Intelligent control filling valve

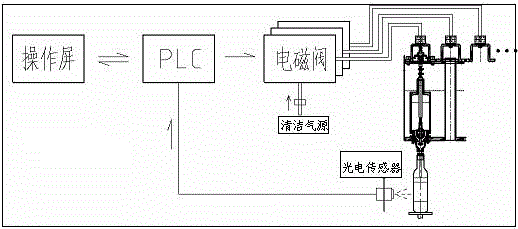

An intelligent control and filling valve technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as mutual interference, failure to achieve precision, impact, etc., to ensure product taste, easy cleaning and emptying, and strong market competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

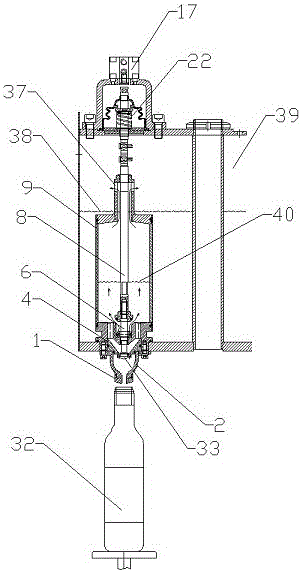

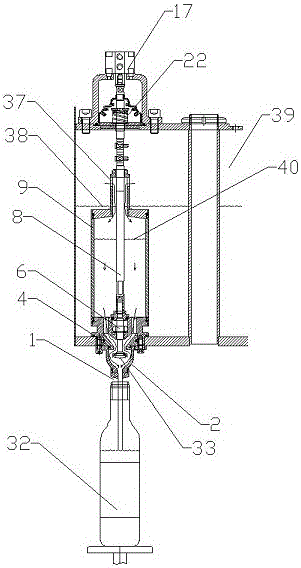

[0043] Examples such as figure 1 As shown, an intelligent control filling valve includes a closed valve cup 9, and the upper end of the valve cup 9 is sealed and connected with a valve cup end cover 10 through a second O-ring 26. The upper end of the valve cup end cap 10 is provided with several air holes 37 in a ring shape.

[0044] The valve cup 9 is a quantitative cup, and when the valve is closed, it is used to store the wine coming in from the wine vat, and when the valve is filled, it is used to separate the wine in the valve cup from the wine in the wine vat. Thereby stabilizing the filling liquid level.

[0045] The lower end of the valve cup 9 is equipped with a valve mouth 1 for filling, that is, a wine outlet, which is used to determine the size of the filling section, thereby stabilizing the filling flow rate. Moreover, the design is convenient to replace the valve mouth according to different situations, so as to change the filling section. (The filling flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com