Patents

Literature

39results about How to "Improve leveling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

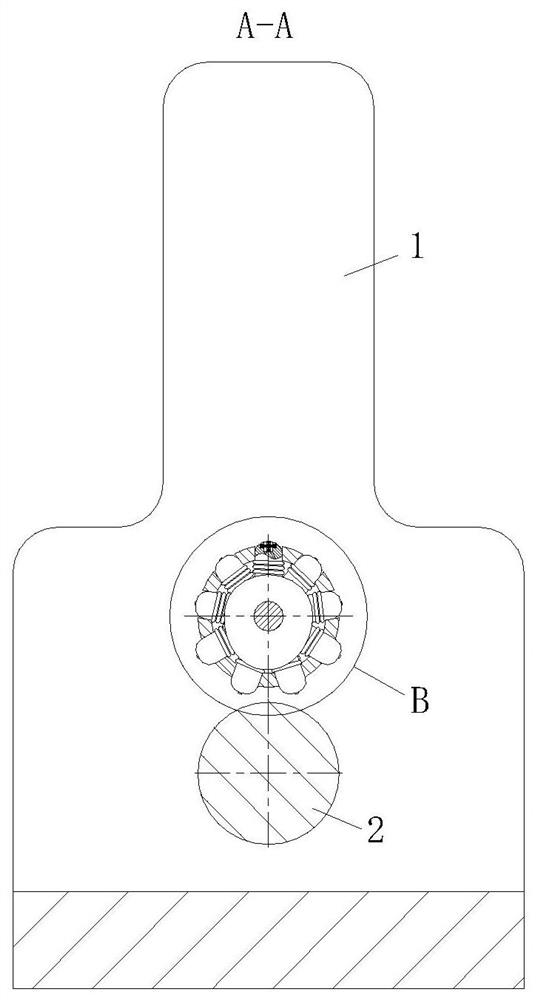

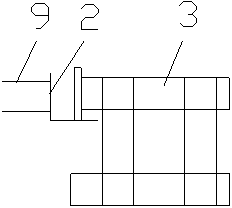

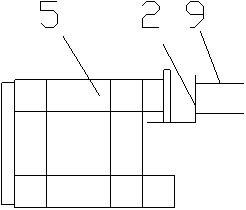

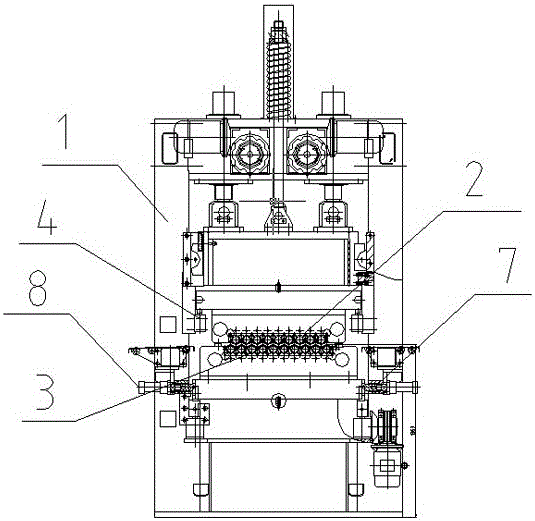

Working roll adjusting device for roll leveler

The invention discloses a working roll adjusting device for a roll leveler. In the invention, each working roll is provided with a wedge I and a wedge II of which the inclined surfaces are matched up and down along the axial direction; a support roll assembly is arranged on the wedge I; a wedge adjusting device is arranged on the end part of the wedge II; the wedge adjusting device is used for driving the wedge II to move transversely; and the wedge II is used for pushing the wedge I upwards and downwards. The work roll adjusting device can be used for independently adjusting the vertical direction of each working roll, so that the leveling quality is improved.

Owner:SHANDONG HONGKANG MACHINERY MFG

Plastic bag flattening mechanism characterized by combination of trowelling rollers and hot air

InactiveCN109016677AImprove leveling qualityEasy post-processingBag making operationsPaper-makingEngineeringWork in process

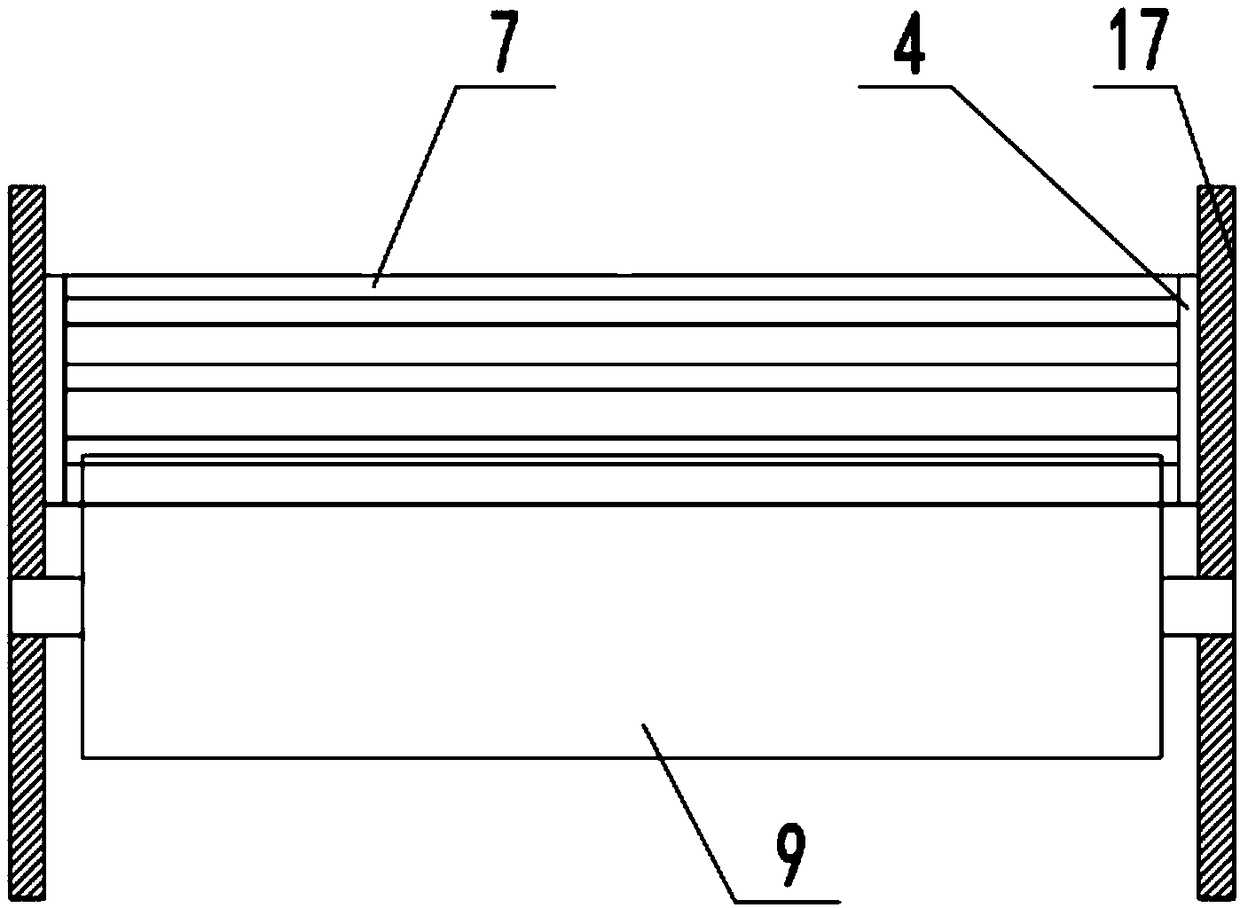

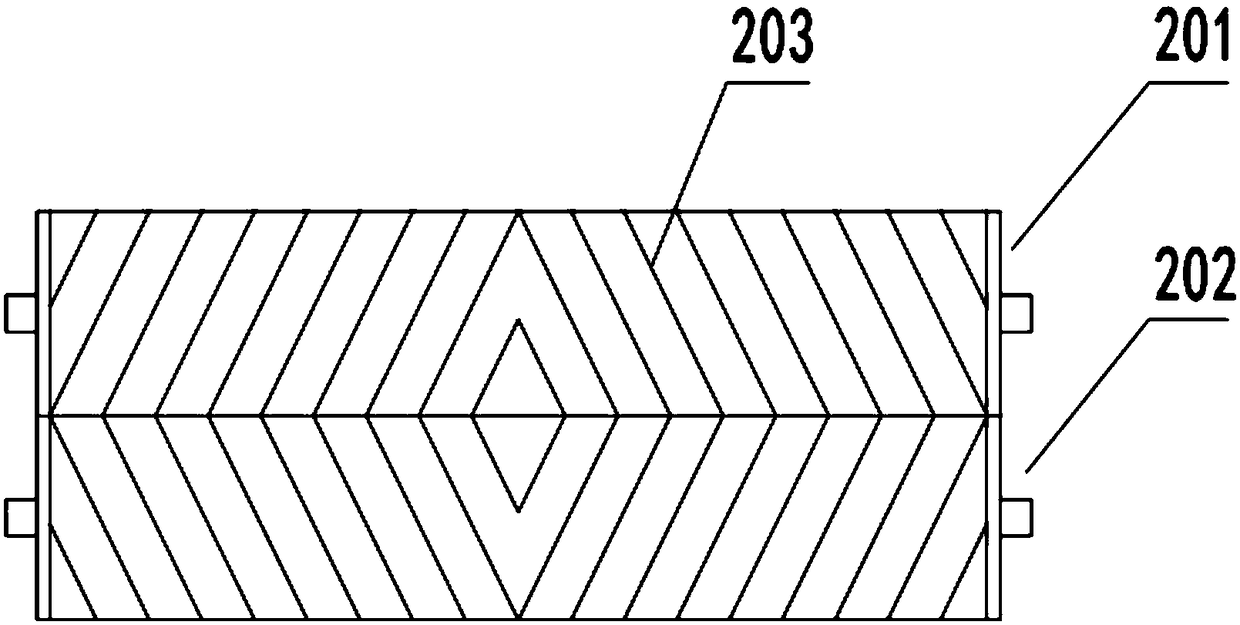

The invention discloses a plastic bag flattening mechanism characterized by combination of trowelling rollers and hot air. The plastic bag flattening mechanism comprises a machine frame, a trowellingmechanism, a fan, an electric heating roller and a tensioning mechanism. Side plates are fixedly arranged on the two sides of the machine frame, the machine frame and the side plates are combined in an encircling mode to form a channel which allows a semi-finished plastic bag to pass through, and the trowelling mechanism and the tensioning mechanism are installed in the channel. The trowelling mechanism comprises the first trowelling roller and the second trowelling roller, wherein the first trowelling roller and the second trowelling roller are opposite in position and are driven by an external power mechanism to rotate in an opposite mode. The plastic bag flattening mechanism has the beneficial effects that folds on the surface of the semi-finished plastic bag can be stretched towards the two sides by inclined lines which are outwards diffused, and therefore the surface of the semi-finished plastic bag can be flat; then the semi-finished plastic bag is heated and cooled, and therefore the shape of the plastic bag is fixed; and the flattening quality of the plastic bag can be greatly improved, and the later-period processing of the plastic bag is facilitated.

