High-temperature planar transformer employing metal coated ceramic substrate

A technology for planar transformers and ceramic substrates, applied in transformer/inductor cores, transformer/inductor components, transformer/inductor coils/windings/connections, etc., can solve the problem of magnetic permeability reduction, metal wire width and thickness Limited, low Curie temperature, etc., to improve energy conversion efficiency, facilitate miniaturization, and improve coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

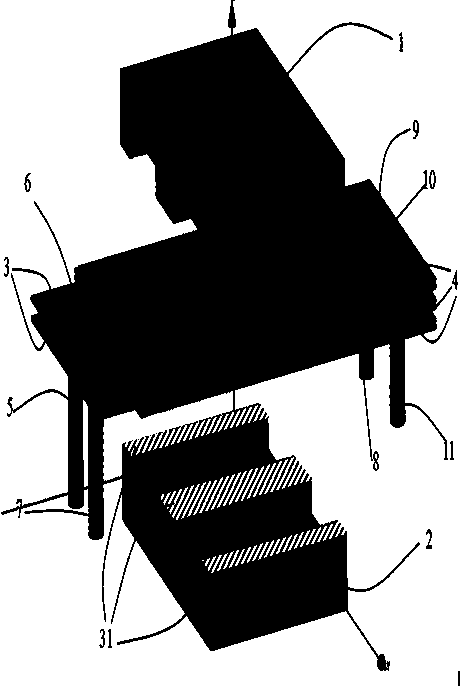

[0027] Depend on figure 2 It can be clearly seen that the examples of the high-temperature planar transformer of the present invention include: E-type iron-nickel-molybdenum metal magnetic powder cores 1 and 2 opposite to form a double-ring closed structure magnetic core; primary winding 3 and secondary winding 4. The middle part of the coil of each ceramic substrate adopts laser cutting process to process the installation hole matching the size of the middle column of the magnetic core and aligns it along the installation hole. The two parts of the magnetic core pass through the installation hole of the ceramic substrate and are bonded and fixed by the high-temperature magnetic adhesive layer 31 .

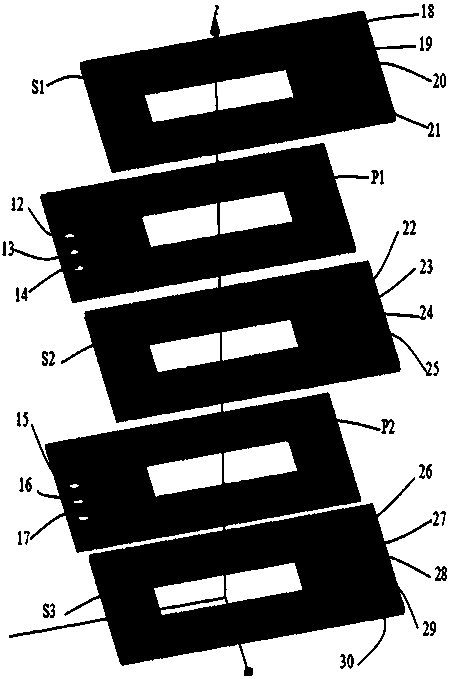

[0028] Depend on image 3 It can be seen that each transformer coil is made of metal-bonded aluminum oxide or aluminum nitride ceramic substrate 30 , and wires of a specific shape are processed on the metal layer through an etching process. According to the number of turns of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com