Working roll adjusting device for roll leveler

An adjustment device and work roll technology, which is applied in the field of sheet metal roller leveling machinery, can solve the problem of large beam shape and mass, the inability to adjust a single leveling work roll independently, and the inability to realize unequal nonlinear changes, etc. Problems, to achieve the effect of improving the quality of leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

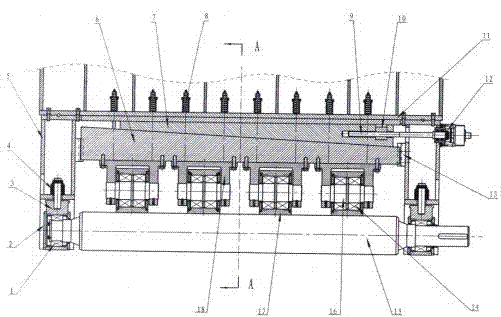

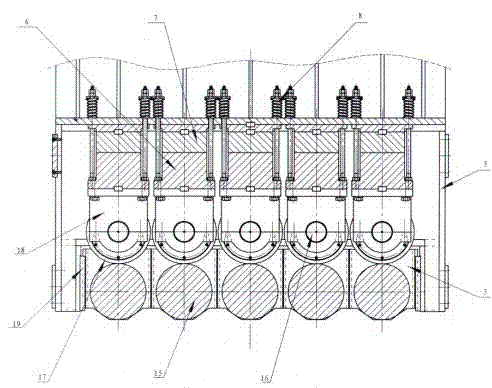

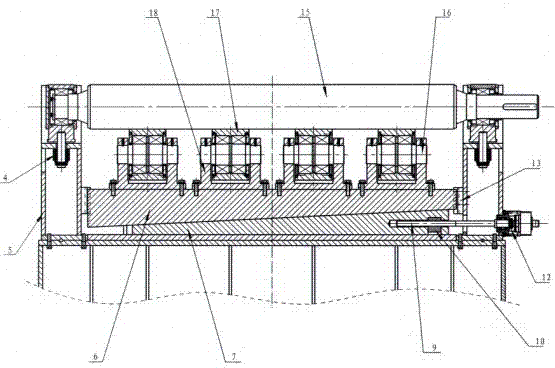

[0010] figure 1 It is a structural schematic diagram of the working roll adjustment device of the roller leveler of the present invention, which is a single support roll upward adjustment type, and the structure of the upper leveling work roll is adjusted, combined with figure 2 It can be seen from the A-A cross-sectional view that the present invention consists of leveling work roll 15, work roll seat 3, work roll support 5, work roll bearing 1, roll seat tensioning device 4, back-up roll assembly, inclined iron I 6, inclined iron Composed of iron II 7, lifting guide rail 13, inclined iron tensioning device 8, adjusting screw 9, screw nut 10, screw feeding device 12 and frame 11, etc., adjusting screw 9, screw nut 10 and screw driving device 12 Adjustment device for inclined iron. Two oblique irons I6 and II7 are arranged axially above each work roll 15, and the supporting rollers 17 are supported on the working rolls 15, and the supporting roller assembly is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com