Owner:吕玉喜

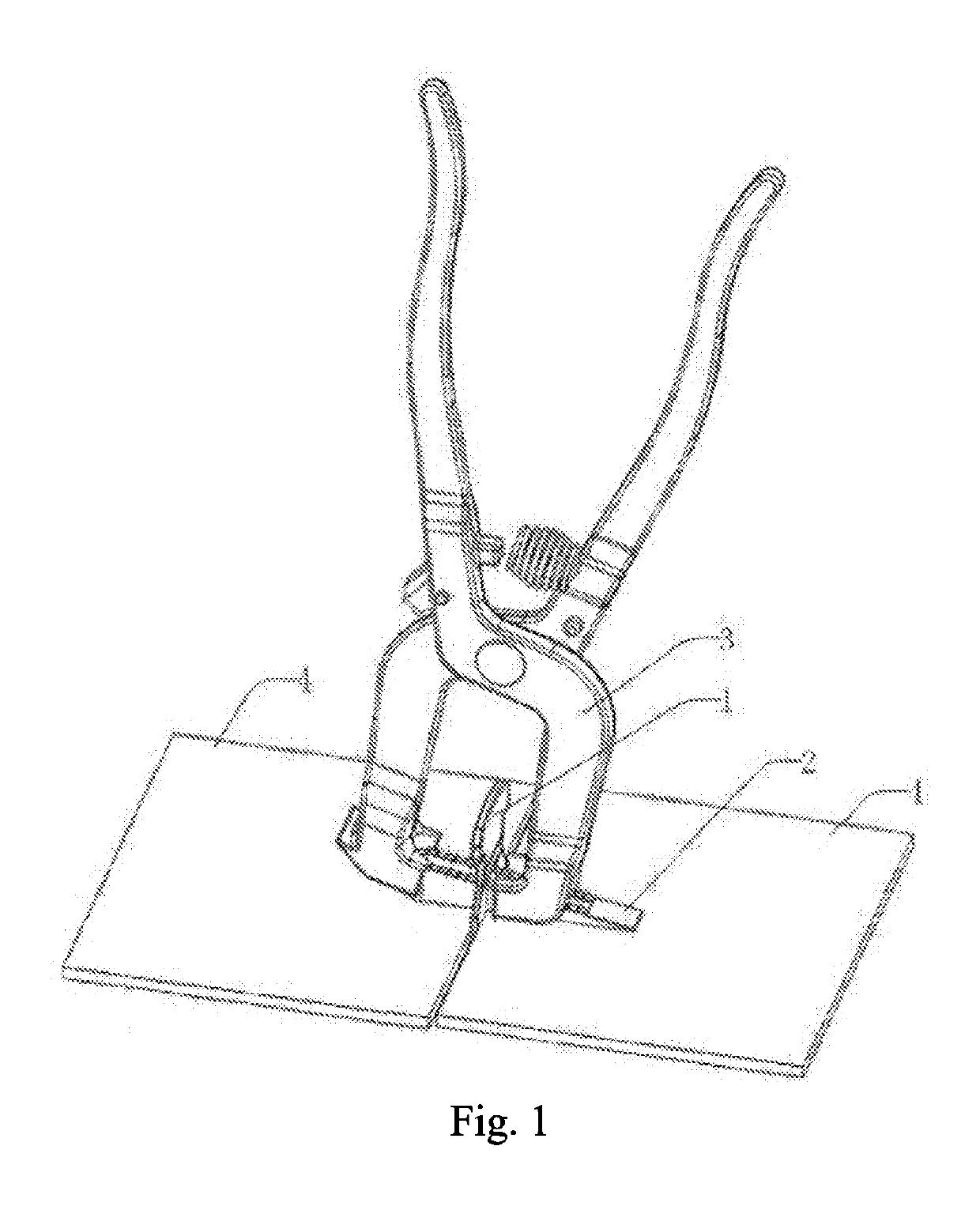

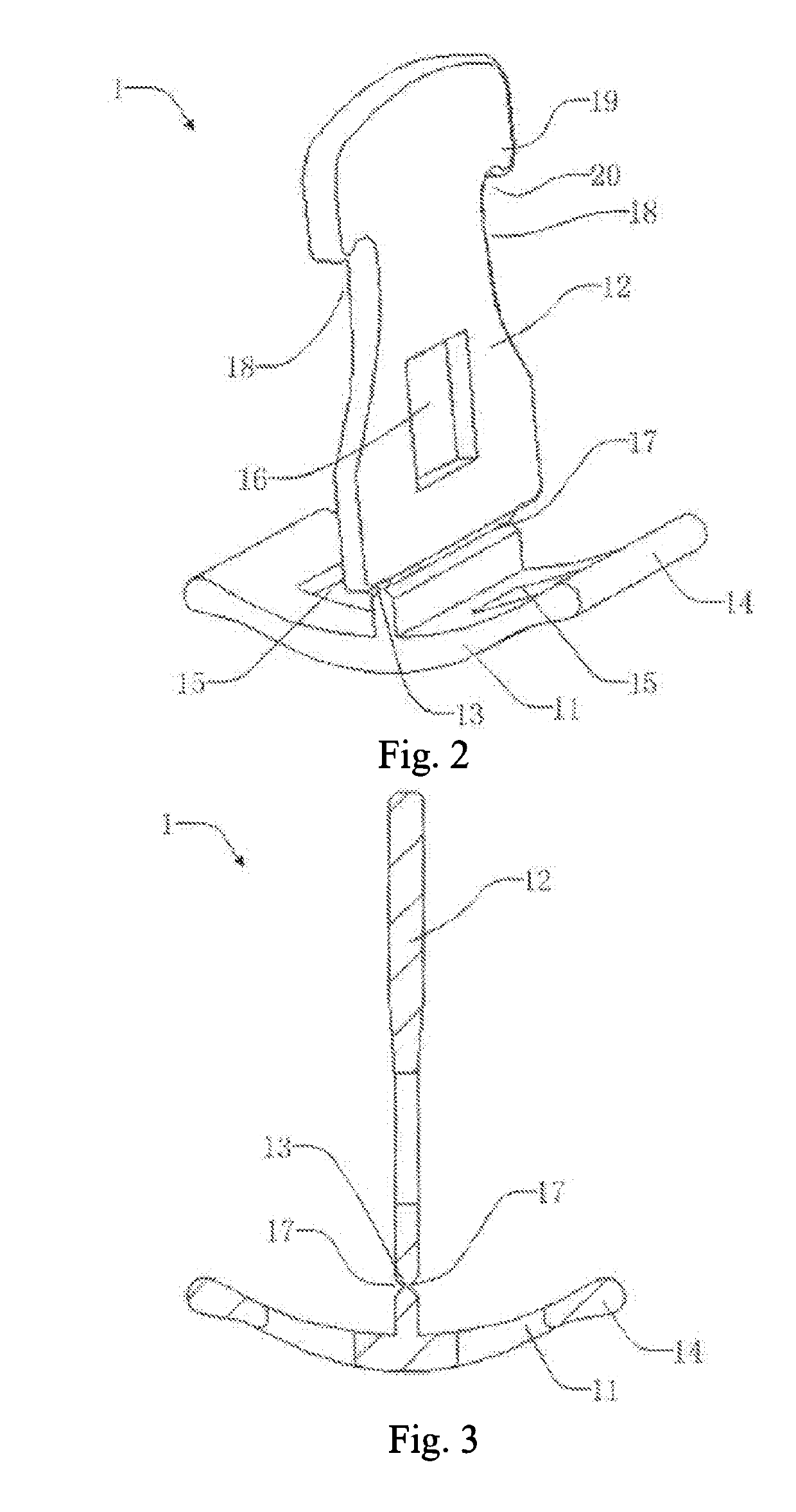

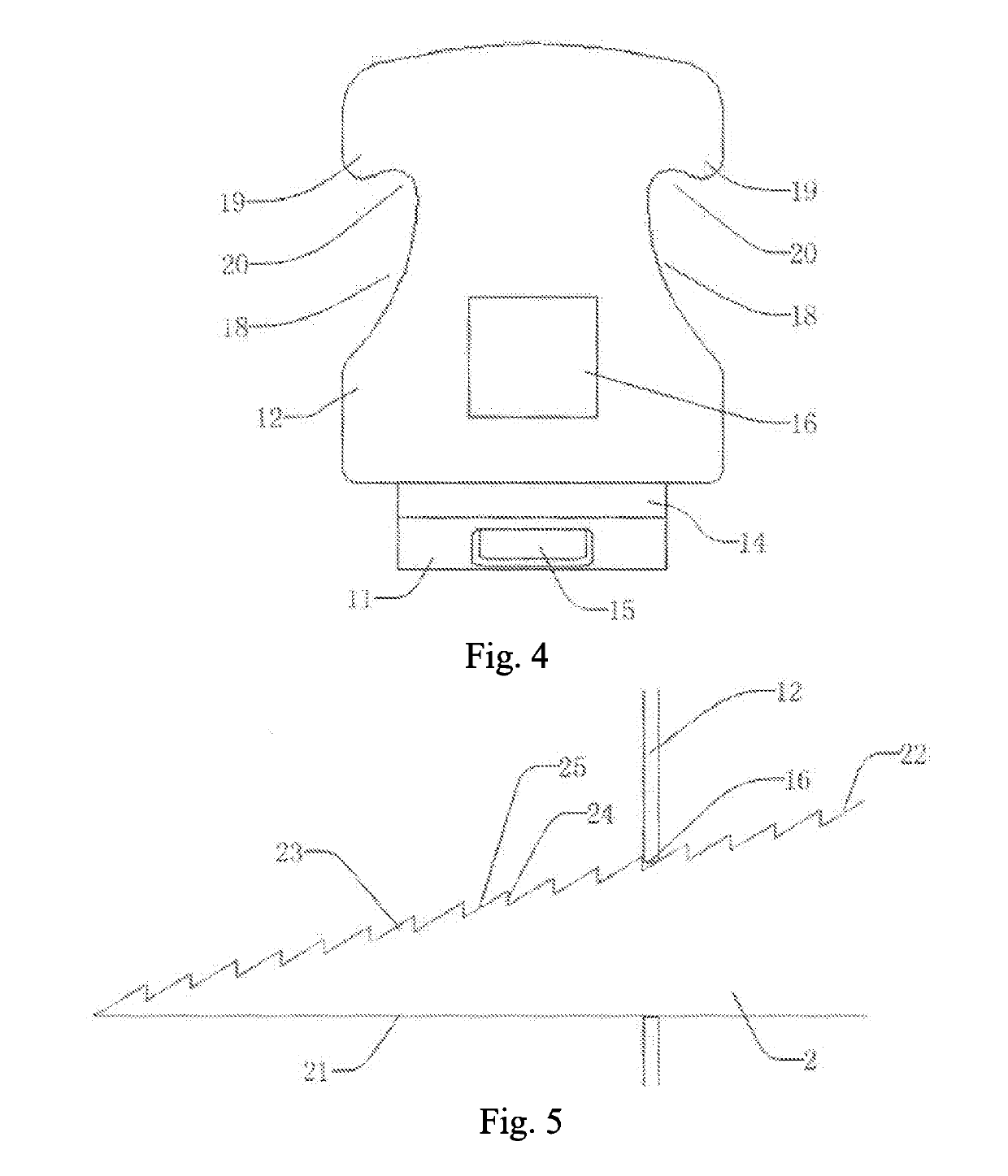

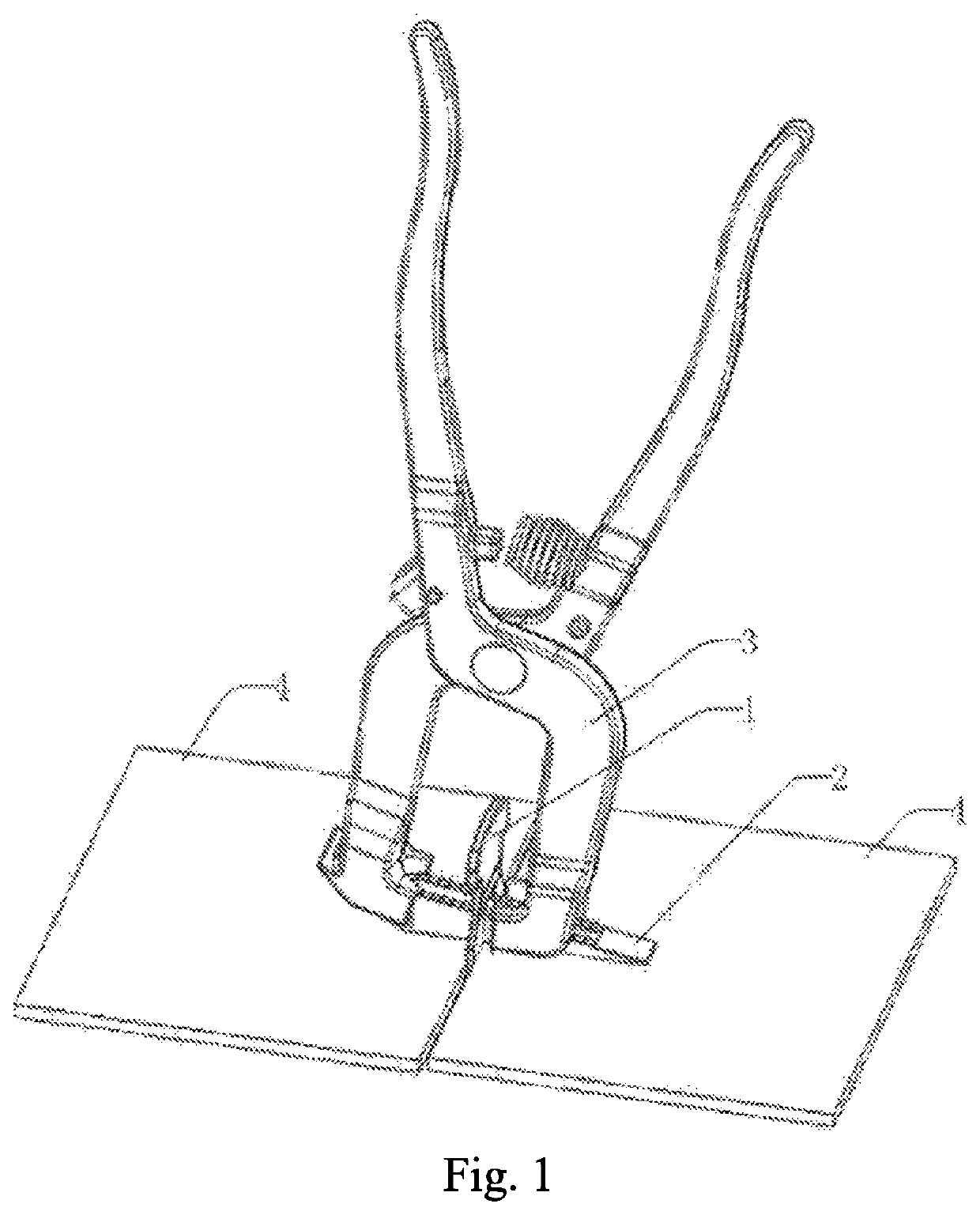

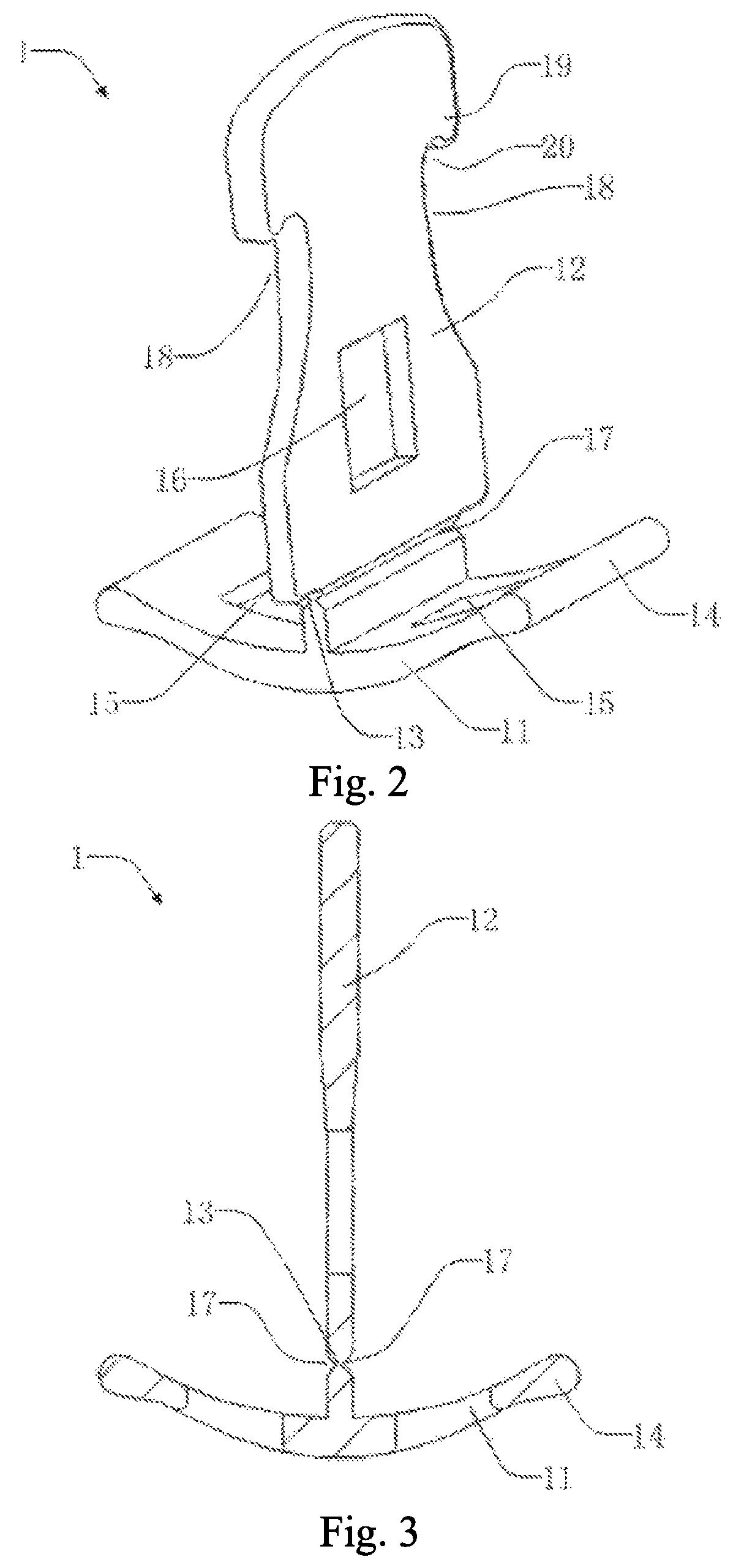

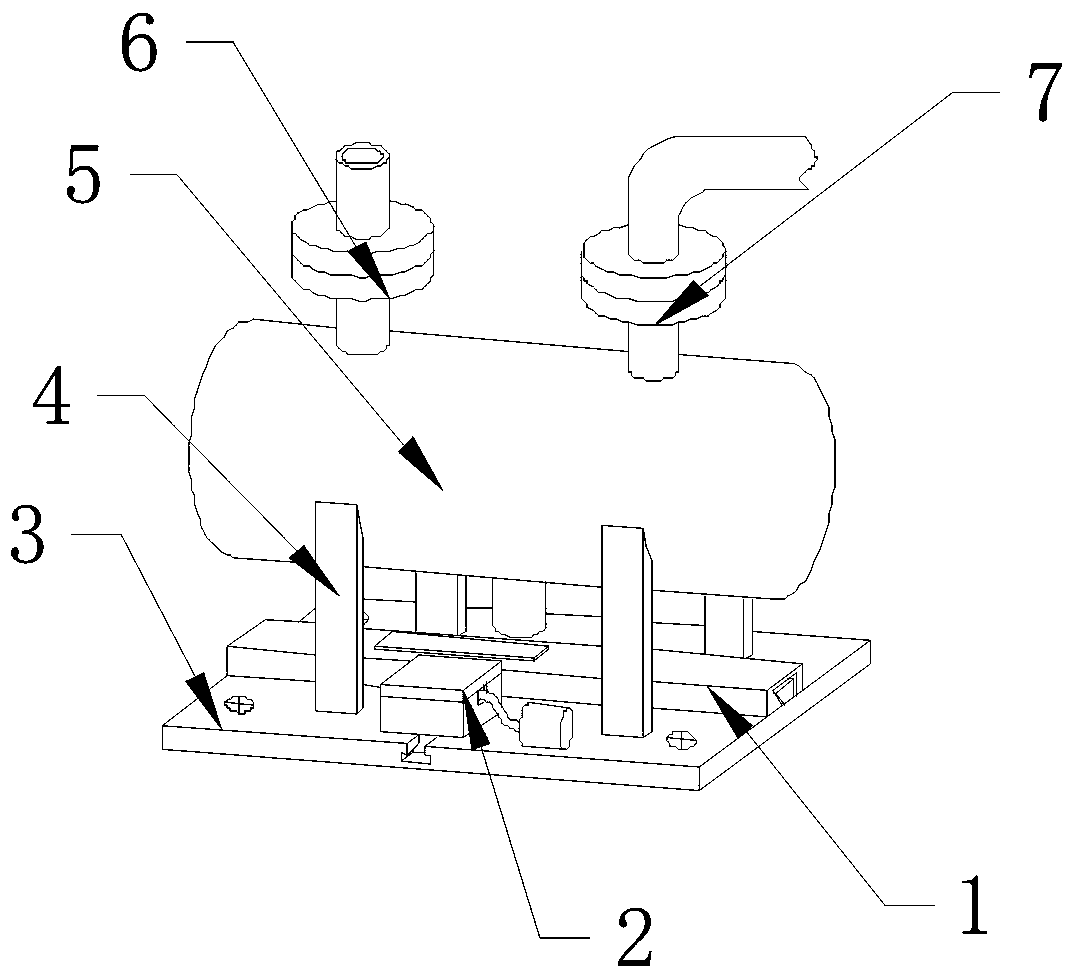

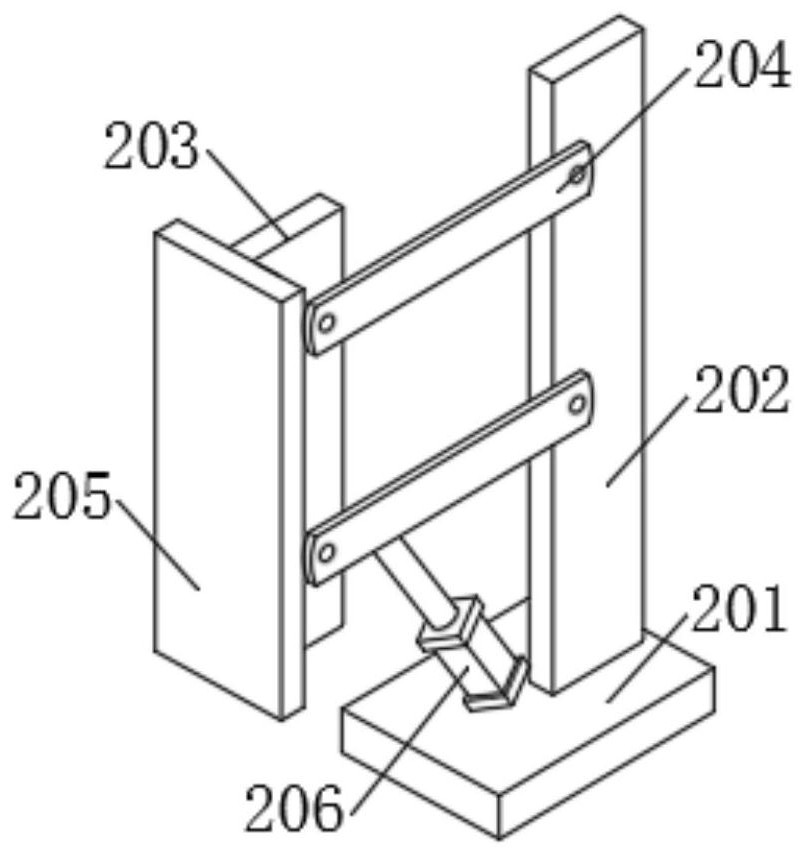

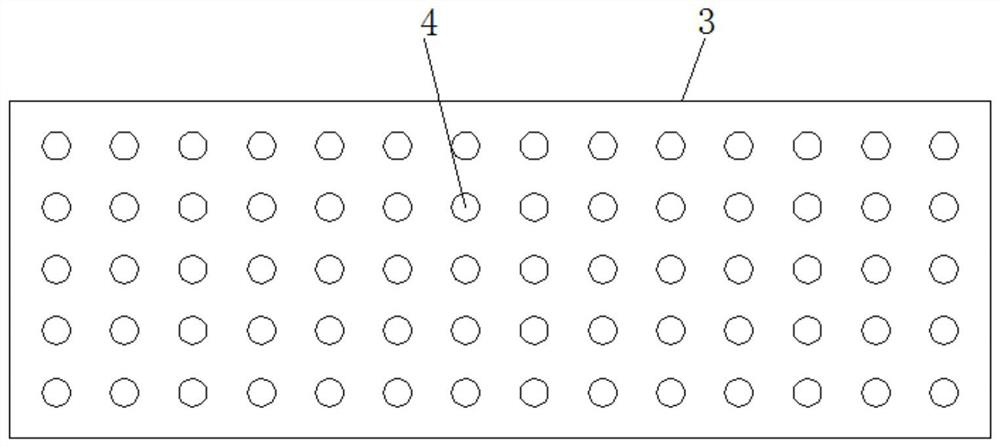

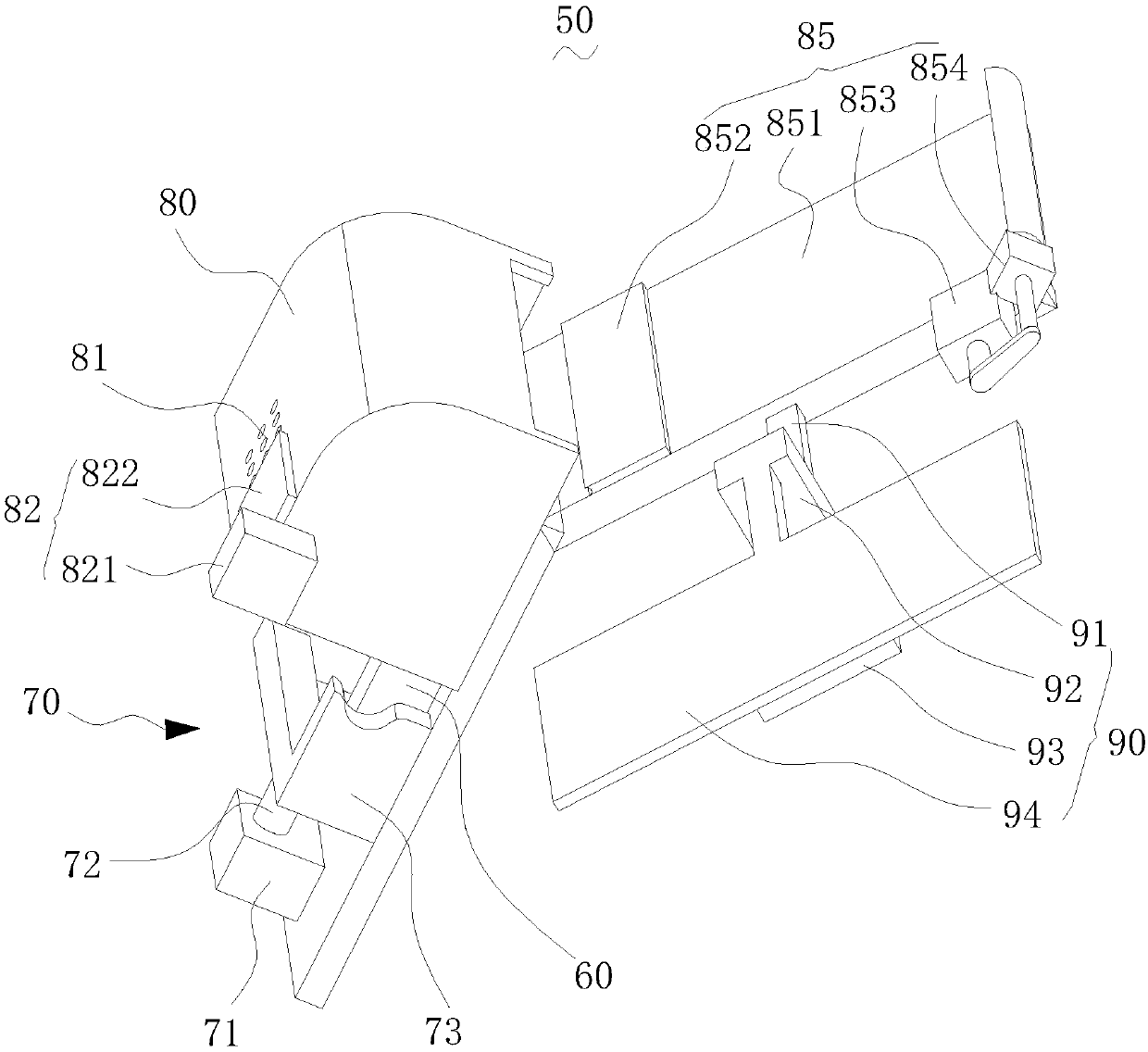

Ceramic tile leveling bracket, pushing and clamping pliers and ceramic tile leveling and laying system

Disclosed are a ceramic tile leveling bracket, pushing and clamping pliers and a ceramic tile leveling and laying system. The ceramic tile leveling and laying system comprises: a ceramic tile leveling bracket (1), an insertion block (2) and pushing and clamping pliers (3), wherein the ceramic tile leveling bracket (1) is provided at the junction between two adjacent ceramic tiles (4), one end of the insertion block (2) is inserted into an insertion block through hole (16) of the ceramic tile leveling bracket (1), and the pushing and clamping pliers (3) push and clamp the insertion block (2) into the insertion block through hole (16), so that an insertion block bottom surface (21) is tangent to upper surfaces of the two ceramic tiles (4). The ceramic tile leveling and laying system is easy to operate, and helps to improve the laying efficiency and laying quality.

Owner:HANGZHOU GREAT STAR IND CO LTD

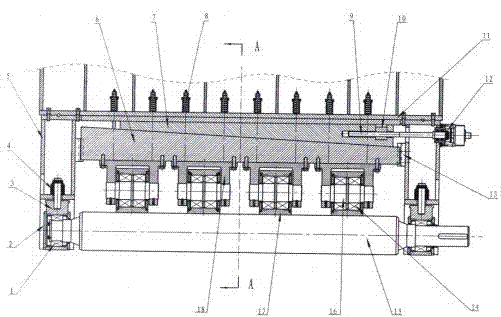

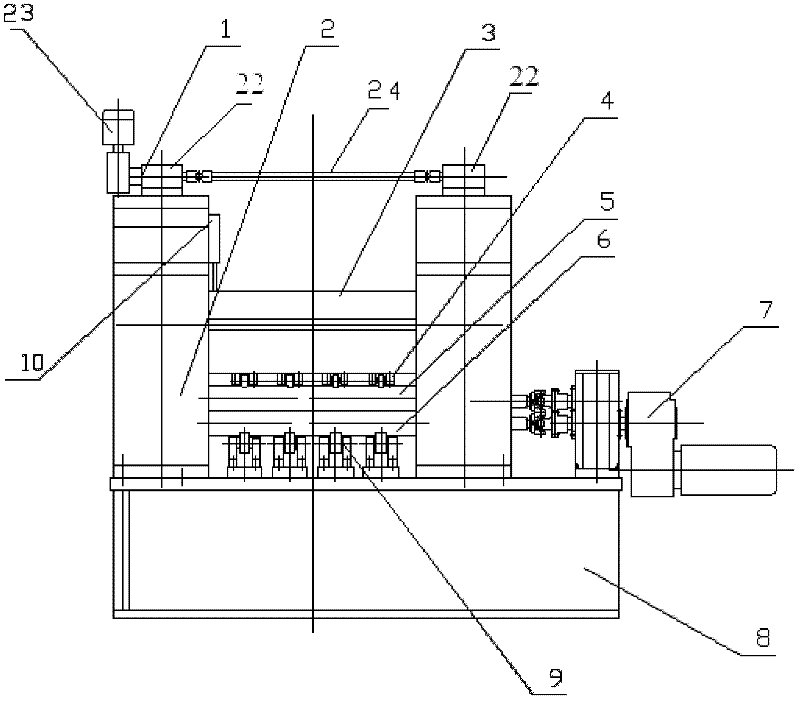

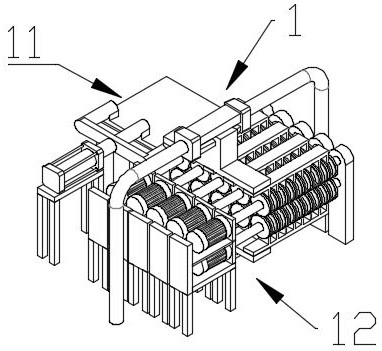

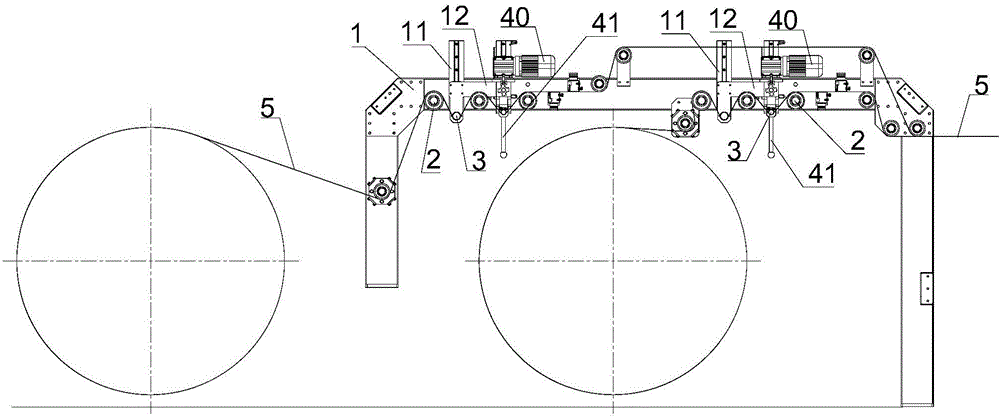

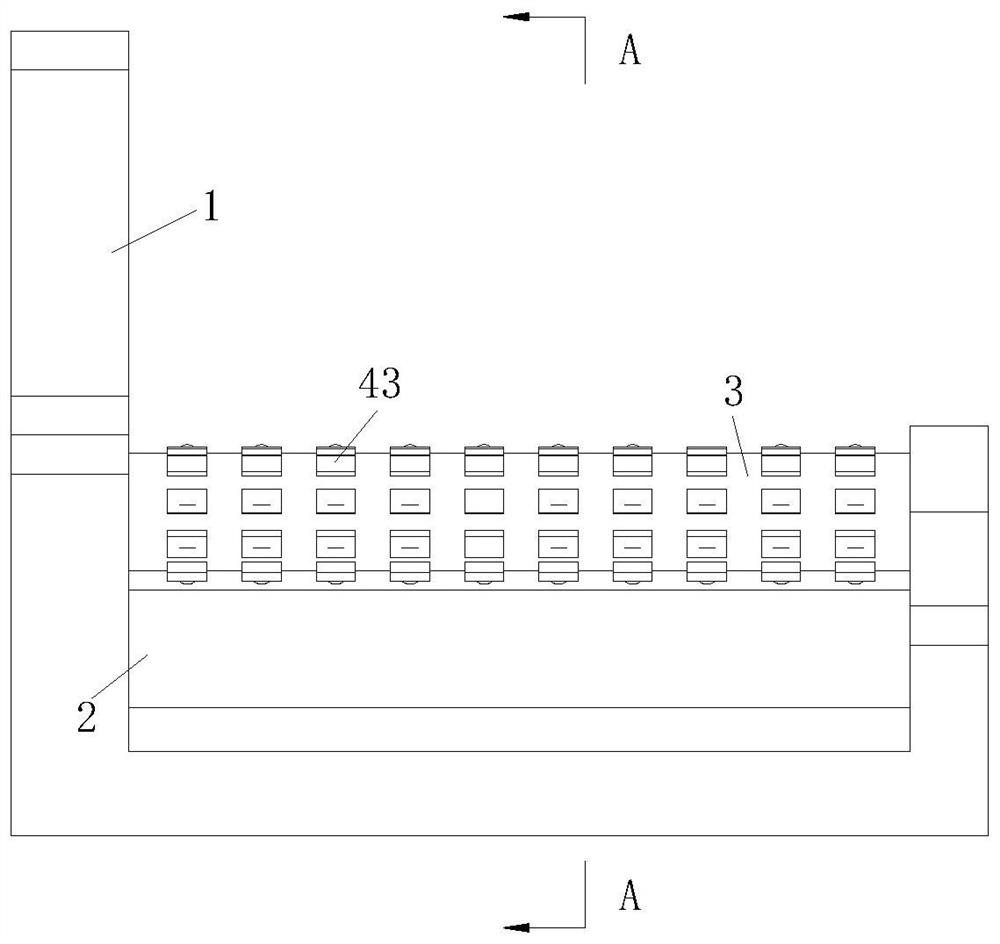

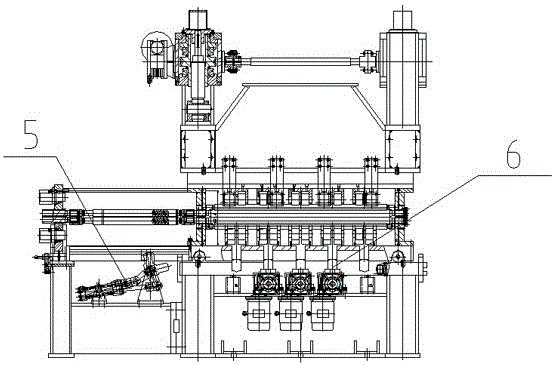

Multi-beam plate leveller

InactiveCN102371291ARealize adjustable leveling patternSolve the problem of difficult levelingMeasurement deviceEngineering

The invention relates to a multi-beam plate leveler, which is structurally characterized in that all screwdown mechanisms are installed on a rack; each set of screwdown mechanism is connected to two upper sides of two sides of each single beam respectively by a screw and a nut; two ends of each upper working roll are respectively fixed on one single beam by an upper roll bearing pedestal; a plurality of sets of upper support rolls are fixed on each single beam; at least one set of support roll is symmetrically arranged or staggered; the single beams are mutually, laterally and rigidly supported in the rack; the single beam on the outer side is thicker and has enough lateral rigidity; a bed body and the rack are fixedly connected; two ends of each lower working roll are respectively fixed on the bed body by a lower roll bearing pedestal; a plurality of sets of lower support rolls are fixed on the bed body; each lower working roll needs to be supported by multiple sets of lower support rolls; a main drive is respectively connected with the upper working roll and the lower working roll by a coupler; and each single beam is provided with a displacement measurement device. The multi-beam plate leveler has the advantages of strong lateral rigidity of the single beams, capability of realizing thin plate leveling and wide application range.

