Cold-rolled strip welding technology method

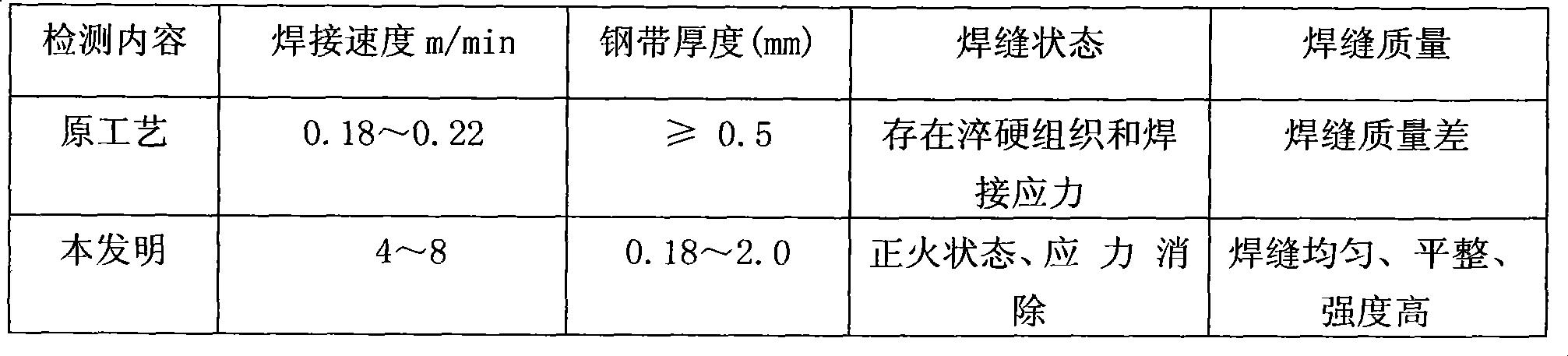

A welding process, a technology of cold-rolled steel strip, applied in the resistance welding process of steel strip, the production process field of cold-rolled steel strip, can solve the problem that the weld cannot be normalized by itself, the toughness of the weld seam, the limitation of the thickness range of the welded steel strip, and the welding Smoke and dust are harmful to workers' health and other problems, and achieve the effect of eliminating residual welding stress, fast welding speed and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

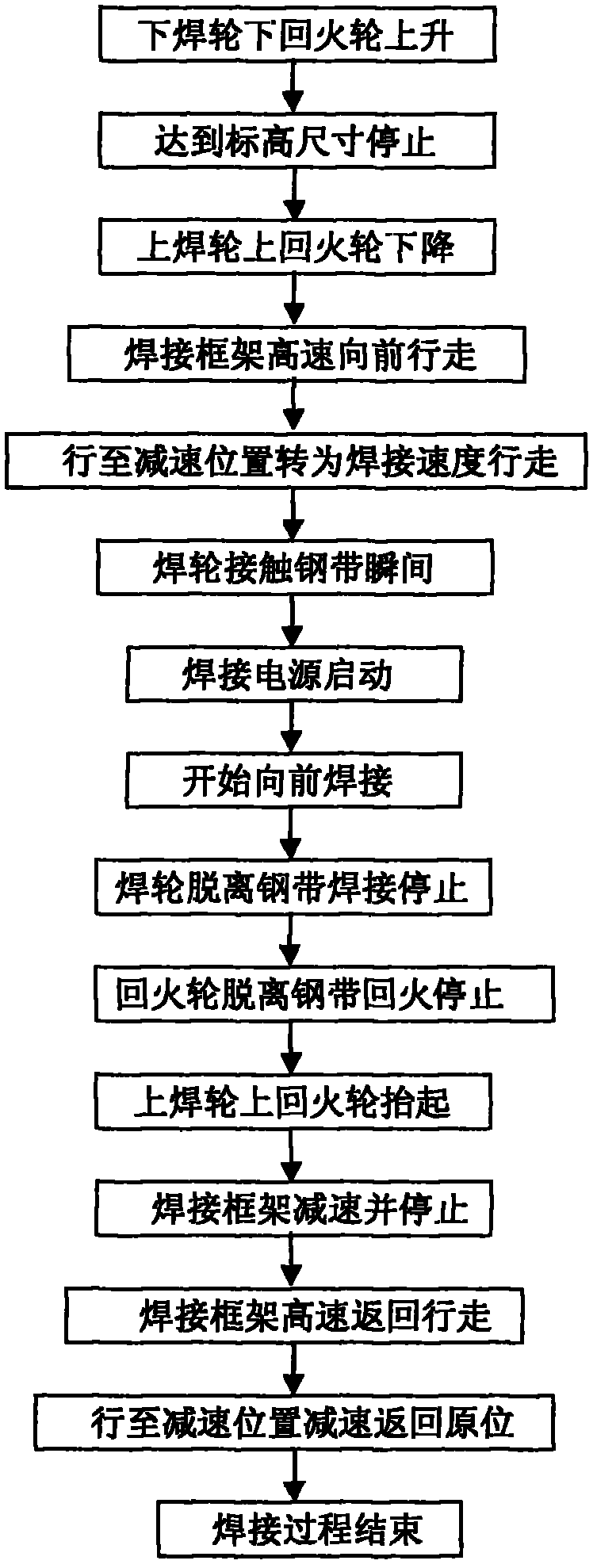

[0018] The lower welding wheel and the lower tempering wheel rise → reach the elevation and stop → the upper welding wheel and the upper tempering wheel go down → the welding frame moves forward at high speed → travel to the deceleration position and turn to the welding speed → the moment the welding wheel touches the steel strip → the welding power starts →Start forward welding→Welding wheel breaks away from the steel strip and welding stops→Tempering wheel breaks away from the steel strip and stops tempering→The upper welding wheel and upper tempering wheel lift up→Welding frame decelerates and stops→Welding frame returns to walk at high speed→Walk to decelerate The position decelerates and returns to the original position → the welding process ends.

