Road leveling device

A technology of leveling device and highway, applied in the direction of road, road, road repair, etc., can solve the problems of small leveling range, lack of guiding structure of leveling device, damage of pressing roller, etc., so as to improve leveling quality and improve leveling. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

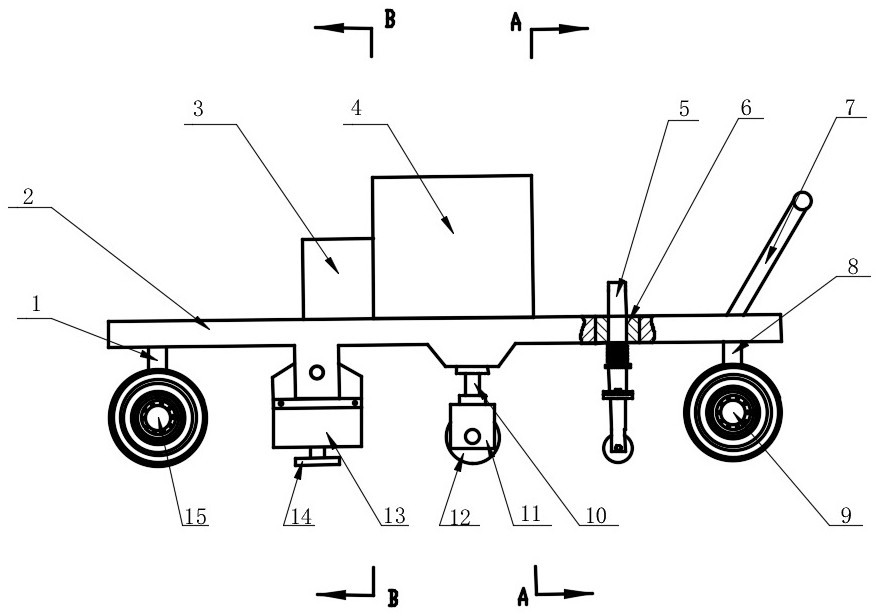

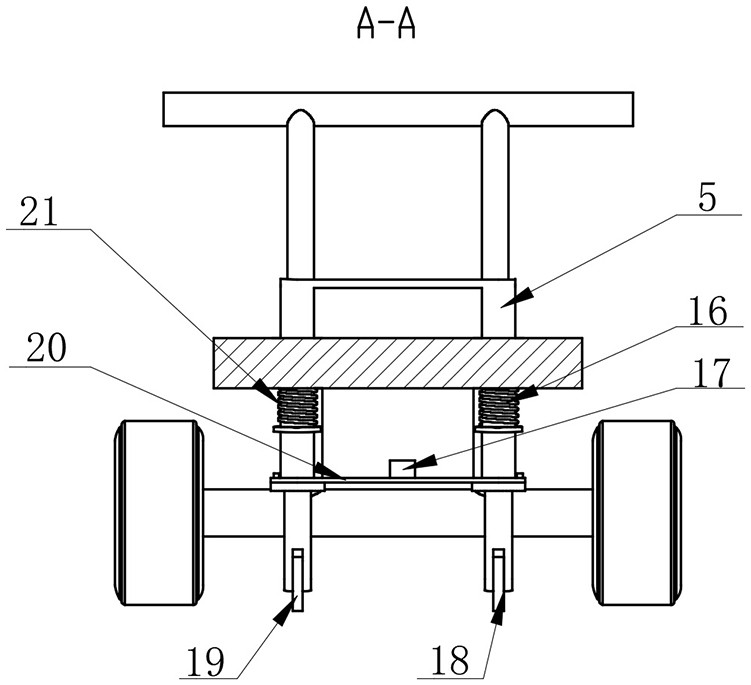

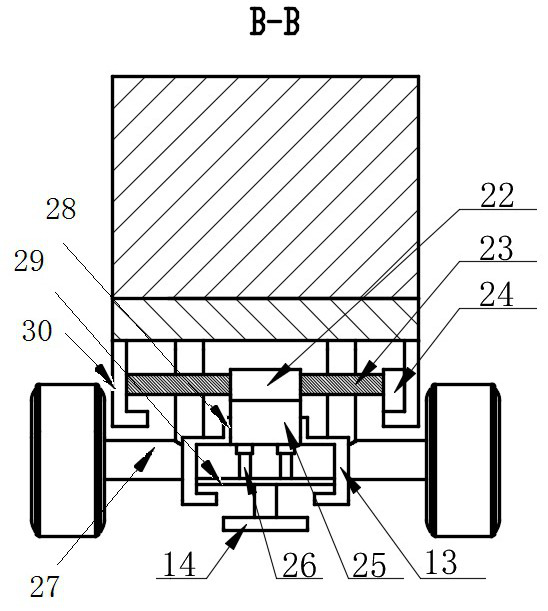

[0028] The structure and working principle of specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Invention point of the present invention realizes and solves technical problem by following module:

[0030] 1. For the first point of the background technology, a multi-degree-of-freedom linkage method is adopted to realize fine adjustment of the leveling position.

[0031] 2. For the second point of the background technology, the design sequence of the horizontal adjustment mechanism at the top and the vertical leveling structure at the bottom is adopted to obtain a large stroke of the leveling plate and the piston plate, thereby obtaining good leveling force.

[0032] 3. For the third point of the background technology, the technology of piston cylinder guidance is adopted, and the connection between the folded edge and the motor box is used to make the alignment and guidance better.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com