Owner:潘耀华 +1

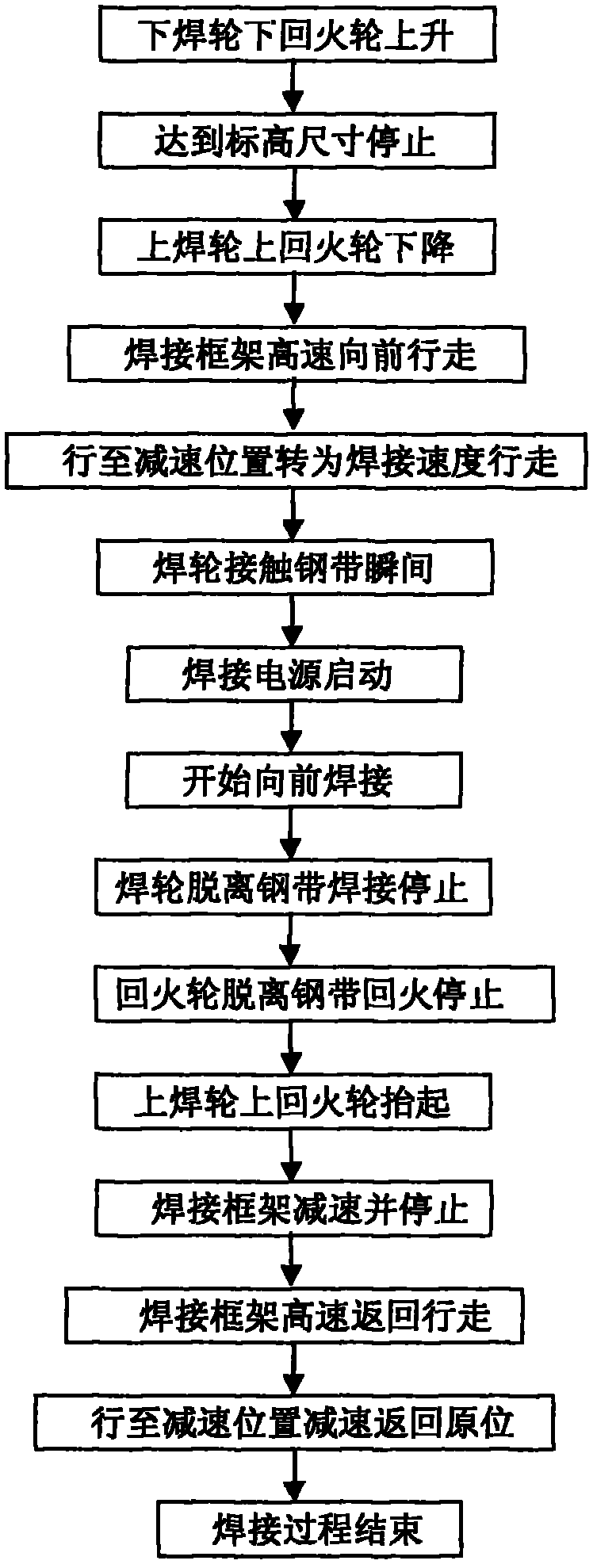

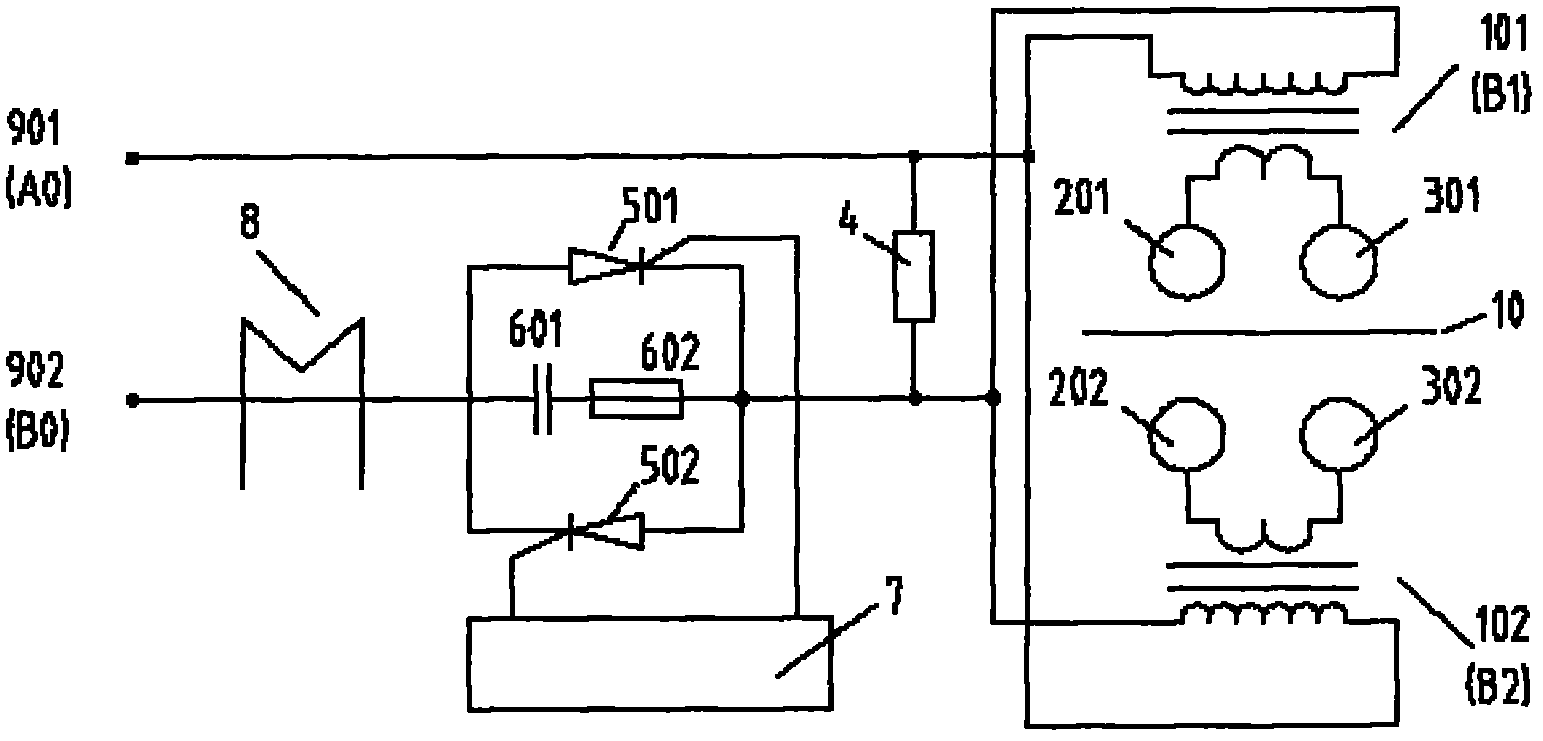

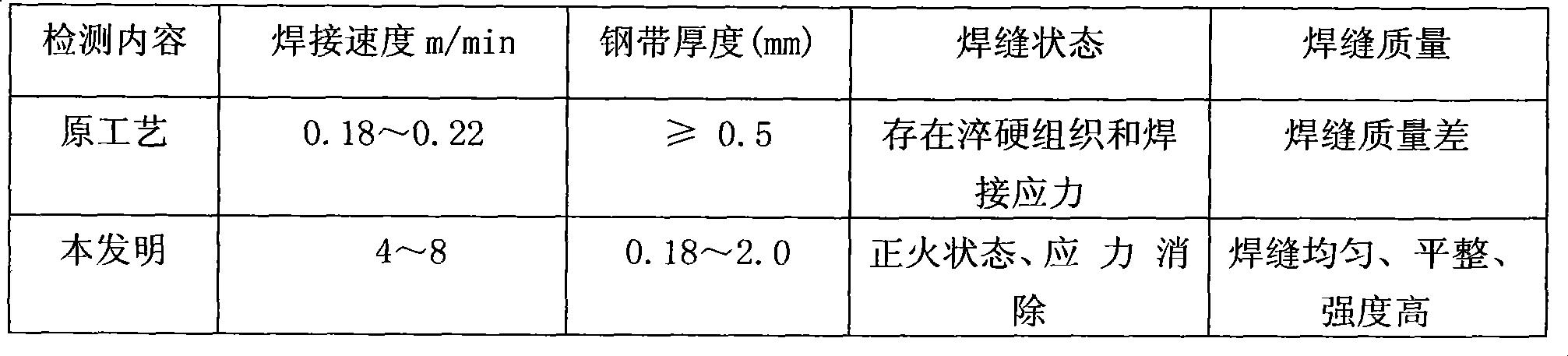

Cold-rolled strip welding technology method

InactiveCN103831520AEliminate residual welding stressAvoid crackingWelding electric supplyRectilinear seam weldingElectrical resistance and conductanceResistance capacitance

The invention relates to a cold-rolled strip welding technology method. A welding framework drives an upper welding wheel, a lower welding wheel, an upper tempering wheel and a lower tempering wheel to walk forwards; the instant the upper and the lower welding wheels are in contact with a steel belt, controlled silicon is closed through a trigger circuit, an original edge of a welding transformer is powered on, a loop of an auxiliary edge of the welding transformer is closed, The current flows through the steel belt to act to generate heat through the resistance of the steel belt, and when the heat is continuously accumulated to enable metal on the welding portions to be combined through fusing; when the welding wheels separate away from the steel belt, welding is stopped; when the fire retuning wheels separate away from the steel belt, tempering is stopped, and the upper welding wheel and the upper tempering are lifted; the welding framework is decelerated and stopped; the welding framework returns at a high speed to walk to the deceleration position to decelerate to return to the original position, and the welding process is over; as shown in the attached chart 2, the resistor is a sucking resistor and equivalently serves as a load to have the buffering effect; the resistance-capacitance circuit is resistance-capacitance sucking protection controlled silicon; a mutual inductor compensates for sampled signals.

Owner:TIANJIN YIBO STEEL MAKING

Emergency supporting mechanism capable of changing elastic deformation for concrete paver

InactiveCN108691261AResidue reductionImprove leveling qualityRoads maintainenceElastic componentDrive wheel

Owner:马力

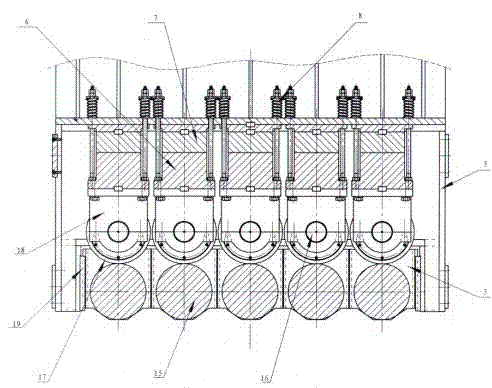

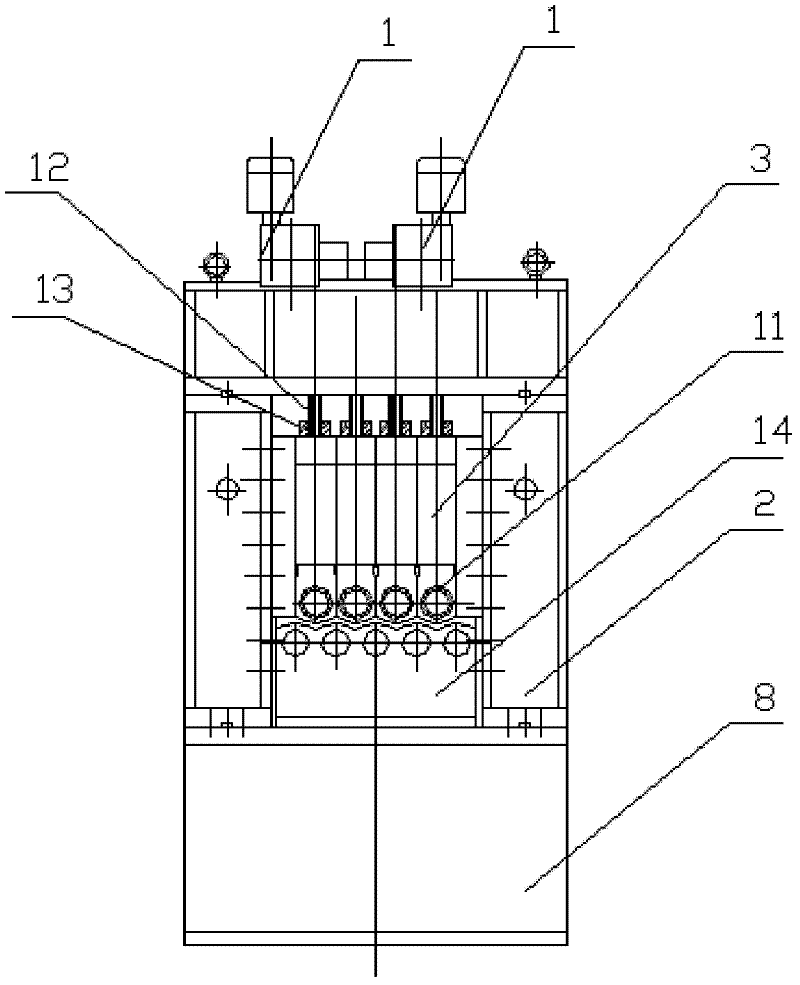

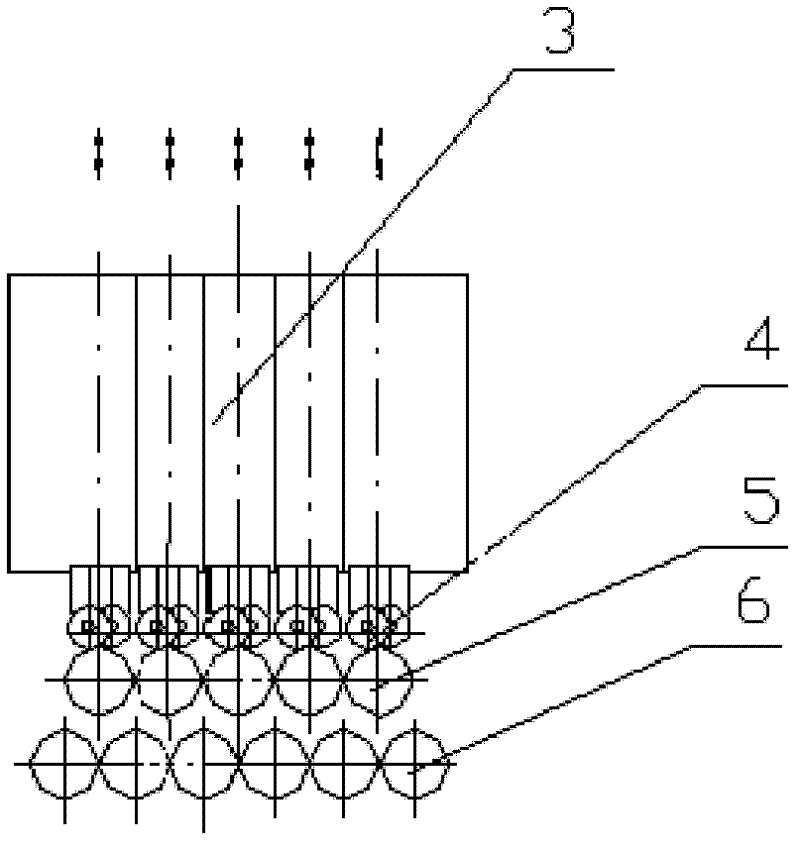

Roller type plate leveling machine

The invention discloses a roller type plate leveling machine. An upper roller frame is arranged above a lower roller frame, a moving beam is arranged between the upper roller frame and the lower roller frame, hydraulic telescoping cylinders are arranged at the bottom of the upper roller frame, telescopic heads of the hydraulic telescoping cylinders are connected with the moving beam, a plurality of upper operating rollers are mounted at the bottom of the moving beam, a plurality of lower operating rollers are arranged on the lower roller frame, the upper operating rollers and the lower operating rollers are staggered, and two ends of each of the upper operating rollers and the lower operating rollers are connected with corresponding power transmission mechanisms. A plurality of first uppersupporting rollers and a plurality of second upper supporting rollers are arranged between the upper operating rollers and the moving beam, and a plurality of first lower supporting rollers and a plurality of second lower supporting rollers are arranged between the lower operating rollers and the lower roller frame. The lower roller frame is fixedly connected to one end of each guide column, andthe other end of each guide column penetrates the moving beam to be fixedly connected with the upper roller frame. Problems of nonuniformity in stress of two ends of operating rollers, low leveling accuracy, small contact area of supporting rollers and the operating rollers, low supporting strength and poor stability of plate leveling machines in the prior art are solved.

Owner:陕西钛普稀有金属材料有限公司

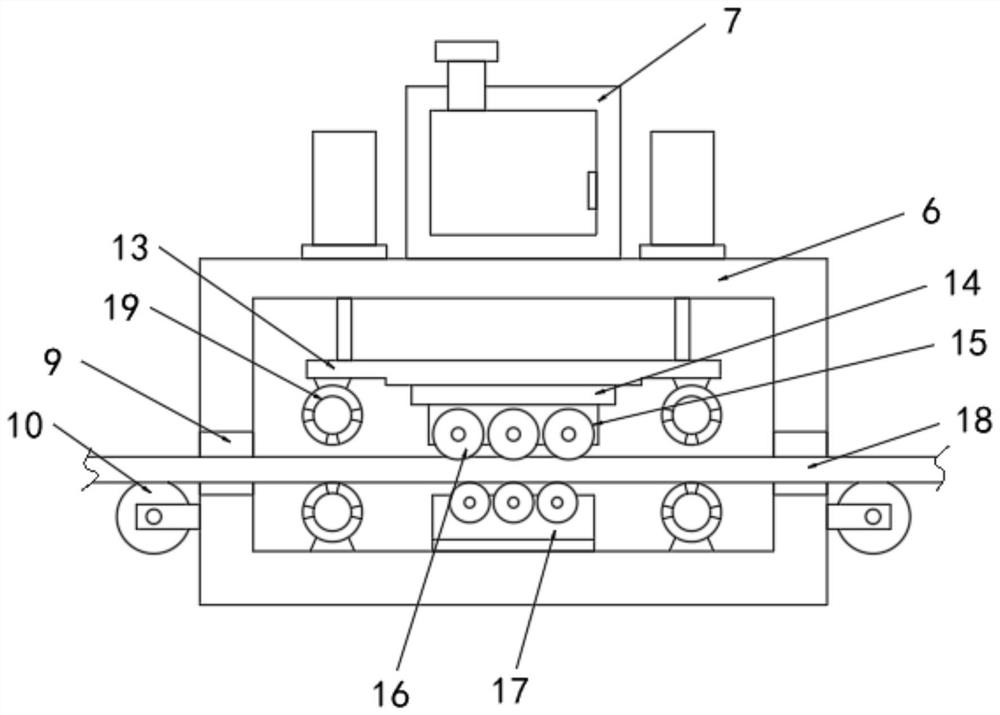

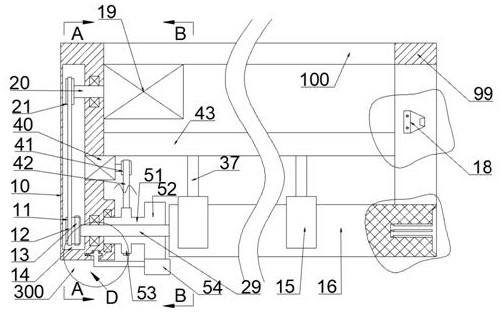

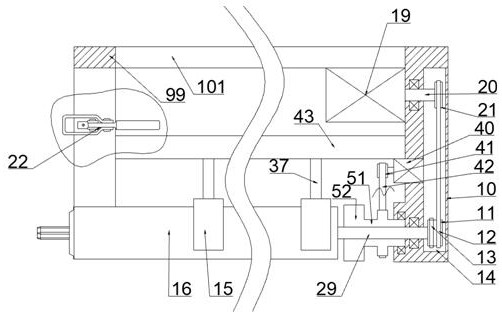

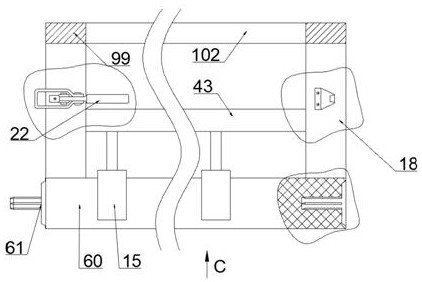

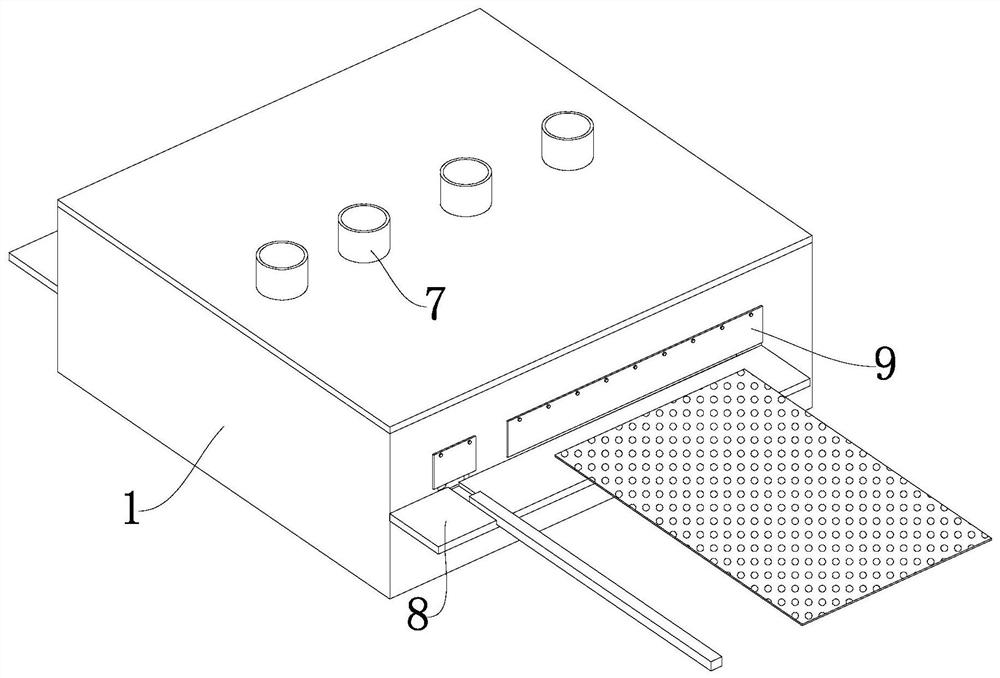

Leveling and packaging equipment applied to textile production

PendingCN114873345AEasy levelingGuaranteed to softenPackagingLiquid/gas/vapor textile treatmentTextile productionMechanical engineering

The invention discloses leveling and packaging equipment applied to textile production, and particularly relates to the technical field of textile production equipment.The leveling and packaging equipment is provided with a steam leveling chamber, steam reaches an upper steam pipe and a lower steam pipe, steam on the surface of textile fabric is soaked through a plurality of steam outlet holes formed in parallel, and it is guaranteed that the surface of the textile fabric is softened; the textile fabric leveling device is simple in structure and convenient to use, leveling treatment of textile fabric is facilitated, the driven textile fabric is leveled through the upper leveling roller and the lower leveling roller, telescopic deformation is generated on the top of an inner cavity of a mounting base through a telescopic rod, the leveling rollers in a movable base have elasticity when the textile fabric is leveled, and the leveling effect is better; the winding roller is pulled by the transverse moving rail to be at the position where the winding roller is transmitted to the conveying belt, the winding roller is conveyed to a packaging area through the conveying belt, and transferring of the winding roller is achieved; the textile fabric is arranged in a z shape, the distance between the movable roller and the fixed roller is adjusted through the second electric push rod, the textile fabric can be tensioned, and the leveling quality of the textile fabric is improved.

