Polymer-based substrate and method for the production thereof

A technology of matrix polymer and polymer material, used in polyamide coatings, devices for coating liquids on surfaces, coatings, etc., can solve the problems of insufficient paint adhesion, insufficient powder paint coverage, etc., and achieve process stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] Embodiment 1 (reference):

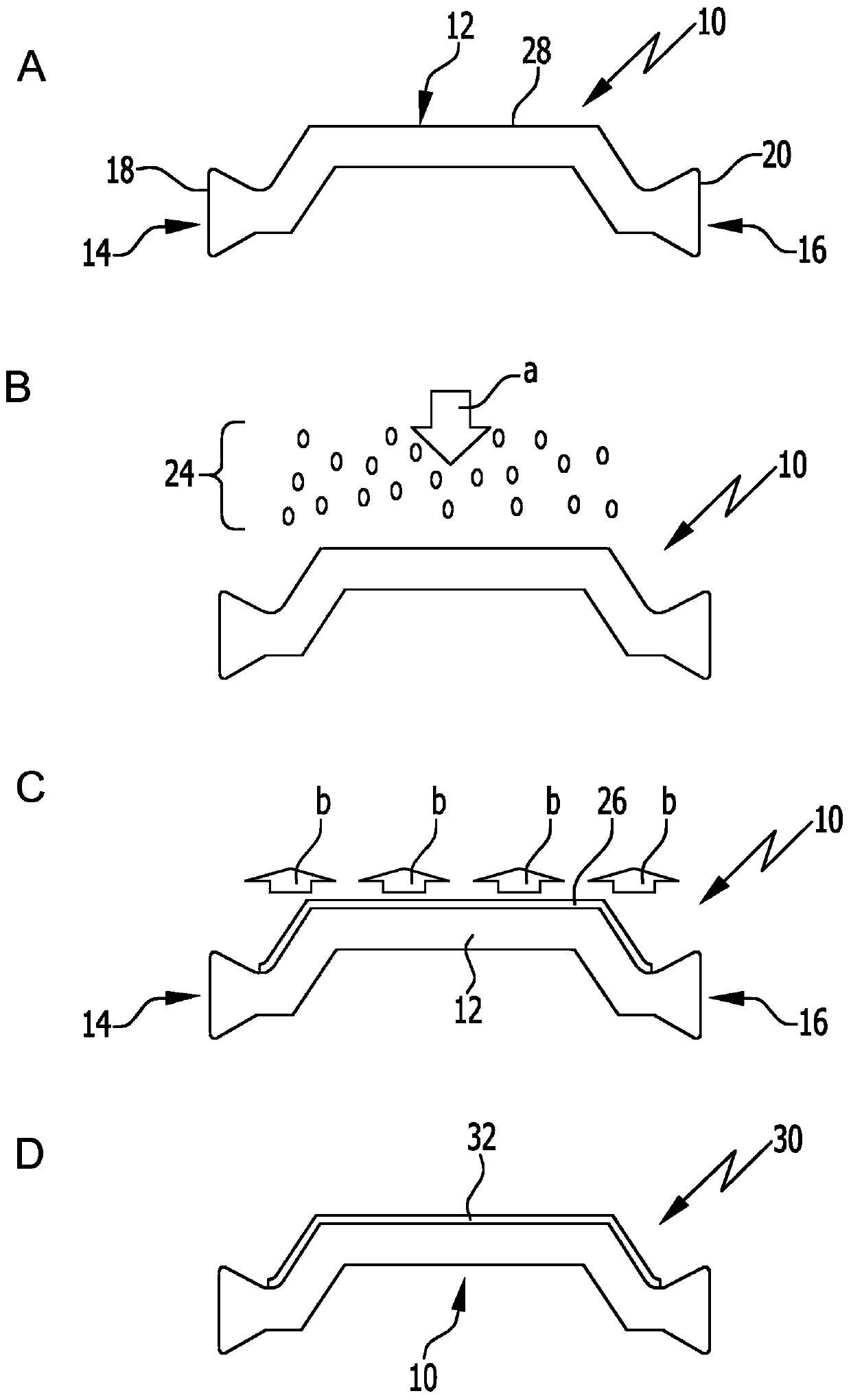

[0197] In this example, using something like figure 1 A solid extruded insulation profile 10 of flat middle section shown in A, wherein the insulation profile is made of a polymer material (polymer blend of PA66 and PPE with similar weight fractions) and contains 10% by weight of glass fibers (GF). PA66 is used here as the first polymer and forms a continuous phase in a blend with PPE which is dispersed discontinuously in microscopic fine droplets.

[0198] A flat test piece is then milled from this profile, which is suitable for measuring the specific surface resistance.

[0199] Table 1 gives the measured values of the specific surface resistance measured under various conditions.

Embodiment 2

[0200] Embodiment 2 (reference):

[0201] In this example, a similar figure 1 The solid extruded insulating profile 10 of the flat middle section shown in A, wherein the insulating profile is manufactured by Ensinger GmbH Made of LO polymer material. It is a polymer blend made of PA66 and PPE (in similar weight fractions) with a glass fiber (GF) content of 20% by weight. PA66 is used here as the first polymer and forms a continuous phase in a blend with PPE which is dispersed discontinuously in micron-sized droplets.

[0202] A flat test piece is then milled from this profile, which is suitable for measuring the specific surface resistance.

[0203] Table 1 gives the measured values of the specific surface resistance measured under various conditions. Due to the higher proportion of glass fibers, the specific surface resistance is slightly increased compared to the measured value of Example 1.

Embodiment 3

[0204] Embodiment 3 (reference):

[0205] In this example, again using a figure 1 The solid extruded insulating profile 10 of the flat middle section shown in A, wherein the insulating profile REG Polymer Materials by Ensinger GmbH Made of 66GF. Here, PA66 was used as the first polymer and reinforced with glass fibers (GF) in an amount of 25% by weight. A flat test piece is then milled from this profile, which is suitable for measuring the specific surface resistance.

[0206] Table 1 gives the measured values of the specific surface resistance measured under various conditions. Due to the different composition of the polymer material (without PPE), especially due to the higher proportion of (hygroscopic) PA66, the specific surface resistance is further reduced compared to the measured values of Examples 1 and 2.

[0207] The paint coverage of the dried and powder-coated profile was only about 56% and was therefore clearly insufficient. The paint tests were carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com