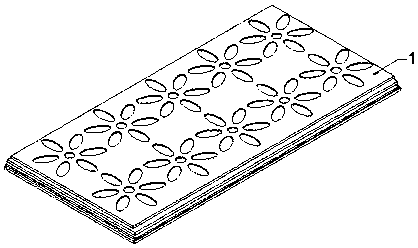

Three-dimensional printed and dyed fabric

A three-dimensional and fabric technology, applied in the direction of lamination, layered products, lamination devices, etc., can solve the problems of bloated clothing and inconvenient movement, and achieve the effect of not easy to fade, improve the three-dimensional effect, and light and thin fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

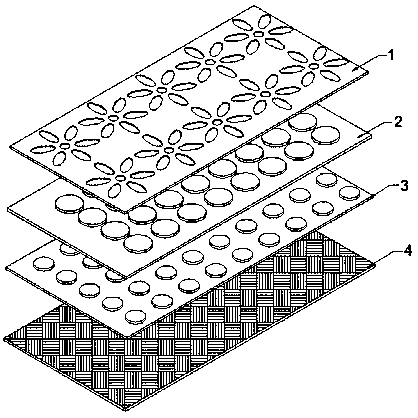

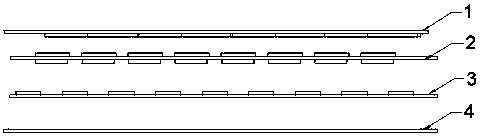

[0018] Such as Figure 1-3 As shown, a three-dimensional printing and dyeing fabric includes a printing and dyeing layer 1, a first thermal insulation layer 2, a second thermal insulation layer 3 and an inner lining 4 from outside to inside, and the printing and dyeing layer 1, the first thermal insulation layer 2, the second thermal insulation layer The layer 3 and the inner lining 4 are bonded together through a hot pressing process. In order to bond each functional layer into one, each functional layer is bonded into one through a point bonding hot-pressing process, so that the service life of the present invention and the smooth quality of the surface of the fabric can be significantly improved.

[0019] In order to improve the printing and dyeing performance of the fabric, the printing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com