Owner:泉州市欣宇潮品贸易有限公司

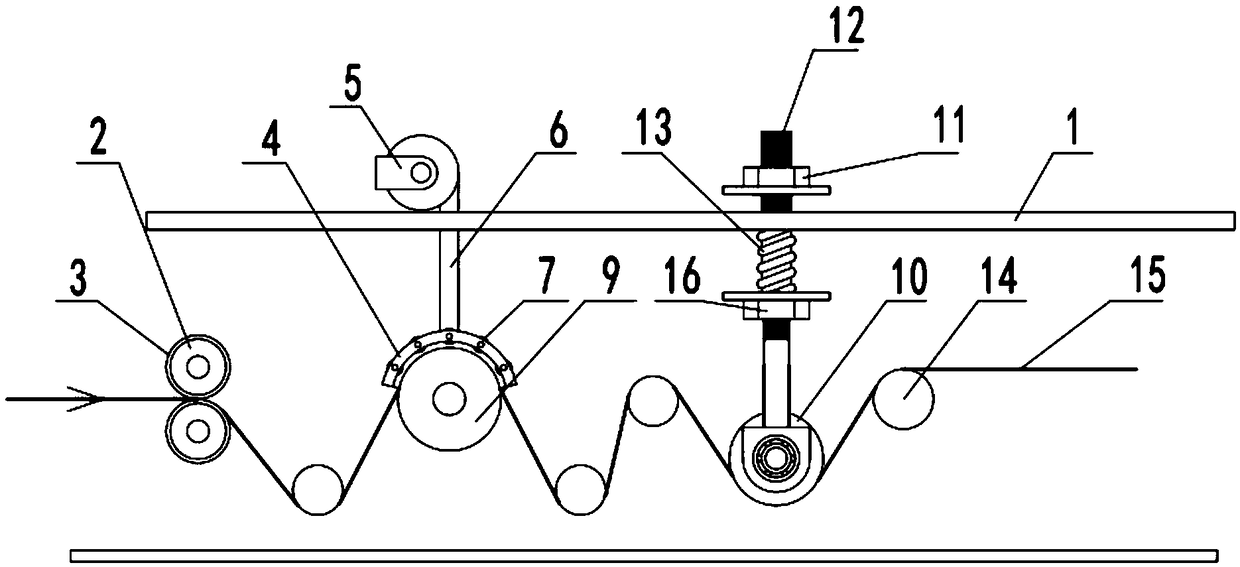

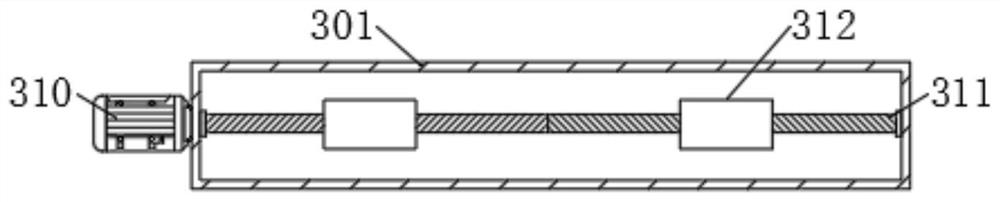

Flat wire material leveling and winding machine

ActiveCN110170914AQuality improvementEasy to collectEdge grinding machinesPolishing machinesWinding machineEngineering

The invention belongs to the technical field of flat wire material appliances, and particularly relates to a flat wire material leveling and winding machine. The flat wire material leveling and winding machine comprises a machine frame, wherein a leveling guide wheel and a straightening oil cylinder are arranged on the machine frame, the output end of the straightening oil cylinder is connected with a wire drawing hook, a leveling mechanism is arranged at the position, between the leveling guide wheel and the straightening oil cylinder, of the machine frame, the leveling mechanism comprises amaterial grinding groove, the material grinding groove is filled with grinding materials, the wire drawing hook is fixed on a winding mechanism along with the head end of a straightened flat wire material, and the winding mechanism is driven by a winding motor to carry out winding. The flat wire material leveling and winding machine has the beneficial effects that generated metal waste can be separated from grinding powder in the flattening process of the flat wire material, so that the flattening quality of the flat wire material is improved, the flat wire material can be easily taken down from the winding mechanism after being wound, so that the working efficiency is improved.

Owner:南通伊福帮服装科技有限公司

Ceramic tile leveling bracket, pushing and clamping pliers and ceramic tile leveling and laying system

Disclosed are a ceramic tile leveling bracket, pushing and clamping pliers and a ceramic tile leveling and laying system. The ceramic tile leveling and laying system comprises: a ceramic tile leveling bracket (1), an insertion block (2) and pushing and clamping pliers (3), wherein the ceramic tile leveling bracket (1) is provided at the junction between two adjacent ceramic tiles (4), one end of the insertion block (2) is inserted into an insertion block through hole (16) of the ceramic tile leveling bracket (1), and the pushing and clamping pliers (3) push and clamp the insertion block (2) into the insertion block through hole (16), so that an insertion block bottom surface (21) is tangent to upper surfaces of the two ceramic tiles (4). The ceramic tile leveling and laying system is easy to operate, and helps to improve the laying efficiency and laying quality.

Owner:HANGZHOU GREAT STAR IND CO LTD

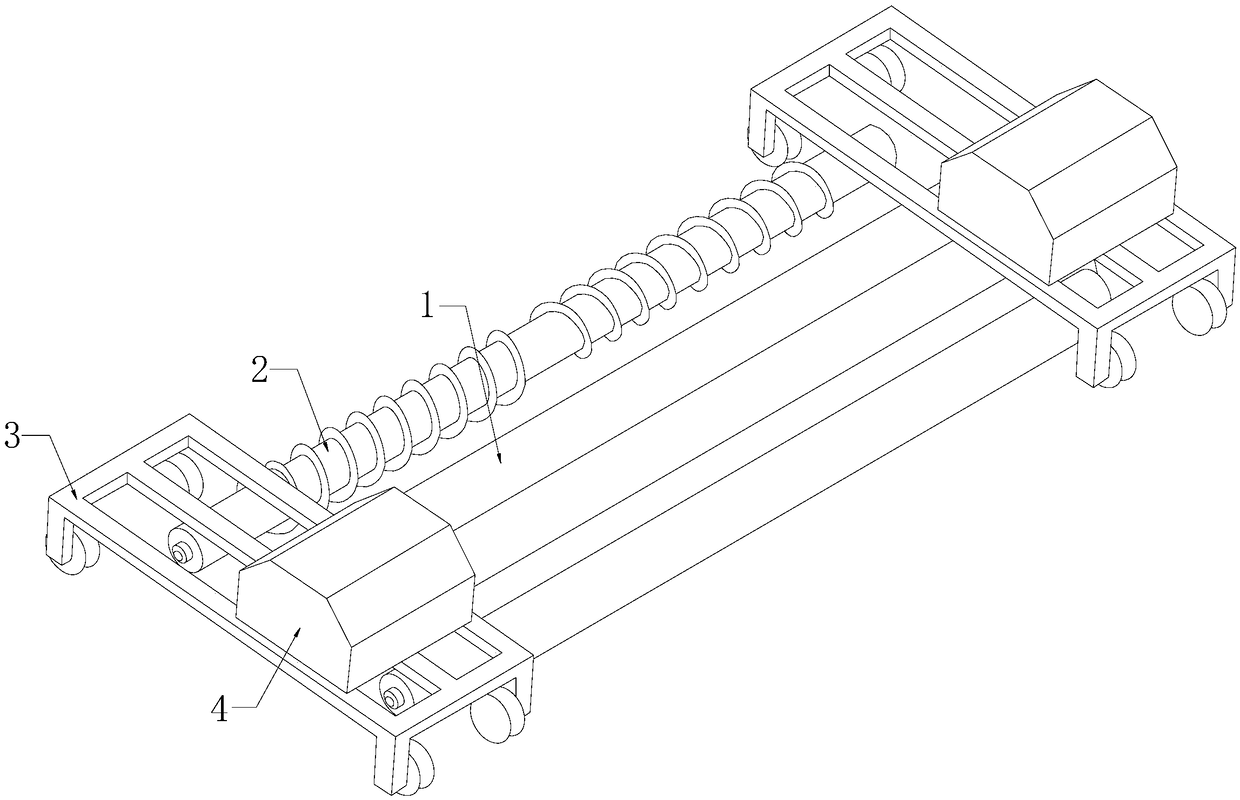

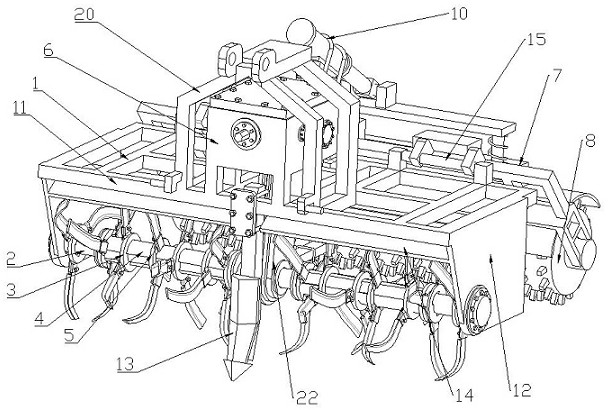

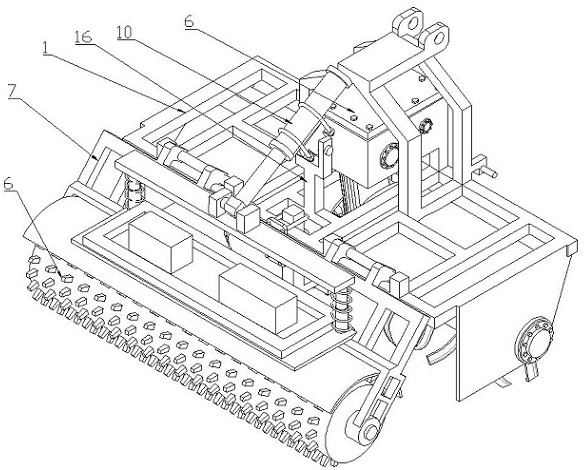

Farmland rotary tillage device and method

ActiveCN114793495AAdjustable Axial DensityPromote growthSpadesTilling equipmentsAgricultural scienceHigh humidity

The invention discloses a farmland rotary tillage device and method, and relates to the technical field of farming equipment and method.According to the farmland rotary tillage device and method, a main shaft is driven through transmission connection between the main shaft and a main shaft box on a rack, an auxiliary shaft is arranged on the main shaft in a sliding mode, a main cutter head is fixedly arranged on the main shaft, and an auxiliary cutter head is arranged on the auxiliary shaft; therefore, the distance between the main cutter head and the auxiliary cutter head can be adjusted, and the axial density of the rotary blades on the rotary tillage harrow can be adjusted. A hydraulic distance adjusting mechanism matched with the auxiliary shaft is arranged, so that the distance between the main cutter head and the auxiliary cutter head is mechanically adjusted, the control is more accurate, and the manpower is saved; according to the method, the land airing time can be greatly shortened, the autumn planting time is greatly advanced, the wheat head growing rate is increased, and the phenomenon that the cost is increased due to the increase of the seeding rate is avoided; the problems that the airing time is long when the soil humidity is high before autumn sowing, and the leveling effect of an existing rotary tillage device and an existing rotary tillage method on a farmland with the high humidity is poor are solved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

