A billet speed measuring jet printer

A jet printing machine and billet technology, applied in printing, typewriters, printing devices, etc., can solve problems such as inaccurate speed measurement, printing position, and adverse effects of printing speed, so as to improve the leveling quality, accurate and reliable speed measurement data, and improve The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

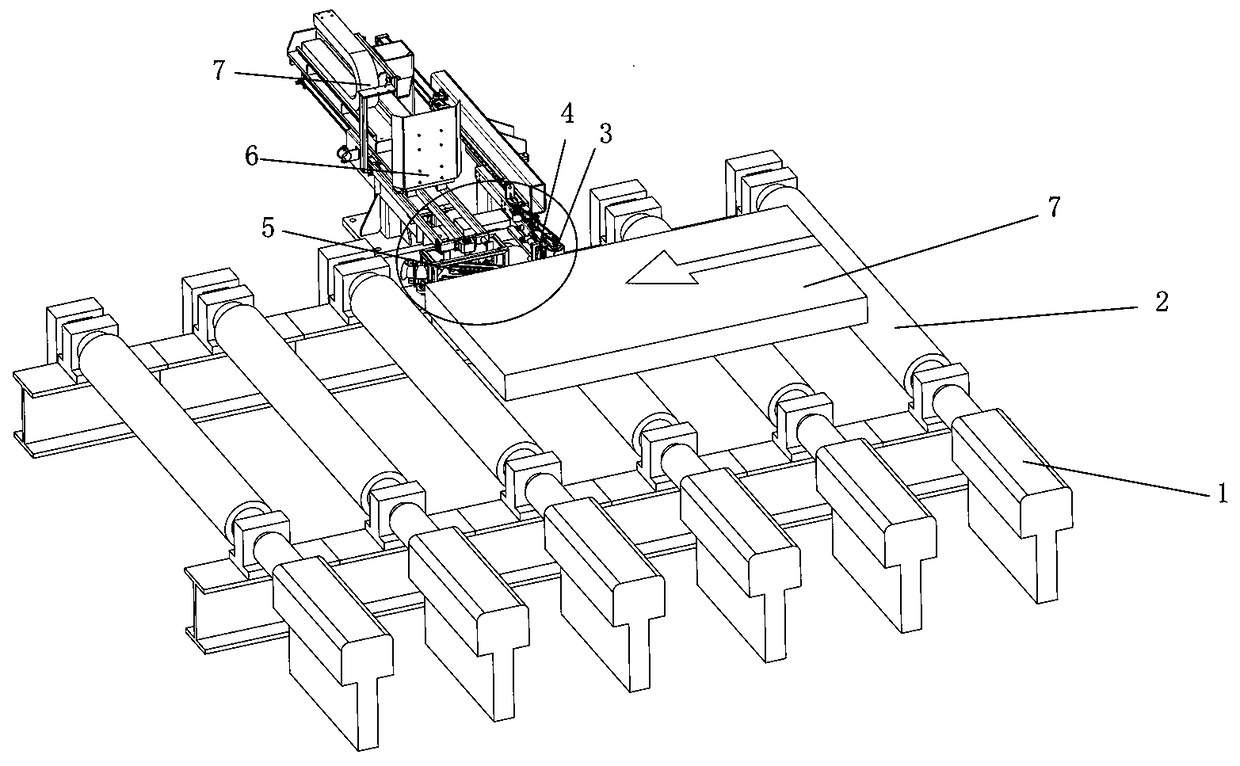

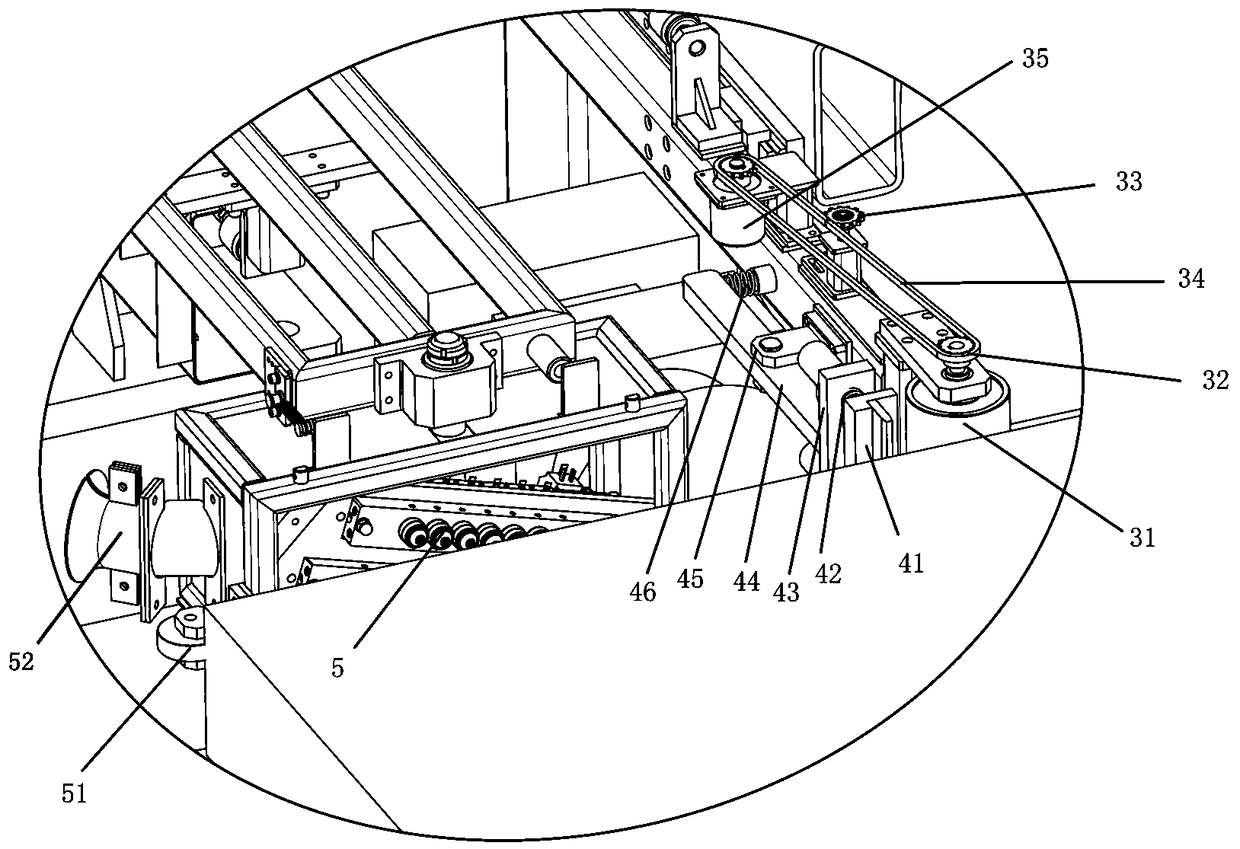

[0022] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

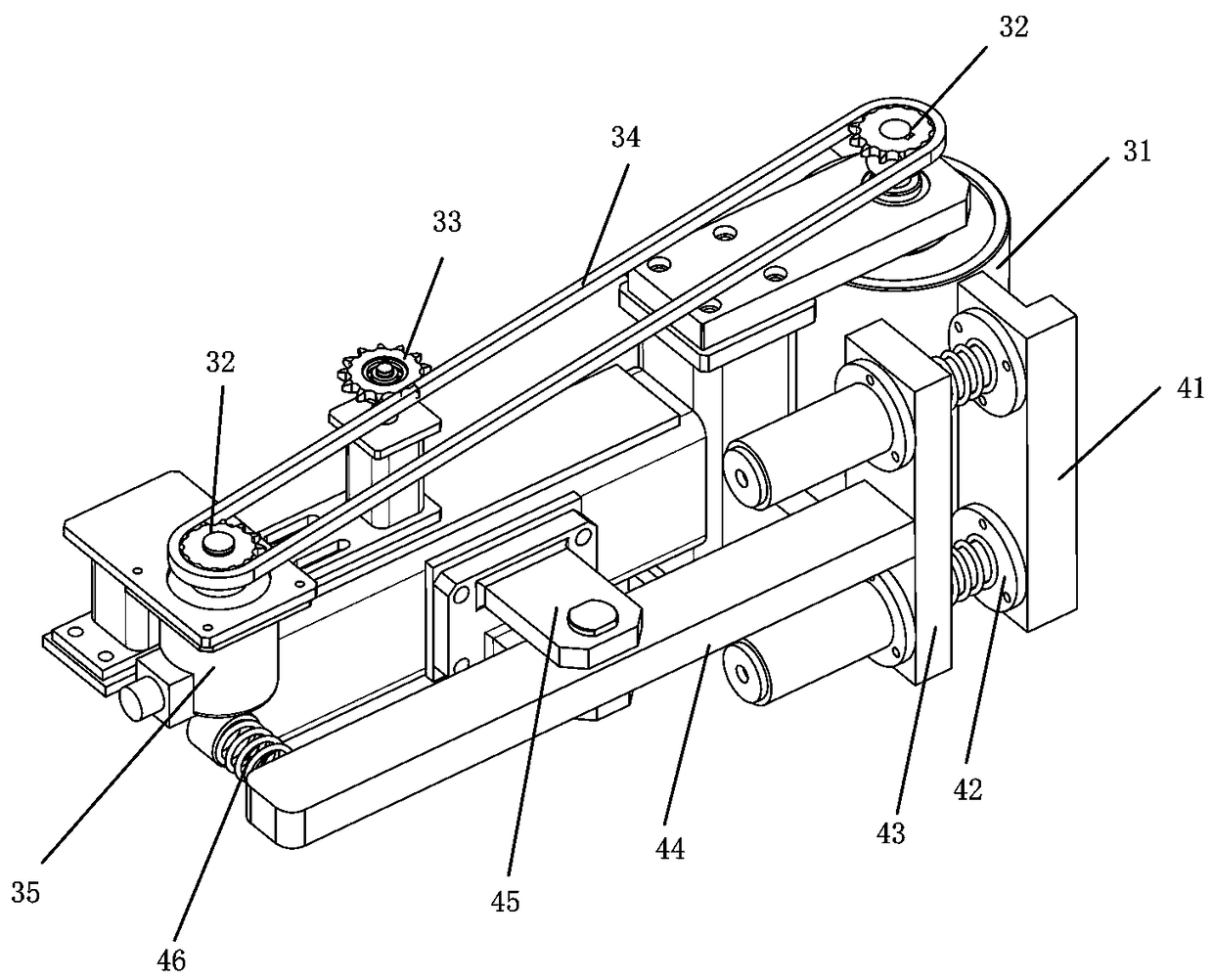

[0023] see Figure 1-3 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. The present invention is a steel billet speed measuring spray printing machine. A speed measuring device 3 is arranged on one side of the steel billet 7, and the speed measuring device 3 is driven by the steel billet 7 in progress. Rotating roller 31, the rotating roller 31 feeds back the rotation rate to the speed sensor 35 through the connecting device. The connecting device is composed of a belt gear 32 and a belt 34. The two belt gears 32 are installed on the rotating roller 31 and the speed sensor 35 respectively. When moving, the rotating roller 31 in contact with it rotates synchronously, and the belt gear 32 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com