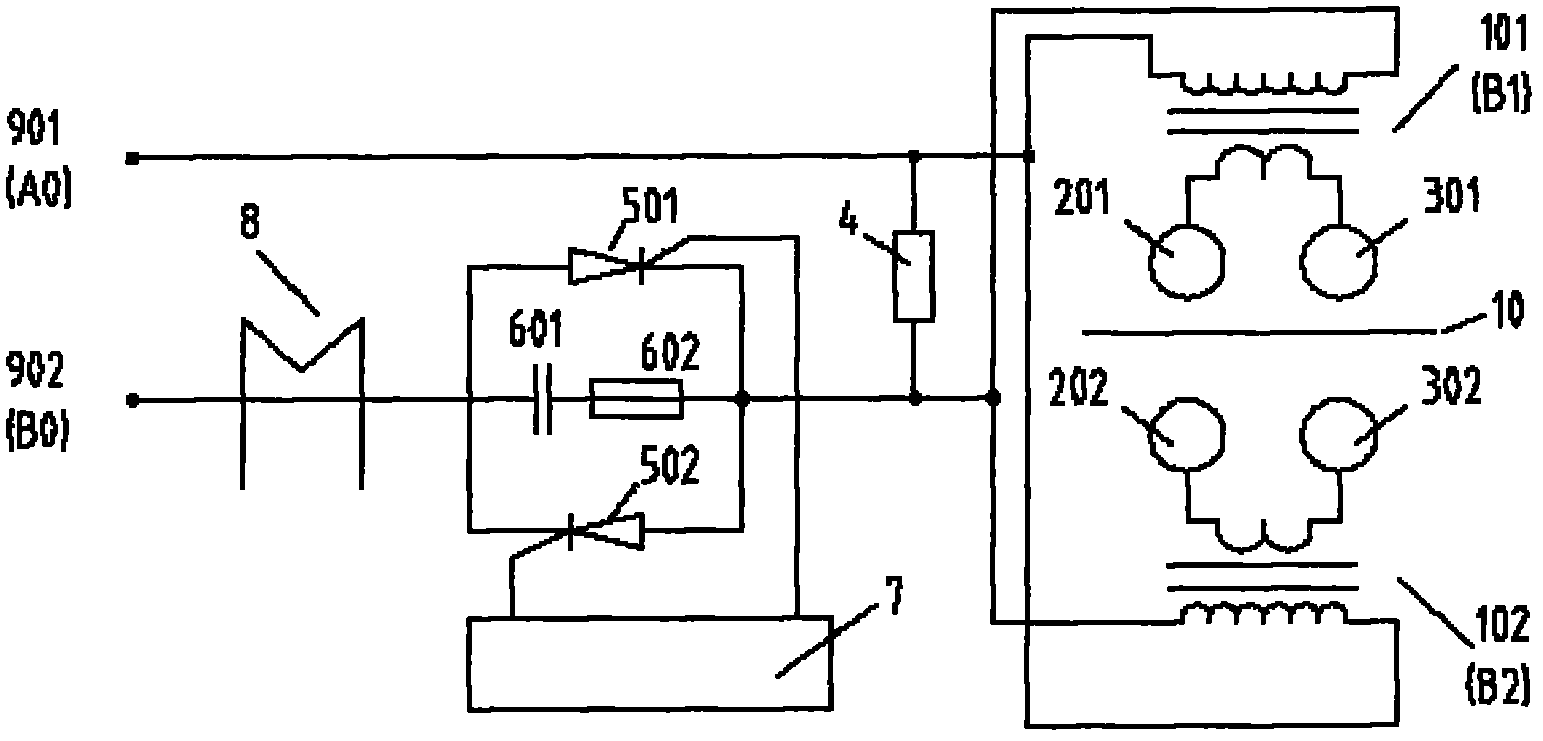

[0019] The welding frame walks forward with the upper welding wheel 201, the lower welding wheel 202, the upper tempering wheel 301, and the lower tempering wheel 302; When the welding transformer 101 (B1), 102 (B2) is powered...

Embodiment 2

[0021] The welding frame walks forward with the upper welding wheel 201, the lower welding wheel 202, the upper tempering wheel 301, and the lower tempering wheel 302; On, welding transformers 101 (B1), 102 (B2) are energized on the primary side, and the secondary side circuit is closed. The current flows through the steel strip 10 and generates heat through the resistance of the steel strip itself. ;When the welding wheels 201, 202 are separated from the steel strip, the welding stops, and the tempering stops when the tempering wheels 301, 302 are separated from the steel strip, and the upper welding wheel 201 and the upper tempering 301 wheel are lifted; the welding frame decelerates and stops; the welding frame returns to walk at a high speed , go to the deceleration position and decelerate to return to the original position; the welding process is over. In the schematic diagram, resistor 4 is an absorbing resistor, which is equivalent to the load as a buffer; RC circuits 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com