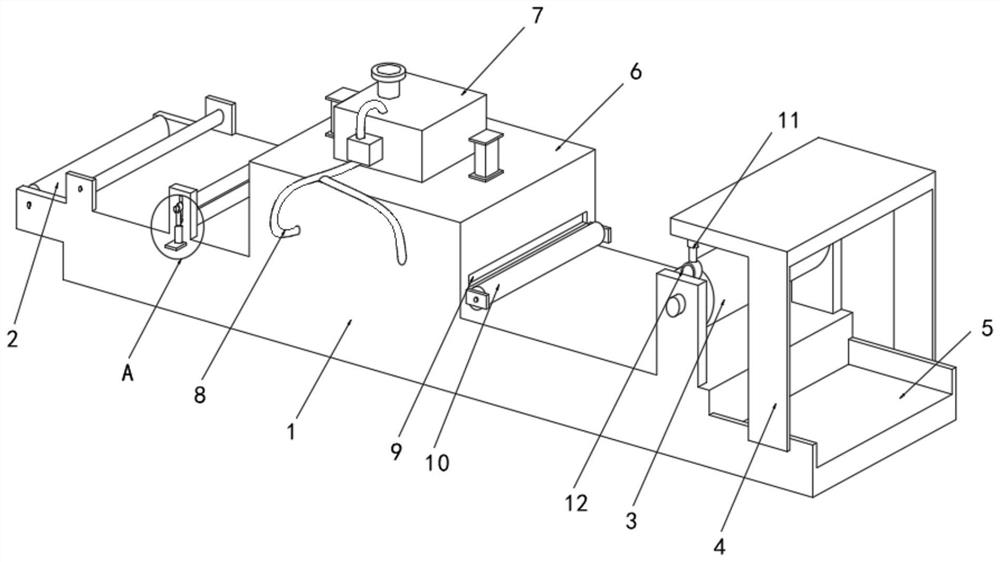

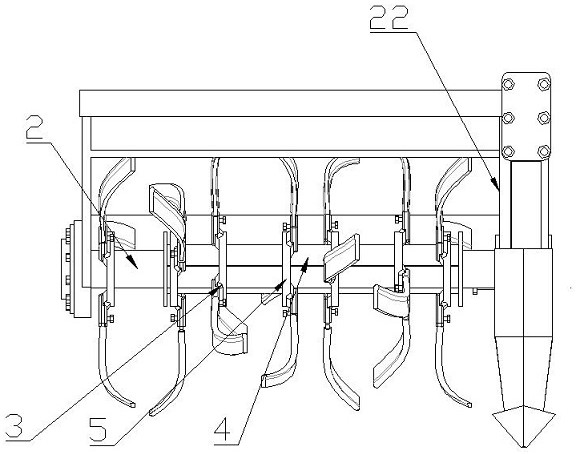

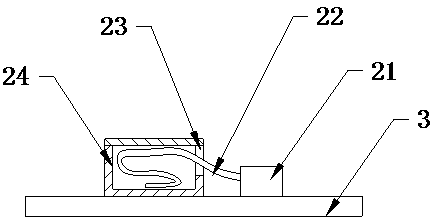

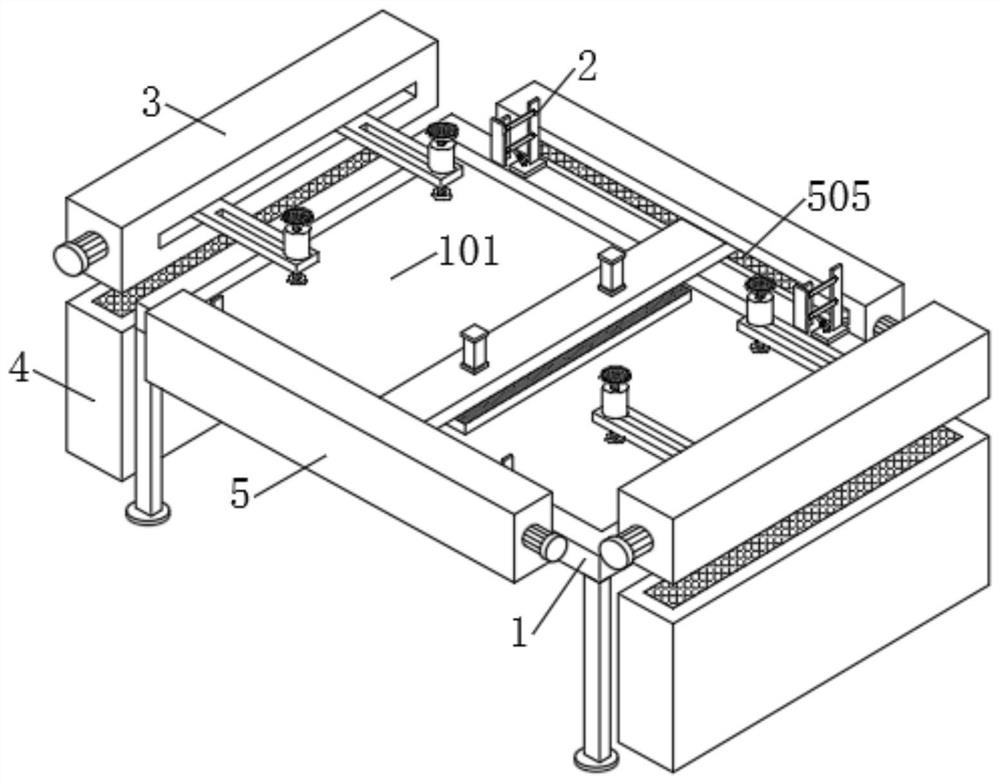

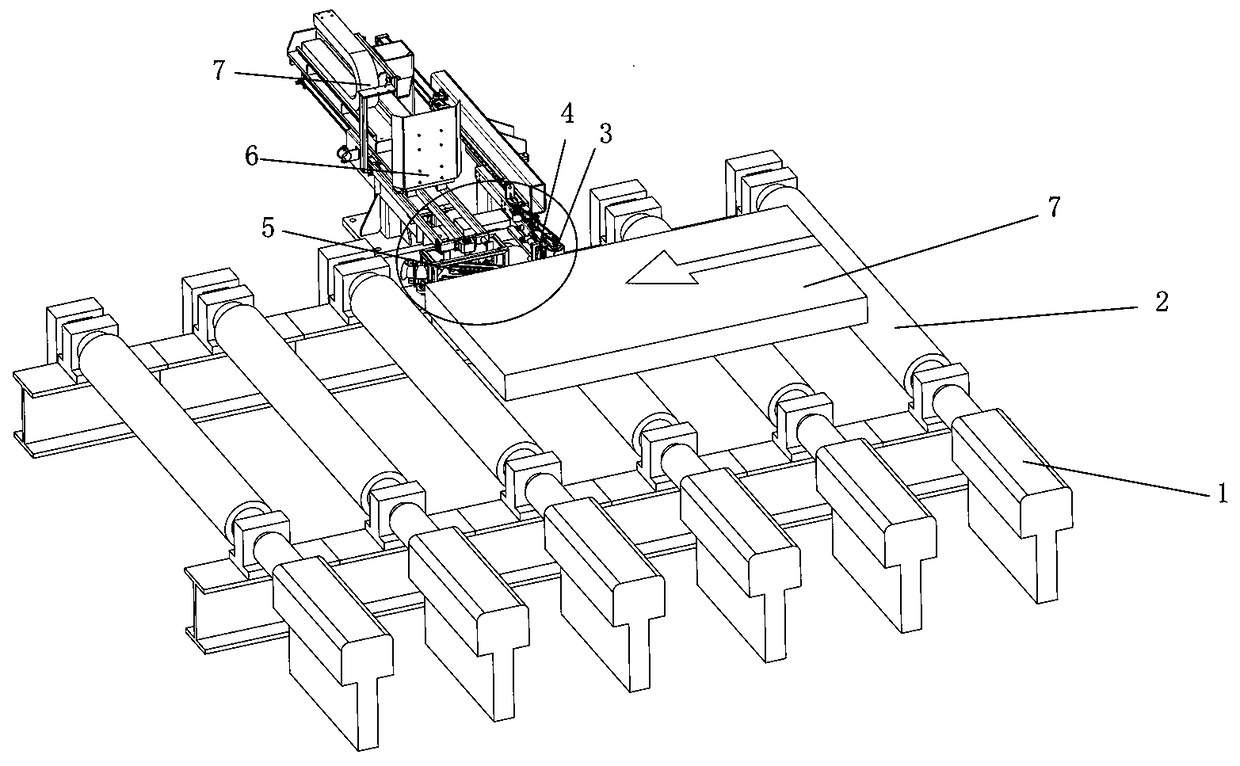

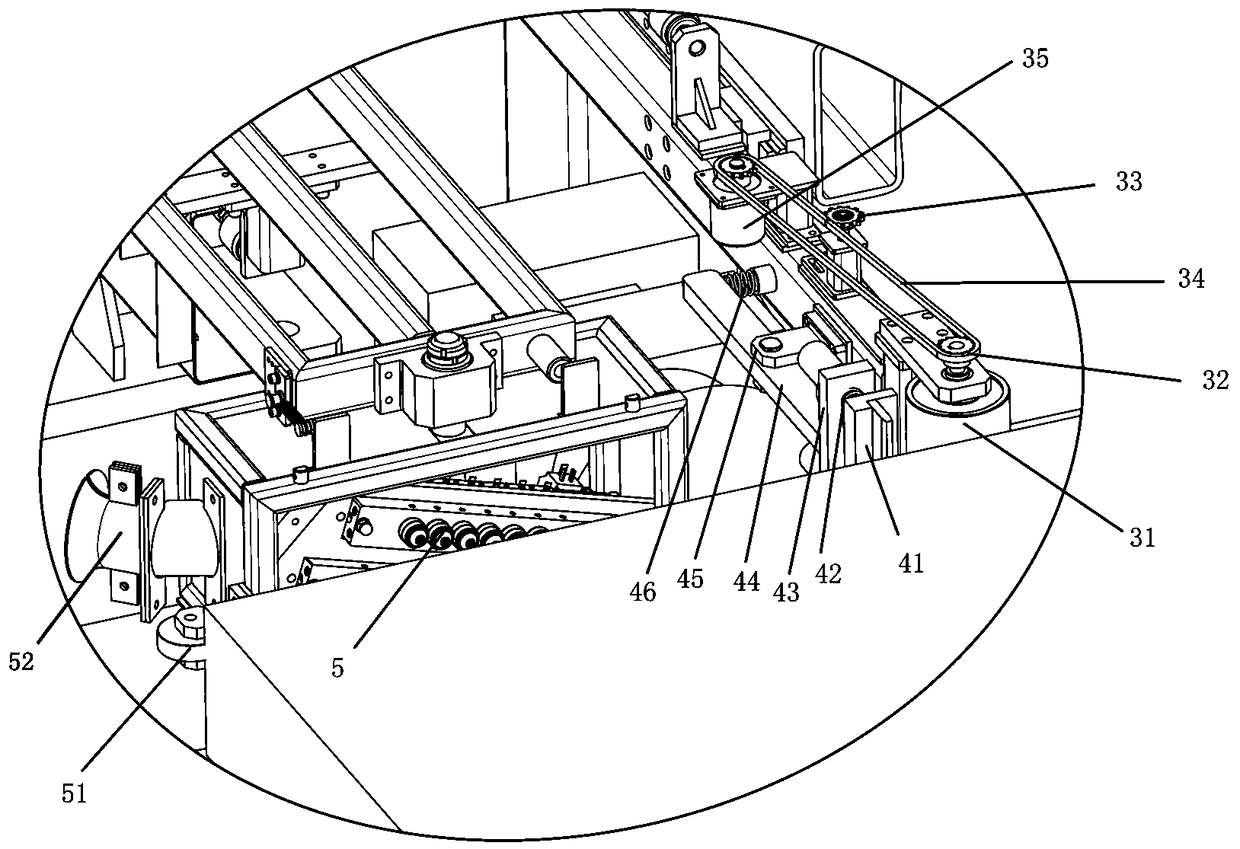

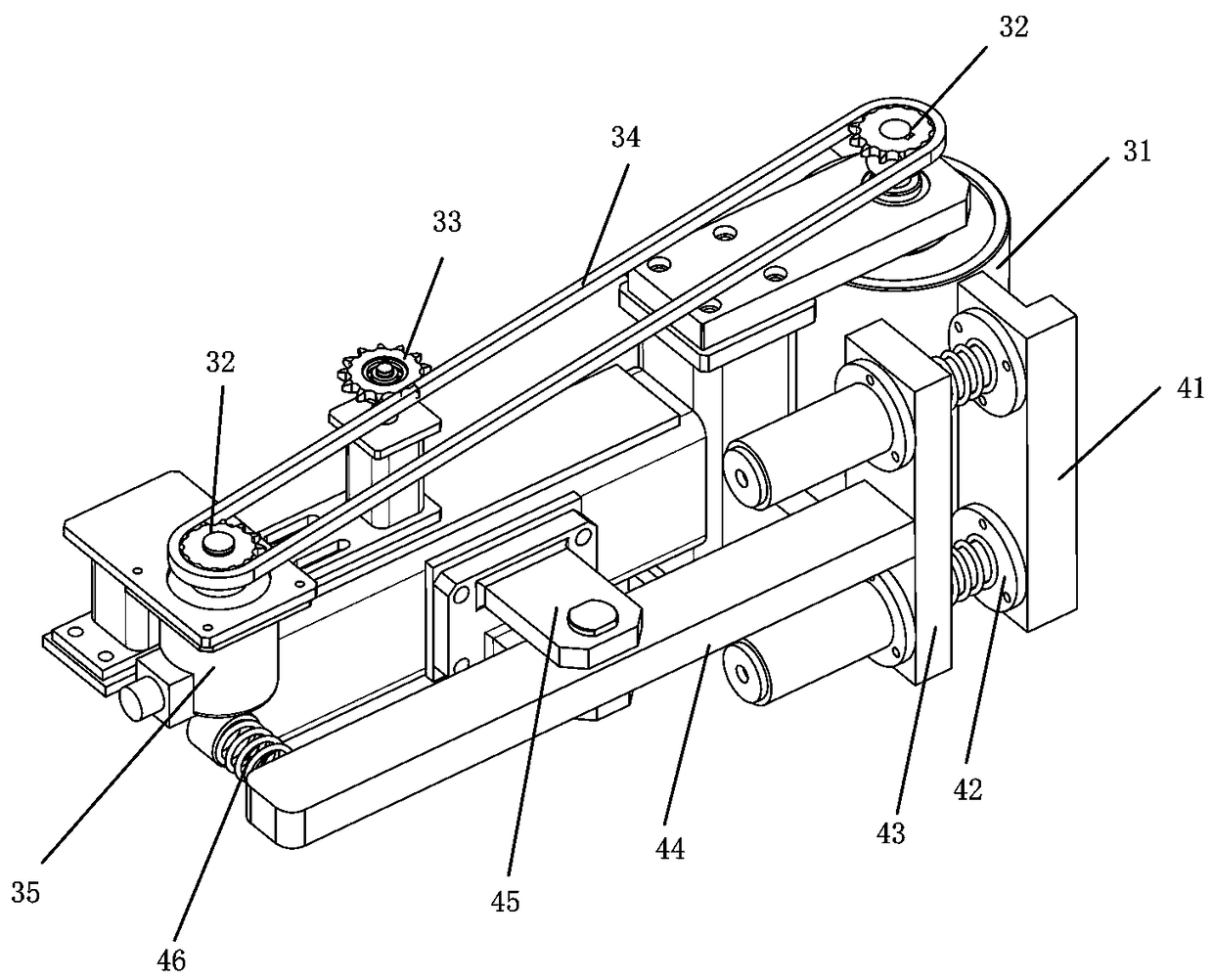

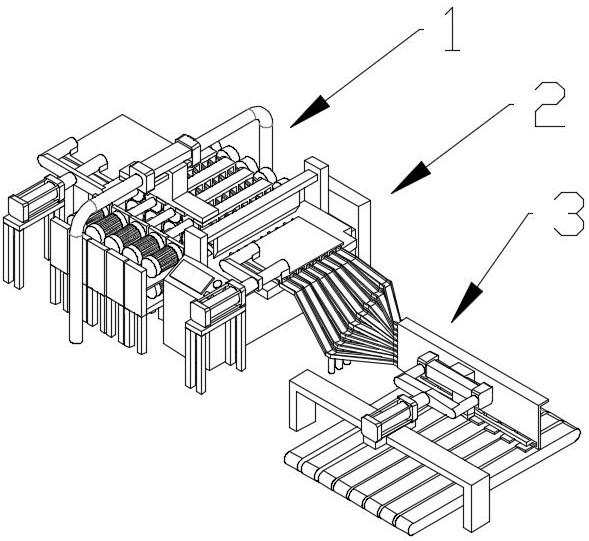

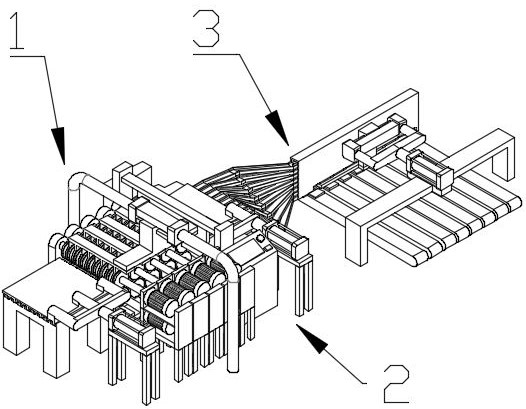

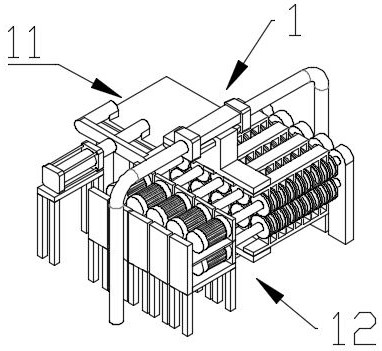

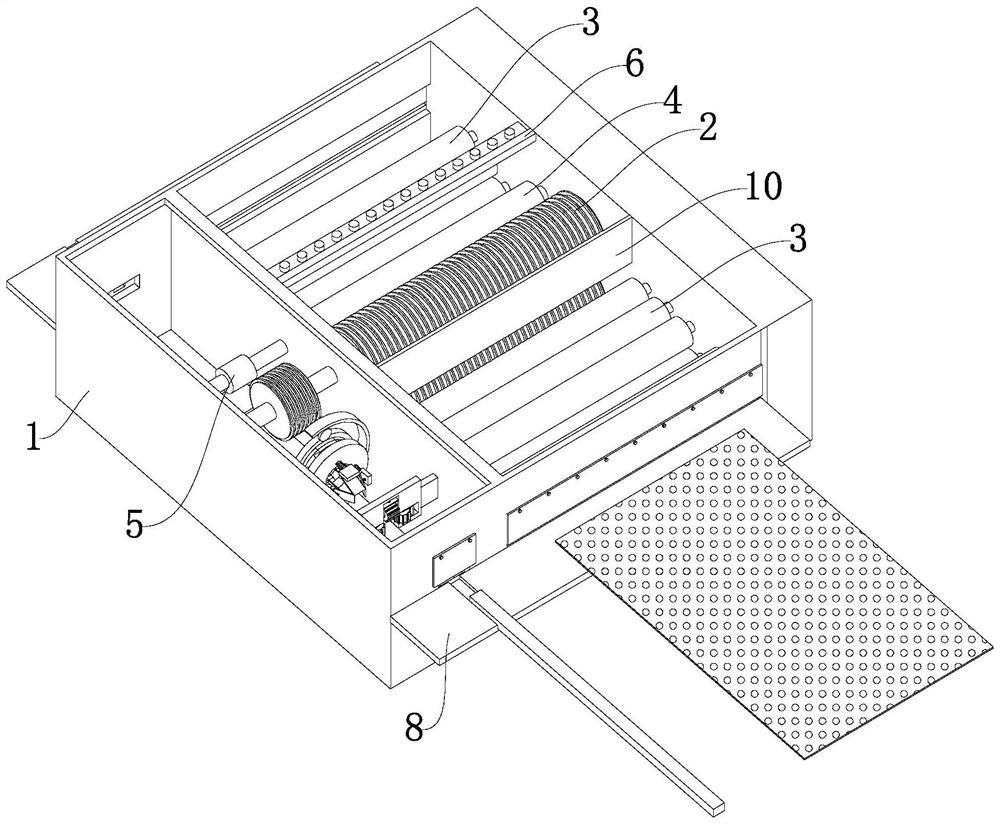

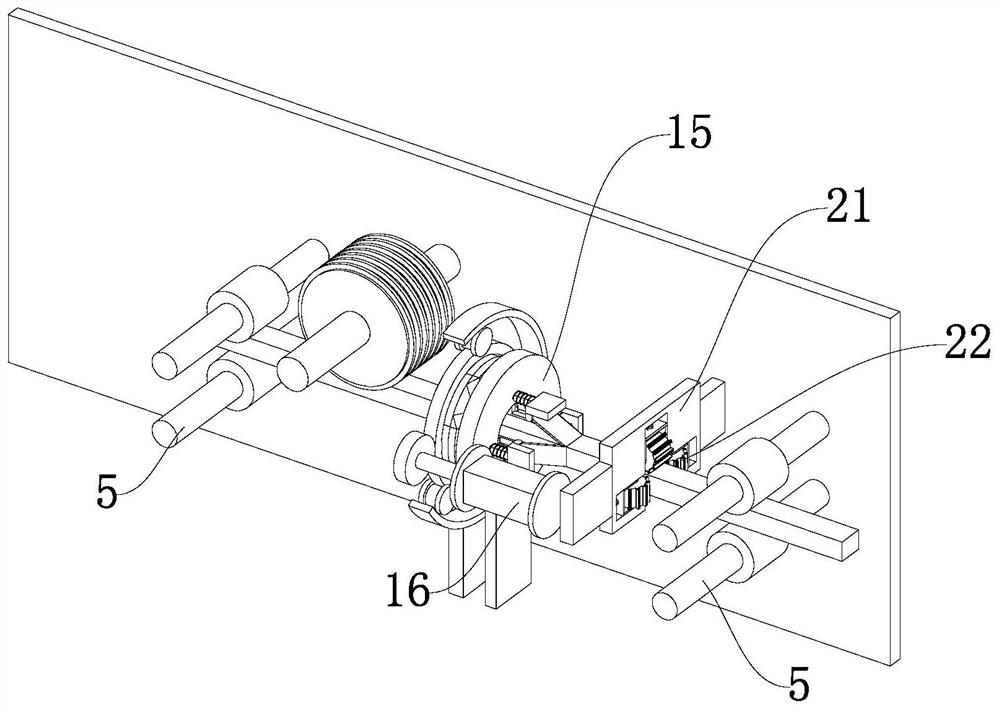

Batch leveling and slicing device for lead frame copper strips

ActiveCN112496764APrevents compromising section uniformityImprove leveling qualityMetal-working feeding devicesShearing machinesBatch operationProcess engineering

The invention discloses a batch leveling and slicing device for lead frame copper strips. The batch leveling and slicing device comprises a leveling unit, a slicing unit and a steering collection unit, the leveling unit is used for leveling the lead frame copper strips and comprises a first guide mechanism and a leveling mechanism, the slicing unit is arranged at one end of the leveling unit, is used for cutting the lead frame copper strips into copper sheets and comprises a strip cutting machine and a second guide mechanism, the strip cutting machine comprises a control box, the control box is provided with a cutter, and the steering collection unit is arranged at one end of the slicing unit, is used for converting the conveying direction of the lead frame copper sheets into the width direction of the lead frame copper sheets and comprises a transferring mechanism, an arranging mechanism, a horizontal moving mechanism and a conveying mechanism. According to the batch leveling and slicing device, simultaneous batch operation can be carried out on the multiple various lead frame copper strips within a certain width range, in addition, leveling operation is carried out before the slicing step, so that the slicing uniformity and flatness are improved, the copper sheets can be conveyed in the width direction after slicing, and the energy consumption used for conveying is saved.

Owner:四川富美达微电子有限公司

Water supply system safety supercharging equipment

PendingCN108560644AEasy to assemble and disassembleEasy to adjust levelService pipe systemsWater mainsAir pumpEngineering

The invention provides water supply system safety supercharging equipment which comprises a sliding block, a dovetail groove, a gradienter, a trapezoidal strip, an air pump, an air pump, a through groove and a storage box. The lower end face of the sliding block is attached to the upper end face of a base, and the dovetail groove is formed in the lower end face of the sliding block. The gradienteris assembled in the middle of the upper end face of the sliding block, and the dovetail strip is fixed to the middle of the upper end face of the base and assembled in the dovetail groove. Accordingto the design, the function of convenient leveling is achieved, the air pump and the storage box are both mounted on the front side of the upper end face of the base, the right end of an air pipe is mounted at the left end of the air pump through a fast connector, the left end of the air pipe penetrates through a through groove and mounted in the storage box, and the through groove is formed in the upper side of the right end face of the storage box. According to the design, the function of fast impurity removal is achieved, the water supply system safety supercharging equipment achieves the leveling function and fast impurity removal, and is convenient to use, safe and reliable.

Owner:洛阳明创矿山冶金设备有限公司

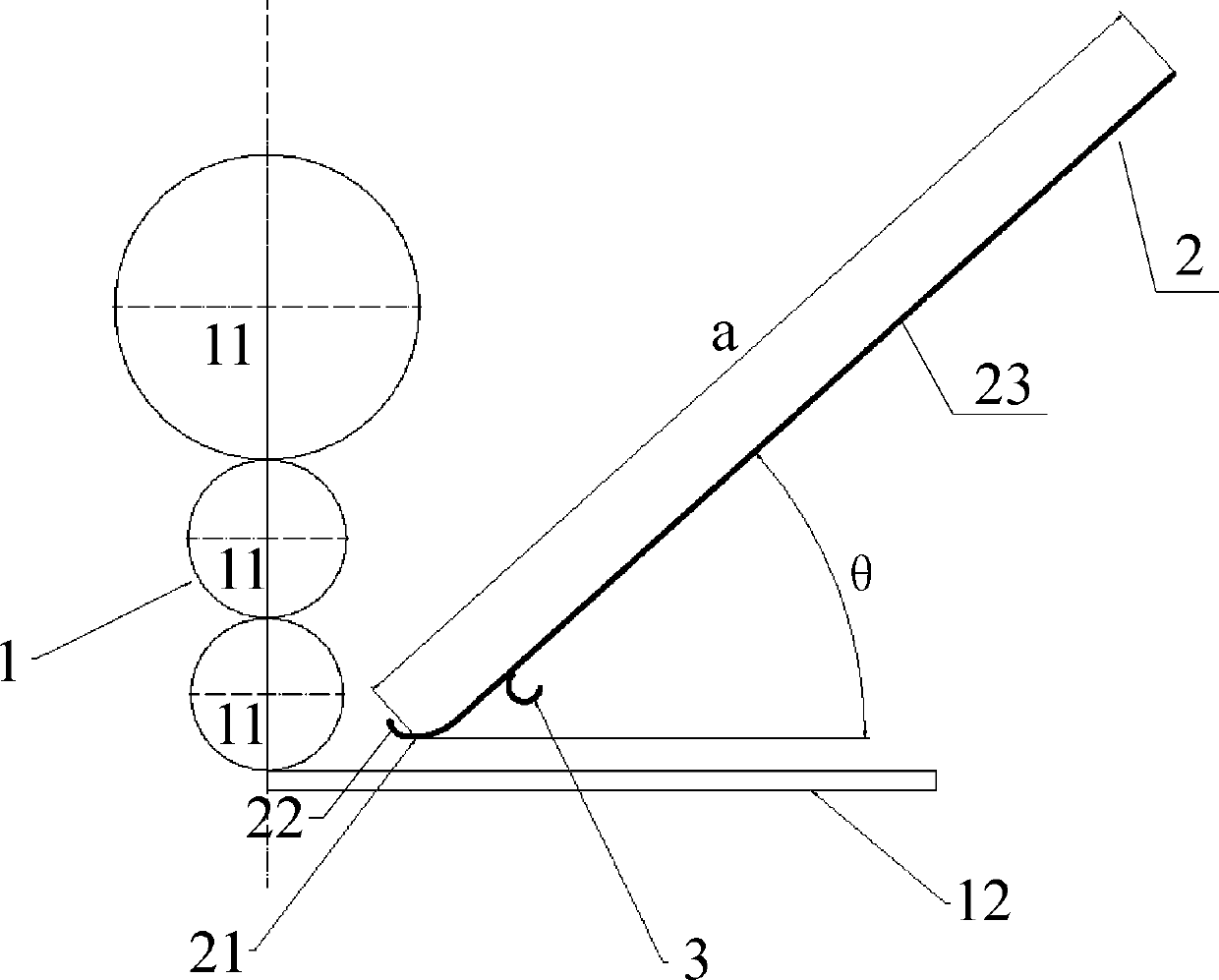

Paper reverse-curling device and paper cutting machine

The invention provides a paper reverse-curling device and a paper cutting machine. Paper leveling quality is improved. The paper reverse-curling device comprises at least three transition rollers which are sequentially arranged at intervals from front to back and further comprises at least two curling shafts which are sequentially arranged at intervals from front to back; one curling shaft is arranged between any two adjacent transition rollers, and first contact points used for being in contact with paper so as to allow paper to be wound around the first contact points are arranged on the transition rollers; the curling shafts are provided with second contacts which are used for being in contact with paper so as to allow the paper to be wound around the second contacts; the included angle theta formed between the connecting line of each second contact point and the adjacent first contact point on the front side of the second contact point and the connecting line of the second contact point and the adjacent first contact point on the rear side of the second contact point is larger than 0 degree and smaller than 180 degrees; and the included angle theta formed between the second contact on the front side and two corresponding adjacent first contact points is larger than the included angle theta formed between the second contact point on the rear side and two corresponding adjacent first contact points.

Owner:雅高机械(太仓)有限公司

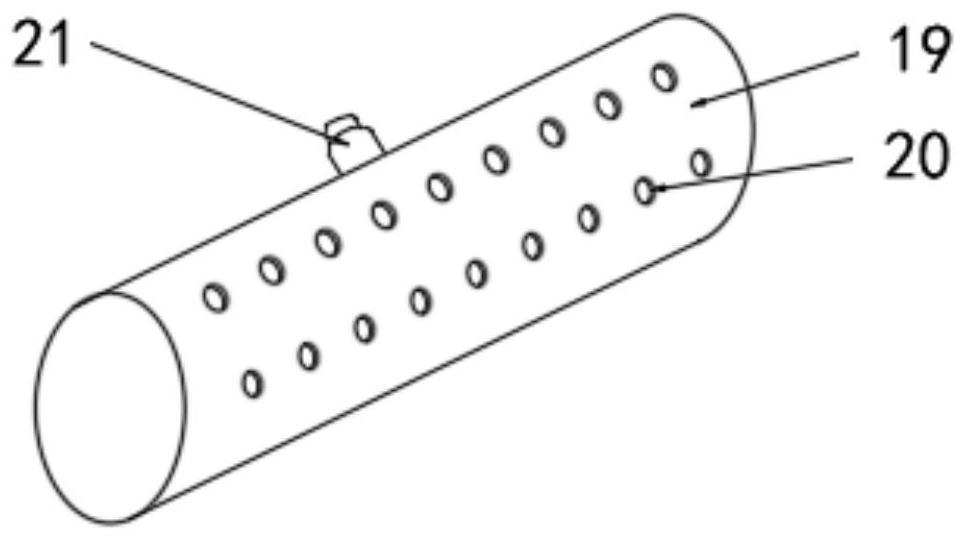

Metal plate leveling machine

The invention belongs to the technical field of leveling machines, and particularly relates to a metal plate leveling machine. The metal plate leveling machine comprises a rack, a fixed roller, a working roller and a controller, wherein the two ends of the fixed roller and the two ends of the working roller are rotatably arranged on the rack, and the working roller is arranged above the fixed roller; and a first cavity is arranged in the working roller, a set of first holes are uniformly arranged in the working roller at equal intervals, the set of first holes are communicated with the first cavity, and an anti-rebound mechanism is arranged in the first cavity and comprises a motor, a first shaft, a cam and an anti-rebound protruding block. Through the arrangement of the anti-rebound mechanism, anti-rebound treatment is carried out in real time in the metal plate leveling process, rebounding possibly occurring after metal plate leveling is eliminated, meanwhile, the stress balance state of materials in the metal plate is changed through the anti-rebound mechanism, rebounding is eliminated, and the metal plate leveling quality is further improved.

Owner:李学海

Material surface leveling device for wood product processing

PendingCN113580279AEasy to operateImprove leveling qualityProfiling/shaping machinesEngineeringStructural engineering

The invention relates to the technical field of wooden product processing, in particular to a material surface leveling device for wooden product processing, which comprises a placing table, a placing groove for placing a wooden plate is arranged on the upper surface of the placing table, and two symmetrically distributed bulldozing assemblies for keeping the wooden plate placed orderly are arranged on each of the two sides of the top of the placing table; symmetrically-distributed clamping mechanisms are arranged at the two ends of the placing table, and symmetrically-distributed adjusting mechanisms used for adjusting the heights of the clamping mechanisms are arranged below the clamping mechanisms; and a leveling mechanism for flattening the surface of the wooden plate is arranged above the placing table. The problems that an existing leveling device can only level wooden boards of the same size, the leveling requirements of different sizes cannot be met, the application range is low, and the machining efficiency is reduced are solved; and an existing leveling device is low in leveling efficiency, poor in leveling effect and the like during leveling.

