Non-magnetic steel for improving corrosion resistance of water-cooled jacket of submerged arc furnace

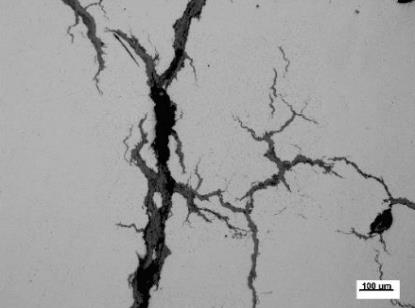

A technology of non-magnetic steel and water-cooled jacket, applied in the field of non-magnetic steel, can solve the problems of non-magnetic steel being easily corroded and cracked, and achieve the effects of outstanding corrosion resistance, good toughness, and acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a non-magnetic steel for improving the corrosion resistance of the water cooling jacket of a submerged arc furnace, and its chemical composition by weight percentage is: C: 0.16%, Si: 0.95%, Mn: 24.6%, P: 0.01%, S: 0.02%, A1: 2.5%, Mo: 0.4%, Ti: 0.05%, Cr: 1.1%, Ti: 0.15%, and the rest are Fe and inevitable impurities.

[0033] The preparation steps of the non-magnetic steel of the present embodiment are as follows:

[0034] Vacuum smelting: iron raw materials are first melted into molten iron in the smelting chamber of the vacuum induction melting furnace, and argon gas is introduced into the smelting chamber until the indoor pressure reaches 0.50Pa, which is close to vacuum. The molten steel enters the smelting chamber one after another, and the molten steel is stirred by argon and sent to electricity for refining for 40 minutes to obtain an ingot.

[0035] The oxide layer on the surface of the ingot is removed by a slag scraper, and t...

Embodiment 2

[0038]The present embodiment provides a non-magnetic steel for improving the corrosion resistance of the water cooling jacket of a submerged arc furnace, and its chemical composition by weight percentage is: C: 0.18%, Si: 1.15%, Mn: 23.5%, P: 0.02%, S: 0.01%, A1: 3%, Mo: 0.5%, Ti: 0.03%, Cr: 0.8%, Ti: 0.02%, and the rest are Fe and inevitable impurities.

[0039] The preparation steps of the non-magnetic steel in this example are the same as those in Example 1.

Embodiment 3

[0041] This embodiment provides a non-magnetic steel for improving the corrosion resistance of the water cooling jacket of a submerged arc furnace, and its chemical composition by weight percentage is: C: 0.17%, Si: 0.98%, Mn: 23.7%, P: 0.005%, S: 0.015%, A1: 3.6%, Mo: 0.45%, Ti: 0.04%, Cr: 1.1%, Ti: 0.07%, and the rest are Fe and inevitable impurities.

[0042] The preparation steps of the non-magnetic steel in this example are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com