High-precision guide rail straightness calibration structure and method

A straightness and high-precision technology, used in linear motion bearings, angle/taper measurement, bearings, etc., to solve the problems of complex equipment structure, adjustable position, few directions to meet work requirements, and single adjustment and control means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

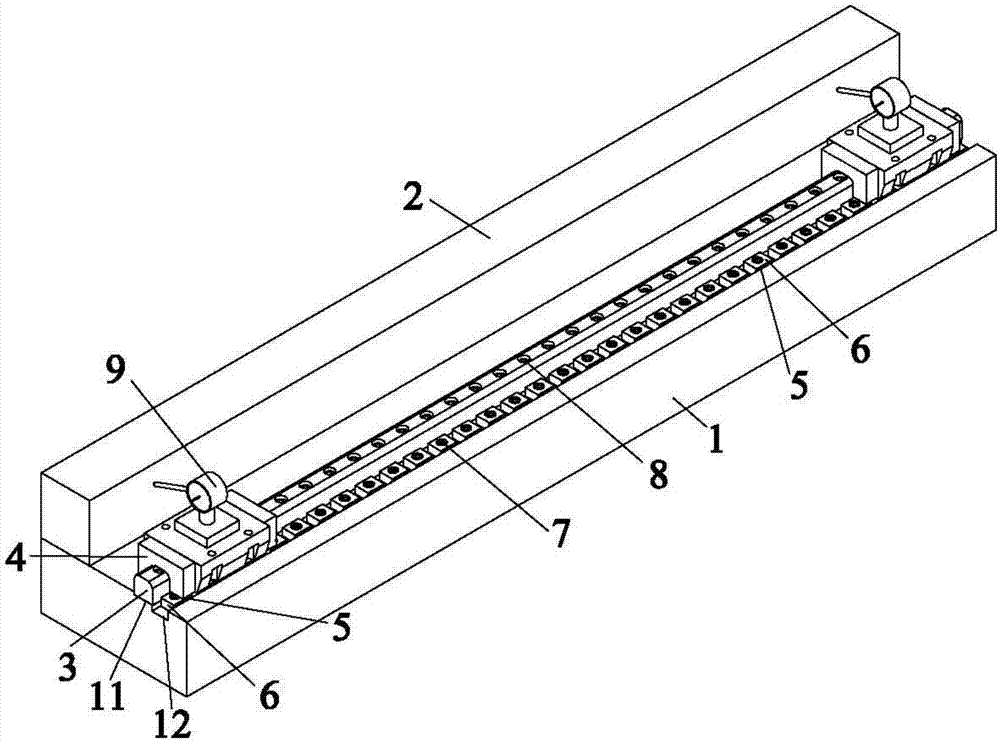

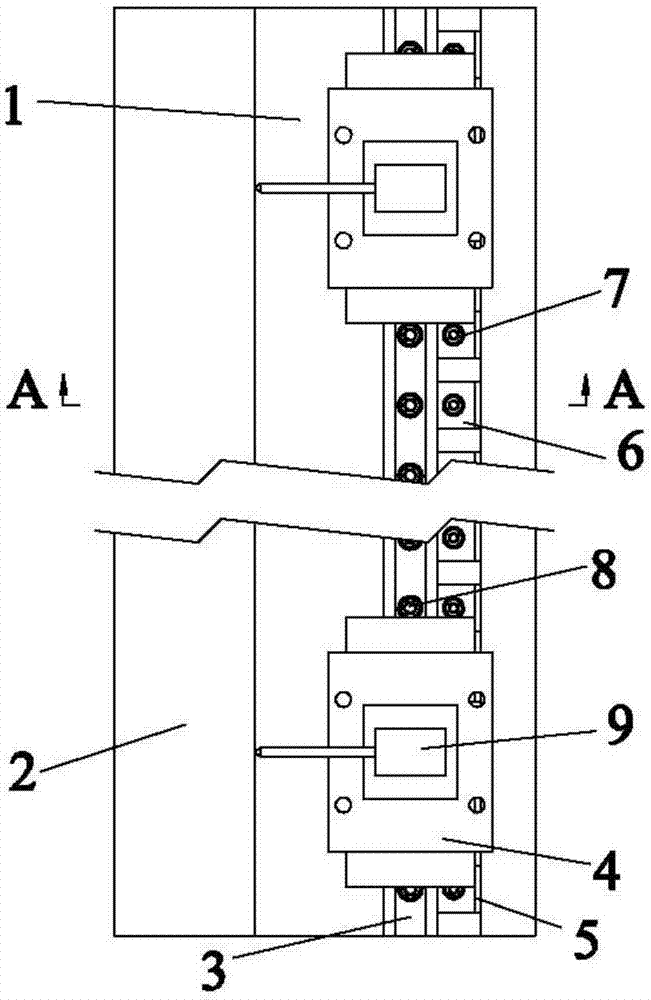

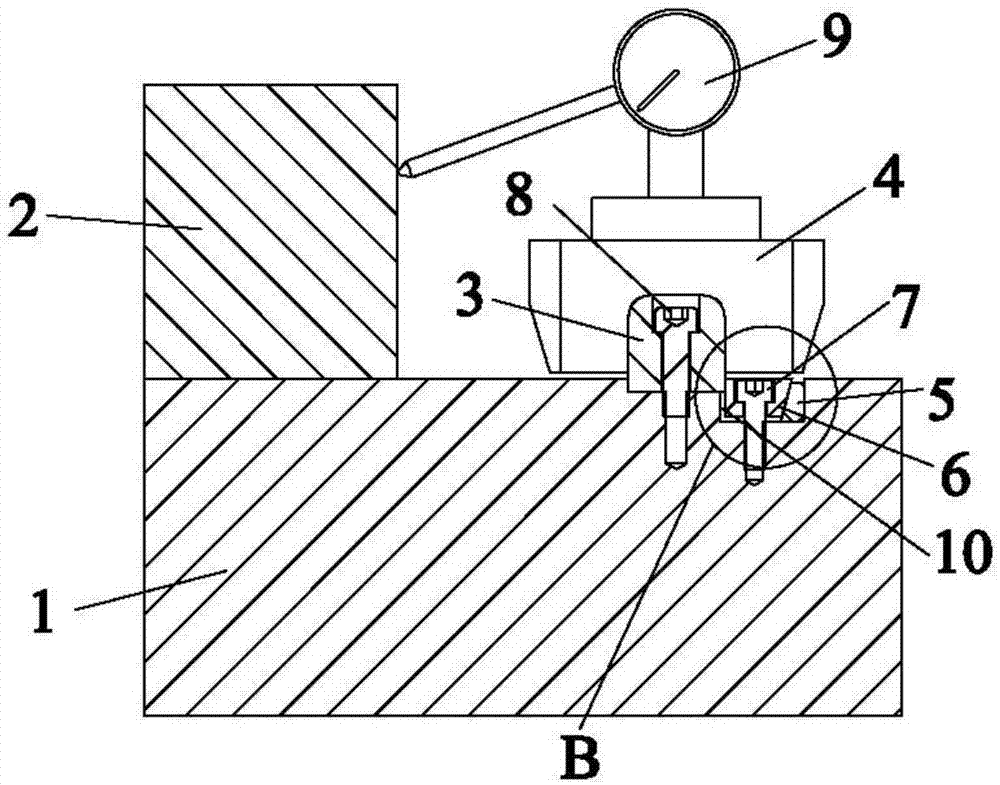

[0025] Example 1, such as Figure 1~4 As shown, a calibration structure for the straightness of a high-precision guide rail includes a base 1, a marble parallel ruler 2, a guide rail 3, a slider 4, a wedge 5, a top tightening block 6, an adjusting screw 7 and a fixing screw 8, and the marble parallel ruler 2 Installed on one side of the base 1, the base 1 is provided with an installation groove 11 and an adjustment groove 12 connected with the installation groove 11, the guide rail 3 is locked in the installation groove 11 by the fixing screw 8, and the guide rail 3 is closely attached to the installation groove 11 On the side wall, the slider 4 is slidably arranged on the guide rail 3, and a dial indicator 9 for calibrating the straightness of the guide rail 3 is placed on the top of the slider 4. The wedge 5 and the top tightening block 6 are all installed in the adjustment groove 12, and the top tightening block One end surface of 6 abuts against the guide rail 3 , the othe...

Embodiment 2

[0029] Embodiment 2, realize the calibration method to guide rail straightness by the structure of embodiment 1, comprise the following steps:

[0030] 1) Install the marble parallel ruler 2 on the side of the base 1, make the marble parallel ruler 2 and the guide rail 3 in a parallel state as much as possible, and place the dial gauge 9 on the slider 4 slidingly connected with the guide rail 3, so that the dial gauge 9 The measuring head is in contact with the side wall of the marble parallel ruler 2. At this time, measure the reading at point A of one end of the marble parallel ruler 2, then move the slider 4 to the other end, and measure the marble parallel ruler 2 without moving at the position of the dial indicator 9. The value of point B at one end, if the readings of points A and B are consistent, it means that the straightness of the marble has been calibrated, if the readings of points A and B are inconsistent, it means that the straightness of the marble is not calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com