Owner:安徽恒昕儿童用品有限公司

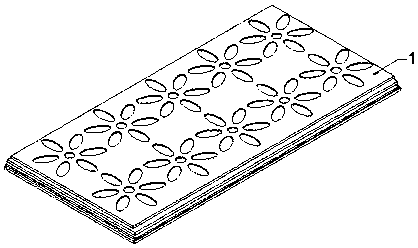

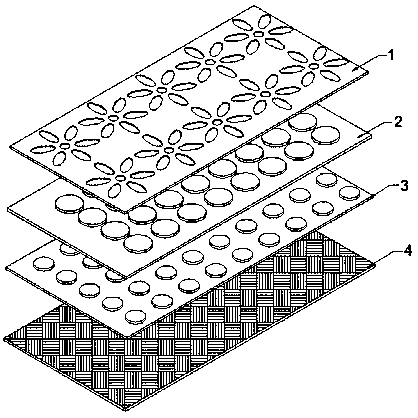

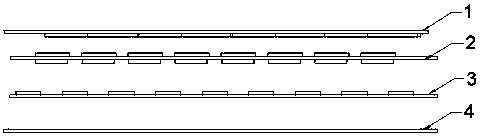

Three-dimensional printed and dyed fabric

InactiveCN109421331AAdd dimensionImprove leveling qualitySynthetic resin layered productsLaminationEngineeringPolyamide fibers

The invention provides a three-dimensional printed and dyed fabric. The three-dimensional printed and dyed fabric sequentially comprises a printing and dyeing layer, a first warm-keeping layer, a second warm-keeping layer and a lining from outside to inside, wherein the printing and dyeing layer, the first warm-keeping layer, the second warm-keeping layer and the lining are bonded into a whole through a hot-pressing process; the printing and dyeing layer is woven by taking polyamide fibers as warp yarn and weft yarn; the surface of the printing and dyeing layer is provided with a hollowed pattern; and the inner part of the hollowed pattern is processed into a three-dimensional pattern structure with a different color with the upper surface of the printing and dyeing layer through a printing and dyeing process. The first warm-keeping layer and the second warm-keeping layer are made of wool spinning yarn, the upper end surface and the lower end surface of the first warm-keeping layer, the upper end surface of the second warm-keeping layer and the lower end surface of the printing and dyeing layer are all provided with protrusions which are distributed at equal intervals by crocheting; the protrusions of the upper end surface of the first warm-keeping layer and the protrusions of the lower end surface of the printing and dyeing layer are crosswise arranged and fixed; and the protrusions of the upper end face of the first warm-keeping layer and the protrusions of the upper end face of the second warm-keeping layer are crosswise arranged and fixed. The three-dimensional printedand dyed fabric has the beneficial effects that the fabric is light and thin, the comfort level is high, the heat preservation performance is good, and the tridimensional character is high.

Owner:天津朗福服饰有限公司

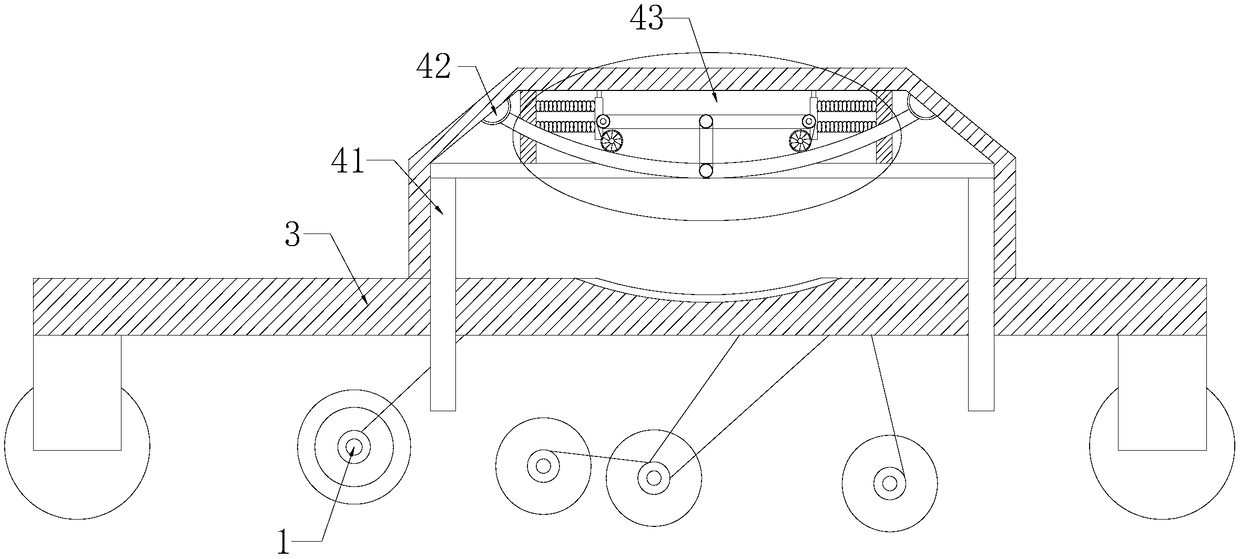

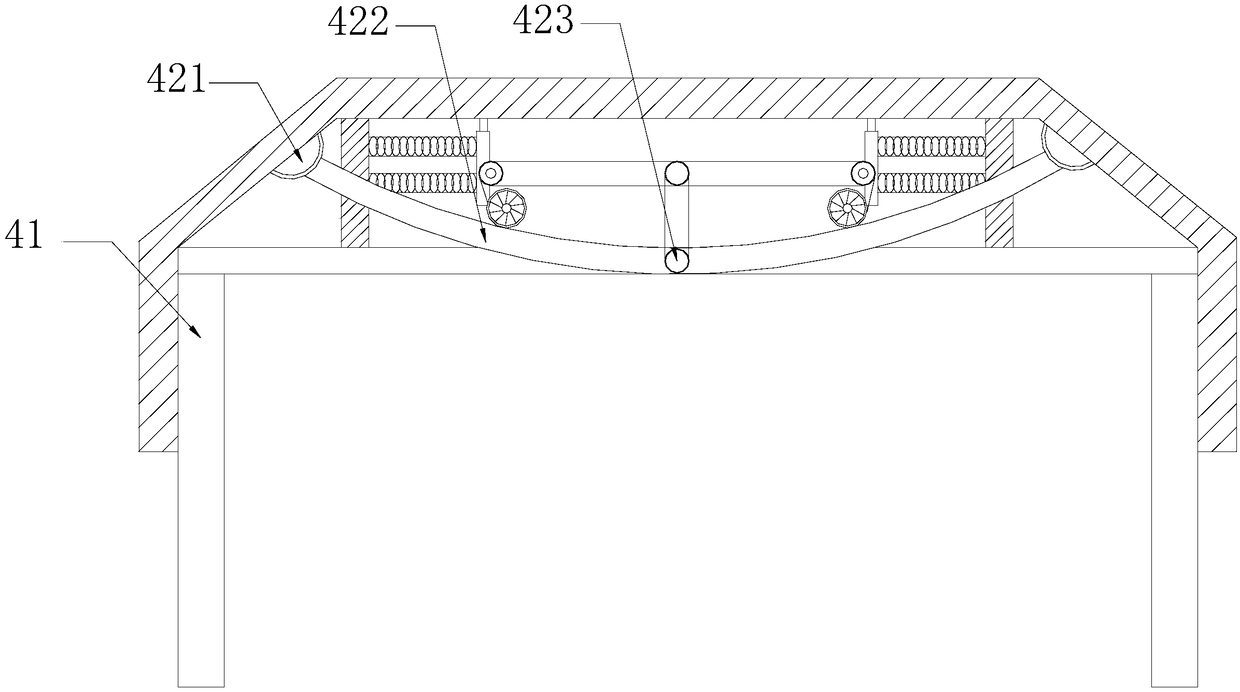

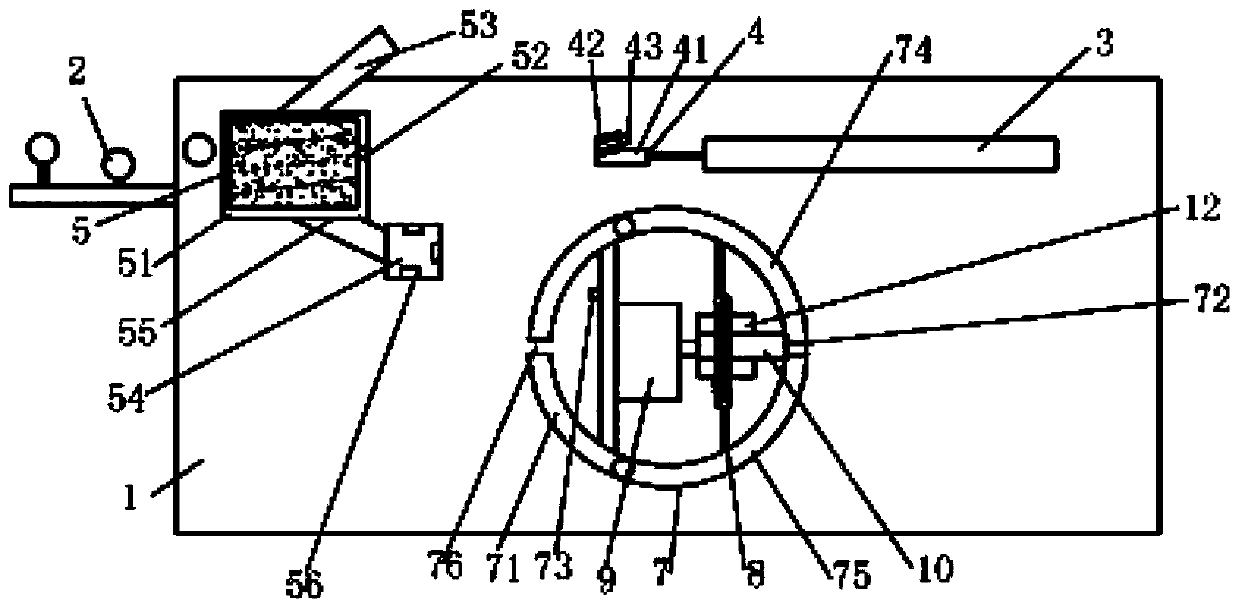

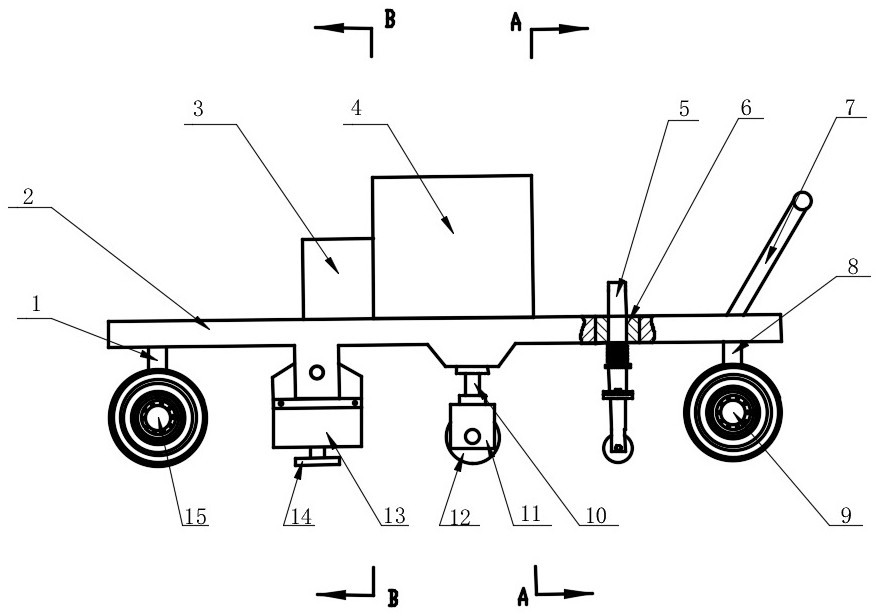

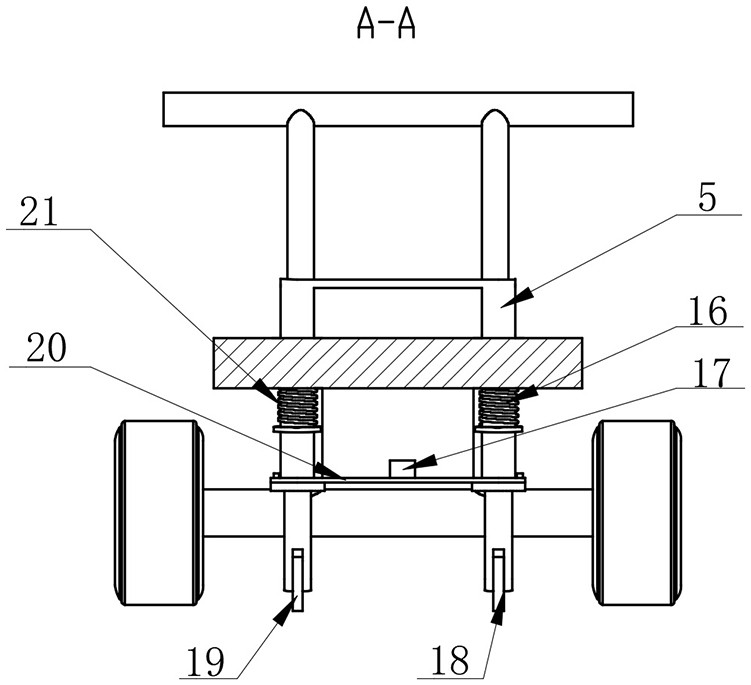

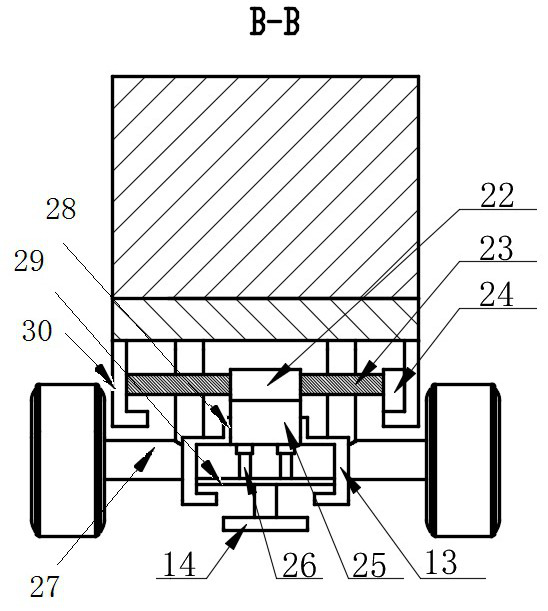

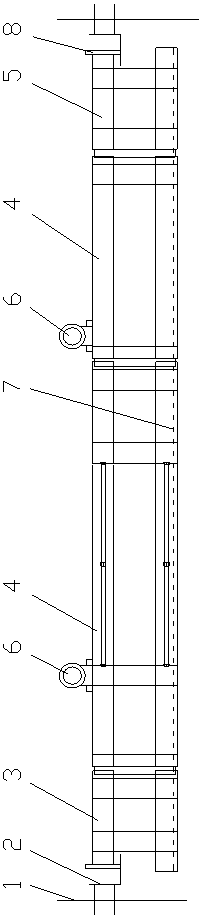

Road leveling device

ActiveCN110952424BImprove leveling qualityRealize horizontal repeated movementRoads maintainenceVehicle frameRoad surface

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Leveling device and method for fabricated floor

InactiveCN107762155AEasy to fixSimple and quick straighteningBuilding material handlingModular designEngineering

The invention relates to a leveling device for a fabricated floor. The leveling device comprises a pair of rails, one or more cross beam segments, a mortise end segment and a tenon end segment; the pair of rails is fixedly mounted on wall bodies or column inserting bars on the two sides of the floor correspondingly; each cross beam segment is of a cuboid structure, mortises are arranged at one ends of the cross beam segments, and tenons are arranged at the other ends of the cross beam segments; the mortise end segment is of a cuboid structure, a mortise is arranged at one end of the mortise end segment, and a rail wheel is arranged at the other end of the mortise end segment; the tenon end segment is of a cuboid structure, a tenon is arranged at one end of the tenon end segment, and a railwheel is arranged at the other end of the tenon end segment; the one or more cross beam segments, the mortise end segment and the tenon end segment are assembled into an integral cross beam through mortise-tenon structures, and the rail wheels at the two ends of the integral cross beam are located on the two rails correspondingly; two steel wire ropes are fixedly mounted at the bottoms of the mortise end segment and the tenon end segment correspondingly and are connected in a tightened mode through a turn buckle; and a plurality of vibration motors are mounted on the upper portions of the cross beam segments. According to the leveling device, by adopting the fabricated type structure and the modular design, the leveling device with any width can be combined, and the leveling quality is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

