] Step 2: The casting solution is spun into a vacuum fiber membrane through a spinning machine, and then immersed in a 50°C deionized water coagulation bath to obtain a hollow fiber ultrafiltration membrane; the hollow fiber ultrafiltration membrane is spun and stretched; the coagulation bath includes External coagulation liquid and internal coagul...

Embodiment 3

[0047] A water purifier hollow fiber ultrafiltration membrane is composed of the following components in mass percentage:

[0048] Polyethersulfone resin 10%

[0049] PVC 10%

[0050] Polar solvents 65%

[0051] Polar small molecule porogen 10%

[0052] Hydrophilic agent 5%

[0053] Concrete preparation method comprises the following steps:

[0054] Step 1: Weigh each component according to the above formula, put each component into the spinning kettle, stir and dissolve at 75°C for 9 hours to make a uniformly mixed spinning casting solution, vacuum static defoaming and keep At the required spinning temperature of 90°C;

[0055] Step 2: The casting solution is spun into a vacuum fiber membrane through a spinning machine, and then immersed in a 50°C deionized water coagulation bath to obtain a hollow fiber ultrafiltration membrane; the hollow fiber ultrafiltration membrane is spun and stretched; the coagulation bath includes An external coagulation liquid and an internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com