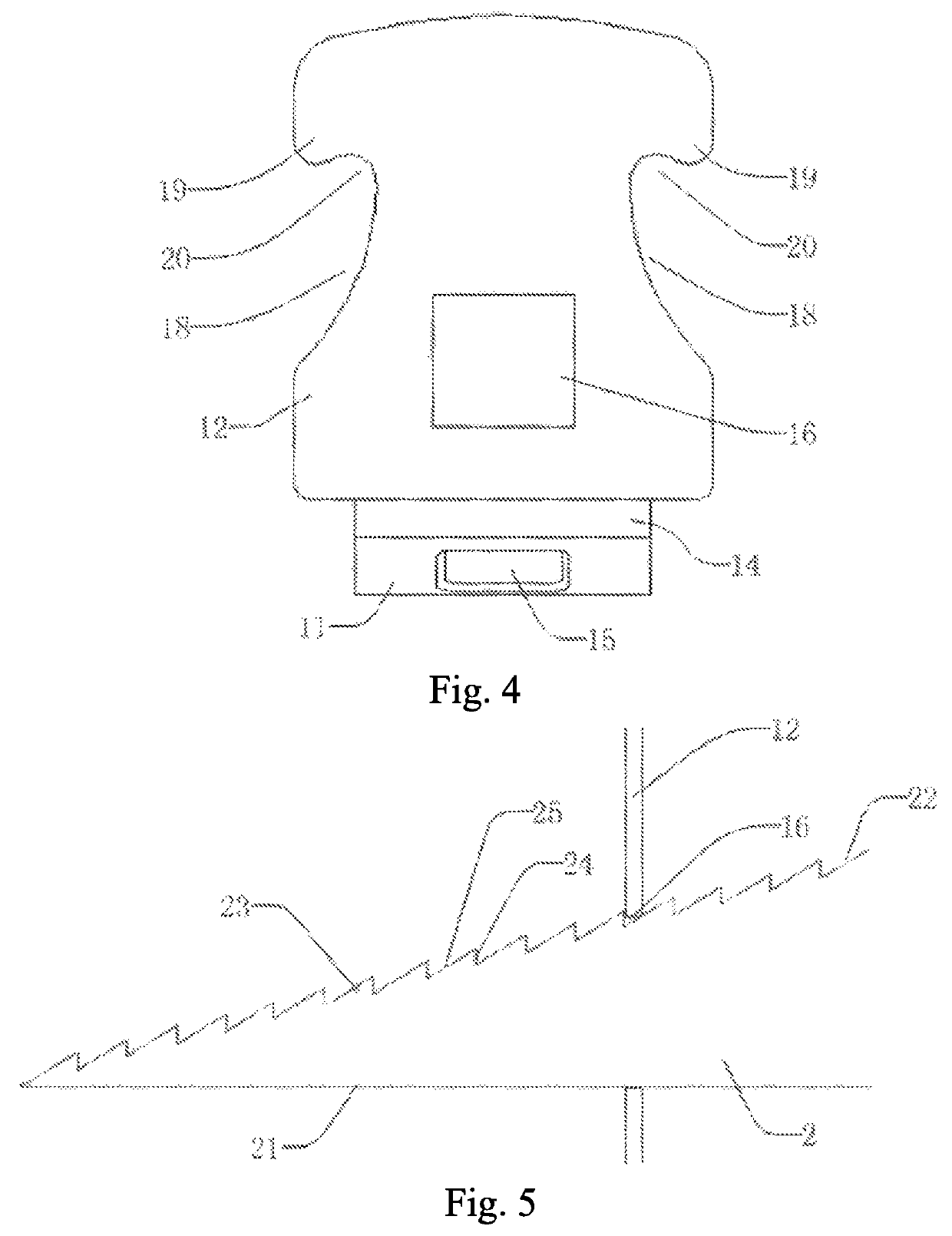

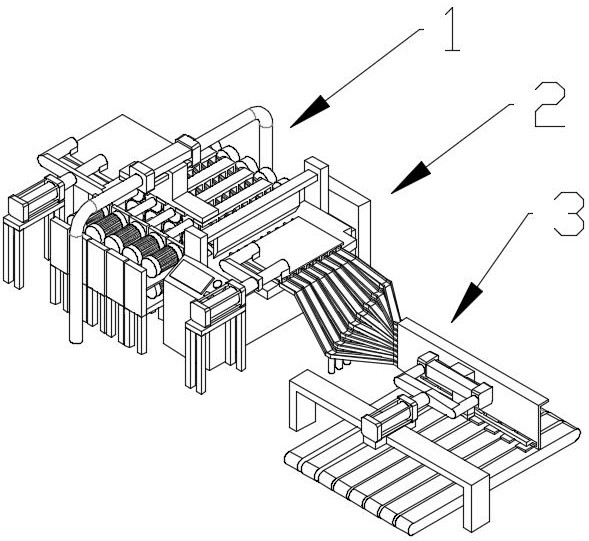

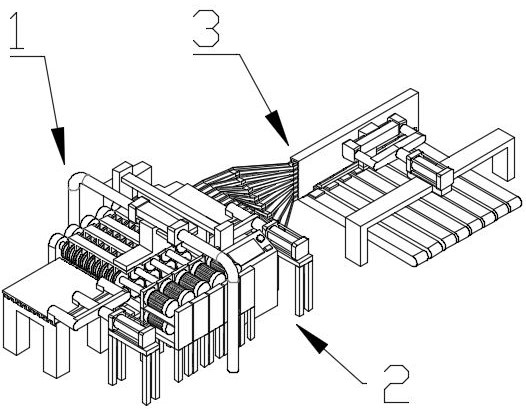

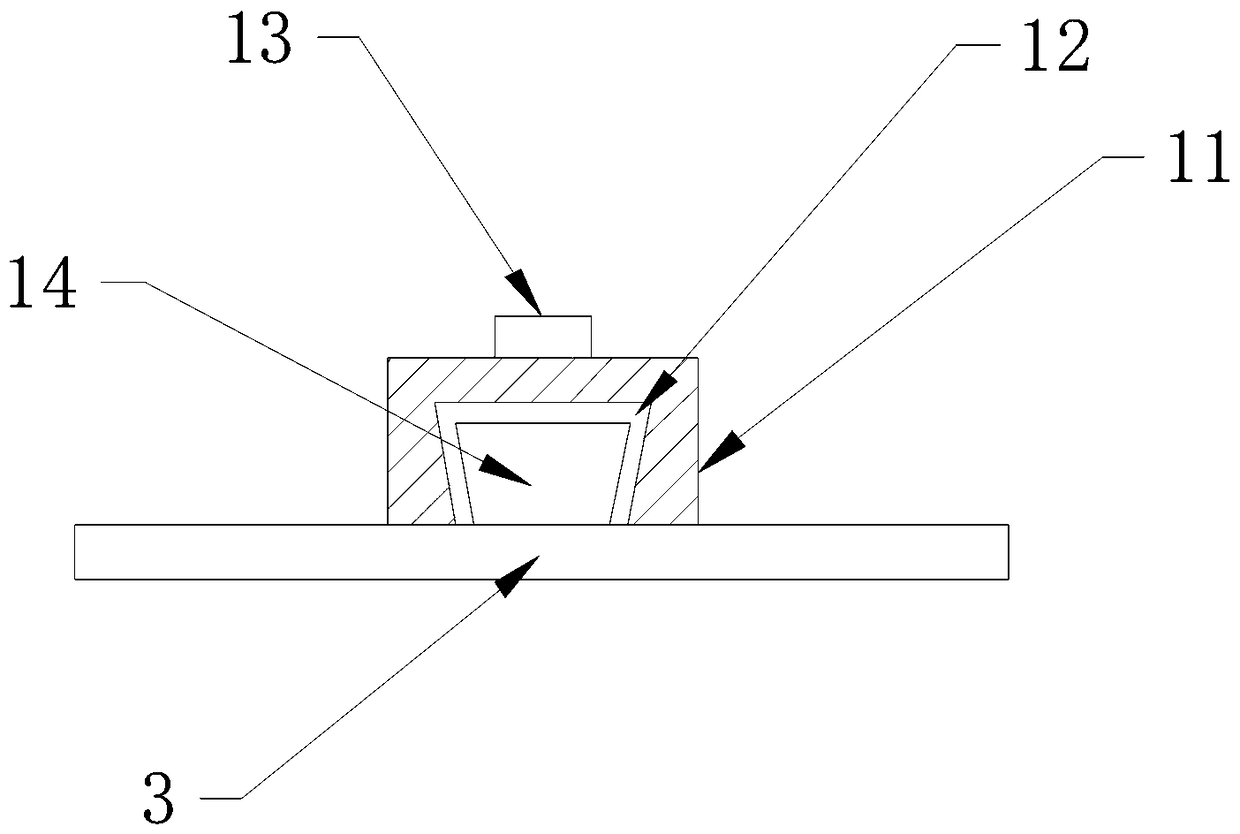

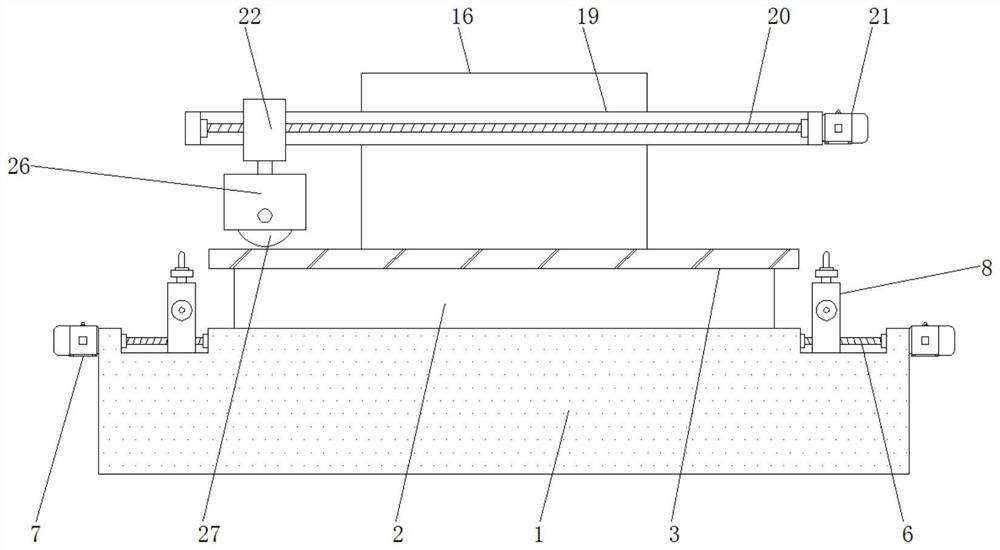

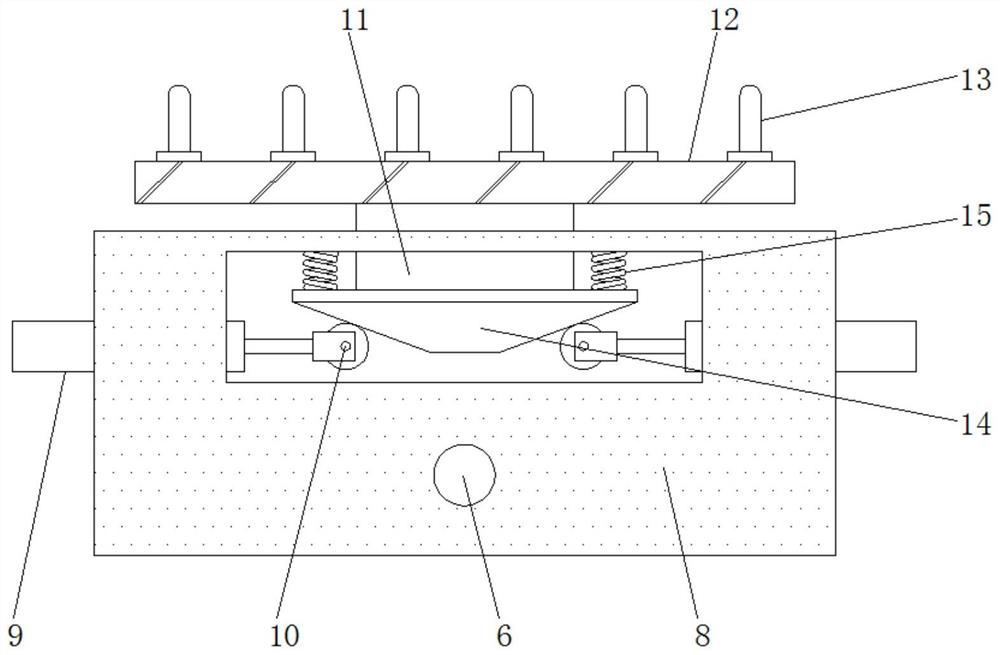

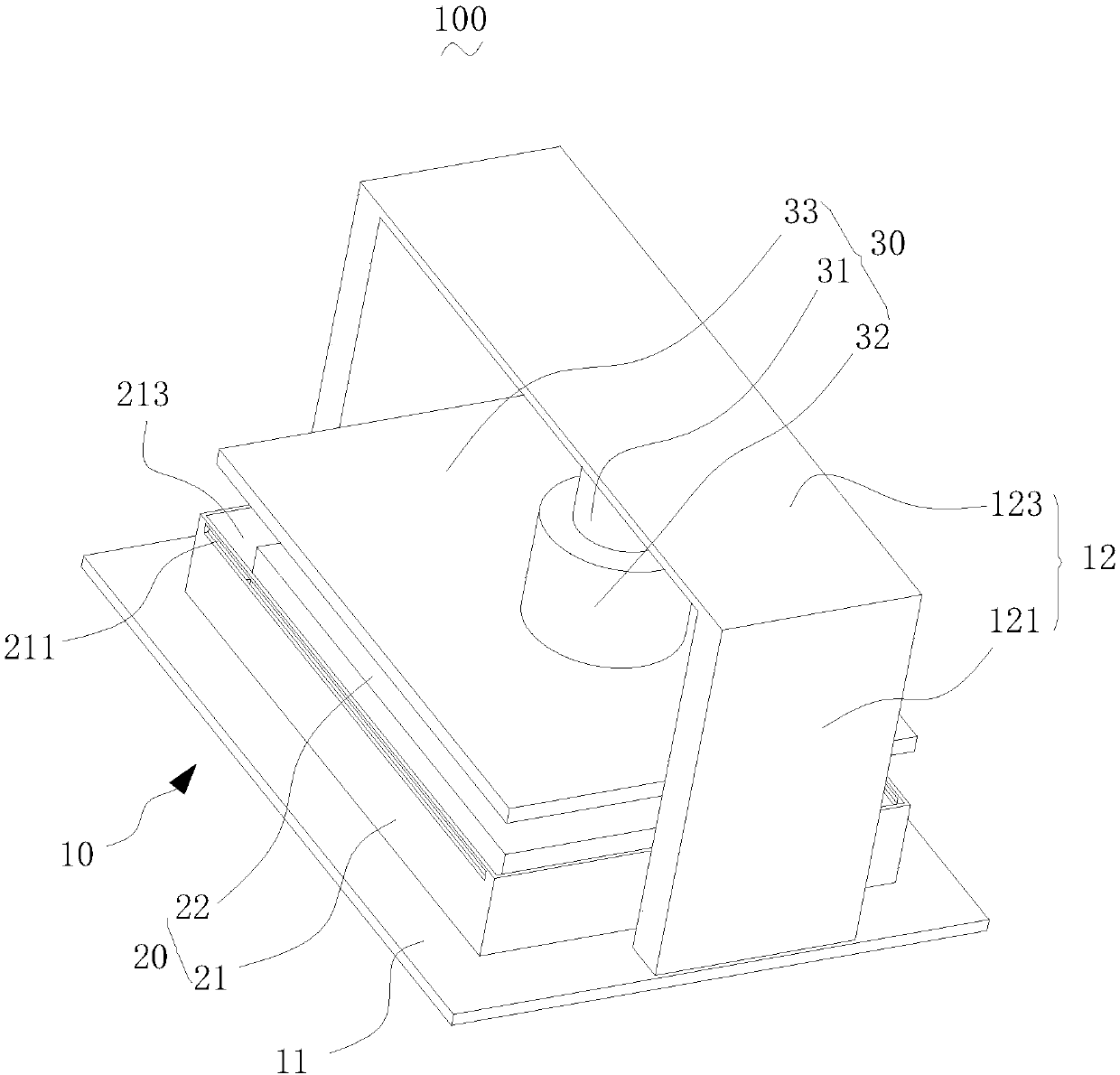

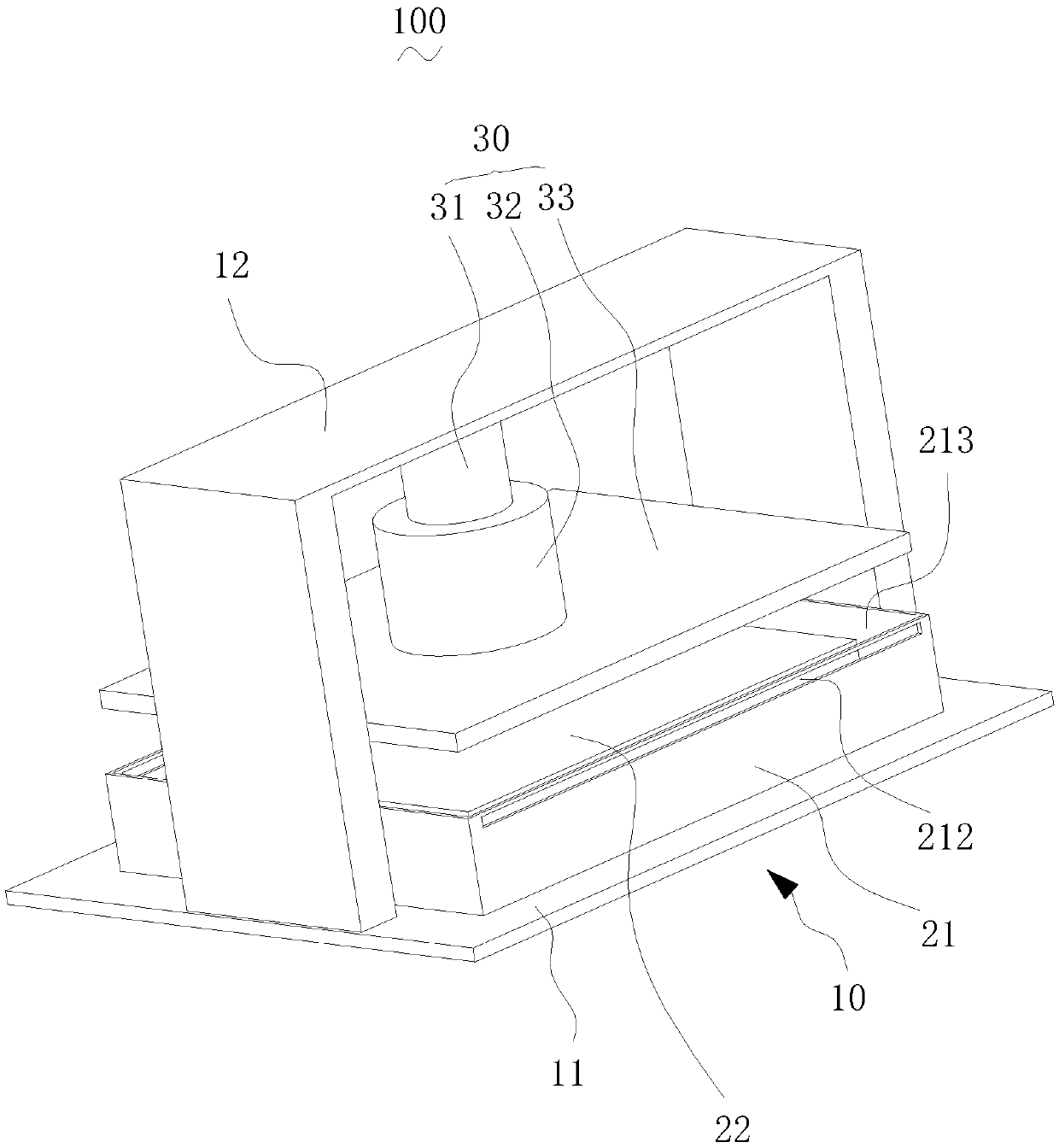

Temper mill outlet condensate water collecting device and using method thereof

InactiveCN111069342AAvoid dripping onto the stripSimple structureShaping toolsThermodynamicsStructural engineering

The invention relates to the field of straightening, reshaping or removing local deformation of a metal plate or a specific product manufactured by the metal plate by adopting rollers, in particular to a temper mill outlet condensate water collecting device and a using method thereof. The temper mill outlet condensate water collecting device comprises a temper mill (1) and is characterized by further comprising a main convergence plate (2) and a branch convergence groove (3); the main convergence plate (2) comprises a horizontal plate (21), a baffle (22) and an inclined plate (23); one side ofthe horizontal plate (21) is connected with one side edge of the baffle (22), and the other side of the horizontal plate (21) is connected with one side edge of the inclined plate (23); the other side of the inclined plate (23) obliquely extends upwards and forms an obtuse included angle with the horizontal plate (21); the horizontal plate (21) and the inclined plate (23) are both arranged abovethe outlet end of the temper mill (1); and the branch convergence groove (3) is a groove. The temper mill outlet condensate water collecting device has the beneficial effects that the structure is simple, the use is convenient, and the leveling quality is improved.

Owner:BAOSTEEL ENG & TECH GRP

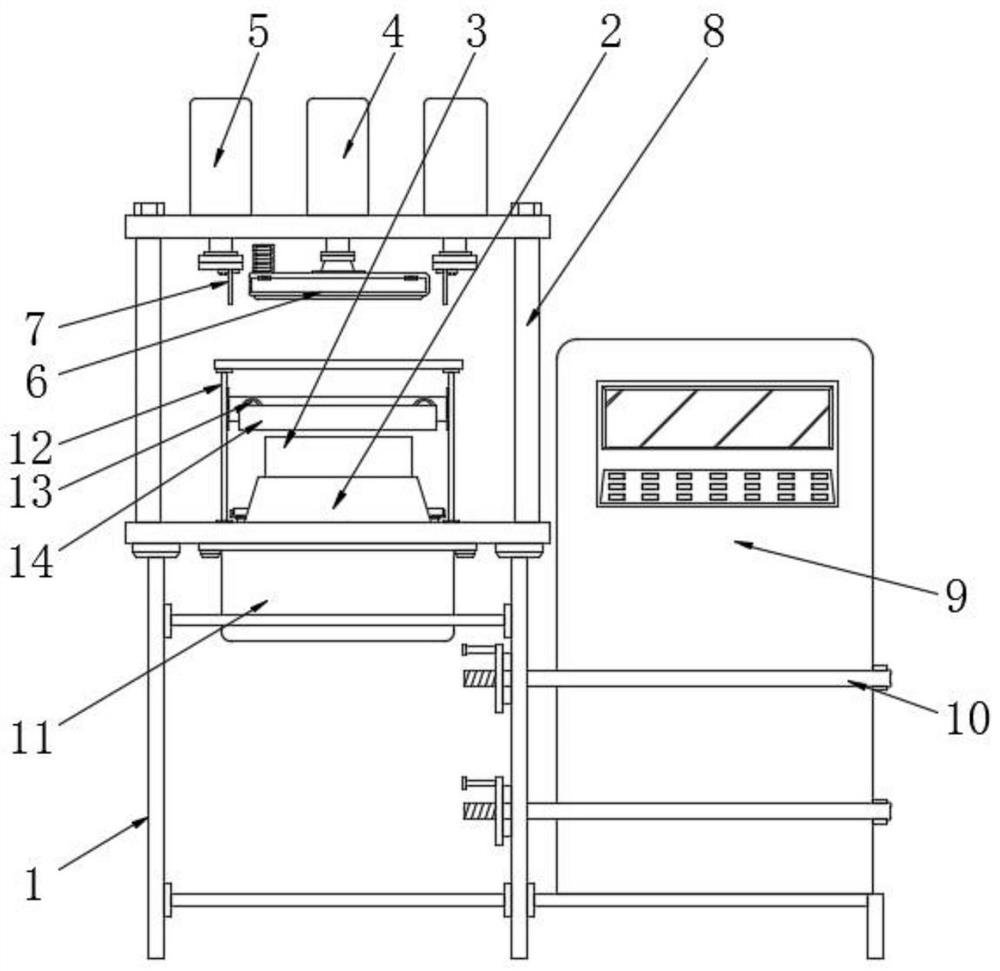

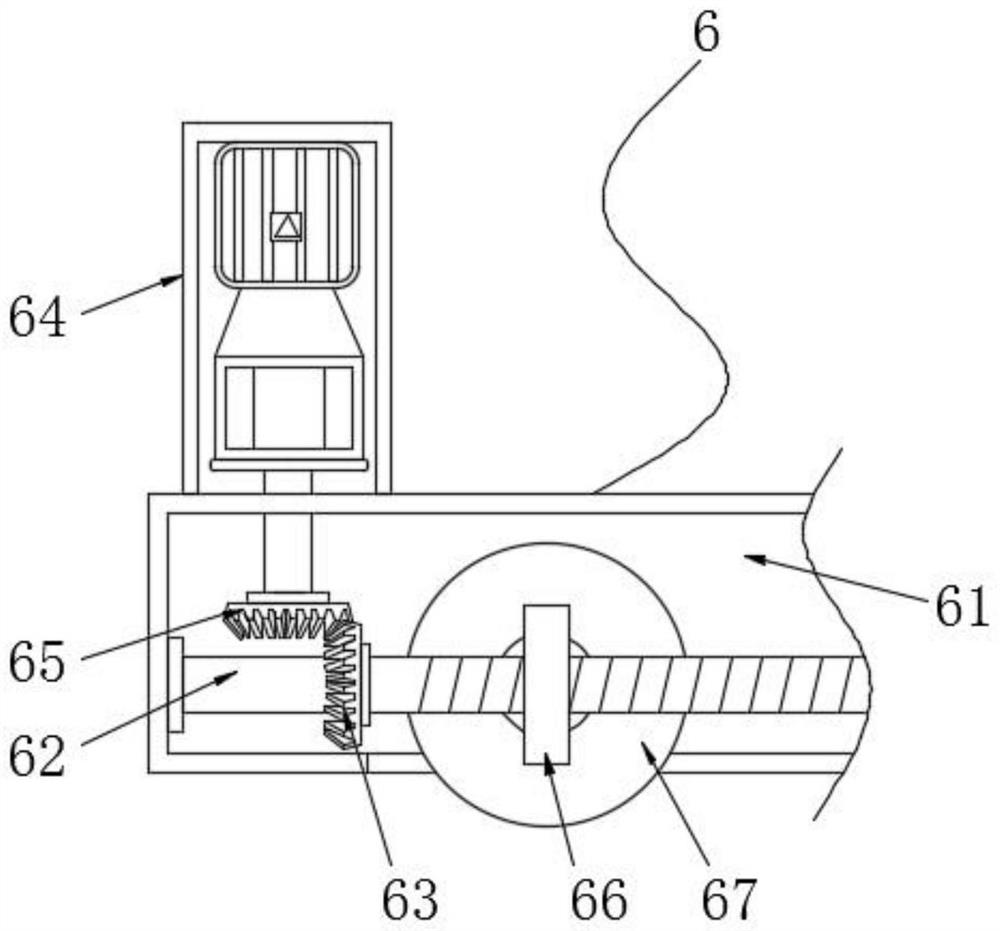

A billet speed measuring jet printer

ActiveCN106379050BAvoid contactNo distortionTypewritersOther printing apparatusGear wheelEngineering

The invention relates to a steel accessory marking device, and particularly relates to a hot steel billet speed measurement jet printing marking machine. The characteristics lie in that one side of a steel billet is provided with a speed measurement device, the speed measurement device drives a rotating roller through the proceeding steel billet, the rotating roller feeds back the rotation rate to a speed measurement sensor through a connecting device, the connecting device is composed of a belt gears and a belt, and the two belt gears are installed on the rotating roller and the speed measurement sensor respectively; and one side of the speed measurement device is provided with a descaling device, a scraping plate of the descaling device presses against the steel billet, a turning fine adjustment device is arranged between the scraping plate and a transition plate, and transverse stress adjustment is performed on one side of a support plate on the transition plate through a spring device. According to the invention, data is transmitted to the speed measurement sensor by using the rotating roller, so that the speed measurement sensor is avoided from being contacted with the high-temperature steel billet, speed measurement data is ensured to be more accurate and more reliable, and data distortion caused by the high temperature is avoided; and the descaling device removes an oxidation part of the steel billet before jet printing, so that the surface evenness of the steel billet is improved, and the mark printing quality is improved.

Owner:SHANTOU JUNGUO MECHANICAL & ELECTRICAL TECH CO LTD

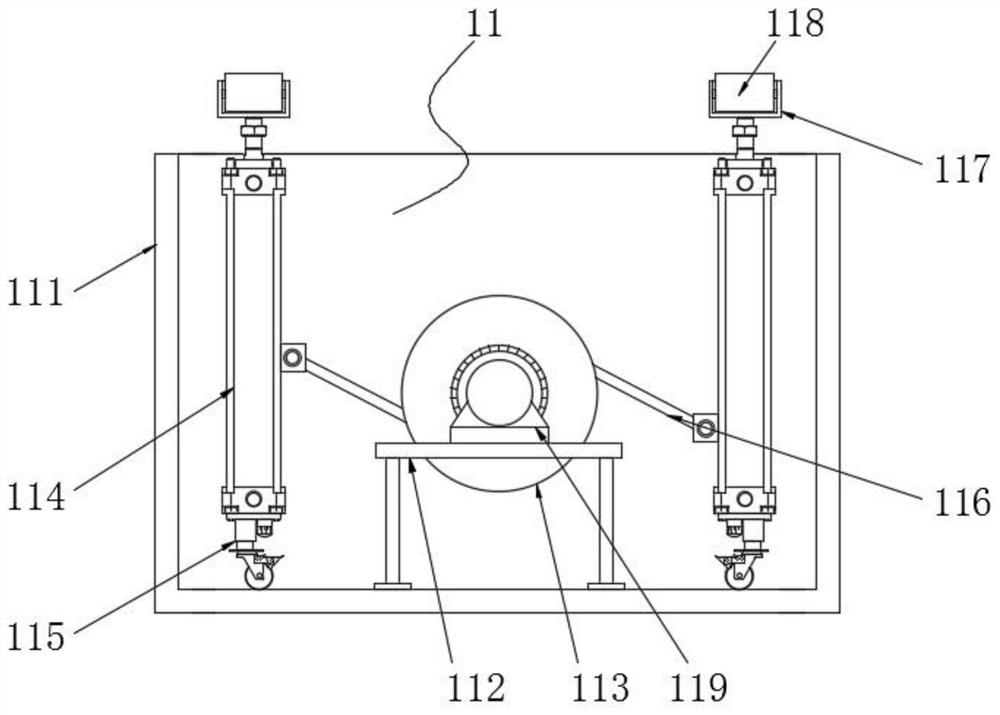

Case leveling device

ActiveCN113369334AAvoid displacementQuality improvementMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention discloses a case leveling device, and relates to the technical field of case machining. The case leveling device comprises a machining frame and a hydraulic station, wherein a fixing frame is fixedly connected to the upper surface of the machining frame; the hydraulic station is placed on one side of the machining frame; a plurality of reinforcing frames connected with the machining frame are installed on the outer side of the hydraulic station; a base table is fixedly connected to the position, close to the interior of the fixing frame, of the upper surface of the machining frame; a leveling table is fixedly connected to the upper surface of the base table; a case pushing mechanism is fixedly connected to the position, close to the rear side of the base table, of the upper surface of the machining frame; and a jacking frame is installed on the position, close to the lower side of the base table, of the interior of the machining frame. According to the case leveling device, case limiting plates are arranged on the two sides of a case leveler, and a case can be limited from the two sides of the case through the case limiting plates, so that the problem of displacement of the case during leveling can be prevented, and then the leveling quality can be improved.

Owner:安徽瑞林精科股份有限公司

Cement pavement paver capable of being spliced

InactiveCN111851213AGuaranteed smoothSimple structureRoads maintainenceStructural engineeringRoad surface

The invention discloses a cement pavement paver capable of being spliced. The paver comprises a left machine body, a right machine body and one or more auxiliary machine bodies. The left machine bodycomprises a rack. A transmission box is fixedly arranged on the left side of the rack; a transmission cavity is formed in the transmission box; and an auger shaft and a rolling shaft which extend rightwards are arranged between the left end wall and the right end wall of the transmission cavity in a front-back symmetrical rotating mode. According to the cement pavement paver capable of being spliced, the paver is simple in structure, convenient to use, ingenuous in concept, reasonable in design, and convenient to operate; the cement laid on a roadbed does not need to be leveled manually with great effort by using a tool; and labor intensity is reduced, working time is shortened, working efficiency is improved, a leveling effect is good, road surface smoothness is ensured, leveling qualityis improved, inconvenience brought in a transportation process is reduced through a splicing design, country lanes in mountainous areas can be constructed, and automatic adjustment can be performed according to a route trend through self setting.

Owner:温州市洛港科技有限公司

A lead frame copper strip batch leveling and slicing device

ActiveCN112496764BPrevents compromising section uniformityImprove leveling qualityMetal-working feeding devicesShearing machinesBatch operationEngineering

A lead frame copper strip batch leveling and slicing device includes a leveling unit, a slicing unit, and a turning collection unit. The leveling unit is used for leveling the copper strip of the lead frame. The leveling unit includes a first guiding mechanism and a flattening mechanism; The tape machine, the second guide mechanism, the tape cutting machine includes a control box, and the control box is equipped with a cutter; the steering collection unit is located at one end of the slicing unit, which is used to change the transportation direction of the copper sheet of the lead frame to be transported along its width direction, and turn to the collection unit Including transfer mechanism, alignment mechanism, translation mechanism, transmission mechanism. The present invention can perform multiple simultaneous batch operations on various lead frame copper strips within a certain width range, and perform a leveling operation before the slicing step to improve the uniformity and flatness of the slicing, and after slicing, the copper strips can be cut along the width Conveying in the opposite direction saves energy consumption for conveying.

Owner:四川富美达微电子有限公司

Whole piece leveling device for rhombic metal net production line

PendingCN114769368AAvoid damageImprove the leveling effectShaping toolsMetal-working feeding devicesProduction lineScrew thread

The invention discloses a whole piece leveling device for a rhombic metal net production line, which comprises a rack and a transverse plate, supports are fixed on the two sides of the top of the rack, a storage table is fixed on the tops of the supports, a first screw rod is arranged in a first groove, a lifting plate is arranged on the top of a movable plate in a penetrating manner, and the lifting plate is arranged on the top of the movable plate. And a fixed plate and a conical block are fixed to the upper end and the lower end of the lifting plate correspondingly, a second lead screw is arranged in the third groove, and the surface of the second lead screw is in threaded connection with a movable block. The whole-piece leveling device for the rhombic metal net production line is provided with a first lead screw and a limiting rod, before leveling, pulleys can be driven by first air cylinders on the two sides of a movable plate to abut against a conical block, so that a fixed plate can be driven to ascend, and the limiting rod on the surface of the fixed plate is clamped into meshes in the surface of a rhombic metal net; and the two first lead screws drive the two movable plates to be away from each other, so that the limiting rods stretch the rhombic metal net, deviation is avoided during leveling, and the leveling effect is improved.

Owner:徐州威博工贸有限公司

Cloth flatting device

InactiveCN107675413AImprove leveling qualityNot easy to shrinkHeating/cooling textile fabricsStretchingScreedEngineering

The invention relates to a cloth leveling device. The cloth leveling device includes a base, a support assembly and a leveling assembly; the base includes a bottom plate and a mounting frame, and the mounting frame is arranged on the bottom plate; the support assembly includes a guide frame and a support body, and the guide The frame is arranged on the bottom plate, the guide frame is provided with an introduction groove and an outlet groove, the introduction groove and the outlet groove are arranged opposite to each other, the support body is arranged on the bottom plate and is located in the guide frame . The leveling quality of the cloth leveling device is better.

Owner:惠州市熊宝科技有限公司

Leveler

The invention provides a leveler. The leveler comprises a rack, a roller part, a moving crossbeam, a screwdown, left and right main drives, a centralized grease lubrication part, an electrical control system and a feed and discharge roller table, wherein the roller part comprises five upper work rollers and four lower work rollers; all the work rollers are drive rollers; the screwdown comprises two same mechanisms; each mechanism comprises a transmission shaft, a speed reducer, a coupling, a screw, a screwdown motor and a worm speed reducer; the speed reducer, the coupling and the screw are connected with the transmission shaft; the screwdown motor is connected with the speed reducer; the worm speed reducer is connected with the screw. The leveler has the beneficial effects that by improving the leveler, the leveling quality is improved and the quality can be ensured when thick steel plates are leveled; after being leveled by the leveler, materials are smooth and indentation-free and can be used as various metal plates.

Owner:NANTONG ATLANTIC MACHINERY

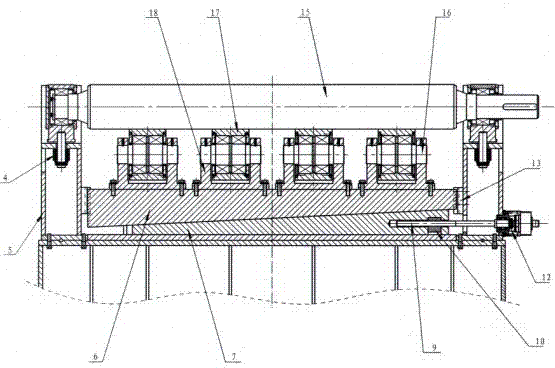

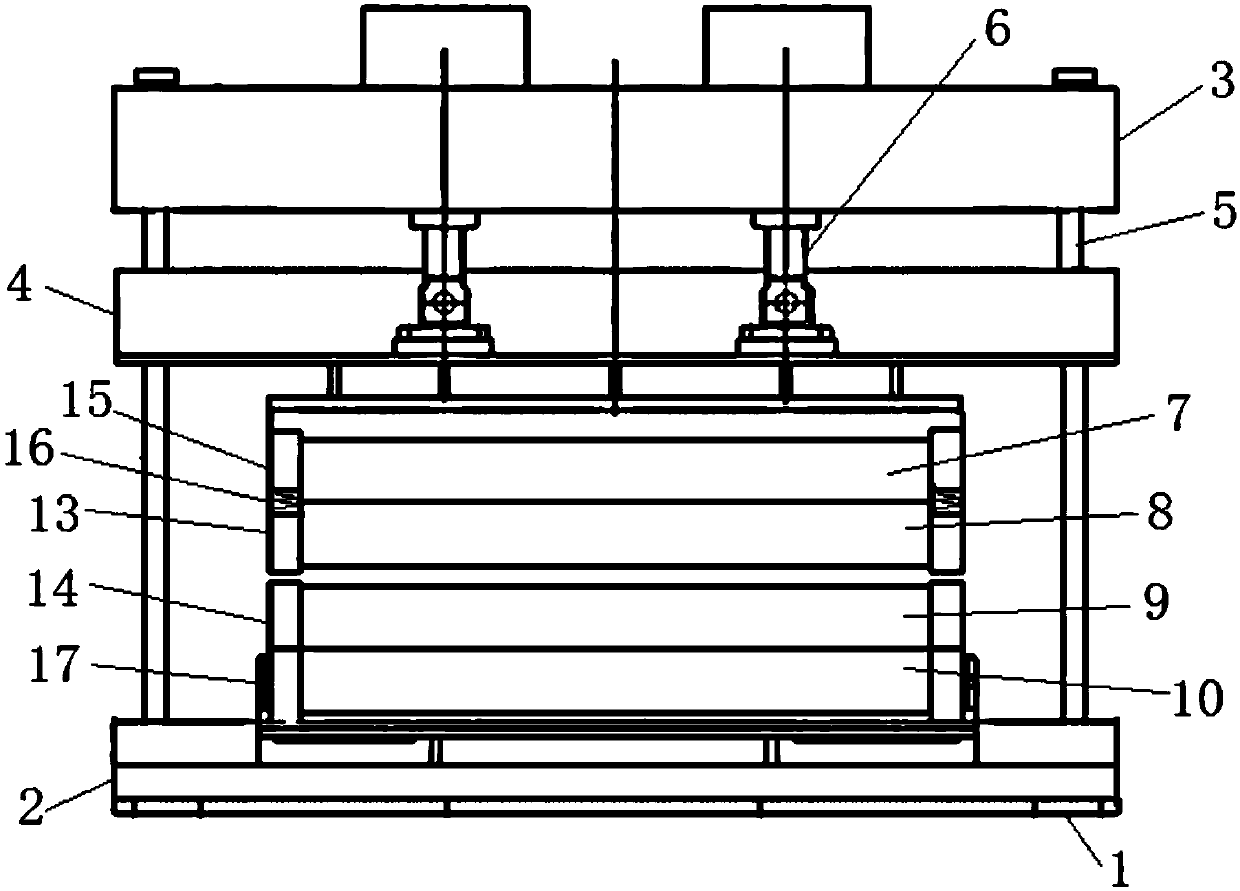

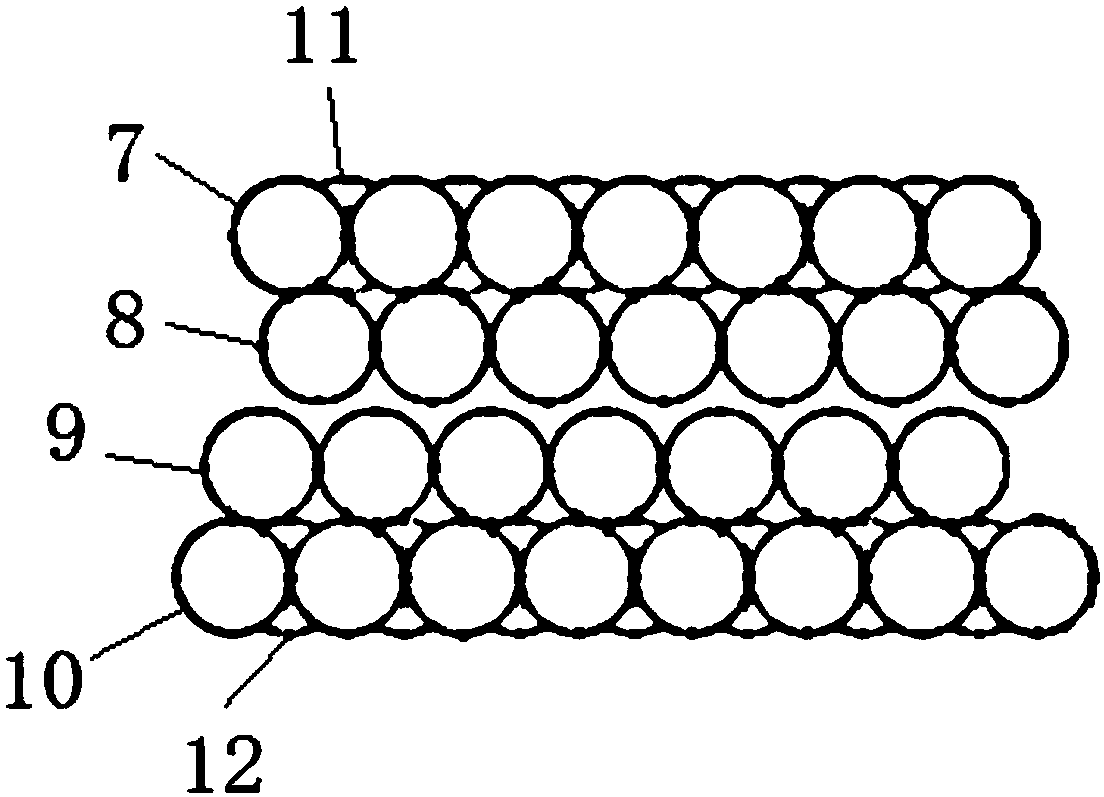

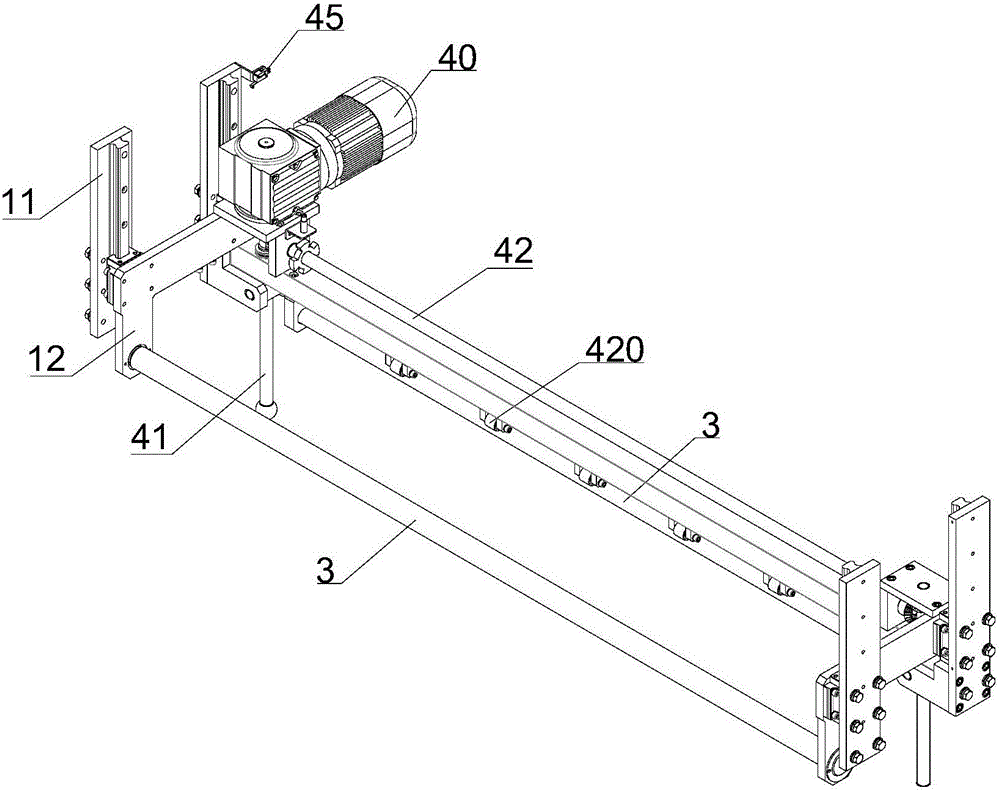

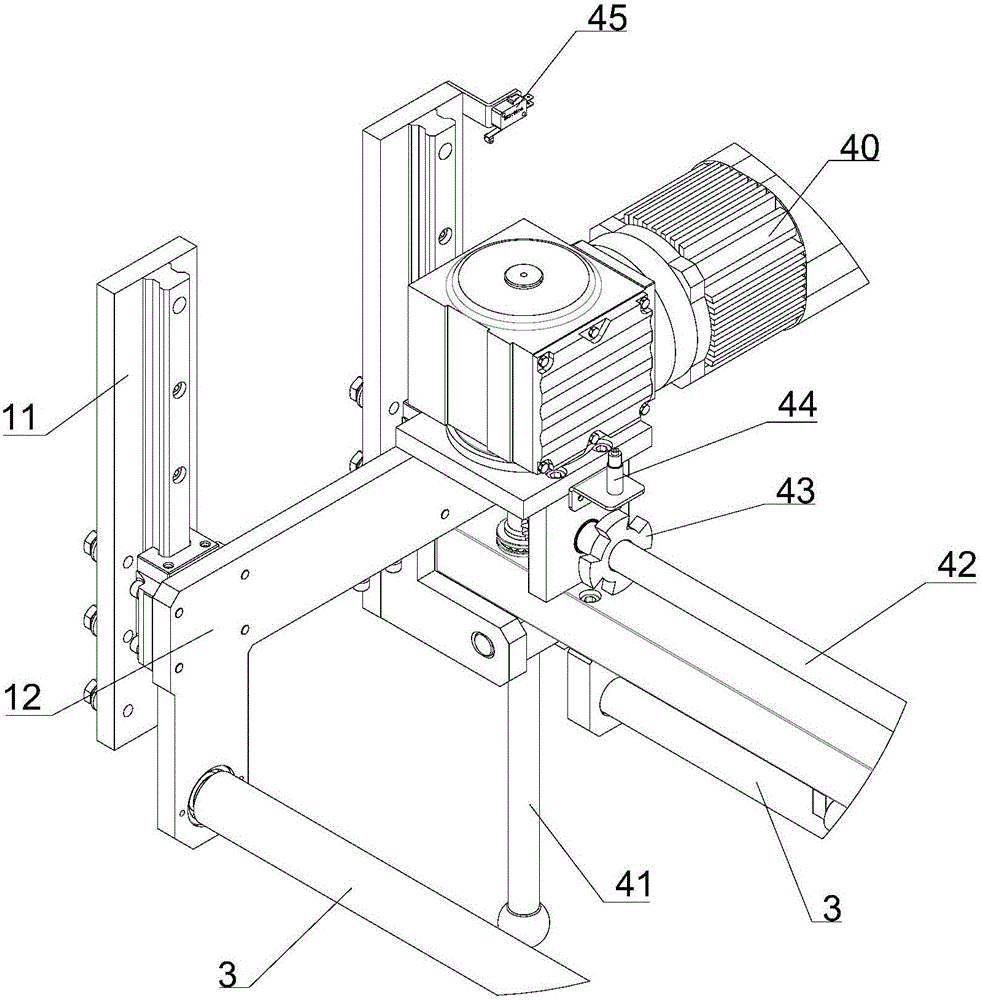

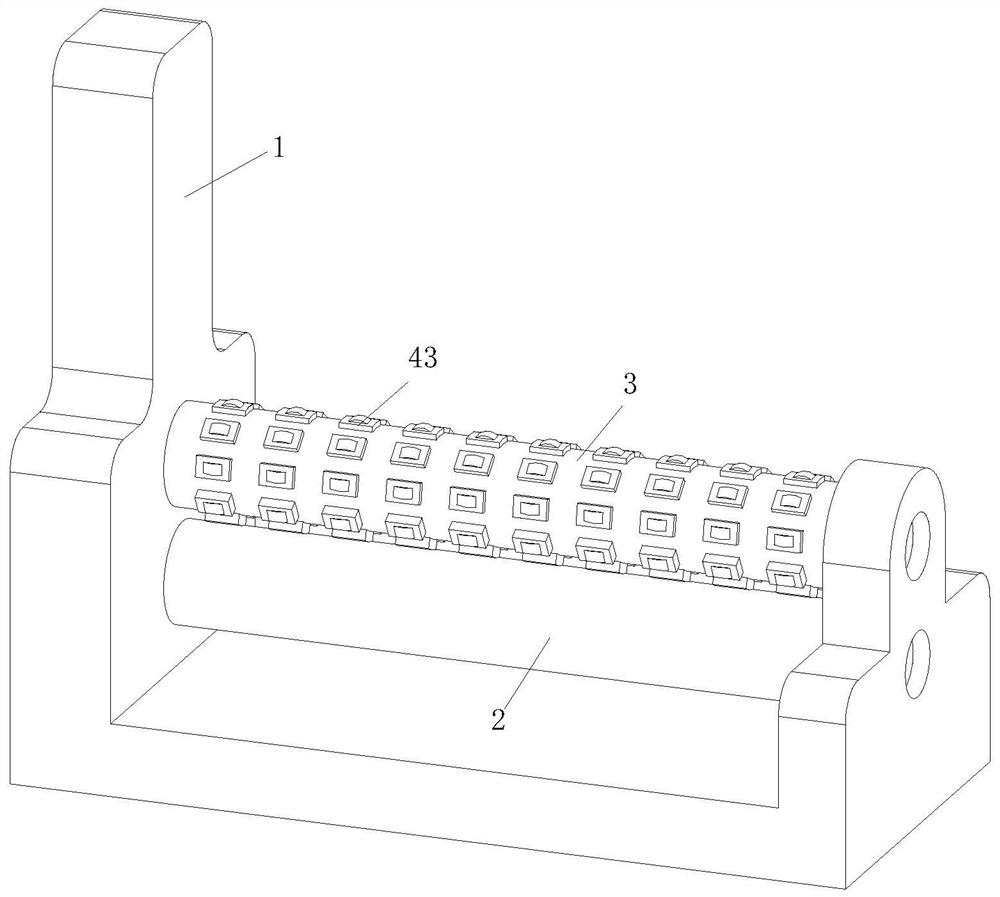

Quadruple roller type leveler

The invention provides a four-fold roller leveler, which includes a frame, a roller part, a movable beam, a pressing mechanism, a left and right main drive, a dry oil centralized lubrication part, an electrical control system and a roller table for feeding and discharging. The roller part includes upper and lower working rollers and upper and lower support rollers, and there are four rows of rollers in total. The roller part is connected with a quick roll changing device. Two upper and lower work roll chocks on the guide rail, a connecting plate connected with the upper and lower work roll chocks, and a guide wheel arranged between the two upper and lower work roll chocks. The invention improves the leveling quality by improving the leveling machine, and can also ensure the quality when leveling thick steel plates. After being straightened by the straightening machine of the present invention, the material is smooth and smooth without indentation, and can be used for various metal plates.

Owner:NANTONG ATLANTIC MACHINERY

Renovation device for building climbing frame

ActiveCN113351688BReduce laborImprove refurbishment efficiencyMetal-working feeding devicesCleaning using toolsArchitectural engineeringStructural engineering

The invention discloses a refurbishment device for a building climbing frame, which comprises a frame, a traction assembly, a refurbishment assembly of a climbing frame net plate and a refurbishment assembly of a climbing frame net frame arranged in the frame; the refurbishment assembly of a climbing frame net plate It includes a grinding mechanism, two leveling mechanisms respectively arranged on both sides of the grinding mechanism, and a rotating mechanism for driving the grinding mechanism and the leveling mechanism to rotate; the climbing frame net frame renovation assembly includes at least one concrete Scraping mechanism, the concrete scraping mechanism can simultaneously perform concrete scraping work on multiple sides of the climbing frame net frame; When the climbing frame panels and frames are refurbished, workers only need to send the climbing frame panels and frames into the frame, which effectively reduces the labor load of workers and improves the renovation efficiency.

Owner:JIANGSU SHENGHAO ENG TECH CO LTD

Quick roll change device

Owner:JIANGSU YAWEI MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com